©2014 HYSTER COMPANY

TABLE OF CONTENTS

General .....................................................................................................................................................................1

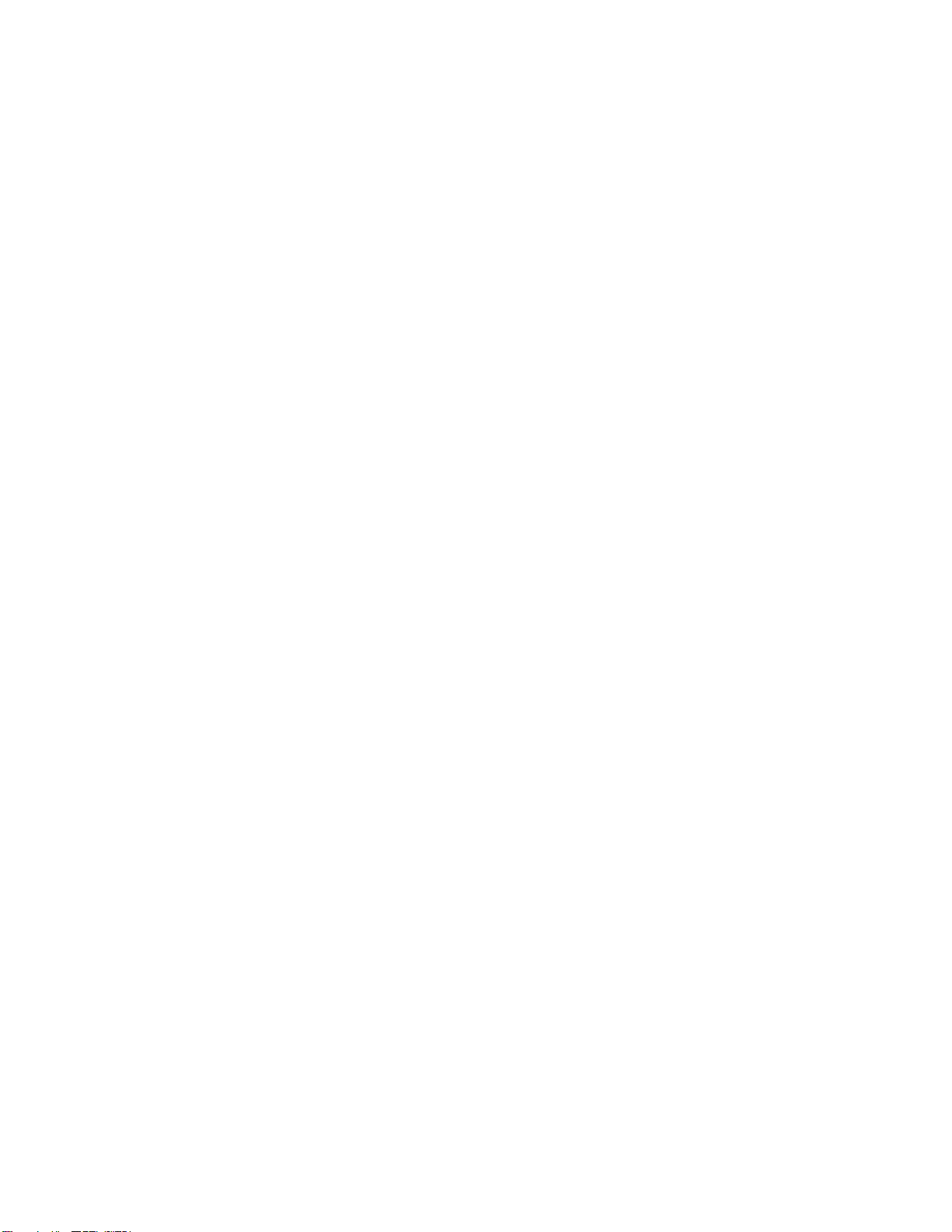

Engine Control Module (ECM), Yanmar Diesel Engine ....................................................................................... 2

Remove ................................................................................................................................................................ 2

Install ...................................................................................................................................................................2

Display Switch Cluster ........................................................................................................................................... 3

Remove ................................................................................................................................................................ 3

Install ...................................................................................................................................................................5

Direction Control Lever ...................................................................................................................................... 5

Remove ............................................................................................................................................................ 5

Install .............................................................................................................................................................. 6

Key Switch ...........................................................................................................................................................6

Remove ............................................................................................................................................................ 6

Install .............................................................................................................................................................. 7

Display Switch Cluster Panel Bezel and Overlay ............................................................................................. 7

Remove ............................................................................................................................................................ 7

Install .............................................................................................................................................................. 7

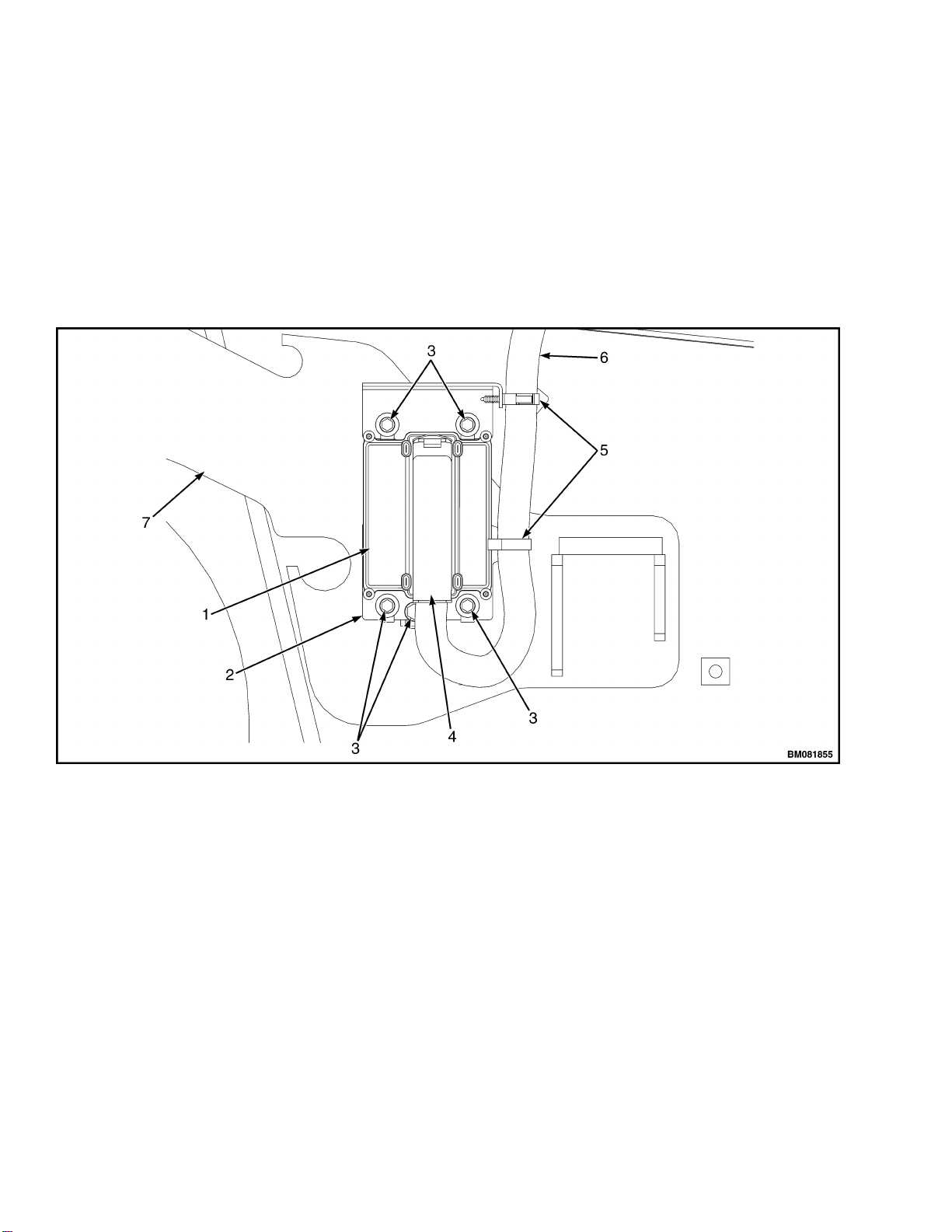

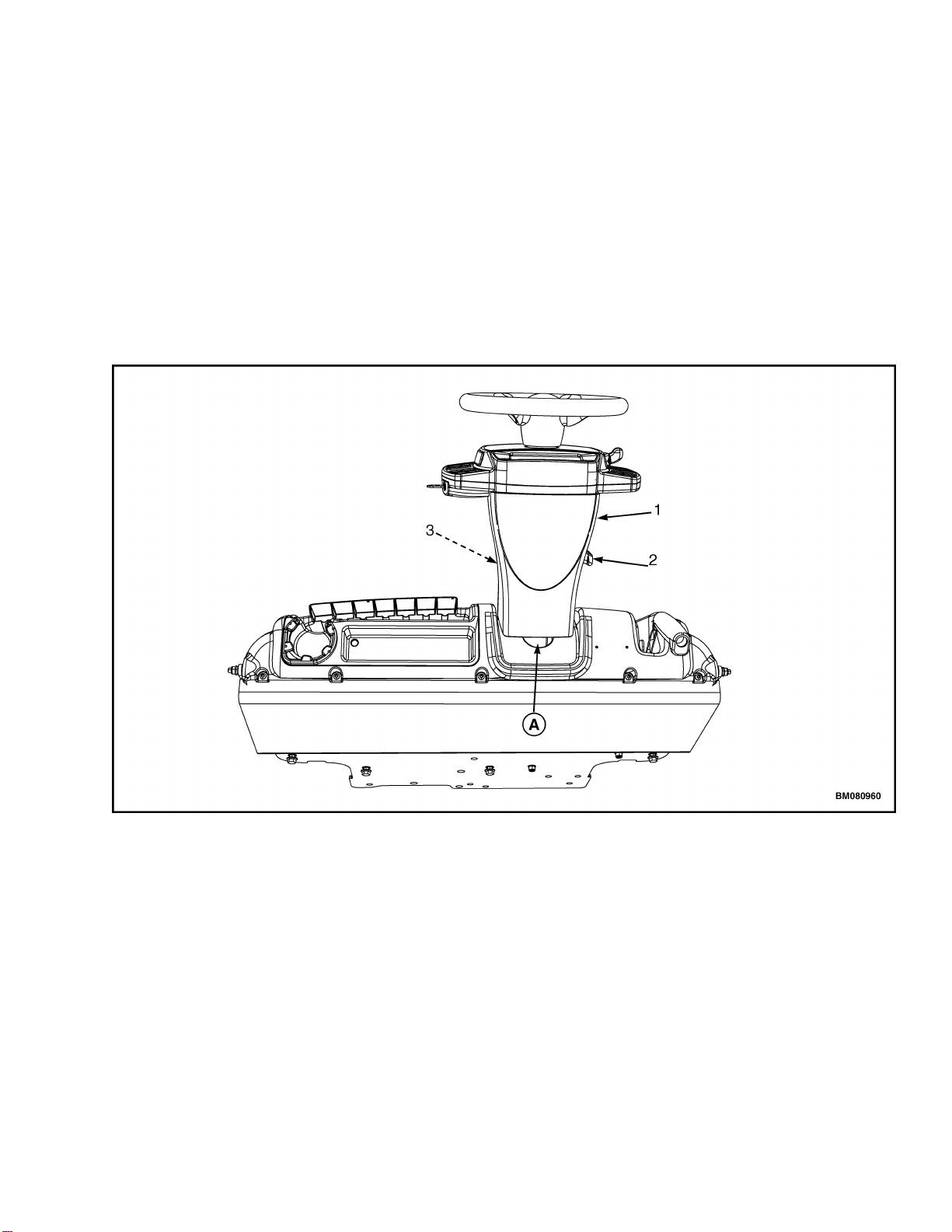

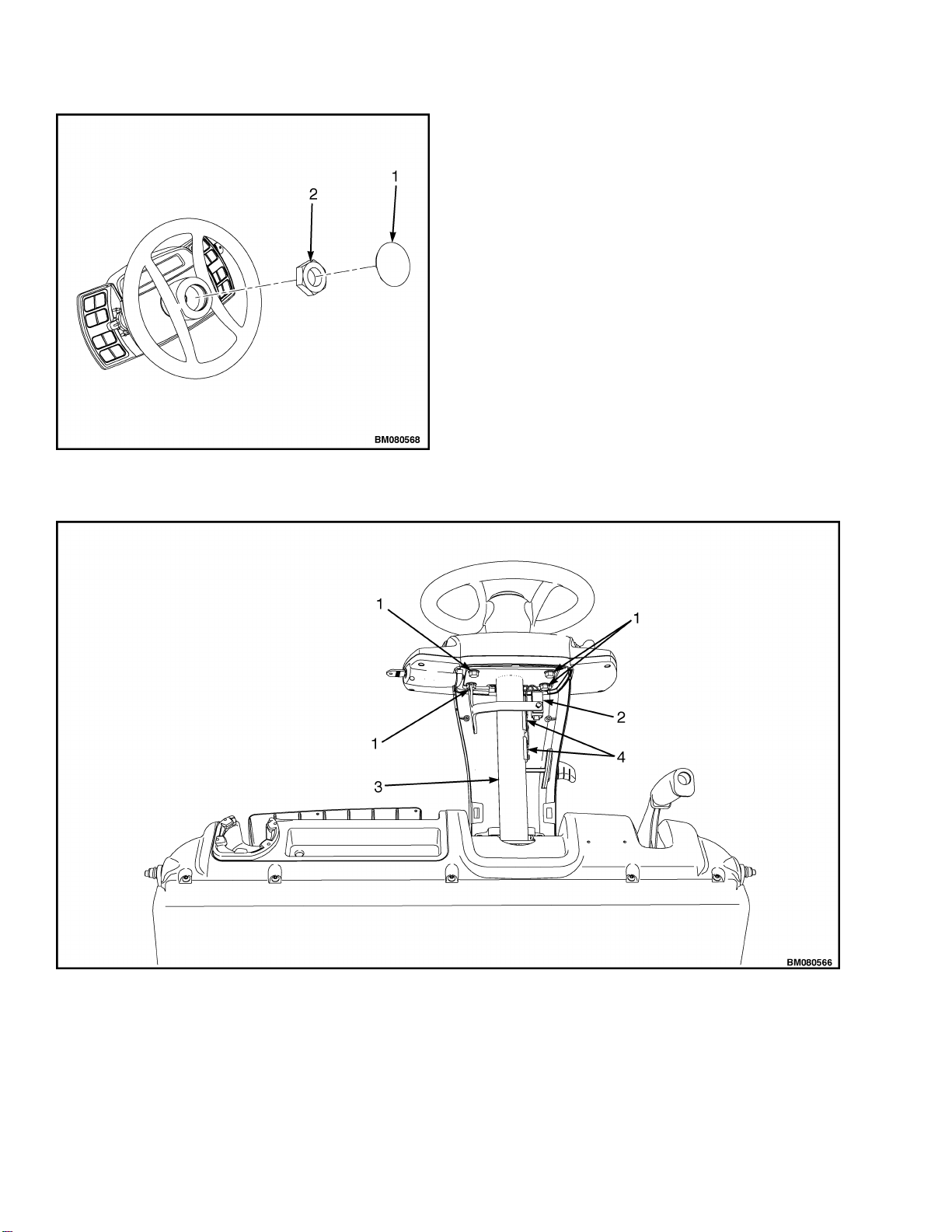

Steering Column Repair ......................................................................................................................................... 8

Remove ................................................................................................................................................................ 8

Disassemble .........................................................................................................................................................9

Assemble ............................................................................................................................................................10

Install .................................................................................................................................................................10

Sensors and Switches ............................................................................................................................................10

General .............................................................................................................................................................. 10

Dash Panel, Kick Panel, and Seal Plate, Remove and Install ................................................................... 10

Remove ......................................................................................................................................................10

Install ........................................................................................................................................................11

Accelerator Pedal Position Sensor ................................................................................................................... 12

Remove .......................................................................................................................................................... 12

Install ............................................................................................................................................................ 13

Brake Fluid Level Switch ................................................................................................................................. 13

Remove .......................................................................................................................................................... 13

Install ............................................................................................................................................................ 14

Brake Pedal Position Sensor ............................................................................................................................ 14

Remove .......................................................................................................................................................... 14

Install ............................................................................................................................................................ 15

Parking Brake Position Sensor ........................................................................................................................ 16

Remove .......................................................................................................................................................... 16

Install ............................................................................................................................................................ 16

Seat Sensor (Operator Presence System) ........................................................................................................ 16

Non-Suspension Seat ....................................................................................................................................16

Remove ......................................................................................................................................................16

Install ........................................................................................................................................................18

Full Suspension Seats .................................................................................................................................. 18

Remove ......................................................................................................................................................18

Install ........................................................................................................................................................18

Transmission Pressure Sensors (Transducers) ............................................................................................... 19

Remove .......................................................................................................................................................... 19

Install ............................................................................................................................................................ 19

Transmission Temperature Sensor ..................................................................................................................19

Remove .......................................................................................................................................................... 19

Table of Contents

i