76

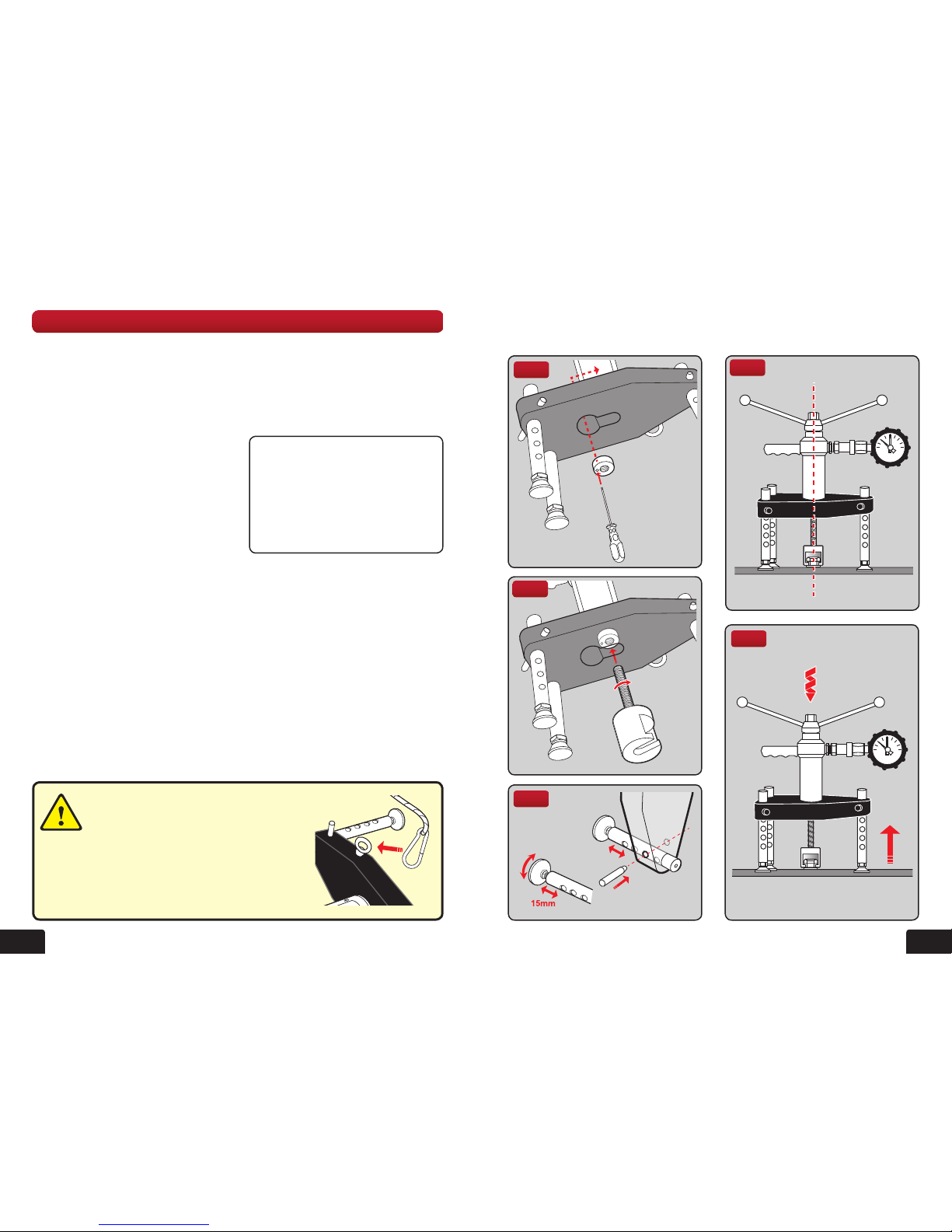

TESTING PROCEDURE

6. Set the red pointer on the gauge to zero

- hold the tester by the grip handle and

proceedtoloadthefastenerbyturning

the operating handle clockwise (g 5).

7. Increase the load until the required

test load is attained. Hold this load and

observeanyfallingbackofthereadings

which would indicate movement and

possiblefailureofthefastener.Record

thesatisfactoryresult.

8.Releasetheloadonthefastenerby

turning the operating handle anti-

clockwise and allowing the test jaw

to return to the original position.

9. Remove the tester and bolt tester

adaptor.

Fig 5

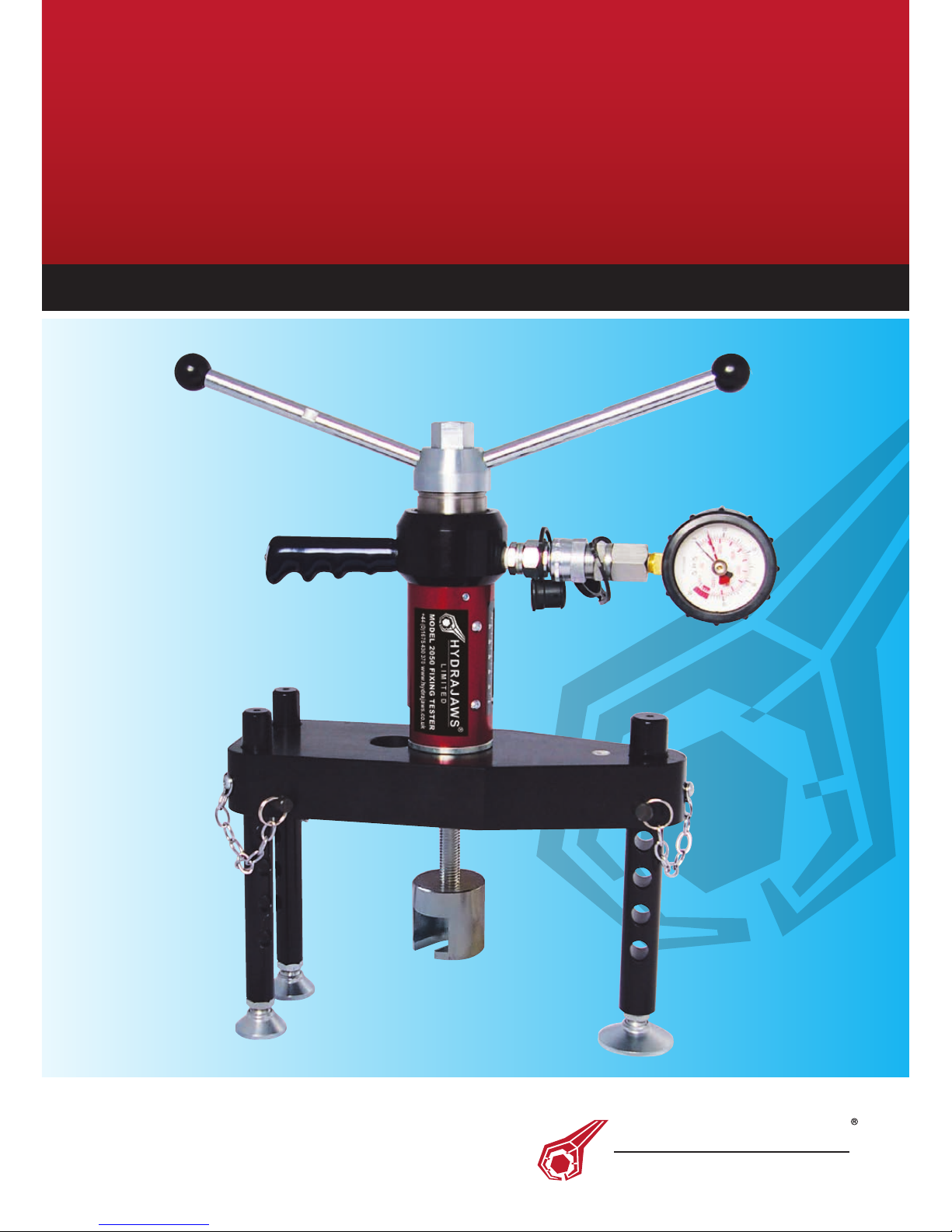

1. GENERAL TESTING PROCEDURE

SETTING UP THE TESTER

1 Fit the appropriate adaptor to the tester.

Exampleshownisabolttesteradaptor.

(Forttingofotheradaptorspleasesee

individual instructions in this manual.)

2. The tester is supplied with a locking

adaptorttedintothetesterbody.

This locking adaptor can be removed

forttingofdifferentadaptorsbyusing

the 3mm Ball Driver. When replacing

backinensureitisfullyengagedinto

thetesterbodybeforetightening

(g 1). Thread the bolt tester adaptor

intothis,untilitisfullyengaged,using

aquarterturnforposition(g 2).

3.Makenaladjustmentssothatthebolt

testeradaptor,testerandxingare

aligned (g 3).

4. Position the tester so that the gauge

can be easily read.

5.Adjustthelengthofthelegssothat

all three are in contact with the base

material and the load spreading bridge

isalignedandlevelbyreferringtothe

bubblelevelsoneachface.

Fine adjustment is available by

unscrewingthefeetbynomore

thanapproximately15mm(g 4).

Fig 3

Fig 4

Fig 1

Fig 2

It is essential when testing on ceilings

(upside down) and/or vertically, that a

safety line is attached from the eyehook

on tester body to a suitable solid xing

point. This will stop the tester falling and prevent

injury to personnel and/or damage to test unit. If

no suitable xing point is available then attach to

safety harness on personnel using the tester.

CAUTION!

Holdthefastenersecurelybythegrip

handleaslongasthefastenerisunder

load.Whentheloadincreases,note

the reading on the displacement scale

onthetester.Indicationoffailureofthe

fastenermaybeobtainedbycomparing

the current reading with the original

reading.