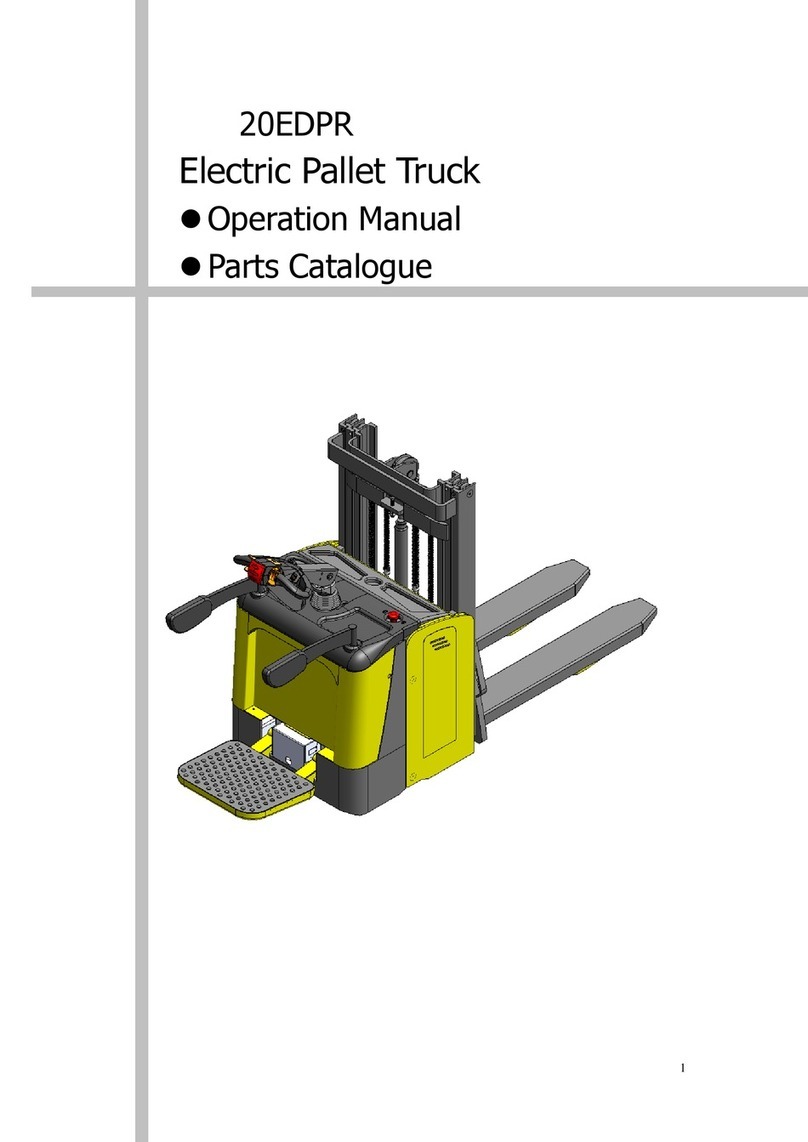

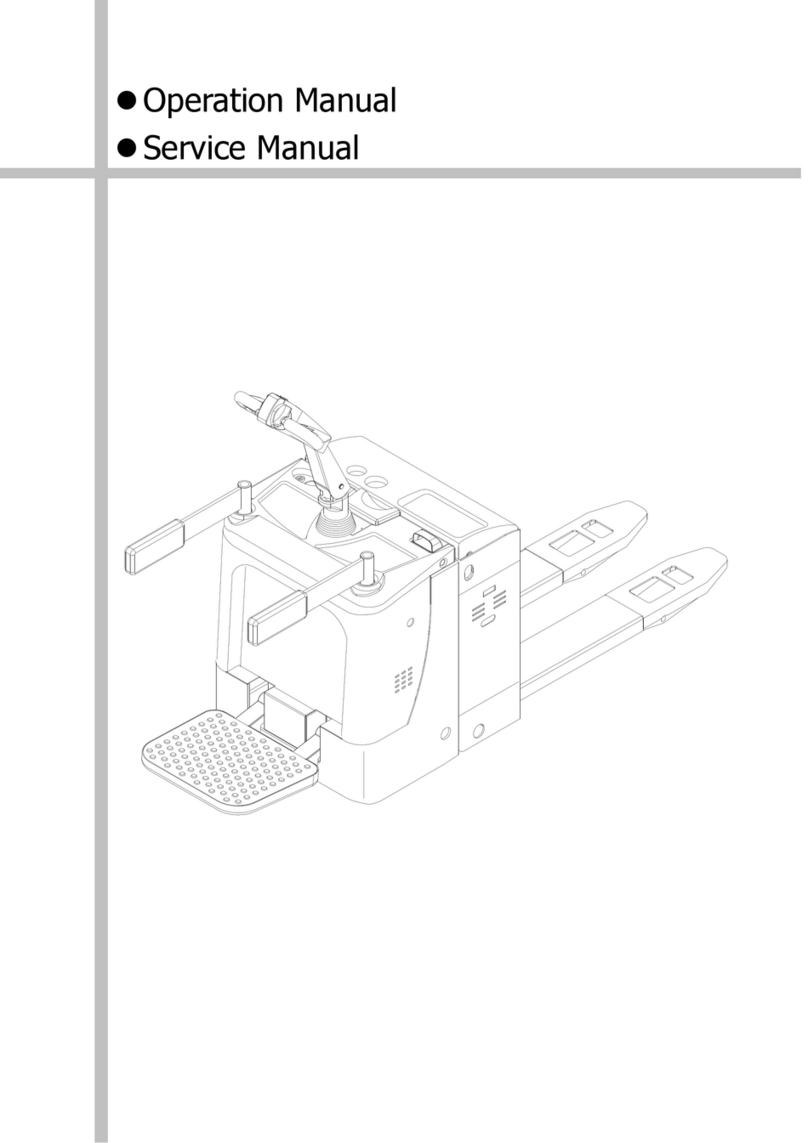

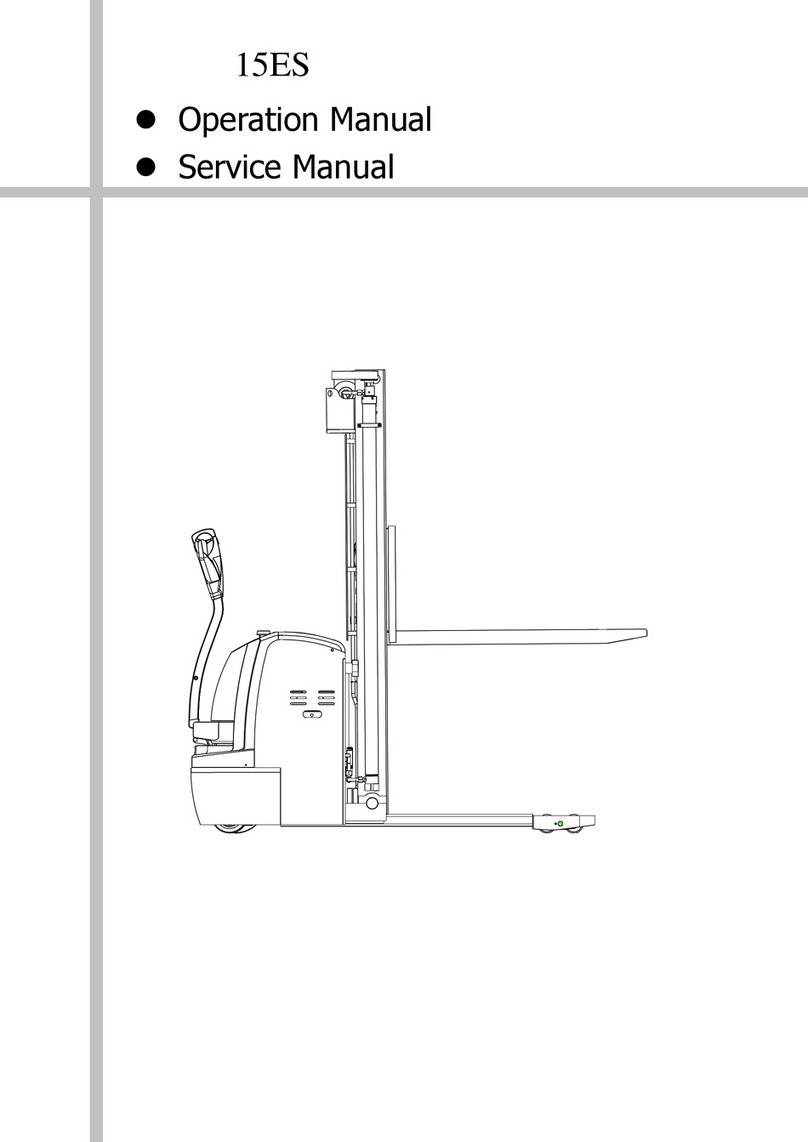

2.Brief introduction of structure (See also the structure diagram

and the principle diagram of the major parts)

The stacker mainly consists of frame, mast, fork, lifting oil cylinder, operation handle, steering

device, driving wheel, storage battery pack, hydraulic power unit and control system for electrical

equipment, etc.

3. Safety Norms:

Warning:

Please pay attention to the following items first before operation of the truck:

1) This electric truck is only limited to utilization indoor with a hard flat floor. Operation in inflammable,

explosive environment or corrosive environment such as acid or alkaline condition shall be strictly

forbidden.

2) Only drivers who have received formal training or are authorized can be allowed to drive the truck.

3) Read this instruction carefully before operation so as to master the performance of the stacker;

check the truck whether it is in its normal condition before each operation. It is forbidden to use

faulty stacker; repair by untrained persons is forbidden as well.

4) Overloading operation is forbidden.

5) As for goods carrying and operation, center of gravity of the goods must be within range of the two

forks. It is forbidden to transport loose goods

6) The truck shall travels slowly when forks pass in or out of pallet.

7) It is strictly forbidden to press the lifting or lowering button during the traveling of the truck.

Meanwhile, don’t switch lifting and lowering buttons rapidly or frequently, because rapid and

frequent lifting or lowering will cause damage to the truck and goods.

8) Don’t load heavy goods on the forks rapidly.

9) Don’t lay the goods on the truck for a long time!

10) It is strictly forbidden to make sharp turn on narrow aisle. When it is turning, slow down the truck so

as to ensure the safety of personnel and goods.

11) Descend the forks to the lowest position when the truck is not used.

12) It is strictly forbidden to put any part of the body under heavy goods and forks.

13) This truck is suitable to be used on flat ground or flat platform. Don’t put the truck on the slope for

a long time.

14) Overloading operation is forbidden. Otherwise the wheel will skid, resulting in the damage of wheel

and motor as well as danger of the human body and goods.

15) It is strictly to use the truck under stipulated voltage of 20.4V.

16) It is strictly forbidden to conduct charge by connecting the plug to AC power directly.

17) It is forbidden to operate the stacker when the lift height of fork exceeds 500mm.

3.1 Safety operation norms:

⑴Training of driver:

Notice

Even though each electric pallet stacker may have the same technical parameters, there

may be differences on features of braking and acceleration as well. Never drive the truck until you

get familiar with all those operations.