1. Introduction

Thank you for purchasing your HYUNDAI product. Please read the user's manual carefully

before operating the machine.

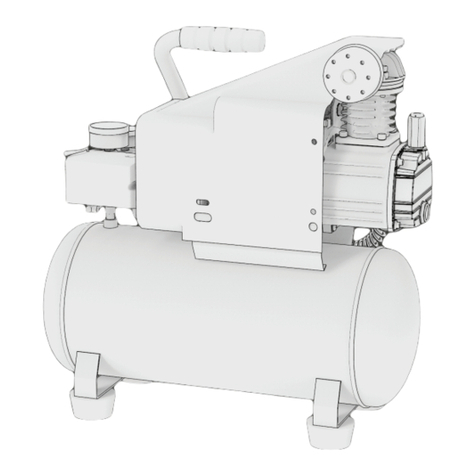

The HYUNDAI screw compressor is a two-shaft positive displacement rotating type air

compressor; with an alternate name of two-shaft air compressor. The compressor has

high and reliable operation characteristics, high gas transmission efficiency characteristics,

excellent dynamic balance characteristics, low noise and vibration as well as easy

operation and maintenance. It is of long performance life and environment protection.

Commonly used in industries of precision machinery and instruments, electronic products

and food, Chemical Fiber and Textile, aerospace application and chemistry, decorative

coating, medical pharmaceutical, traffic transportation and agriculture etc., Products have

a universally acknowledged development prospects.

1.1 Description on the compressor

The screw compressor manufactured by HYUNDAI is an achievement of several years’

research and development. The combination of these prerequisite conditions guarantees a

long performance life, high reliability and operational efficiency. The products meet all

requirements for environment protection.

1.2 Range of application

The machines and units of the series are manufactured according to mature technology

and recognized safety rules. The occurrence of the following, however, might cause threat

to the user or life and body of the third party, which might cause damage to the machines

and other material possessions

Incorrect range of application

Operation by unqualified personnel

Unreasonable modification or transform to the machines

Nonobservance to safety rules

As a result, all staff that has the right to operate, maintain or repair the machines has to

read and obey all safety rules. It can be confirmed by signature if necessary.

The following shall also be obeyed:

Relevant accident prevention rules

Acknowledged safety rules

National laws and regulations.

The machines and units of the series must be operated in perfect technical conditions and

must be operated compliance with the range of application and guideline specified in the

operation manual. The operators shall have strong safety awareness and fully recognize

the risks during the operation of the machines. Any functional breakdowns, especially

those that will threaten the safety, must be repaired in time (or ask others to repair it).