3

SAFETY RULES

•Modicationofthetester,ortampering

with its parts is not permissible.

• Observe the information printed in the

operating instructions applicable to

operation care and maintenance.

• The tester and its accessories may

present hazards when used incorrectly

by untrained personnel or not as

directed.

• Use only the genuine Hydrajaws

accessories or ancillary equipment

listed in the operating instructions.

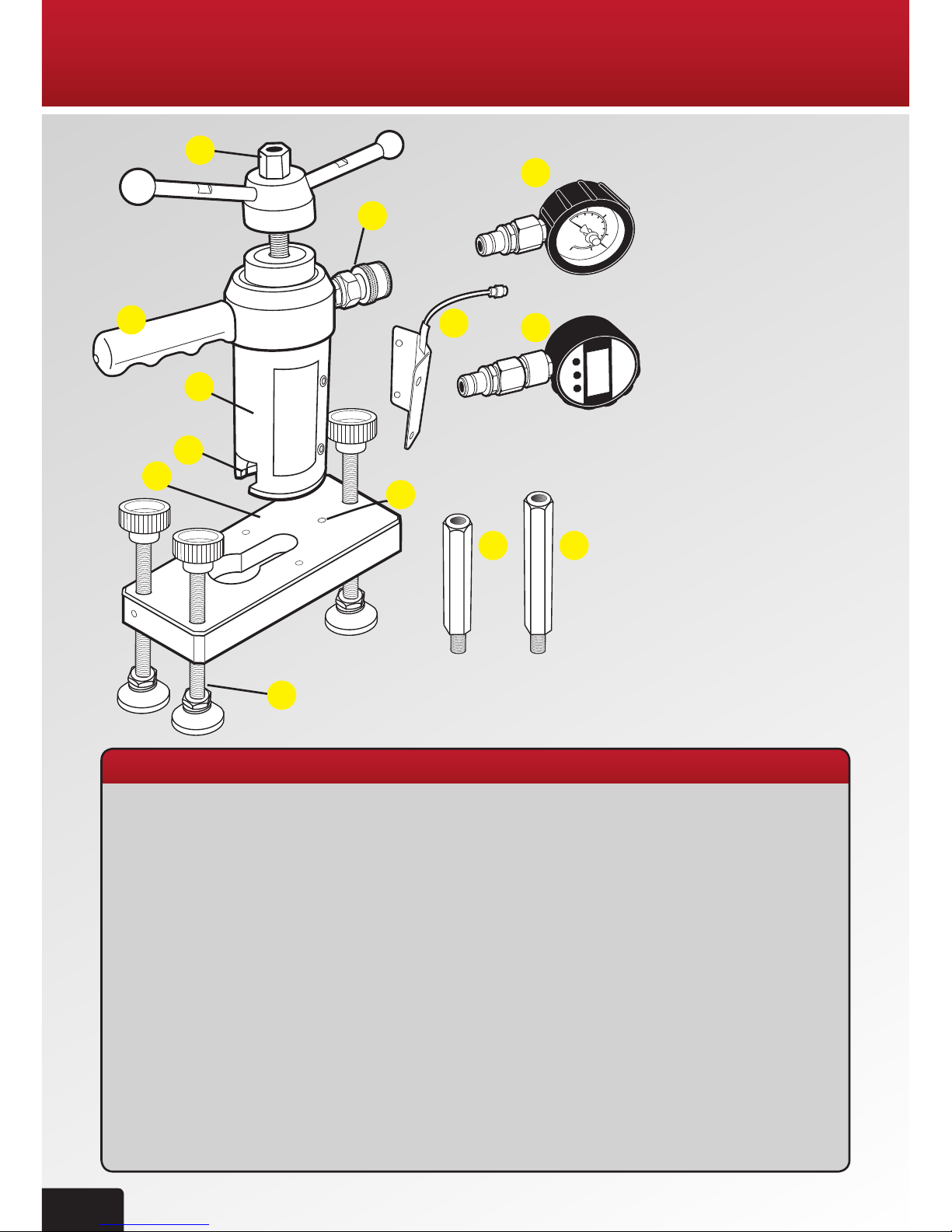

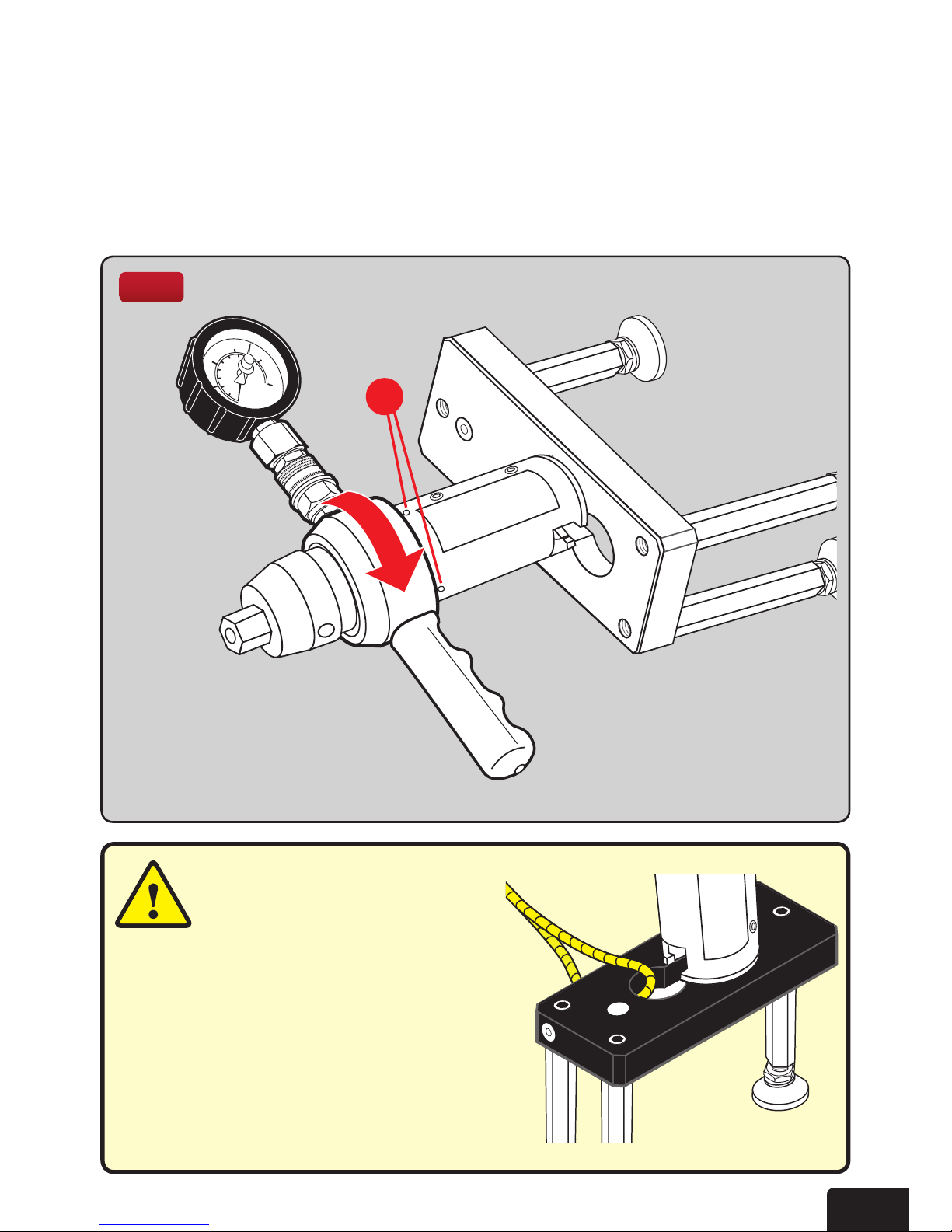

The model 2000 pull-out tester is

a purpose made system for testing

xings, fasteners and anchors. It

consists of a mechanical screw

arrangement acting through a

hydraulic load cell, which measures

the load applied to the xing directly.

The resulting load value is then

indicated on the dial type analogue

gauge or optional digital gauge.

The tester has a built in movement

indicatorscale50mmtoshow“rst

movement”onthexingpriortothe

test load being applied. The tester and

bridge are supplied as an integral part

of all the 2000 tester kit ranges.

A comprehensive range of accessories

is also available, further increasing the

scope of possible testing applications.

USE OF THE TESTER AS DIRECTED

The tester is intended for use by skilled

personnel with the appropriate training

and knowledge of the applicable safety

precautions.

GENERAL DESCRIPTION

It is essential that the

operating instructions

are read before the tester is

operated for the rst time.

Always keep these operating

instructions together with

the tester.

Ensure that the operating

instructions are with the

tester when it is given to

other persons.

CONTENTS

Page

Model 2000 Parts 2

TechnicalSpecications 2

General description 3

Kit contents 4

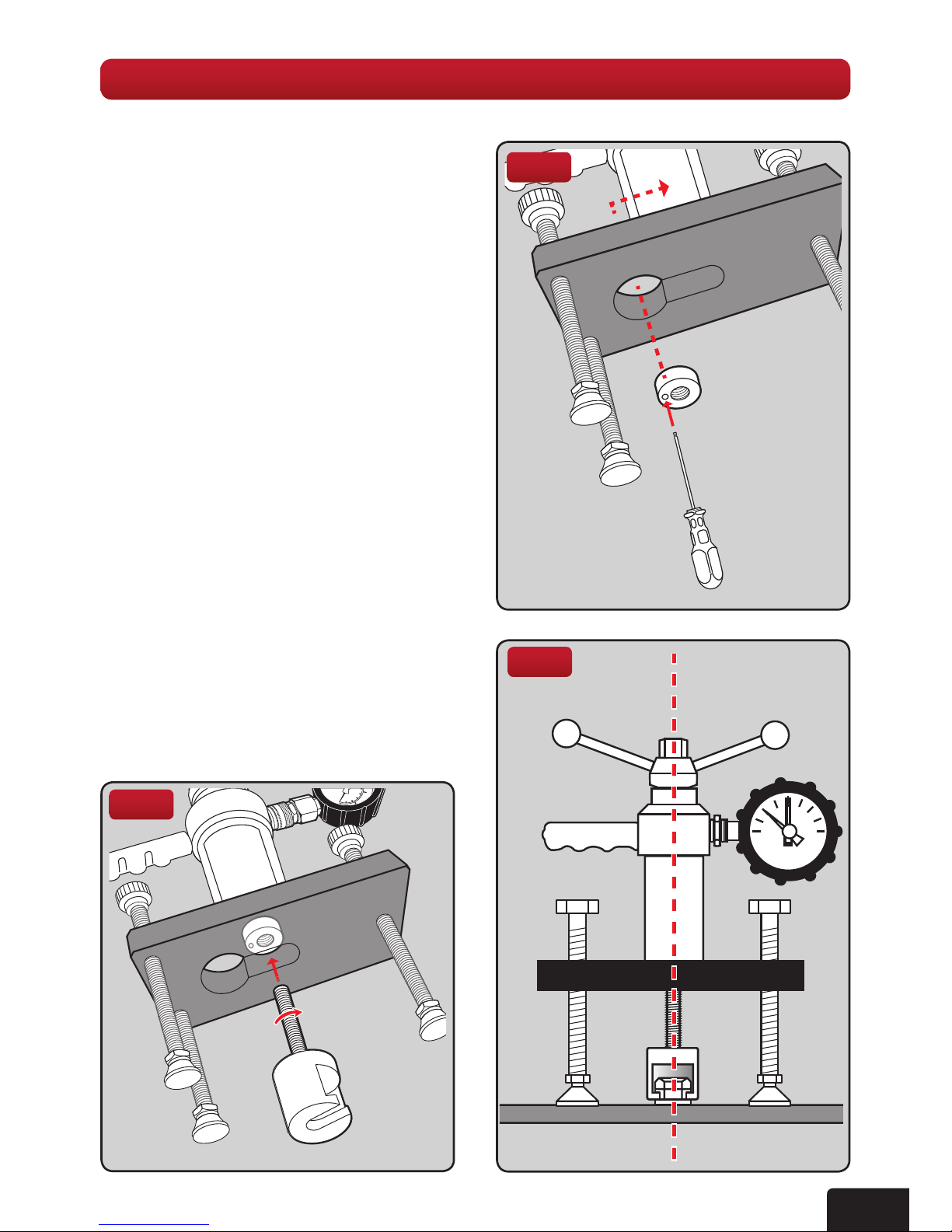

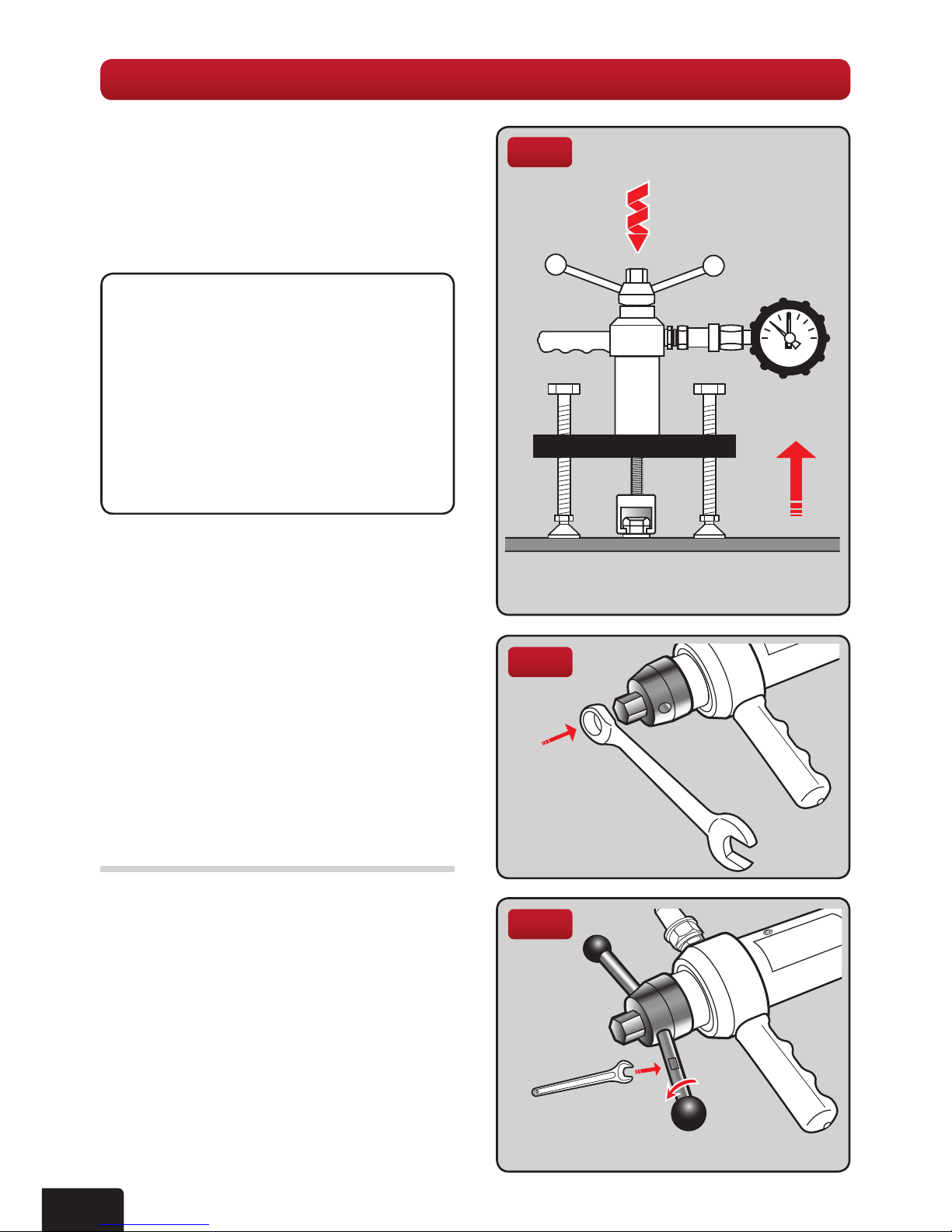

1. GENERAL TESTING

PROCEDURE 5

2. PULLING ADAPTORS 8

2.1 The bolt test adaptor

Slotted button adaptors

Threaded button adaptors

2.2 Threaded stud adaptors 9

2.3 The insulation adaptor

2.4 Threaded rod adaptors 10

2.5 The clevis adaptor

3. SCAFFOLD TESTER KIT 11

4. SAFETY HARNESS EYEBOLT

TESTER KIT 14

5. WALL TIE TESTER KIT 16

6. MATERIAL BOND TESTER KIT 18

7. OPTIONAL LOAD

SPREADING BRIDGES 21

8. FITTING HEX EXTENSION LEGS 21

9. CARE OF TESTER

9.1 Lubrication 22

9.2 Oilrellinginstructions 23

9.3 Calibration