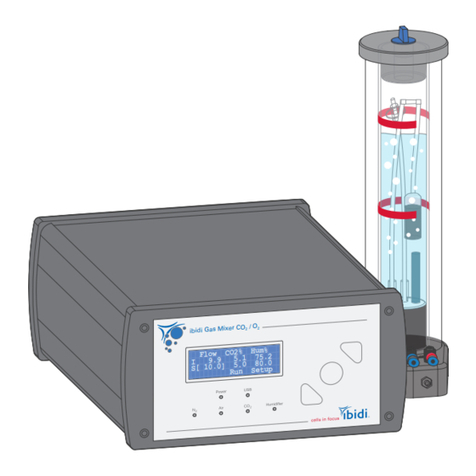

Gas Incubation System

1.5 Disclaimer

• ibidi shall not be held liable, either directly or indirectly, for any damage incurred as a result of

product use.

• The contents of this manual are subject to change without notice for product improvement.

• This manual is considered complete and accurate at publication.

• This manual does not guarantee the validity of any patent rights or other rights.

• If an ibidi software program doesn’t function properly, this may be caused by a conflict from

another program operating on the computer. In this case, take corrective action by uninstalling

the conflicting product(s).

• ibidi is a registered trademark of ibidi GmbH in Germany and other countries.

1.6 Safety Considerations

WARNING!

• Only operate the Gas Incubation System with the supplied components.

• Only use the cables and plugs delivered with the system. The power plug of the control unit

must be inserted in an outlet with a ground (earth) contact.

• Do not replace detachable power cables by power cables with inadequate specifications. By

violating these instructions you risk electric shock and fire.

• Only use extension cables that have a protective ground wire.

• Do not operate the Gas Incubation System under conditions that pose a risk of explosion, implo-

sion, or the release of gases. Only operate the Gas Incubation System with aqueous solutions.

• Do not operate a damaged Gas Incubation System. If the housing seems damaged or something

is rattling inside the controller, contact the ibidi service hotline for repair.

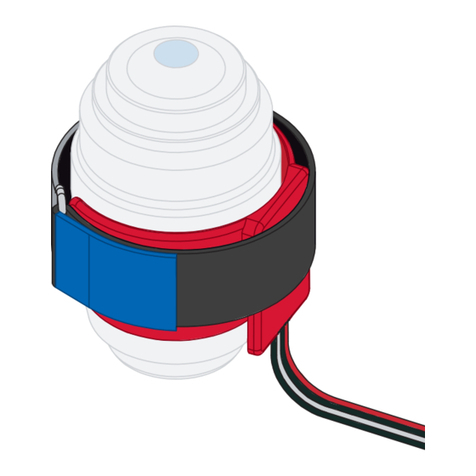

• Some accessible parts of the Gas Incubation System (Humidifying Column base, water inside

the column, and Heated Tubing Package) can reach temperatures up to 55°C/131°F (60°C/140°F

the water inside the column). Avoid touching the temperature-controlled parts of the system

when hot.

CAUTION

• Ensure that the external power supply is easily accessible. The Gas Incubation System must be

installed in a manner such that none of its components hinders access to the external power

supply.

• Immediately replace damaged cords, plugs, or cables to avoid risk of personal injury or damage

to the instrument.

Version 2.2 (May 15, 2019) 10 Instruction Manual