CONTENTS

TABLE OF CONTENTS ----------------------------------------------------------------------- 1

INTRODUCTION, EZ TROUBLESHOOTING ----------------------- --- ------------ 2~3

CLONING MODE ---------------------------------------------------------------------------- 4~5

GETTING STARTED

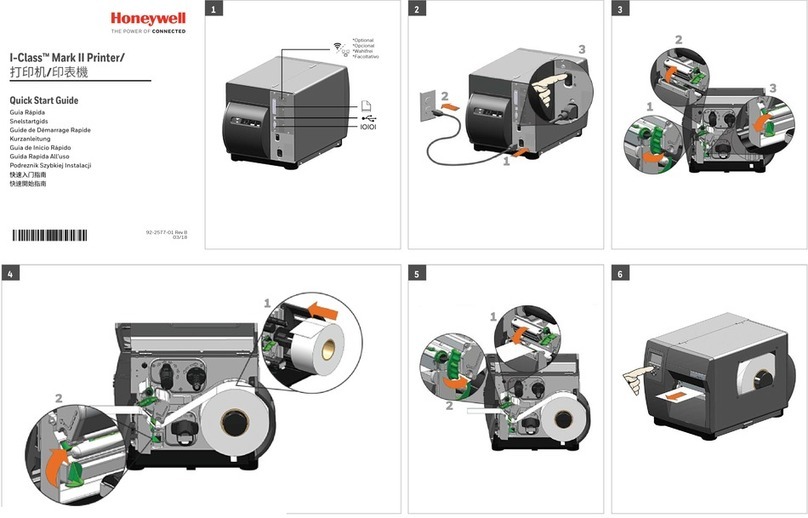

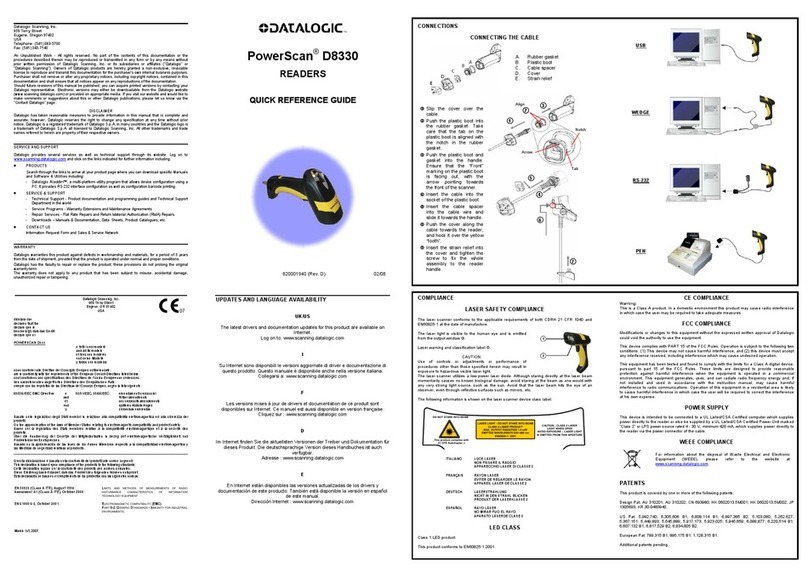

>>> HOW TO FIX THE SCANNER TO THE TERMINAL ----------------------- 6~7

>>> HOW TO CHANGE A CABLE --------------------------------------------------------- 7

>>> HOW TO SETUP THE PARAMETER.----------------------------------------------- 8

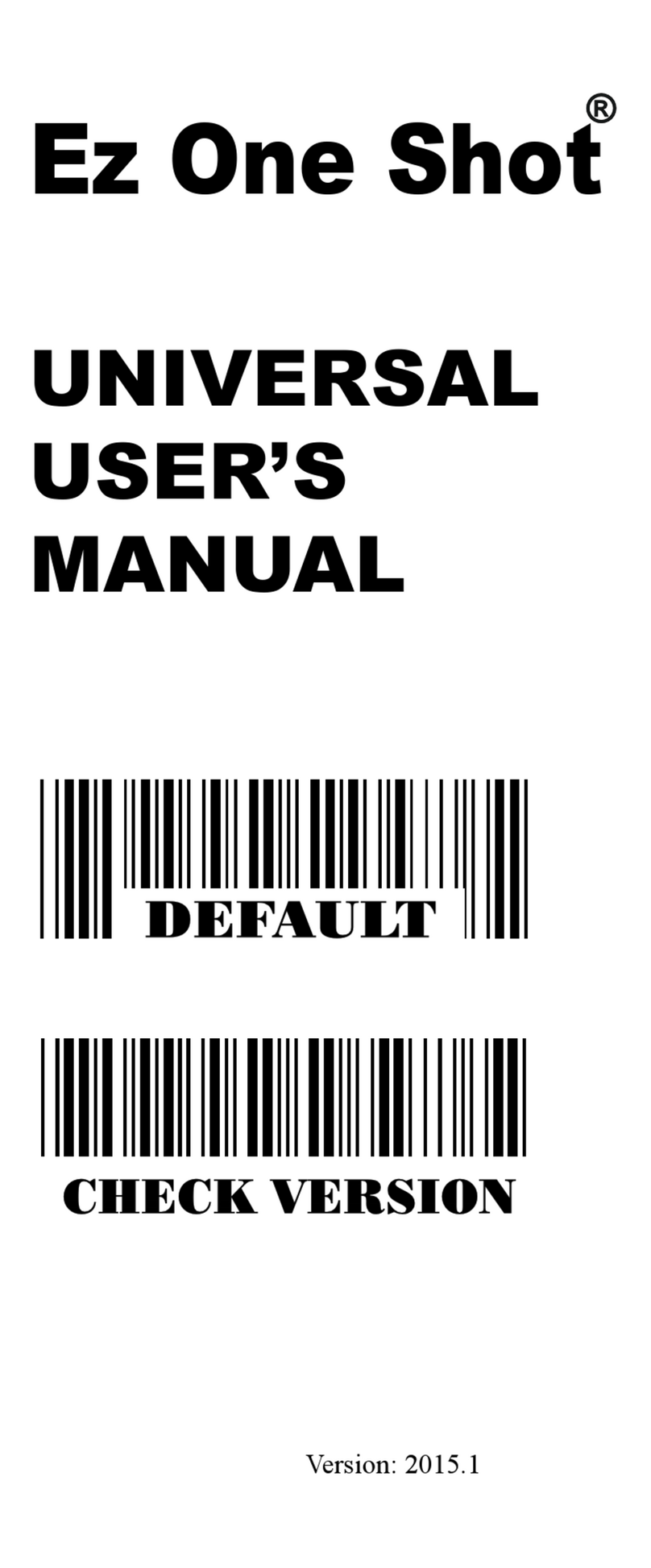

GROUP 1 >>>> INTERFACES SELECTION, COMPUTER TYPE, DEFAULT. ---------- 9

GROUP 2 >>>> READING MODE SETTING. -------------------------------------------- ------ 10

GROUP 3 >>>> CHECK VERSION, BEEP TONE, CAPLOCK MODE.-------------------- 11

GROUP 4 >>>> PREAMBLE AND POSTAMBLE.----------------------------------------------- 12

GROUP 5 >>>> ACCURACY ADJUSTMENT.---------------------------------------------------- 13

GROUP 6 >>>> ENABLE AND DISABLE CODE ID.------------------------------------------- 14

GROUP 7 >>>> SYMBOLOGIES CODE ID IDENTIFIER., SET ID ------------------------ 15

GROUP 8~9 >> CODE ID CONFIGURATION: SET CODE ID ----------------------- 16~17

GROUP 10 >>> DELAY BETWEEN BLOCK AND CHARACTER.-------------------------- 18

GROUP 11 >>> TERMINATOR AND KEYBOARD LAYOUT. -------------------------------- 19

GROUP 12 >>> RS232-BAUD RATE, DATA BITS & PARITY,-------------------------------- 20

GROUP 13 >>> RS232-STOP BIT,HANDSHAKING, ACK/NAK, FLOW CONTROL--- 2 1

GROUP 14 >>> WAND EMULATION PARAMETER SETTING. --------------------------- 22

SYMBOLOGIES FORMATING (GROUP 15~ GROUP 31). ----------------------- 23

GROUP 15 ~16>ENABLE AND DISABLE SYMBOLOGIES. --------------------------- 24~25

GROUP 17 >>> CHINA POST CODE ( TOSHIBA CODE), CODE 32.----------------- 26

APPEND 1 >>> NUMERIC TABLE, MIN/MAX LENGTHS SETTING -------------------- 27

GROUP 18 >>> UK PLESSEY CODE, MSI CODE. ----------------------------------------- 28

APPEND 1 >>> NUMERIC TABLE, MIN/MAX LENGTHS SETTING ------------------ 29

GROUP 19 >>> CODE IATA, CODE93.TELEPEN.-------------------------------------------- 30

APPEND 1 >>> NUMERIC TABLE, MIN/MAX LENGTHS SETTING -------------------- 31

GROUP 20 >>> INTERLEAVED 2 OF 5, CODE 11 .----------------------------------------- 32

APPEND 1 > >> NUMERIC TABLE, MIN/MAX LENGTHS SETTING ------------------- 33

GROUP 21 >>> CODABAR.------------------------------------------------------------------------- 34

APPEND 1 >>> NUMERIC TABLE, MIN/MAX LENGTHS SETTING---------------------- 35

GROUP 22 >>> ABC-CODABAR, CX CODE ----------------.--------------------------------- 36

GROUP 23 >>> CODABAR COUPLING, ------------------------------------------------------- 37

GROUP 24 >>> CODE 128, STANDARD CODE 39, FULL ASCII CODE 39.----------- 38

APPEND 1 >>> NUMERIC TABLE, MIN/MAX LENGTHS SETTING -------------------- 39

GROUP 25 >>> INDUSTRIAL 2 OF 5, MATRIX 2 OF 5.------------------------------------- 40

APPEND 1 >>> NUMERIC TABLE, MIN/MAX LENGTHS SETTING--------------------- 41

GROUP 26 >>> UPC-E. ----------------------------------------------------------------------------- 42

GROUP 27 >>> UPC-E(0), (1) ,UPC-E & UPC-A EXPAND ----------------------------- 43

GROUP 28 >>> UPC-A..----------------------------------------------------------------------------- 44

GROUP 29 >>> EAN 8. ------------------------------------------------------------------------------ 45

GROUP 30 >>> EAN 13 ----------------------------------------------------------------------------- 46

GROUP 31 >>> EAN/ UCC 128 -------------------------------------------------------------------- 47

GROUP 32 ~ 39 >>>> FULL ASCII TABLE ( CODE 39 --------------------- 48 ~55

GROUP 40 >>>>> NUMERIC ( CODE 39 ) TABLE. --------------------------- 56

GROUP 41~ 42 >>>> FUNCTION CODE ( CODE 39 ) FOR PC AT.------ 57~58

GROUP 43~ 46 >>>> TROUBLE SHOOTING --------------------------------- 59~62

Ms6262 CONTROL CODE LIST FOR Rs232. ----------------------------------------- 63

GENERAL

SETTING GROUP

1