4

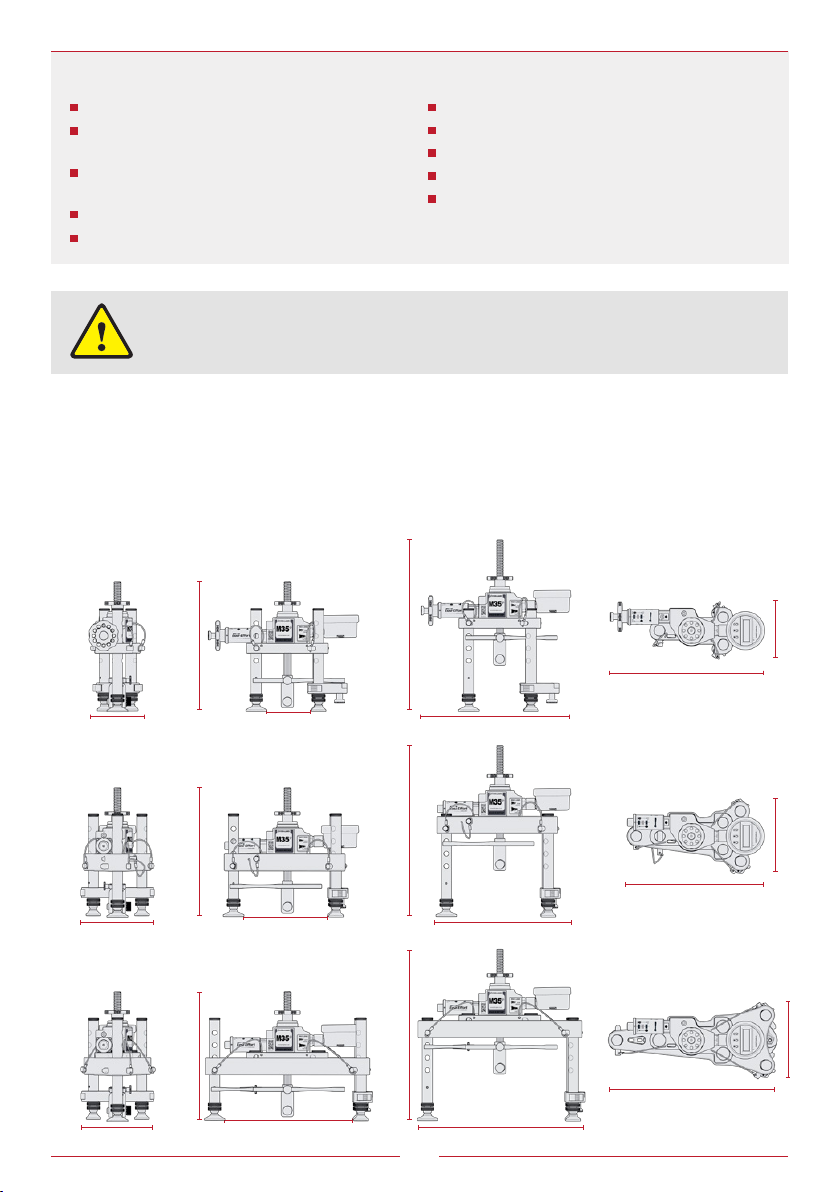

The M35+ is a compact, lightweight, dual

load capacity modular digital pull tester

designed to test eye bolts and anchors.

1. OVERVIEW: M35+ DUAL LOAD MODULAR PULL TESTER

Featuring Easi-Eort® technology, the M35+ can increase

testing frequency whilst reducing operator eort.

1

4

11

7

13

6

5

12

8

14

18

15

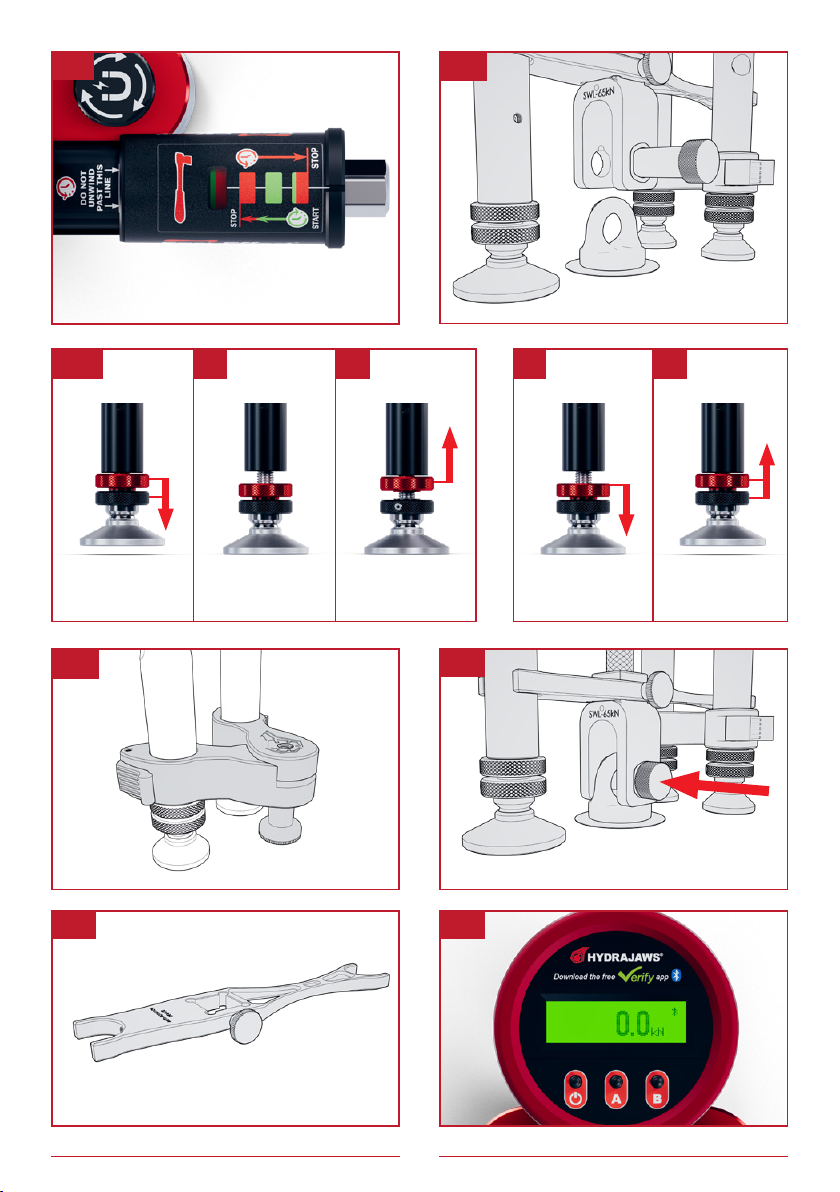

Built-in ‘Easi-Eort®’ technology enables

the load to be applied in a eortless and

consistent action at high loads.

The standard unit has a load capacity of

35kN (7,868lbf), and by coupling to one

of the larger bridges the load capacity is

increased to a maximum of 65kN (14,613lbf)

with the benet of an increased span.

The drop rod incorporates a primary

clevis adaptor (11) which accepts a bolt

test adaptor (13) for use with slotted

and threaded button adaptors which are

included with the kit. It also accepts the

mini-clevis adaptor (12).

The three height adjustable legs (7) oer

four height positions 30mm apart. They are

held in place with steel ball pins, and the

back two legs kept parallel by a brace (10).

The brace will extend to allow the legs to t

optional larger bridges.

The swivel feet oer 12mm of usable ne

adjustment.

The drop rod handwheel (5) is used to

secure and apply a pre-load to the xing.

The ‘Anti-rotation device’ (8) prevents the

adaptor turning during pre-load.

Load is applied with either the operating

handwheel (6) or ratchet driver (16).

The load is displayed by the rechargeable

digital gauge (3), and can be recorded by the

Hydrajaws Verify App.

Tester lanyard and ratchet tether are included

for work at height.