Contents

Safety notices ................................. v

Removing and replacing parts in the 9006-12C ................... 1

Removing and replacing a storage drive in the 9006-12C..................... 2

Removing a front disk drive from the 9006-12C or 9006-22C system ................ 3

Replacing a front disk drive in the 9006-12C or 9006-22C system ................. 6

Removing a drive on module from the 9006-12C system.................... 9

Replacing a drive on module in the 9006-12C system .................... 10

Removing and replacing the disk drive backplane in the 9006-12C ................. 12

Removing the disk drive backplane from the 9006-12C .................... 12

Replacing the disk drive backplane in the 9006-12C ..................... 15

Removing and replacing fans in the 9006-12C ........................ 17

Removing a system fan from the 9006-12C ........................ 17

Replacing a system fan in the 9006-12C ......................... 20

Removing and replacing a graphics processing unit in the 9006-12C ................ 23

Removing the graphics processing unit from the 9006-12C system ................ 23

Replacing the graphics processing unit in the 9006-12C system ................. 25

Removing and replacing memory in the 9006-12C ...................... 27

Removing and replacing PCIe adapters in the 9006-12C .................... 31

Removing a PCIe adapter from the 9006-12C system .................... 31

Replacing a PCIe adapter in the 9006-12C system...................... 35

Removing and replacing the system backplane in the 9006-12C .................. 39

Removing the system backplane in the 9006-12C ...................... 39

Replacing the system backplane in the 9006-12C ...................... 44

Removing and replacing a system processor module in the 9006-12C ................ 55

Removing a system processor module from the 9006-12C system ................ 55

Replacing a system processor module for the 9006-12C .................... 61

Removing and replacing the time-of-day battery in the 9006-12C ................. 69

Removing and replacing the TPM card in the 9006-12C..................... 71

Common procedures for servicing or installing features in the 9006-12C ....... 73

Before you begin ................................. 73

Identifying the system that contains the part to replace..................... 76

LEDs on the 9006-12C system ............................ 76

Identifying the 9006-12C or 9006-22C that needs servicing ................... 77

Preparing the 9006-12C system to remove and replace internal parts ................ 78

Preparing the 9006-12C system for operation after you remove and replace internal parts ......... 80

Starting and stopping the 9006-12C or 9006-22C ....................... 81

Starting the 9006-12C or 9006-22C system ........................ 81

Stopping the 9006-12C or 9006-22C system ........................ 82

Drive commands for 9006-12C or 9006-22C ......................... 82

arcconf commands ................................ 82

StorCLI commands ................................ 83

sas3ircu commands................................ 84

NVMe commands ................................ 84

Sensor readings GUI display ............................. 85

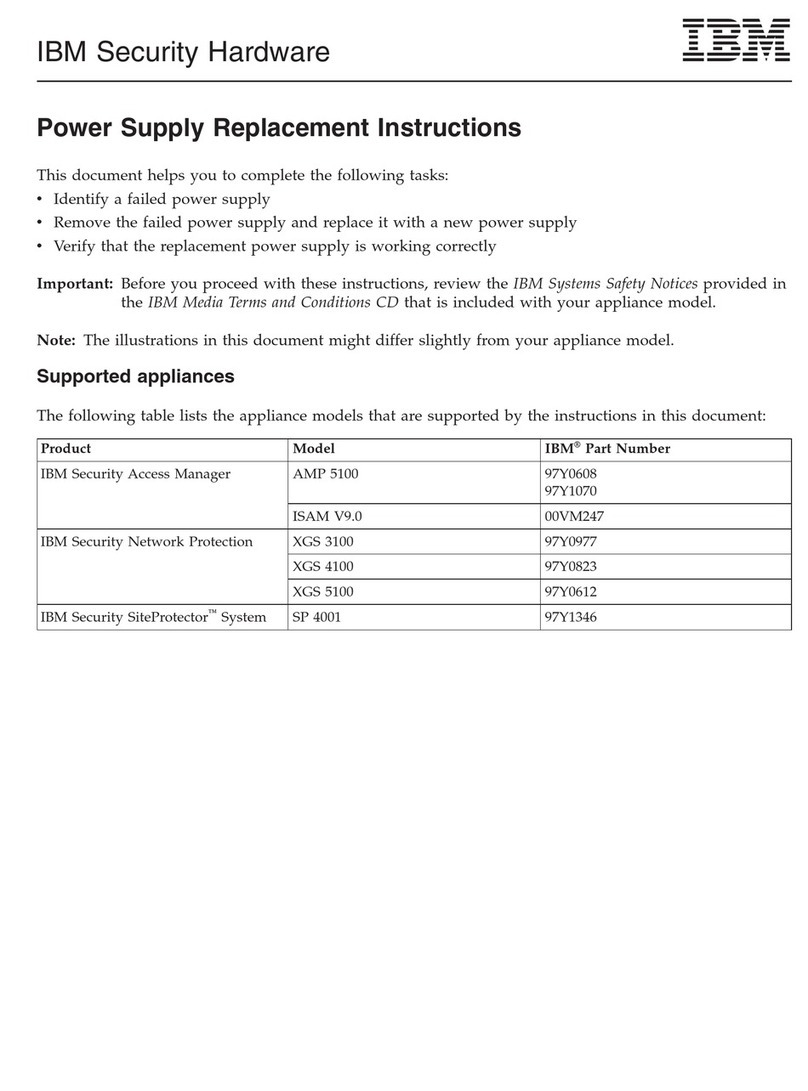

Removing and replacing a power supply in the 9006-12C or 9006-22C................ 85

Removing a power supply from the 9006-12C or 9006-22C................... 86

Replacing a power supply in the 9006-12C or 9006-22C.................... 87

Removing and replacing covers on an 9006-12C system..................... 88

Removing the service access cover from an 9006-12C system .................. 88

Installing the service access cover on an 9006-12C system ................... 89

Service and operating positions for 9006-12C ........................ 90

Placing an 9006-12C system into the service position .................... 90

Placing an 9006-12C system into the operating position.................... 91

© Copyright IBM Corp. 2017 iii