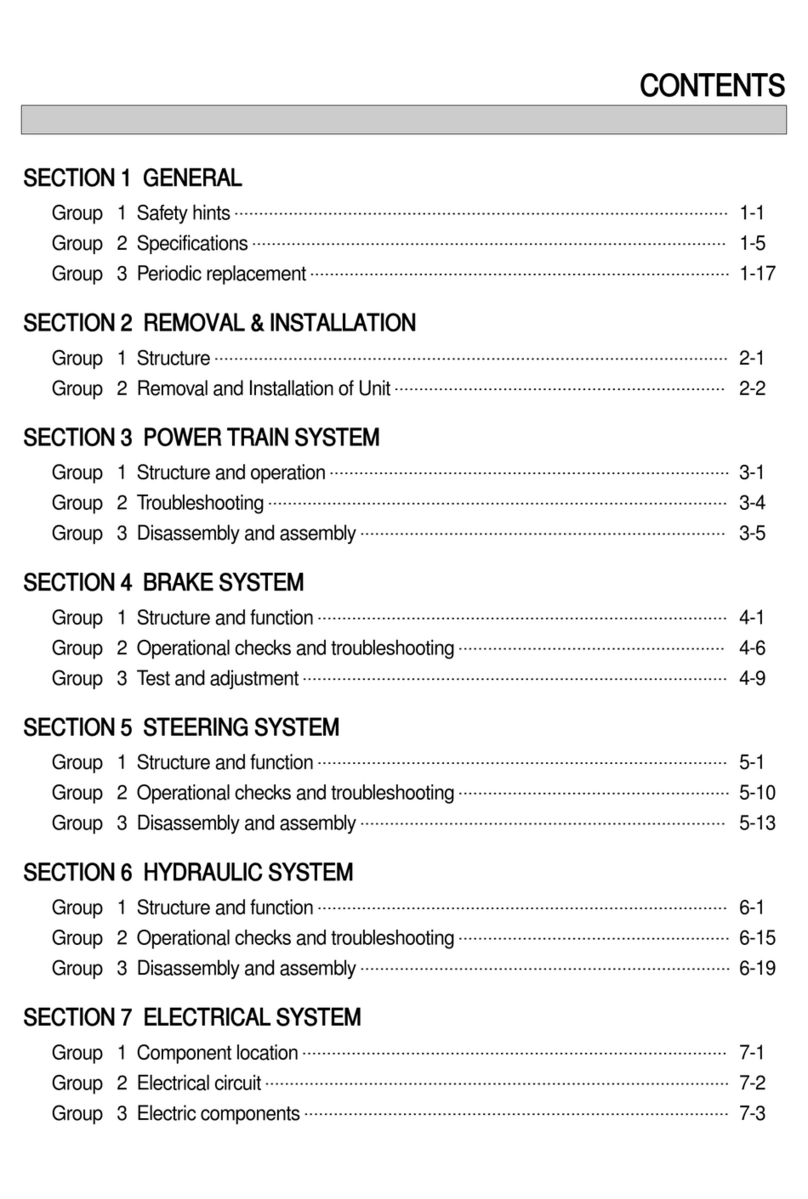

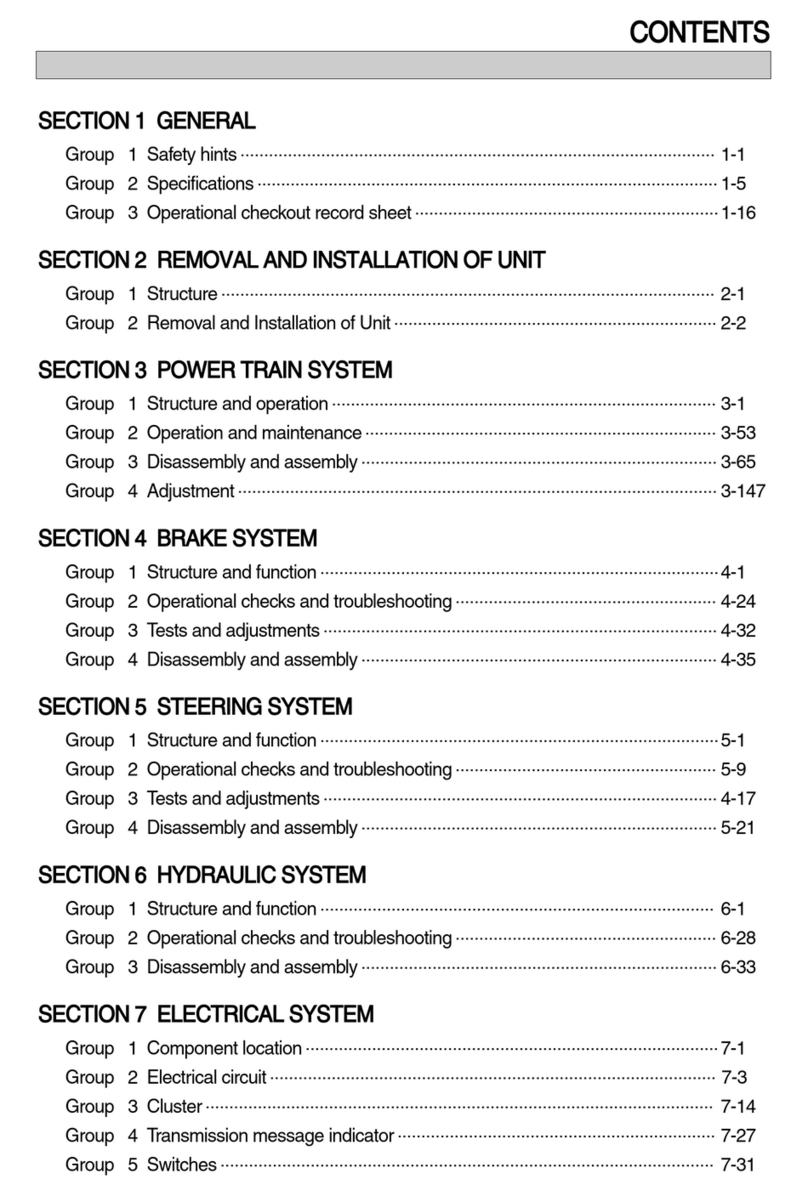

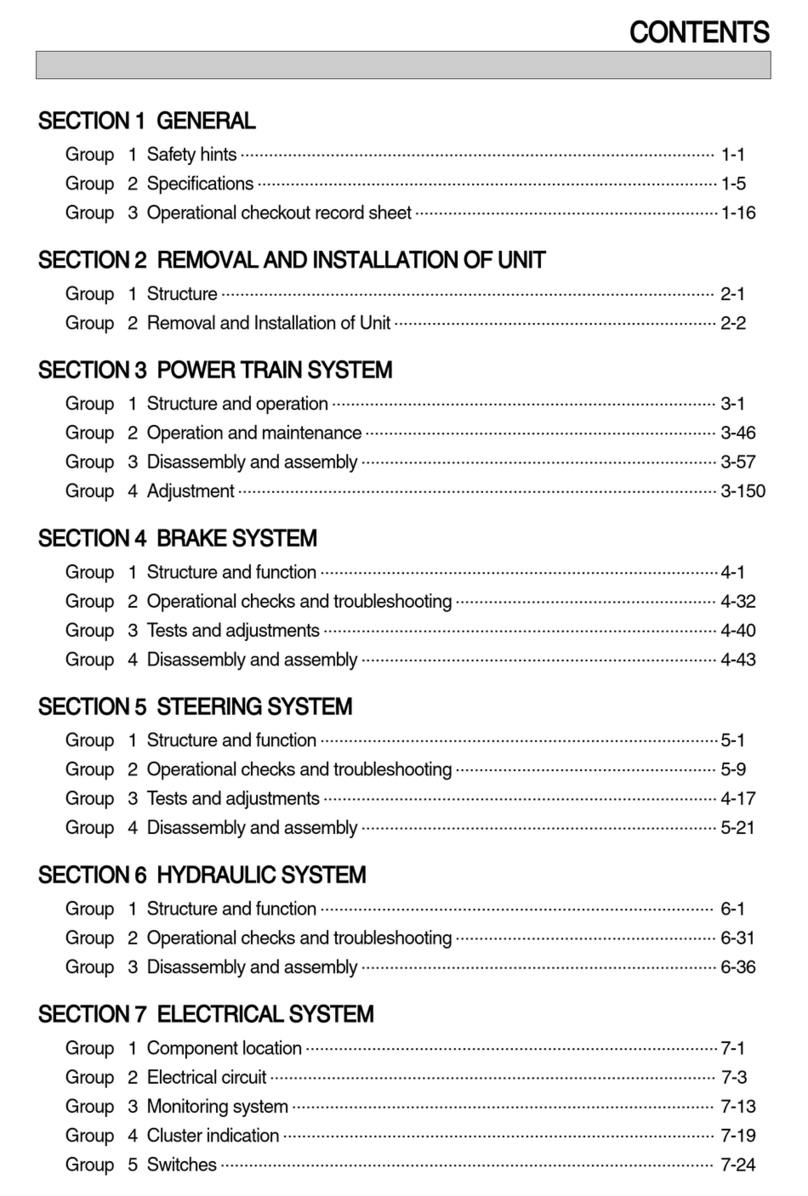

Content

Ⅰ.Specified use ............................................................................................................. 1

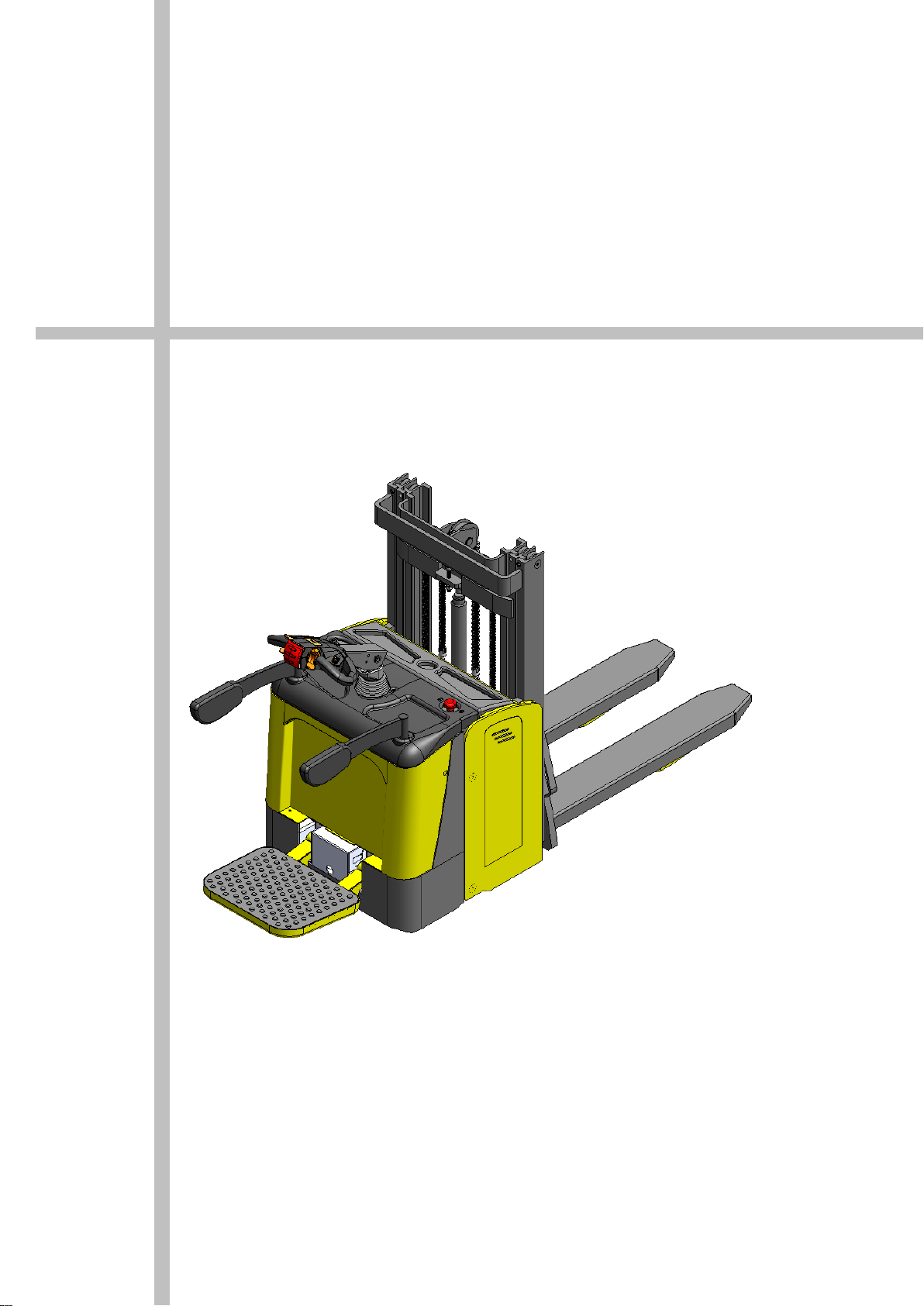

Ⅱ.Forklift introduction .................................................................................................... 1

1. range of application................................................................................................ 1

2. service environment ............................................................................................... 1

3. technical parameters .............................................................................................. 1

3.1 structure....................................................................................................... 2

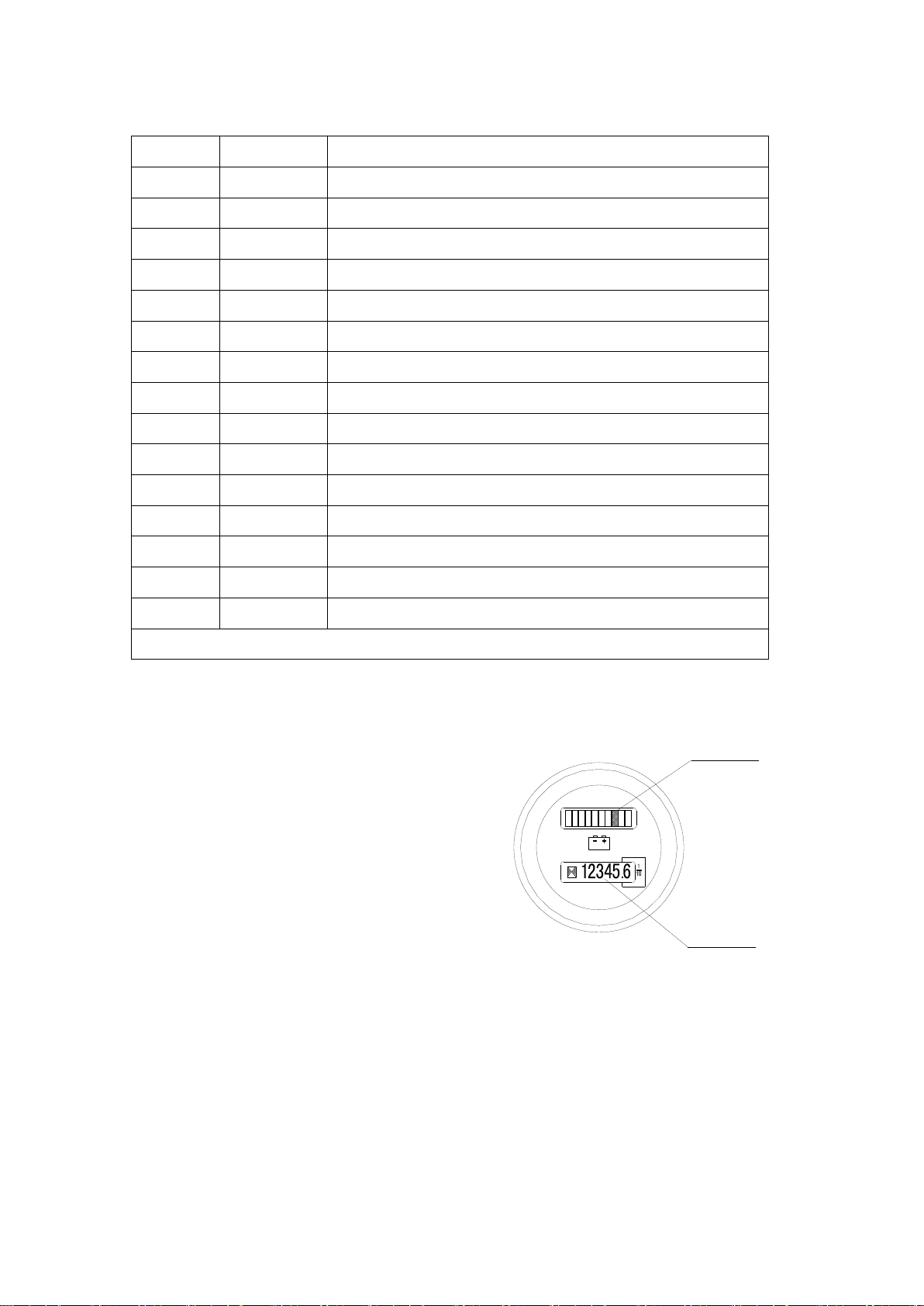

3.2 main technical parameters (20EDPR Electric Pallet Truck) ................................ 2

Ⅲ.Operating instruction ................................................................................................... 7

1.Safety norms……………………………………………………………………………………………..………..9

1.1 safety instructions ......................................................................................... 9

1.2 Safety operation specification…………………………………………………..…………………10

2. Drive and operation.............................................................................................. 11

2.1 inspection before operation ........................................................................ 12

2.2 driving ...................................................................................................... 12

2.3 notice and inspection after operation ......................................................... 17

Ⅳ.Maintenance、charge and replace of battery.............................................................. 17

1. initial charge .................................................................................. ……………………16

2 use and maintenance ........................................................................................... 17

3 storage ............................................................................................................... 18

4 operation of electrolyte.......................................................................................... 18

5 storage battery operation of end service life ........................................................... 18

6.emergency treatment ............................................................................................ 18

7 charger................................................................................................................. 18

8. replacement of battery ......................................................................................... 22

Ⅴ. Maintenance and repair…………………………………………………………………………………………..22

1. Maintenance ........................................................................................................ 23

1.1notice of maintenance .................................................................................. 20

1.2 check and maintenance before use ............................................................. 20

1.3 daily inspection ........................................................................................... 20

1.4 inspection as needed ................................................................................... 21

1.5. inspection and maintenance........................................................................ 21

1.6 working medium recommend ....................................................................... 22

1.7 structure of lift oil cylinder and wearing parts(support leg):......................... 23

1.8 structure of lift oil cylinder and wearing parts(forks)…………………………………….23

1.9 maintenance period of consumables and partial parts ............................... 23

2. Common faults and trouble shooting ..................................................................... 24

Ⅵ. The store, transportation and loading of truck ........................................................... 29

1. loading and unloading of truck .............................................................................. 29

2. transportation ...................................................................................................... 29

3. storage .............................................................................................................. 29

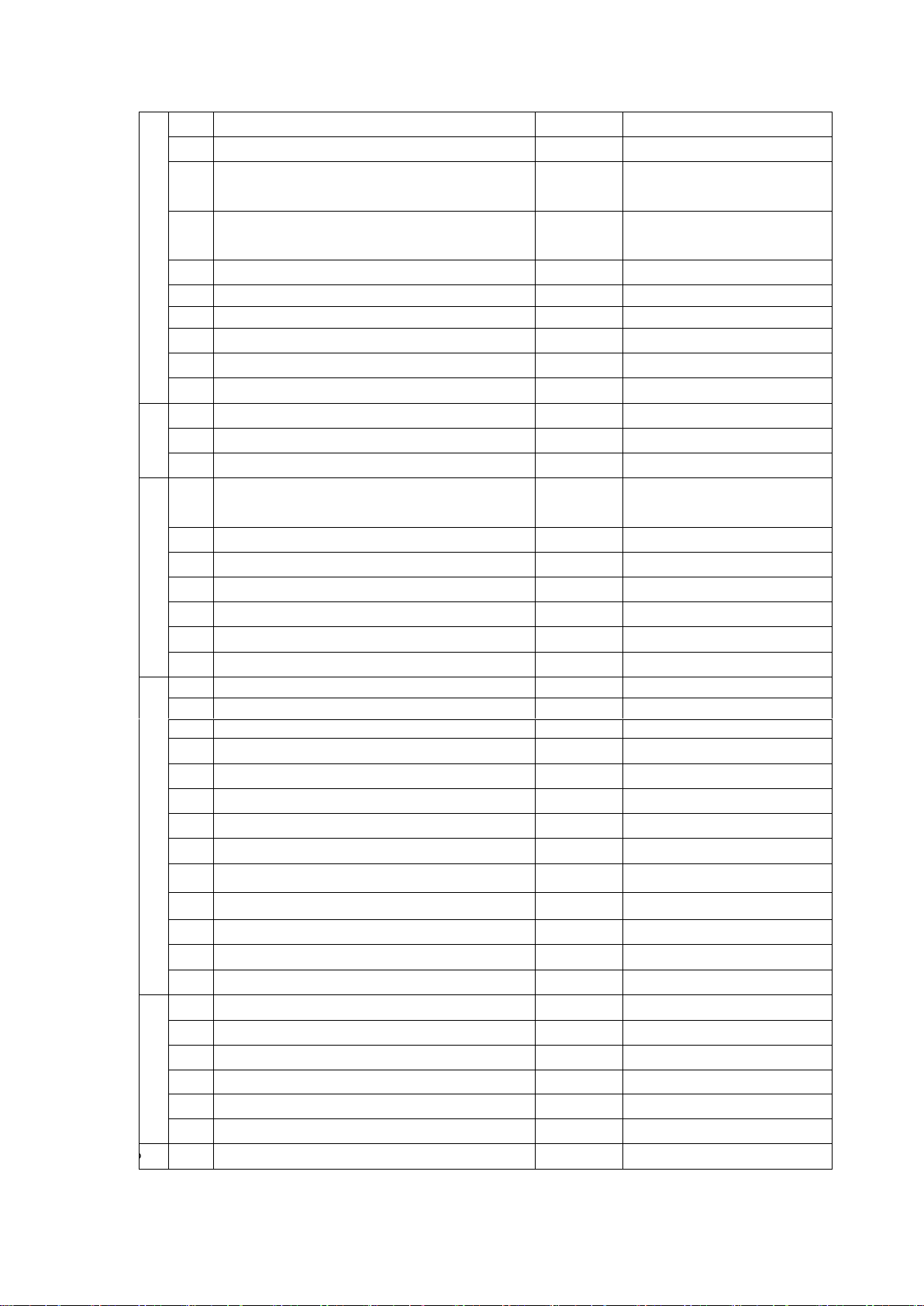

Appendix I...................................................................................................................... 30

Appendix II .................................................................................................................... 31