76

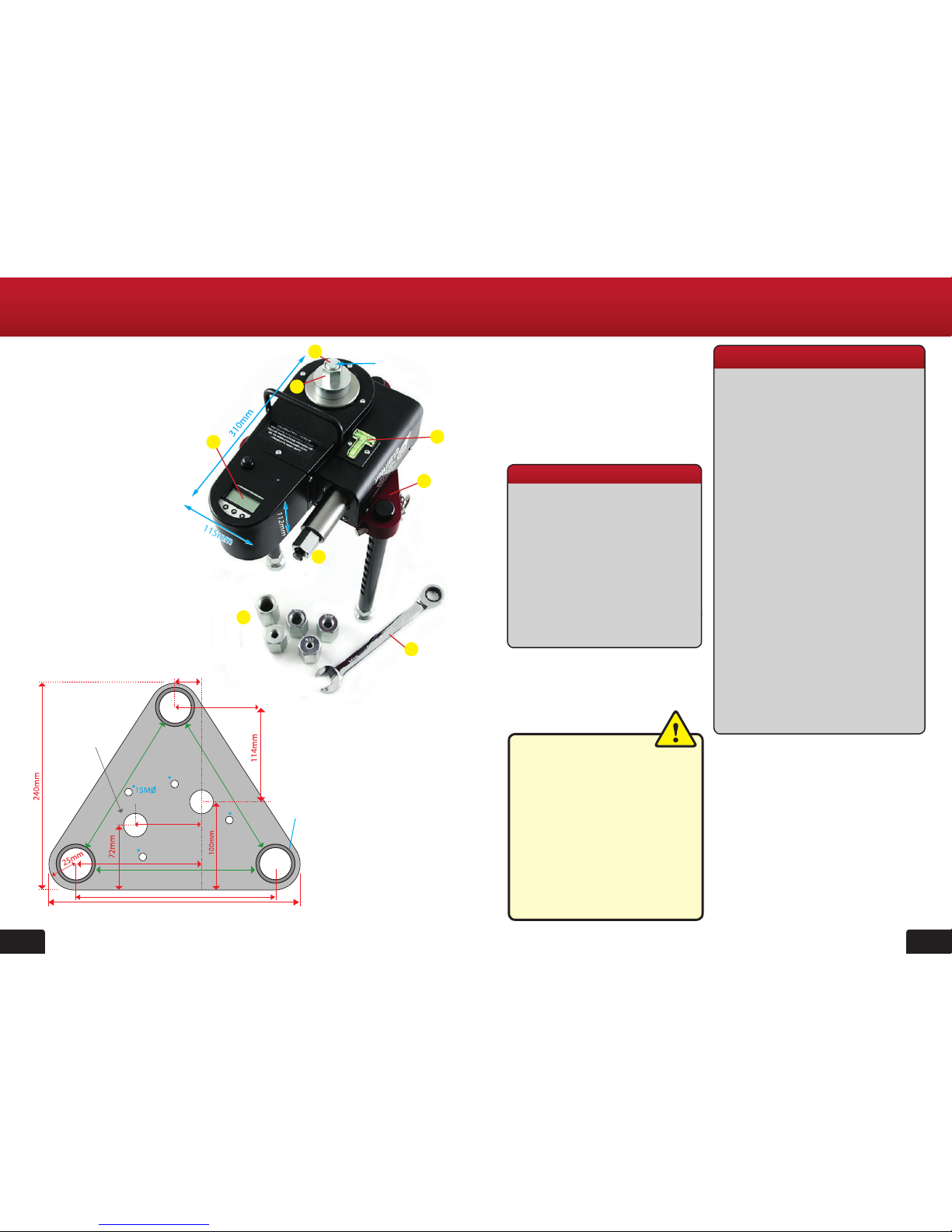

Assemble the load spreading bridge.

Secure the tester to the bridge if

appropriate.

Position the tester and bridge over

the xing and using the M20 connecting

rod pass this through the tester and

bridge (g 5).

Switch the digital gauge on (see separate

gauge operating instructions in this

manual).

Commence applying the load to the xing

by turning the hexagon nut on the end

of the operating piston in a clockwise

direction by hand until tight or reading

appears on gauge.

Apply load using the ratchet spanner (g

10) and observe the reading on the gauge

until the required test load is reached. This

reading could decay due to rst movement

or creep on the anchor. Continue to apply

the load to the required reading and

observe that the loading remains steady.

Should a serious drop in the indicated

load occur again, the xing is likely to be

insecure and should be investigated.

As the digital gauge is very accurate a

drop off will be noticeable but this should

stabilise after a period of time. If the

reading continues to drop off, further

investigation of the xing would be

required.

To release the load, reverse the ratchet

ring spanner and turn the hexagon nut

anticlockwise and observe the load

reading on the gauge until it approaches

zero. Unwind the operating nut by hand

until it is resting on the stop and unwind

the adjustable nut and remove.

DO NOT CONTINUE TO UNWIND

AGAINST THE STOP, OTHERWISE

SERIOUS DAMAGE WILL OCCUR.

Fig 5

Fig 6

2. General Testing Procedure - set up 3. General Testing Procedure - Operating the tester

M20

connecting

rod

Threaded

adaptor

WARNING

DO NOT unwind the

piston past the stop!

If after a test, the operating nut has

been unwound fully however the top

piston remains tight, untighten the

adjustable nut with the ratchet spanner.

Connect the M20 connecting rod to xing

using the appropriate threaded adaptor

(g 6).

The standard tester kit features ve metric

threaded adaptors:

M20>M12, M20>M16, M20>M20,

M20>M24 or M20>M30.

Note: Other metric thread sizes are

available via special order.

Imperial UNC adaptors are available

from stock.

Sizes; 3/8”, ½”, 5/8”, 3/4”& 1”

Install M20 adjusting nut (g 7) on top of

the threaded pull rod.

Adjust the 3 telescopic legs to an

appropriate height, take up any initial

slack using the threaded pull rod so

that the xing under test remains

connected with no movement between

the connecting rod nut and the top of the

tester.

Ensure the tester is level by adjusting the

swivel feet against the level bubble on the

top of the tester body (g 8).

Each threaded swivel foot features 30mm

of ne adjustment.

Tighten with ratchet spanner (g 9).

Fig 8

Fig 10

Fig 7

Fig 9