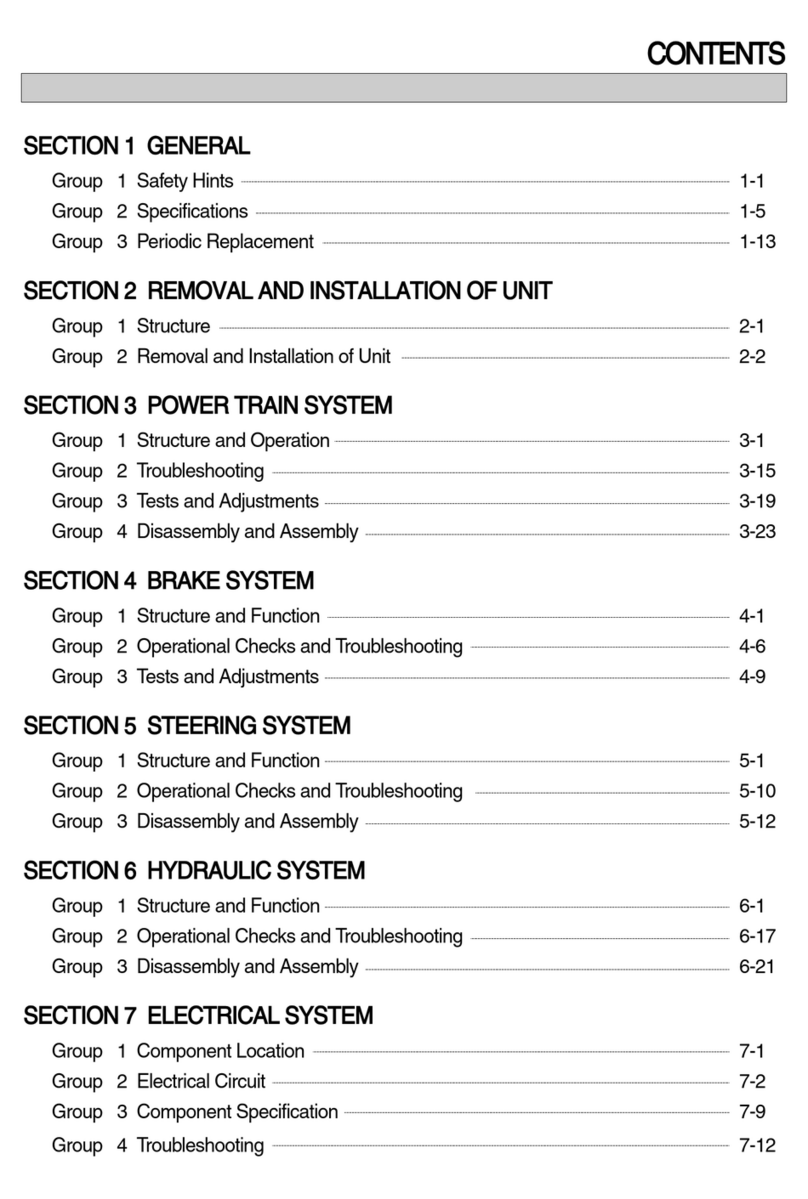

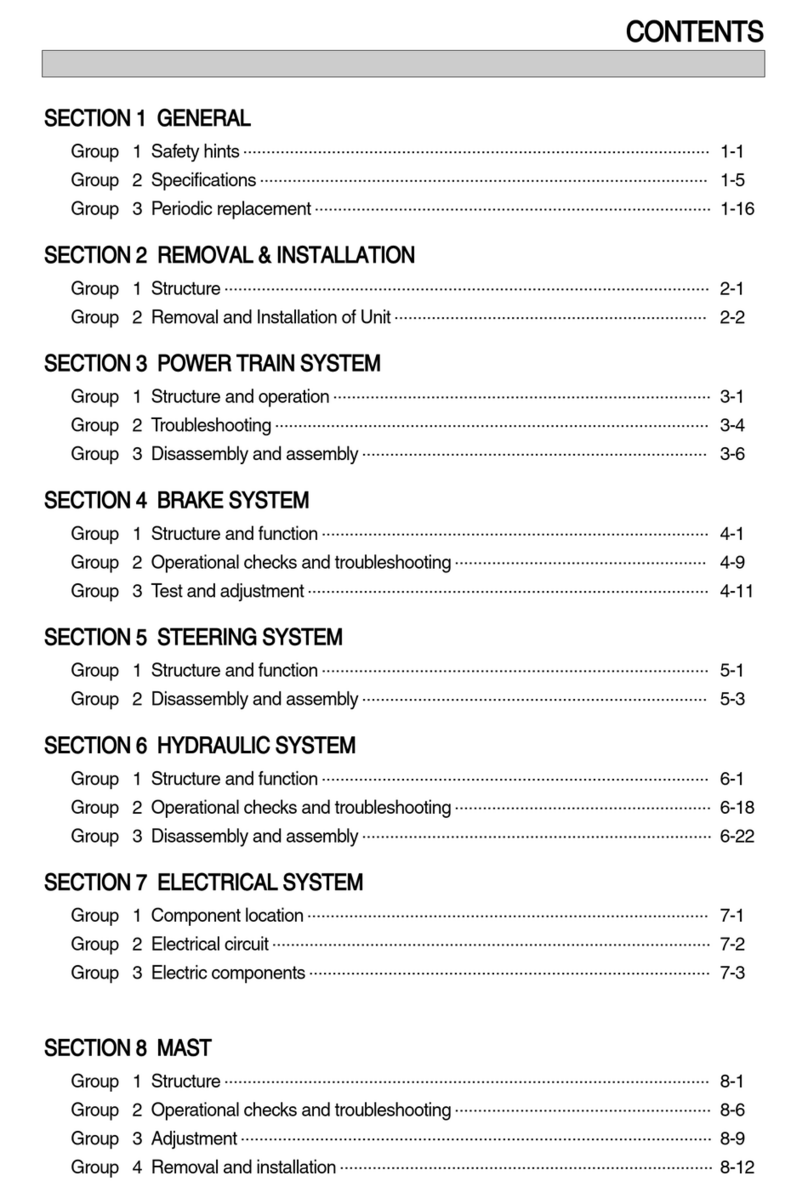

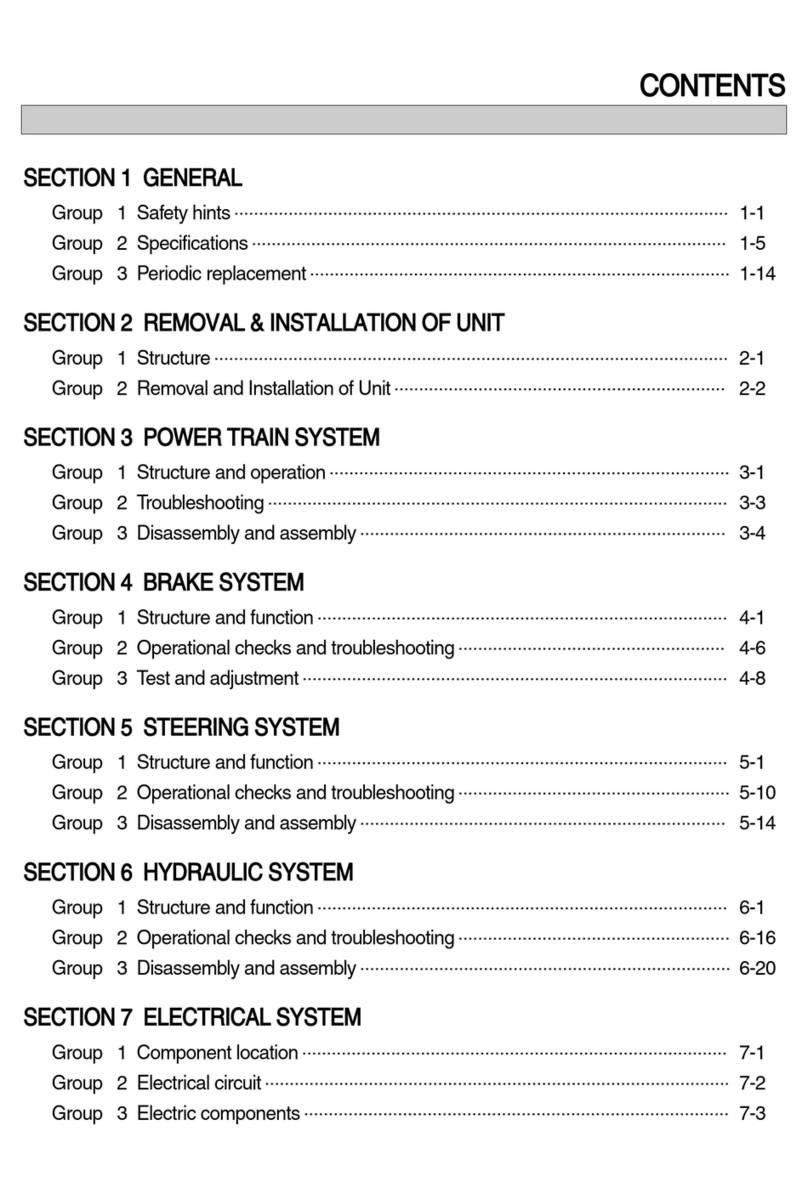

Content

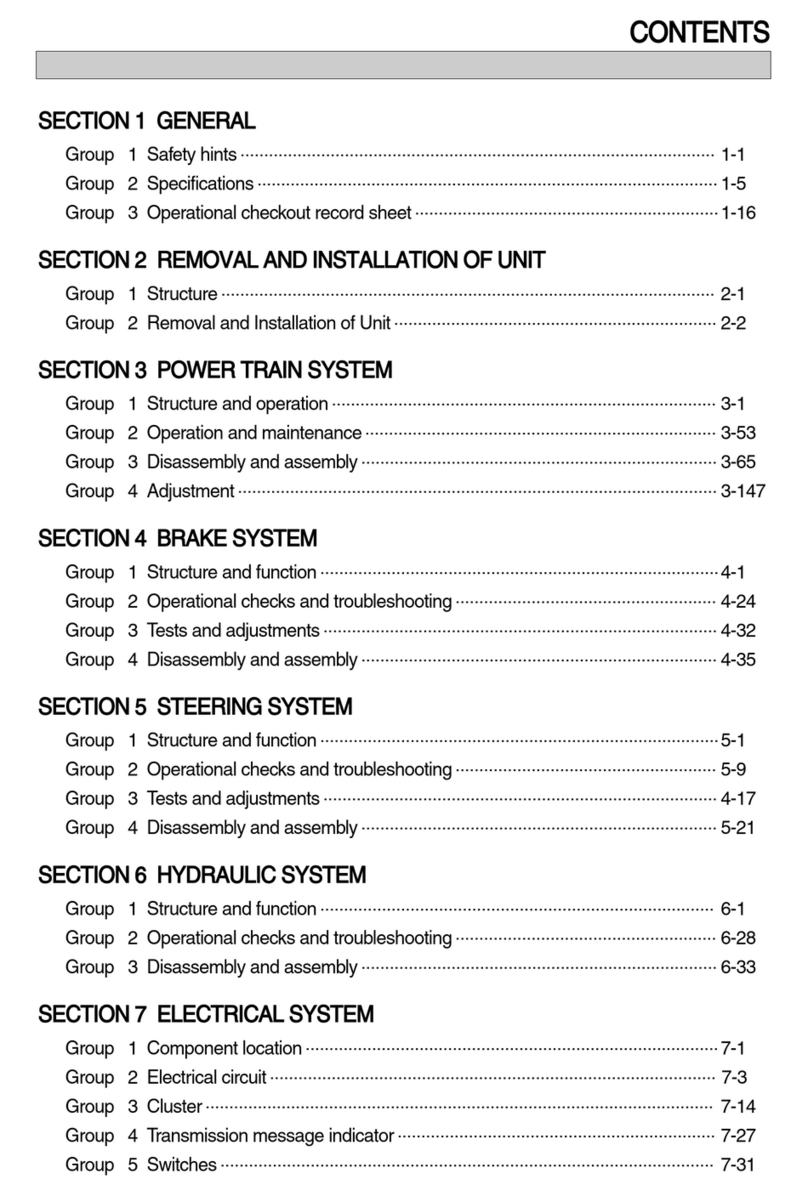

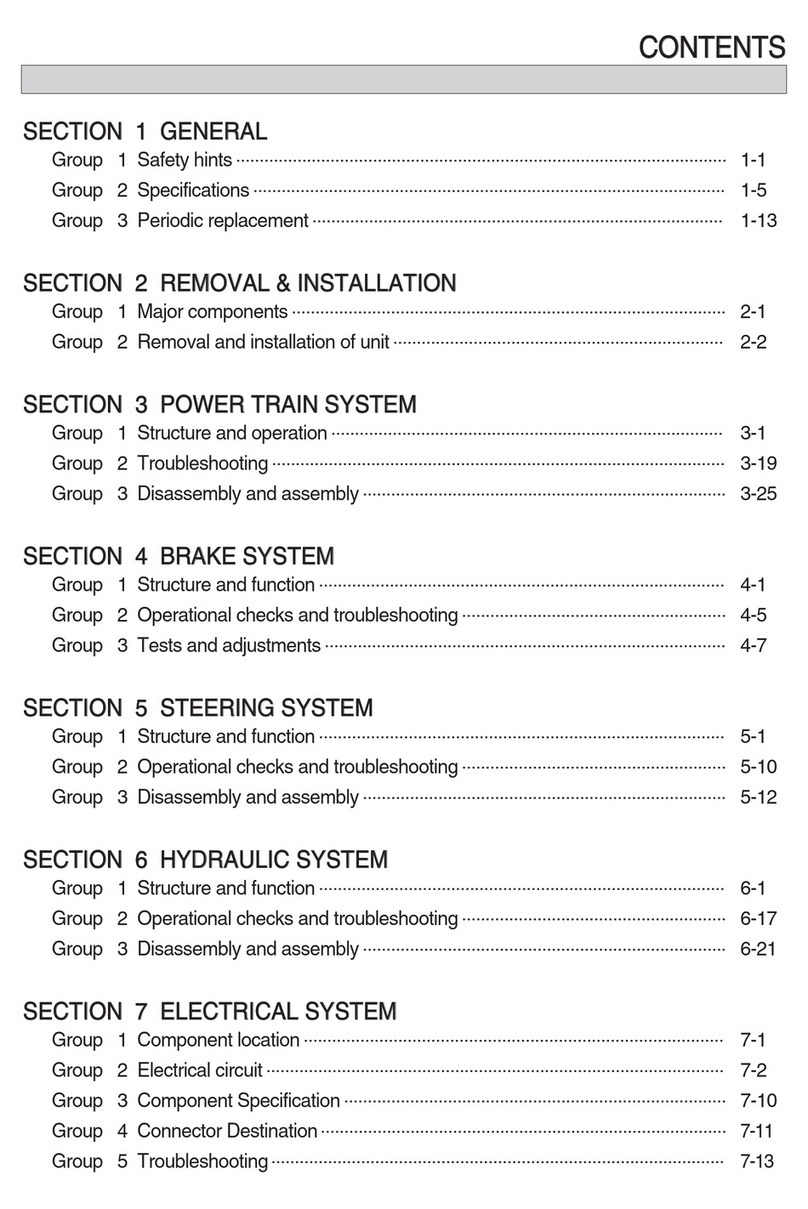

Ⅰ.Specified use ............................................................................................................. 1

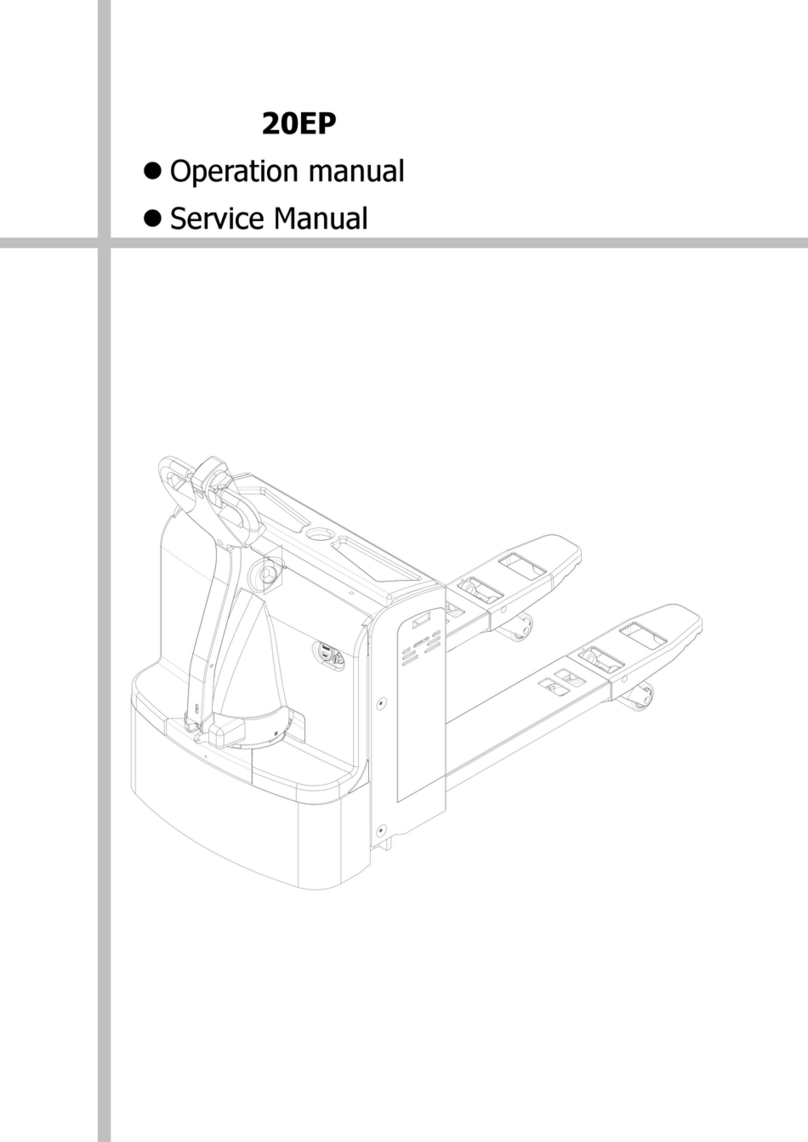

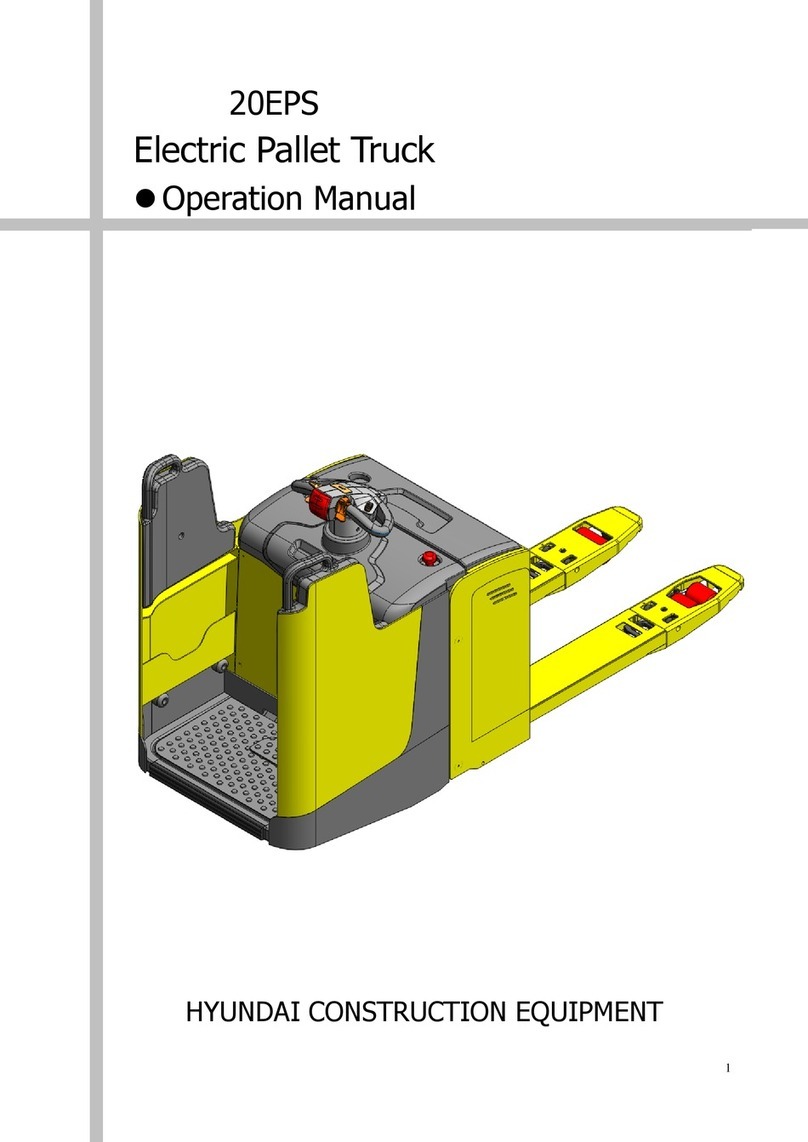

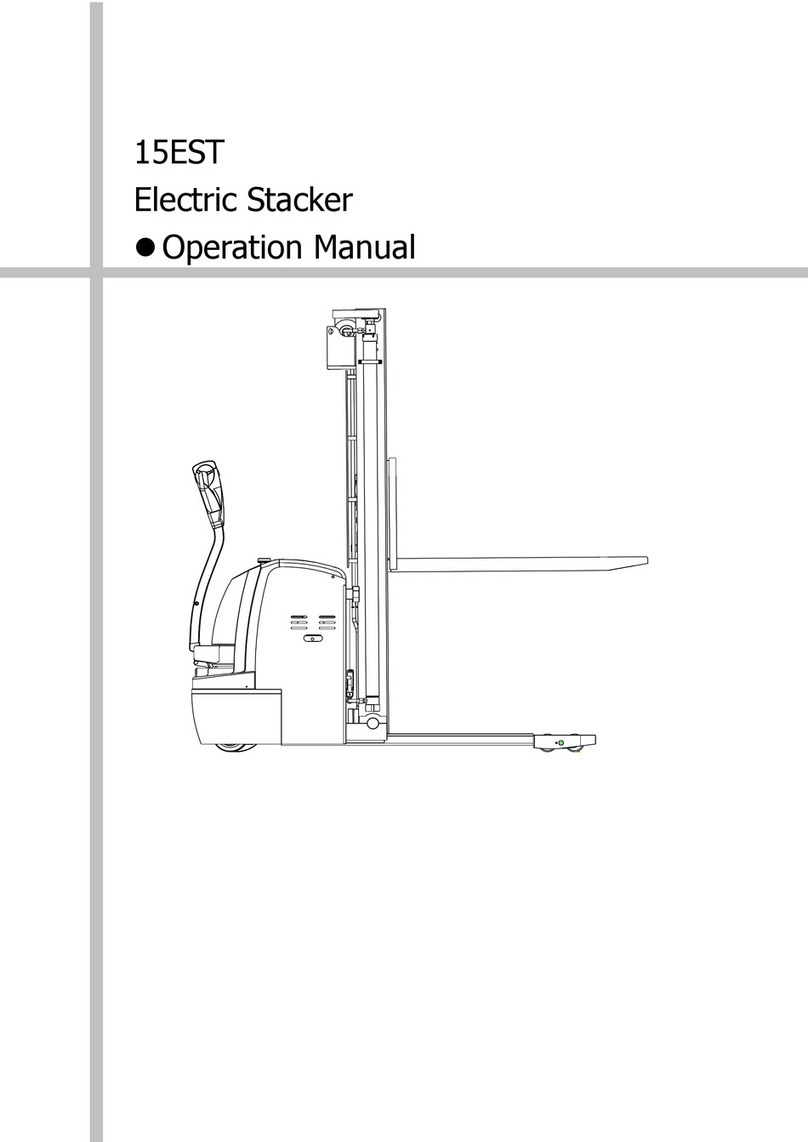

Ⅱ.Forklift introduction.................................................................................................... 1

1. applications ........................................................................................................... 1

2. service environment............................................................................................... 1

3. technical parameters.............................................................................................. 1

3.1 structure ...................................................................................................... 2

3.2 main technical parameters (30EPCR Electric Pallet Truck) ................................ 2

Ⅲ.Operation ................................................................................................................... 7

1Safety norms………………………………………………………………………………………………………..9

1.1 safety instructions......................................................................................... 9

1.2 safe driving standard…………………………………………………………………………………10

2. drive and operation...............................................................................................11

2.1 inspection before operation .........................................................................12

2.2 driving .......................................................................................................12

2.3 Important notice after operation ................................................................13

Ⅳ.Maintenance、charge and replacement of battery.......................................................14

1. initial charge...................................................................................……………………16

2 use and maintenance ...........................................................................................17

3 storage ................................................................................................................18

4 electrolyte operation ..............................................................................................18

5 storage battery operation of end service life ............................................................18

6.emergency treatment.............................................................................................18

7 battery charger......................................................................................................18

8. battery exchange ..................................................................................................17

Ⅴ. Maintenance and repair………………………………………………………………………………………….18

1. Maintenance.........................................................................................................18

1.1 precautions during maintenance ..................................................................20

1.2 check and maintenance before use ..............................................................20

1.3 routine inspection ........................................................................................20

1.4 inspection as needed....................................................................................21

1.5 inspection and maintenance .........................................................................21

1.6 recommended working medium ....................................................................22

1.7 structure of lifting cylinder and wearing parts ................................................23

1.8 maintenance period of consumable and component ..................................23

2. common faults and trouble shooting ......................................................................24

Ⅵ. Loading and unloading, transportation and storage of truck ........................................29

1. loading and unloading...........................................................................................29

2. transportation.......................................................................................................29

3. storage ...............................................................................................................29

Appendix I ......................................................................................................................30

Appendix II .....................................................................................................................31

Appendix III....................................................................................................................32