1

Instruction manual

Please read this manual thoroughly before using the tools and store in a safe place for quick and easy reference at

all times.

Incorrect use of this device or actions non conform to the Directive can cause serious injuries. To be used only by

qualified personnel.

You must observe the following points in the interest of your own safety!!!

Safety instructions:

1. The tool causes considerable noise pressure. Please wear hearing protection in order to avoid noise which can

be Damaging to your health.

2. When working with the tools, small parts may be whirled into the air: Wear protective goggles to prevent eye

injuries. Also take care that the people around you are sufficiently protected.

3. Only use the tools in ventilated spaces.

4. Never operate the tools with more than 8.5 bar.

5. Do not use cleaning agents which are acidic, alkali and/or inflammable. We recommend the use of neutral

cleaning agents.

6. When using cleaning fluids which need to be diluted, always strictly observe the manufacturer's instructions to

make sure. The mixture is correct.

7. The tools nebulizers the cleaning liquid very finely. To prevent health hazards from inhalation, wear appropriate

Respiratory protection.

8. Long hair or clothes can get tangled in the rotating tube in the nozzle and cause serious injuries.

9. Never point the tools towards the face or body.

10. When your tools doesn’t work anymore, turn off the device immediately and take it to a qualified service

engineer.

11. Before you replace parts, cut off the connection to the compressed air supply, so you accidently don’t set the

tools to Work.

12. Keep the tools out of the reach of children.

We recommend you never clean any safety-related components, e.g. safety belts, electrical or electronic modules,

with the tools.

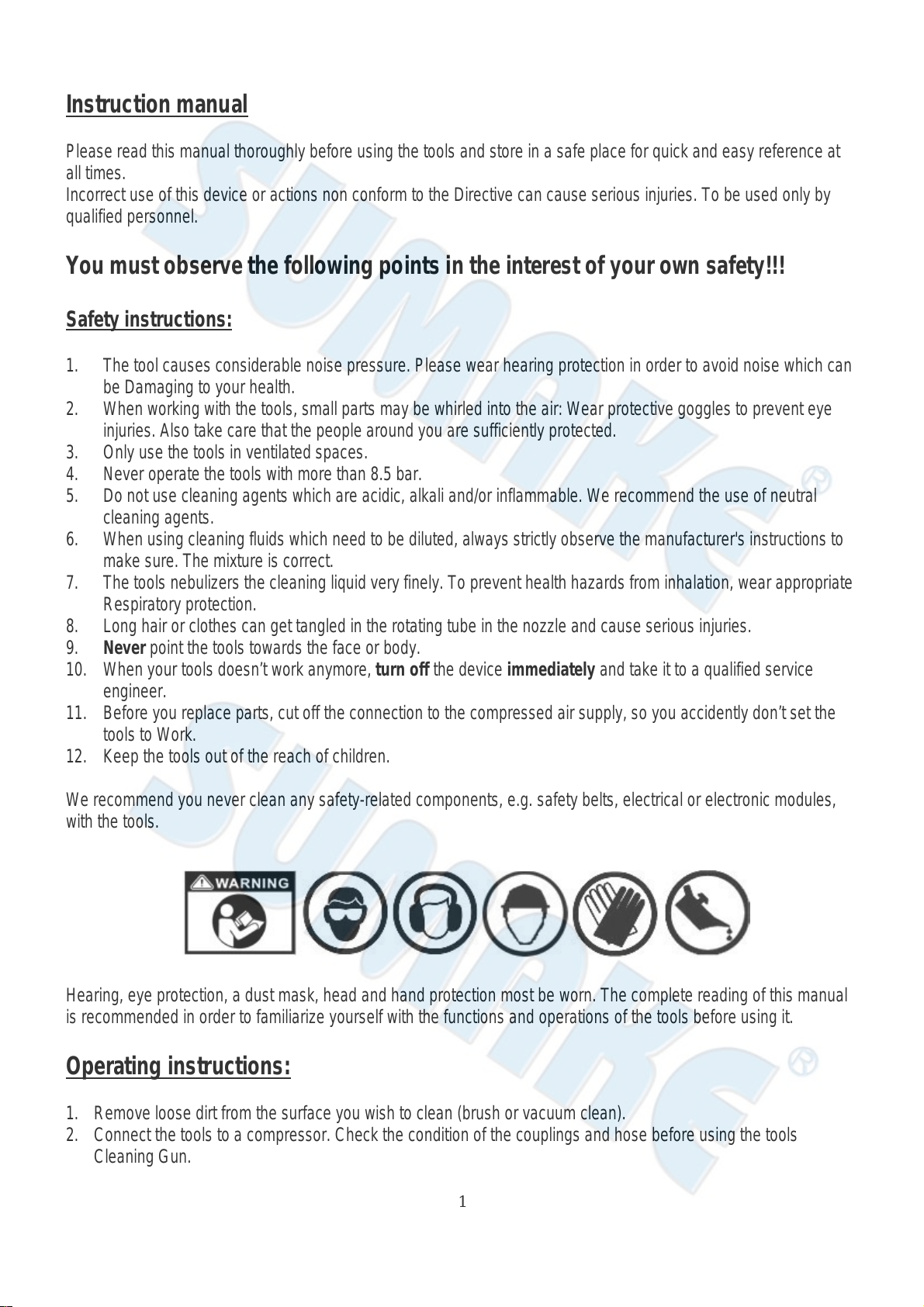

Hearing, eye protection, a dust mask, head and hand protection most be worn. The complete reading of this manual

is recommended in order to familiarize yourself with the functions and operations of the tools before using it.

Operating instructions:

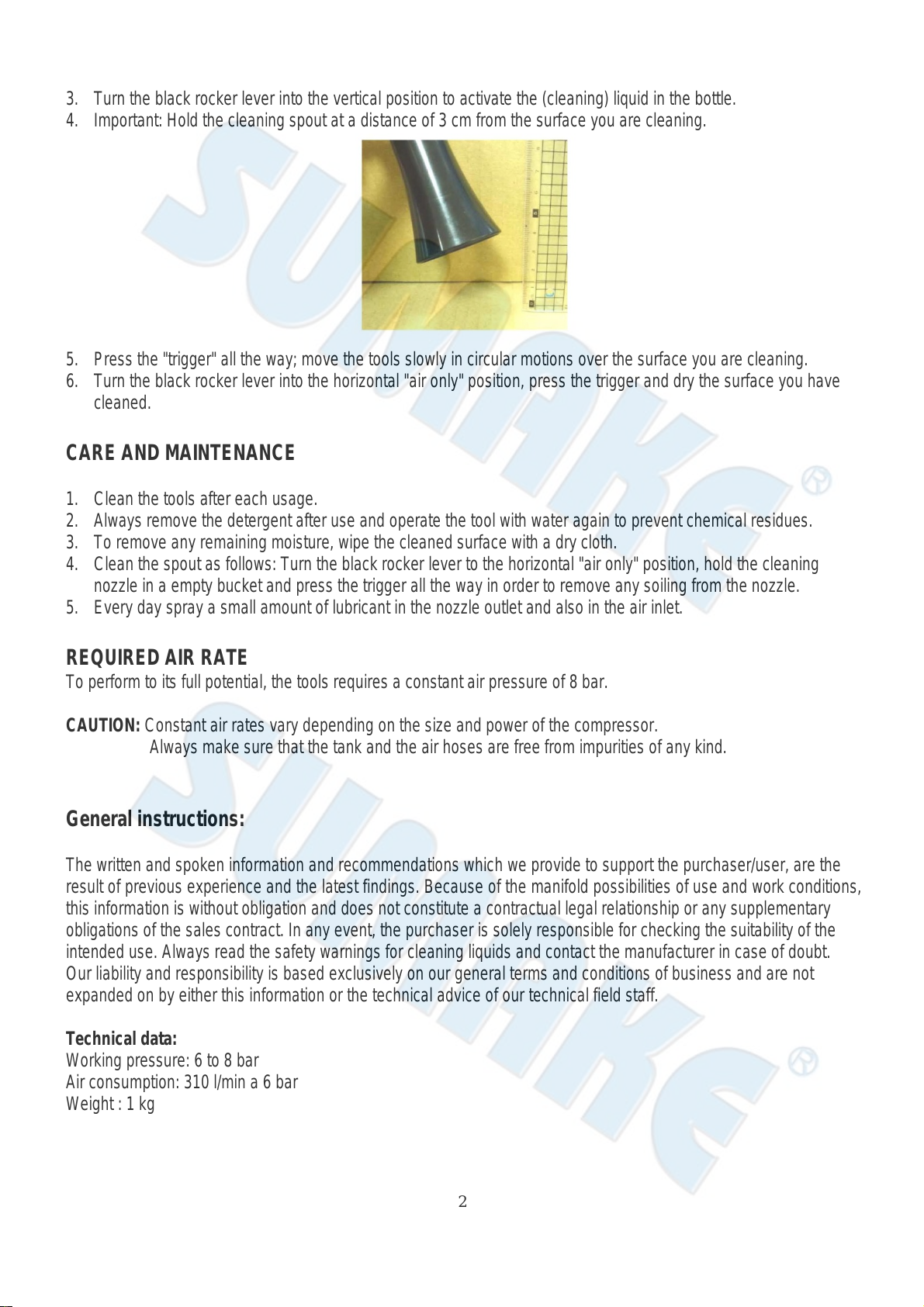

1. Remove loose dirt from the surface you wish to clean (brush or vacuum clean).

2. Connect the tools to a compressor. Check the condition of the couplings and hose before using the tools

Cleaning Gun.