Ver. 1.04.19

© 2012 -2019 by ICS

2

Content

Your dry-ice blasting unit ........................................................................................................................ 3

Introduction & Copyright ........................................................................................................................ 4

Safety equipment ....................................................................................................................................

Emergency stop ....................................................................................................................................... 6

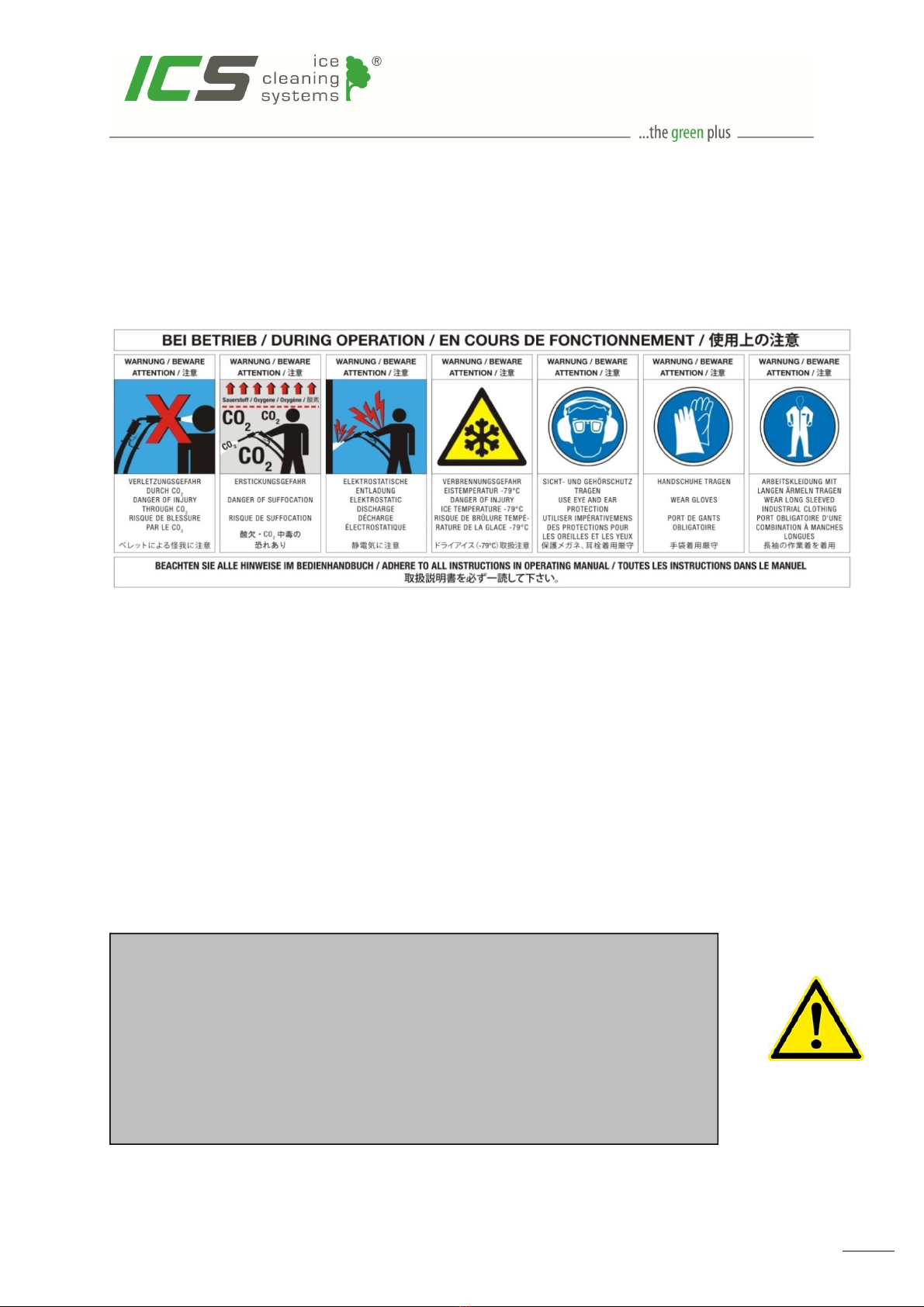

Safety precautions ................................................................................................................................... 7

Technical data of the IC 022 .................................................................................................................... 9

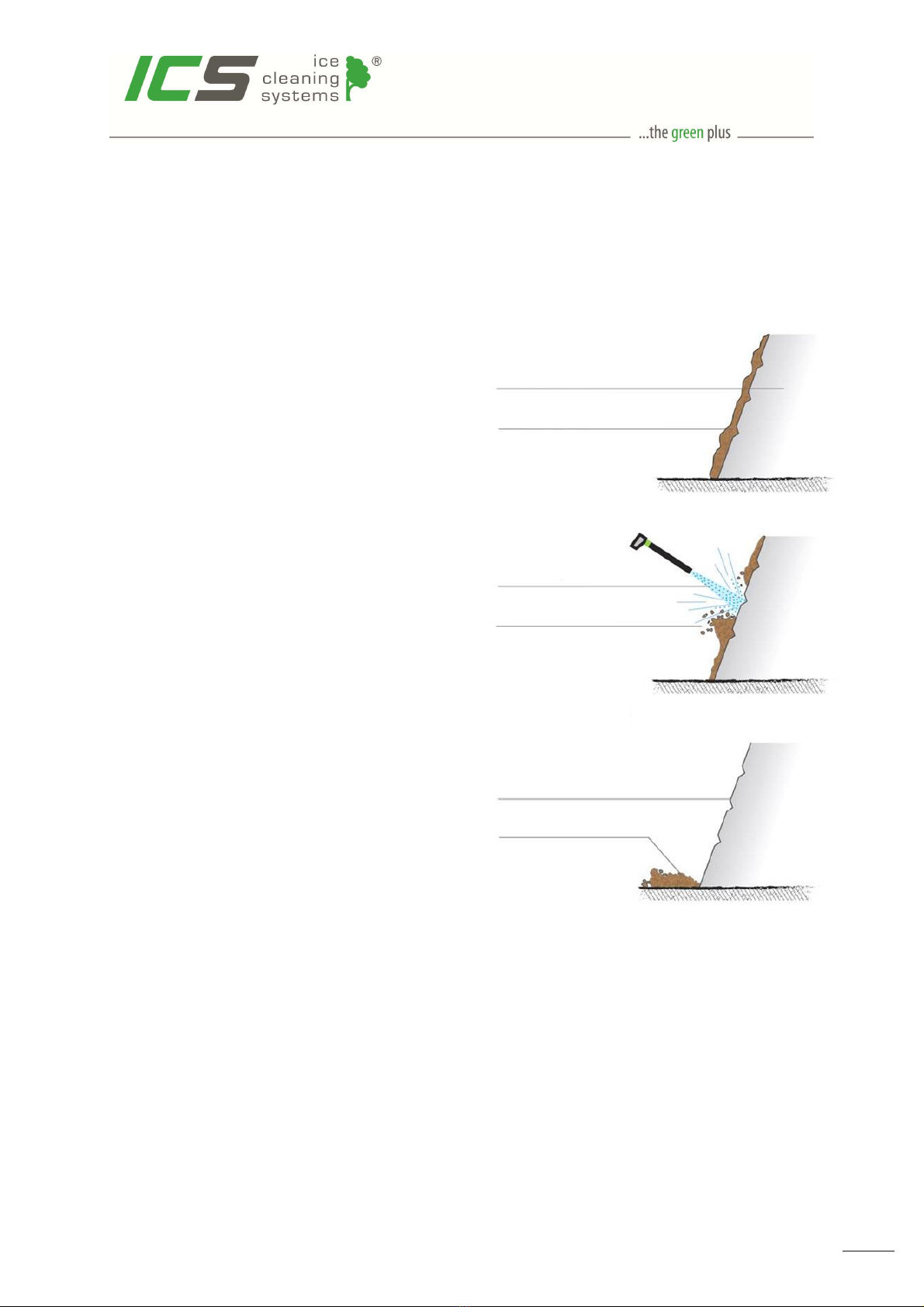

Process description ............................................................................................................................... 10

Connections and components of the IC 022 ......................................................................................... 11

Connections and components of the front side ................................................................................ 11

Connections and components of the back side ................................................................................ 12

Operation of the blasting gun IG 022 .................................................................................................... 13

Start-up .................................................................................................................................................. 14

Shut-down ............................................................................................................................................. 14

Filling the hopper of the IC 022 ............................................................................................................. 1

Transport ............................................................................................................................................... 16

Requirements for the compressed air................................................................................................... 16

Repair, maintenance and warranty ....................................................................................................... 17

Maintenance ..................................................................................................................................... 17

Terms of warranty ............................................................................................................................. 17

Maintenance schedule for IC 022 .......................................................................................................... 18

Troubleshooting .................................................................................................................................... 19

Zeichnung IC 022 ................................................................................................................................... 20

Pneumatic plan IC 022 ........................................................................................................................... 21

Part list Pneumatic IC 022 ..................................................................................................................... 22

EG- ......................................................................................................................................................... 24

ISO Certificate ........................................................................................................................................ 2