Steering Axle Assembly Repair

REMOVE

WARNING

PUTTING THE LIFT TRUCK ON BLOCKS

The lift truck must be put on blocks for some

types of maintenance and repair. The removal of

the mast, drive axle, battery, or counterweight as-

semblies will cause large changes in the center of

gravity. When the lift truck is put on blocks, put

additional blocks in the following positions:

• If the mast and drive axle are removed, put

blocks under the counterweight so the lift

truck cannot fall backward.

• If the counterweight is removed, put blocks

under the mast so that the lift truck cannot

fall forward.

Put the lift truck on blocks on a solid, even, and

level surface. Verify the blocks or stands have

enough capacity to hold the lift truck. Use addi-

tional blocks next to the tires as necessary to pre-

vent movement of the lift truck. Verify the lifting

devices used during repairs can lift the weight of

the parts and assemblies.

See the Operating Manual or Periodic Mainte-

nance manual listed in the General section of this

manual for the procedures to put the lift truck on

blocks.

NOTE: The steering axle can be removed without

removing the counterweight.

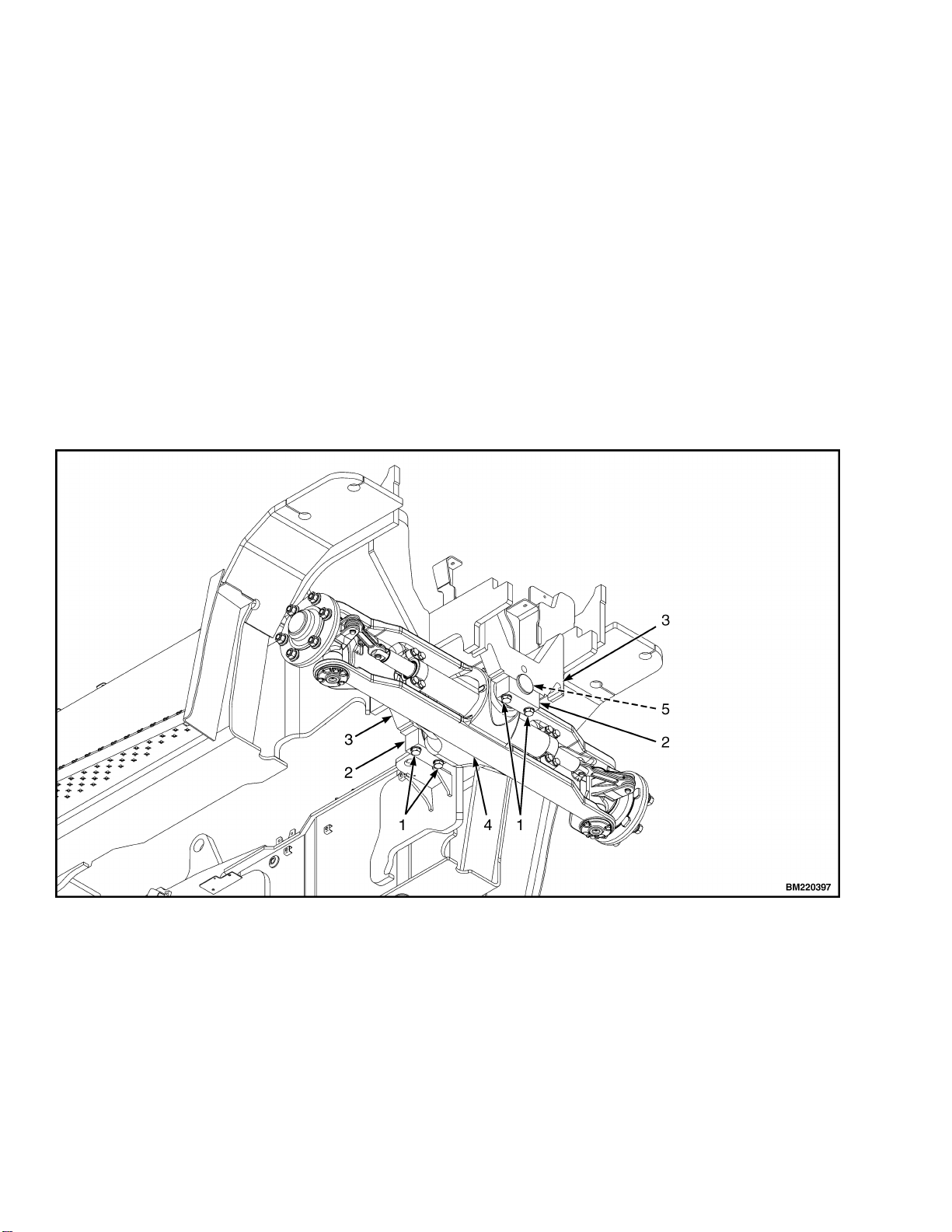

1. Verify wheels are set for straight travel. Put lift

truck on blocks so the steering axle will have

enough clearance to be removed. The top of the

axle frame must have clearance under the bot-

tom of the frame at the rear of the lift truck.

2. Disconnect hydraulic lines at steering cylinder.

Install plug fittings in cylinder and put caps on

hydraulic lines. Plug fittings will prevent spin-

dles from turning as axle is removed from un-

der the lift truck. See Figure 3.

3. Slide floor jack or forks of another lift truck un-

der steering axle. Raise lifting device until it

holds the weight of the axle assembly.

4. Remove four capscrews and washers from two

mounting plates on bottom of steering axle and

lift truck frame. See Figure 3.

5. Remove mounting plates and slowly lower

steering axle assembly onto wheels. Carefully

roll steering axle assembly away from lift truck.

DISASSEMBLE

NOTE: If the spindle, bearings or tie rods need to

be repaired, go to Spindles, Bearings, and Tie Rods

Repair section for repair procedures.

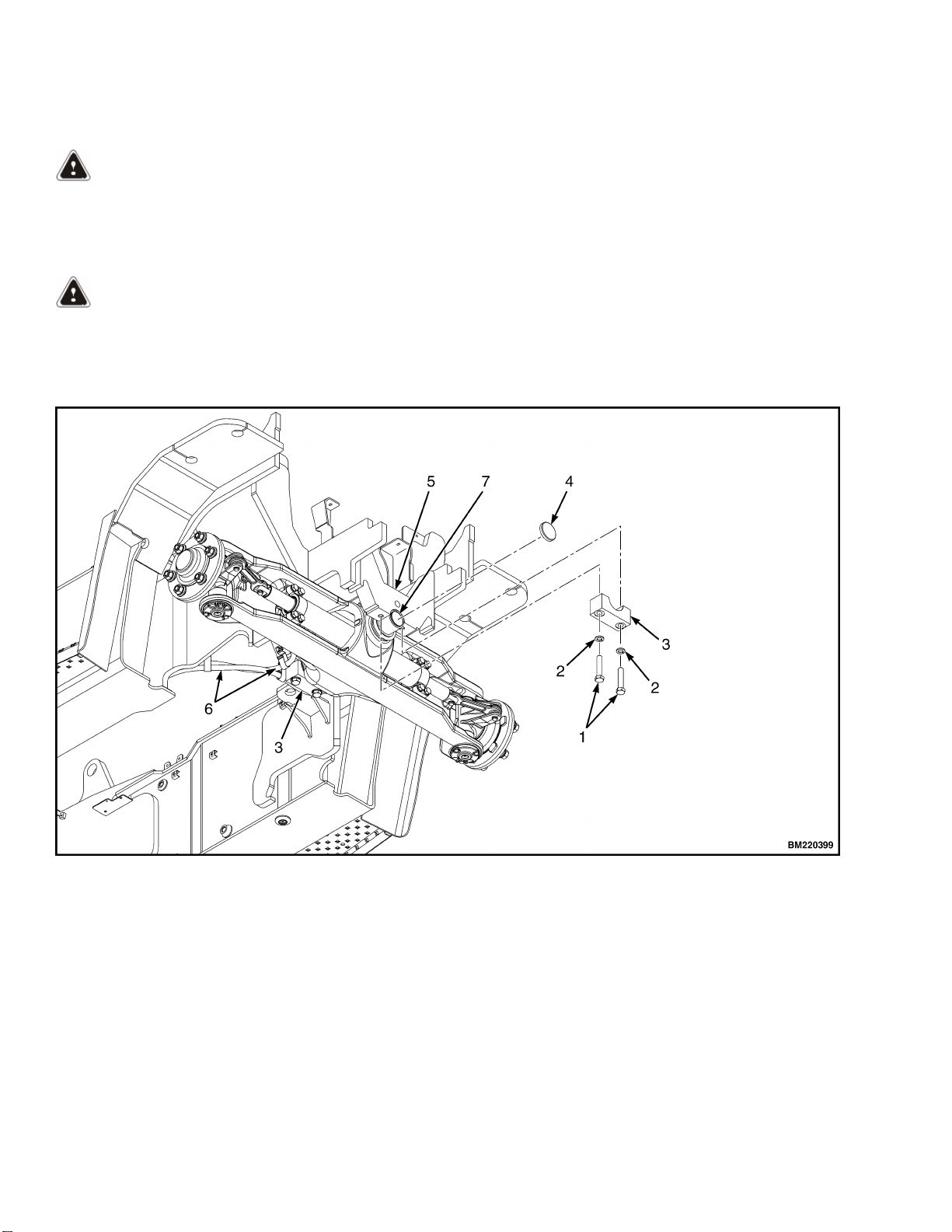

1. Remove ring seal, shims, flange, stub shaft and

bushing from steering axle assembly. See Fig-

ure 4.

2. Put axle on blocks so the wheels just touch the

floor. Remove hub cap. Remove cotter pin,

washer, and castle nut. Remove bearing cone

and discard cotter pin.

NOTE: Identify and tag the outer and inner bear-

ing cones so they can be reassembled in their origi-

nal locations.

3. Slide wheel from spindle. Remove inner bearing

cone, wear ring, and oil seal from spindle. See

Figure 3.

NOTE: If the bearing is replaced, then the associ-

ated bearing cup must be replaced also.

4. If the bearings must be replaced, use a brass

drift pin to remove the bearing cups and wear

ring.

5. Repeat Step 1 through Step 4 for other wheel.

1600 SRM 1952 Steering Axle Assembly Repair

3