IECHO TK4S User manual

1

2

Dear Customer:

FOREWORD

TK4S series high precision digital cutting system can automatically complete the cutting, kiss cutting, carving, drilling,

creasing, marking and so on. With automatic feeding and collecting system, jobs can be done quickly, which is also

suitable for advertising signs, printing and packaging, automotive interior, furniture sofa, composite materials and other

industrial production. It is the almighty champion of material cutting. Thank you for choosing IECHO high speed digital

cutting system.

Here is our sincere hope and forever target for this production specification can be easily and comprehensively to be

understood by you. In order to use this equipment properly, please read this user manual carefully and follow each step

after reading. From the beginning to the end, IECHO “star service” will be accompanied by you, no matter what problem

when you encounter, please check out the telephone number and address below and contact us. Here is our great honor and

responsibility to serve you with any inquiries. Thank you again for choosing IECHO products, if there is any change for

the manual contents due to product improvement, we apologize in advance that we won’t make another notice.

4

Directory

1. Equipment Overview.......................................................................................................................................................................1

1.1 Features..................................................................................................................................................................................1

1.2 Composition.......................................................................................................................................................................... 1

1.3 Working Principles................................................................................................................................................................1

1.4 Technical Parameters............................................................................................................................................................ 2

1.5 Cutting Head.........................................................................................................................................................................3

1.6 TK4S Cutting Tools............................................................................................................................................................. 4

1.7 TK4S Direction Information................................................................................................................................................ 7

1.8 List of Tools......................................................................................................................................................................... 8

2. Preparation.....................................................................................................................................................................................10

2.1 Installation Location............................................................................................................................................................10

2.2 Personnel............................................................................................................................................................................. 10

2.3 Power Requirement............................................................................................................................................................. 10

2.4 Environmental Conditions.................................................................................................................................................. 11

2.5 Basic Device Compressed Air............................................................................................................................................ 11

2.6 Flooring Space Requirement...............................................................................................................................................11

2.7 Operation Space Requirement.............................................................................................................................................11

3. Installation..................................................................................................................................................................................... 12

3.1 Opening and Inspecting Packing Crates............................................................................................................................. 12

3.2 Setting Up the Base Frame Structure..................................................................................................................................13

3.3 Assemble the Cutting Beam................................................................................................................................................16

3.4 Installing the Vacuum Plates.............................................................................................................................................17

3.5 Leveling the Table Plate....................................................................................................................................................19

3.6 Advertising Industry: Installing the Regional Air Valves and PVC Pipes Images........................................................... 22

3.7 Assemble the X Axis Side Covers.................................................................................................................................... 26

3.8 Pneumatic Control.............................................................................................................................................................28

3.9 Connecting the Electric Box............................................................................................................................................. 30

3.10 Assemble main cable etc.................................................................................................................................................31

3.11 Install the Conveyor Belt Guide Rollers Device............................................................................................................ 32

3.12 Install the AKI Device.....................................................................................................................................................35

3.13 Other Cables Function of Instructions............................................................................................................................ 36

3.14 Assemble the Workstation.............................................................................................................................................. 38

3.15 Install the Conveyor Belt................................................................................................................................................ 40

3.16 Tension the Conveyor Belt..............................................................................................................................................42

3.17 Assemble the Milling Support Device............................................................................................................................43

3.18 Install the Covers of The Front and Rear Side................................................................................................................48

3.19 Circuit Boards....................................................................................................................................................................49

4. Danger Areas During Initialization...............................................................................................................................................50

4.1 Danger Area On the Module Carriage.............................................................................................................................. 50

4.2 Safety Device On the Machine and PC Table.................................................................................................................. 51

5. Cutting Head Installation...............................................................................................................................................................52

6. Tool Installation.............................................................................................................................................................................54

7. Operation....................................................................................................................................................................................... 60

7.1 Preparation...........................................................................................................................................................................60

7.2 Steps.................................................................................................................................................................................... 60

8. Maintenance.................................................................................................................................................................................. 61

5

8.1 Daily Maintenance.............................................................................................................................................................. 61

8.2 Weekly Maintenance...........................................................................................................................................................63

8.3 Monthly Maintenance......................................................................................................................................................... 64

8.4 Quarterly Maintenance........................................................................................................................................................64

8.5 Annually Maintenance........................................................................................................................................................ 64

9.Common Error and Troubleshooting............................................................................................................................................ 65

10. Safety Attentions......................................................................................................................................................................... 66

11.Other Information........................................................................................................................................................................66

11.1 Products Details.................................................................................................................................................................66

11.2 Warranty Card................................................................................................................................................................... 66

11.3 Product Maintenance Details............................................................................................................................................ 67

11.4 Statement........................................................................................................................................................................... 67

1

1. Equipment Overview

IECHO Automatic Digital processing line can be used for full-time production, fulfilling the requirement of high

efficiency, by using the maximum capacity of the machine to complete the 24/7 production.

1.1 Features

Regional vacuum zone

Vortex vacuum control

Automatic sheet feeding

Conveyor system

Camera registration system

High-speed and high-precision cutting tools

Collection table for cutout elements picking

No manual operation needed

1.2 Composition

TK4S series digital cutting machine series is composed of Electrical box, Main body, Vacuum and Auxiliary devices.

Software includes file processing part and machine controlling part.

According to user’s demand, one or more tools can be used: Tangent Tool, Oscillating Tool, Kiss-Cut Tool, Router,

V-Cut Tool, Creasing Tool, Driven Rotary Tool, North & Drill Tool, Pen.

User can scan the bar code created by RIP software.

1.3 Working Principles

Import the files into SmartCut/iBrightCut, the user can process the files (editing and nesting) and send the processed

cutting files to CutterServer. According to the cutting files, the controlling system will create motion control signals. With

the signals, servo motors execute the tools lift/down and modules movement. Thereby, the machine achieves the high-

speed and high-precision cutting

2

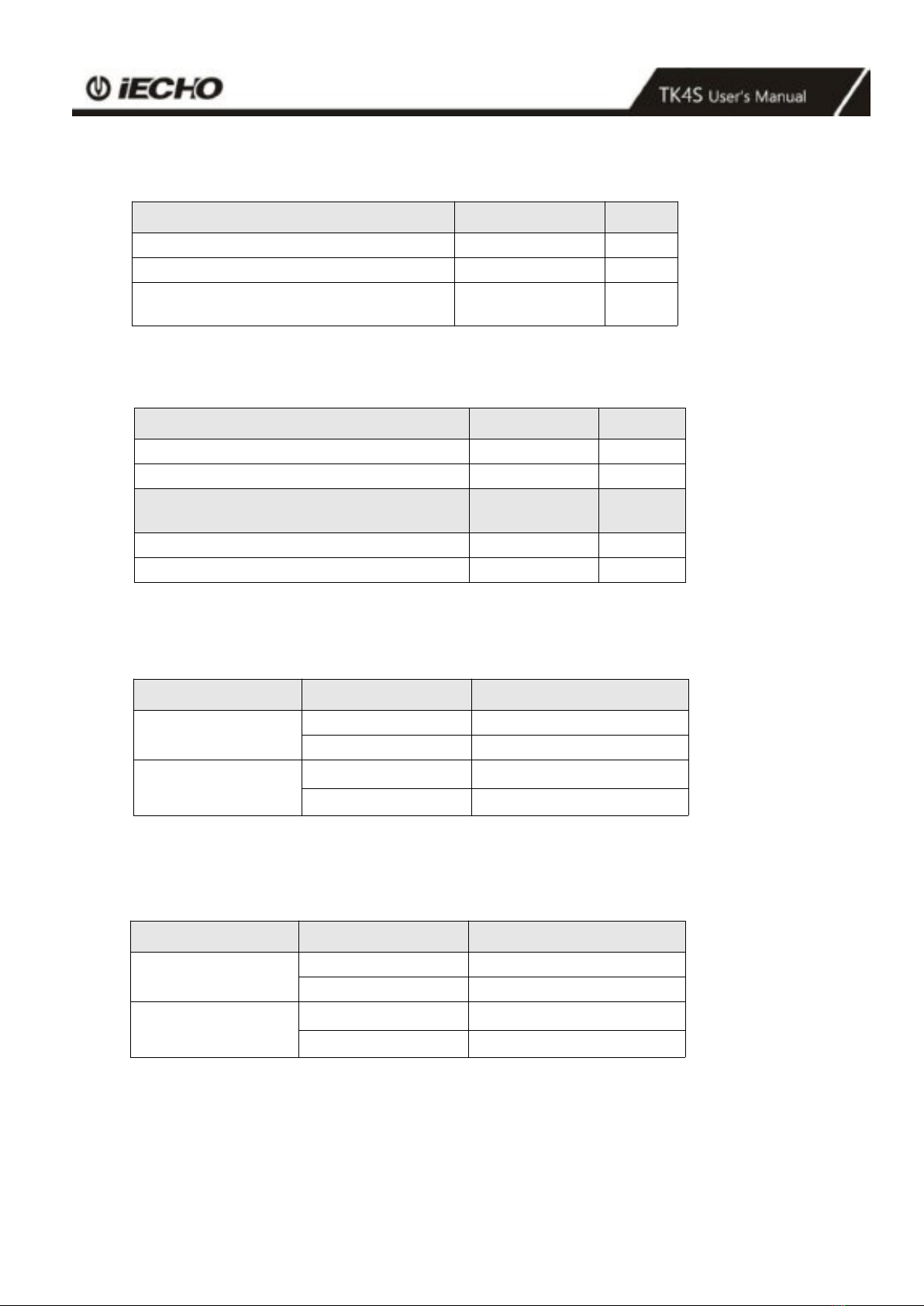

1.4 Technical Parameters

Definition

Parameter

Model

TK4S 2521(TK4S 2521 is just one model, more dimension is available).

Cutting Area

2500*2100 mm (98.4 inch *82.6 inch)

Machine Dimension

3340*3000*1273 mm (131.4 inch *118.1 inch *50.1 inch)

Weight

1550 kg

Vacuum Zones

3 - 24

Max Speed

1500mm/s (59inch/s)

Accuracy

0.1mm

Max Cutting Thickness

50mm (1.96 inch)

Modules

Can be installed up to 3 cutting heads

File Formats

DXF、PLT、PDF、HPG、HPGL、TSK、BRG、XML、CUT、OXF、ISO、

AI、PS、EPS

Interface

Serial Port / USB Port

Adsorption

Vacuum Pump

Power

Single-phase 220V / 2KW (exclude the power of feeder)

Three-phase 220V/380V 5.5KW/7.5KW*n (n is the quantity of vacuum zone,

exclude the power of feeder)

Power Requirement

220V/50/60HZ、380V/50/60HZ (Three-phase five-wire system)

Air Pressure Requirement

0.6~0.85MPa,Dry compressed air

Operating Environment

Temperature:0℃-40℃;Humidity:20%-80%RH

Storage Temperature

- 20 to + 55

°C

3

1.5 Cutting Head

TK3S /TK4S

Universal

Cutting head

All tools can be installed

in(except 1KW router)

Cutting thickness: 50mm

1.8KW Router

Power:1.8K

W

60000rpm

water cooling

cleaning device

Cutting thickness:

2mm-6mm Di-bond

20mm Acrylic

1kw Germany

Router

Power: 1kw

60000rpm

Air cooling

cleaning device

Cutting thickness:

2mm-6mm Di-bond

20mm Acrylic

TK3S/TK4S -

Marking head

Two pens

3 times/s/pen

Material thickness:

50mm

TK3S/TK4S -

North & Drill

head

Two heads

3 times/s/head

Material thickness:

10mm

4

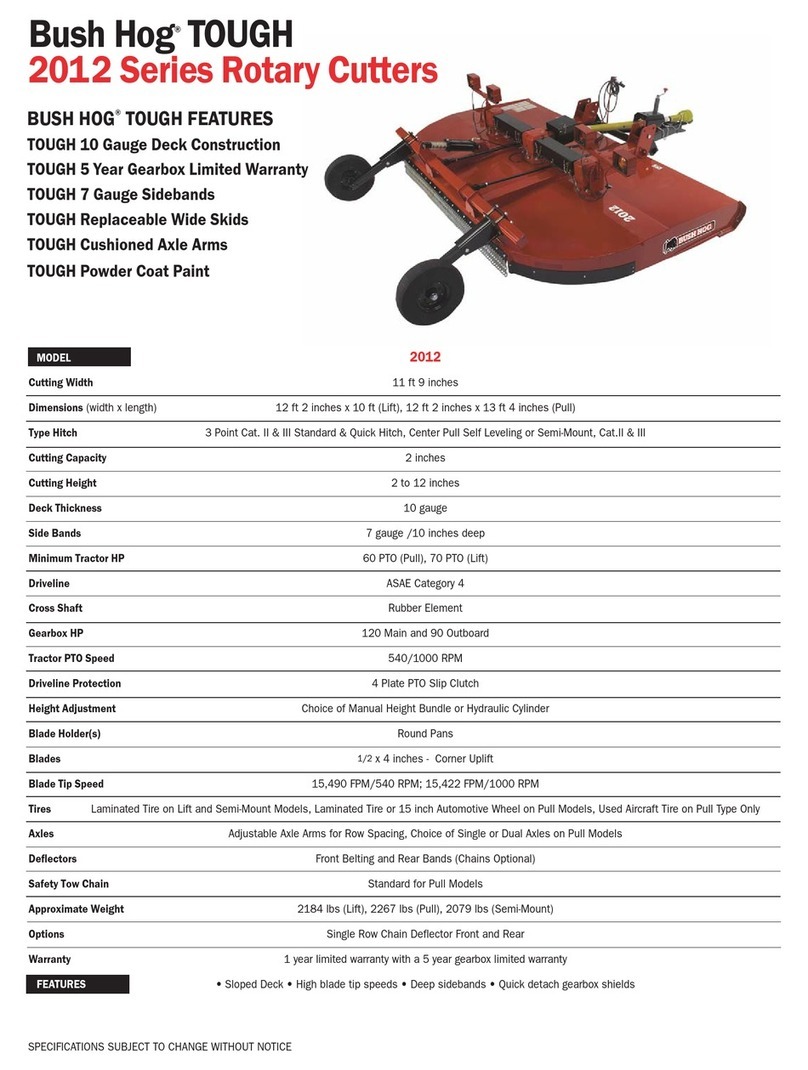

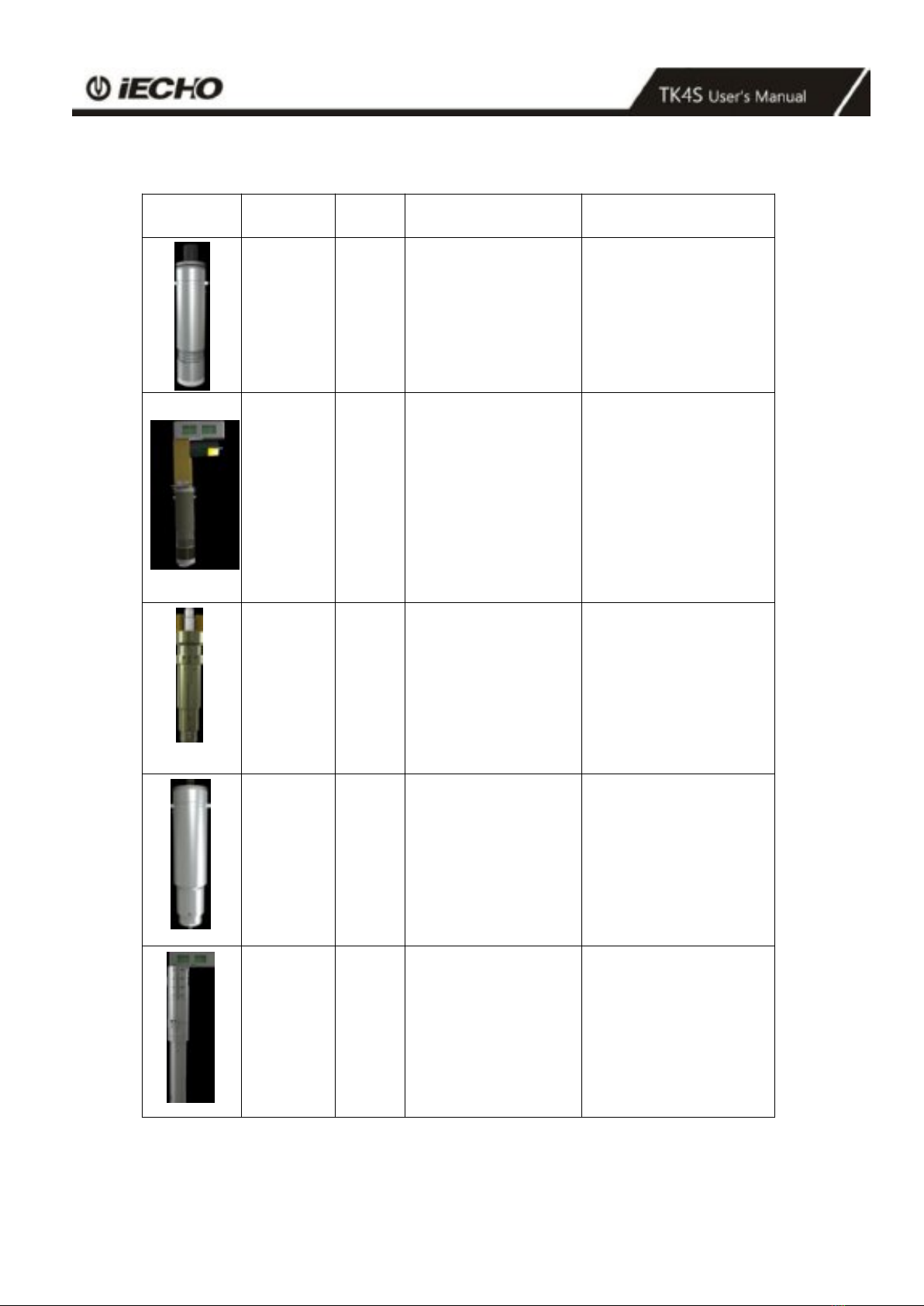

1.6 TK4S Cutting Tools

Illustration

Name

ab.

Feature

Materials

Tangent

Tool

CUT

Universal Cutting Tool

for materials up to

5mm thick.

Fast speed and low

cost.

Cardboard, Chevron

board, ABS board,

Gasket, Carbon fiber

prepreg, PVC tarpaulin,

PE, XPE, Label, etc.

Electric

Oscillating

Tool

EOT

High-frequency

electric-driven tool

with 80W power

options. Max cutting

speed

1m/s for soft and

medium-density

materials.

Chevron board,

Corrugated board, Gasket

board, Gray cardboard,

PE, XPE, EPE,

PU leather composite

sponge, Coil car mat, etc.

Pneumatic

Oscillating

Tool

POT

Powerful air-driven

tool with extended

stroke for dense

materials up to 50mm

thick.

Composites, Honeycomb

board, Asbestos gasket,

Graphite gasket, Sponge,

EPE, etc.

Kiss-Cut

Tool

KCT

Half-cut tool for vinyl

materials.

Vinyl, sticker, reflective

film, etc.

Driven

Rotary

Tool

DRT

Cutting tool with

driven rotary blade for

fabrics and technical

textiles with high

processing speed.

Fabrics, carbon fiber,

glass fiber, aramid,

carpet, etc.

5

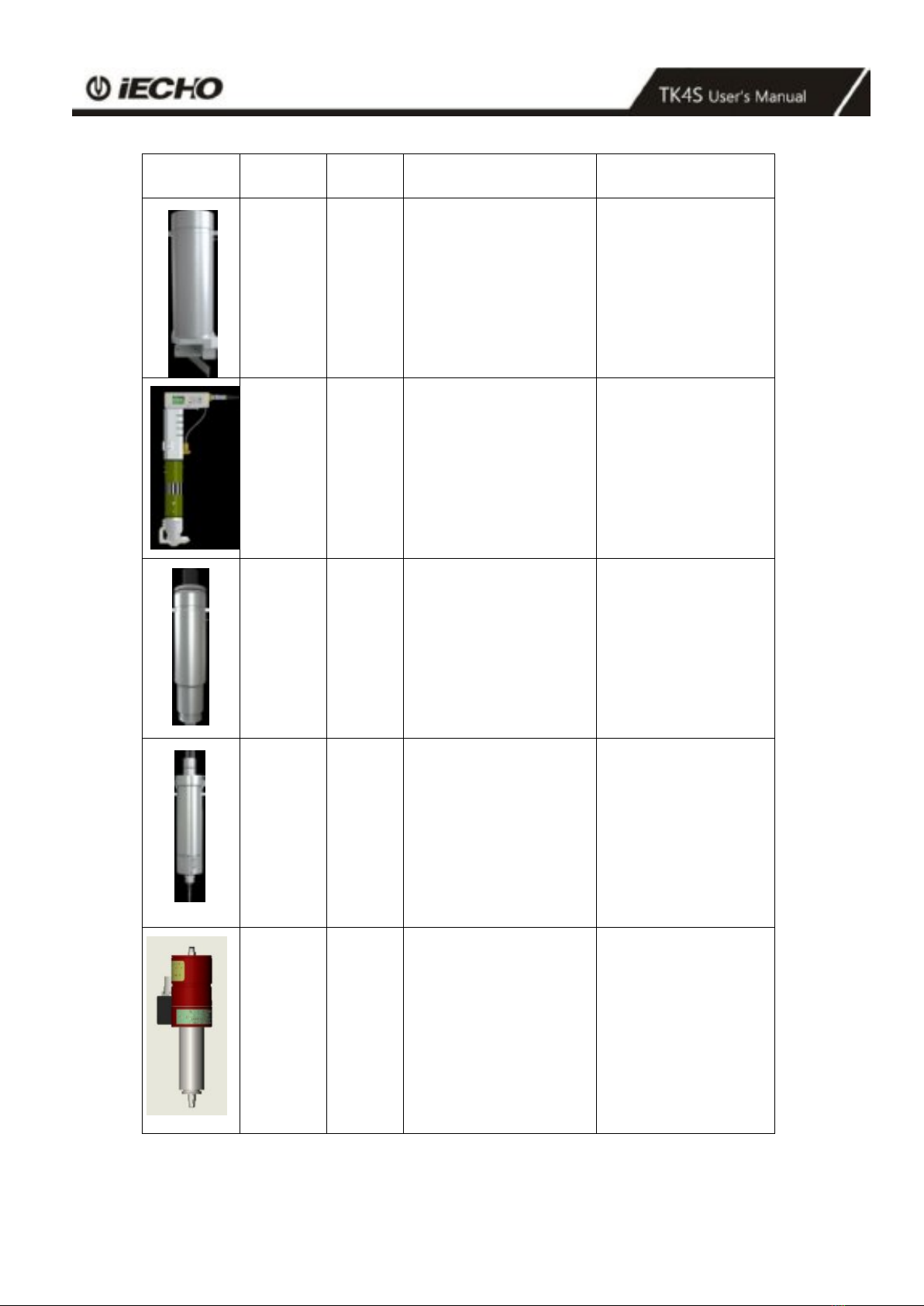

Illustration

Name

Ab

Feature

Material

V-Cut

Tool

V-CUT

Tool with 5 cutting angles

(0°,15°,22.5°, 30°,

45°). Create 3D

structural design.

Honeycomb board,

sandwich board, KT

board, Gray board, etc.

Powerful

Rotary

Tool

PRT

Powerful tool with

driven rotary blade.

textiles, carbon

fiber, glass fiber,

carpet, fur, etc.

Creasing

Tool

CTT

Creasing wheels for

carton box making

Corrugated board,

carton

board, etc.

CNC

Router

MILL

Routing tool with

high-performance

routing on hard and

tough materials up to

16mm thick.

Power: 350W;

RPM:60000rpm;

Max thickness:16mm.

Acrylic, Di-bond,

aluminum composite,

MDF, etc.

CNC

Router

MILL

1KW

Routing tool with

high-performance

routing on hard and

tough materials up to

20mm thick.

Power: 1KW;

RPM:60000rpm;

Max thickness:20mm.

Acrylic, Di-bond,

aluminum composite,

MDF, etc.

6

Illustration

Name

Ab

Feature

Material

CNC

Router

MILL

1.8KW

Routing tool with

high-performance

routing on hard and

tough materials up

to

20mm thick.

Power: 1.8KW;

RPM:60000rpm;

Max thickness:20mm.

Acrylic, Di-bond,

aluminum composite,

MDF, etc.

Electric

Oscillating

Tool

EOT3

High-frequency electric-

driven tool with

200W power options.

Max cutting speed

1m/s for soft and

medium-density

materials.

Chevron board,

Corrugated board,

Gasket, KT board,

Gray cardboard,

PE,XPE, EPE,PU

leather, PUcomposite

sponge, Coil car mat,

etc.

Super

Powerful

Rotary Tool

SPRT

Super Powerful tool

with driven rotary blade.

textiles, carbon fiber,

glass fiber, carpet, fur,

etc.

Perforating

tool

PTK

Perforating tool

KT board、Corrugated

cardboard, paperboard,

cardboard, etc

Universal

drawing tool

UDT

Universal

drawing tool

Stencils, technical

labeling ,labeled

paper,etc,

7

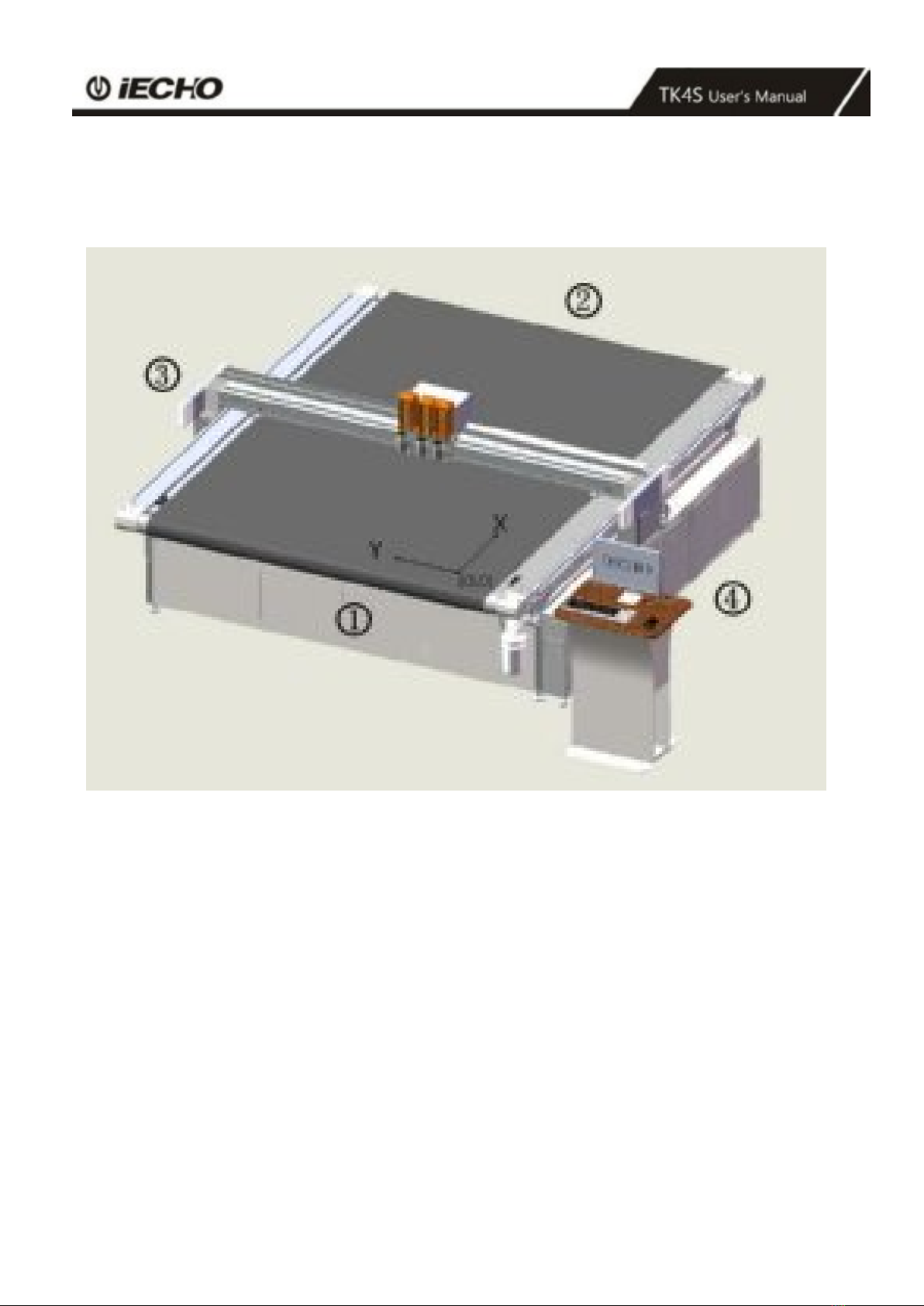

1.7 TK4S Direction Information

Directions such as "right, left" or "front, back" depends on the operator's view of the machine during

operation.

1

front

4

right

2

back

x

X-axis

3

left

Y

Y-axis

8

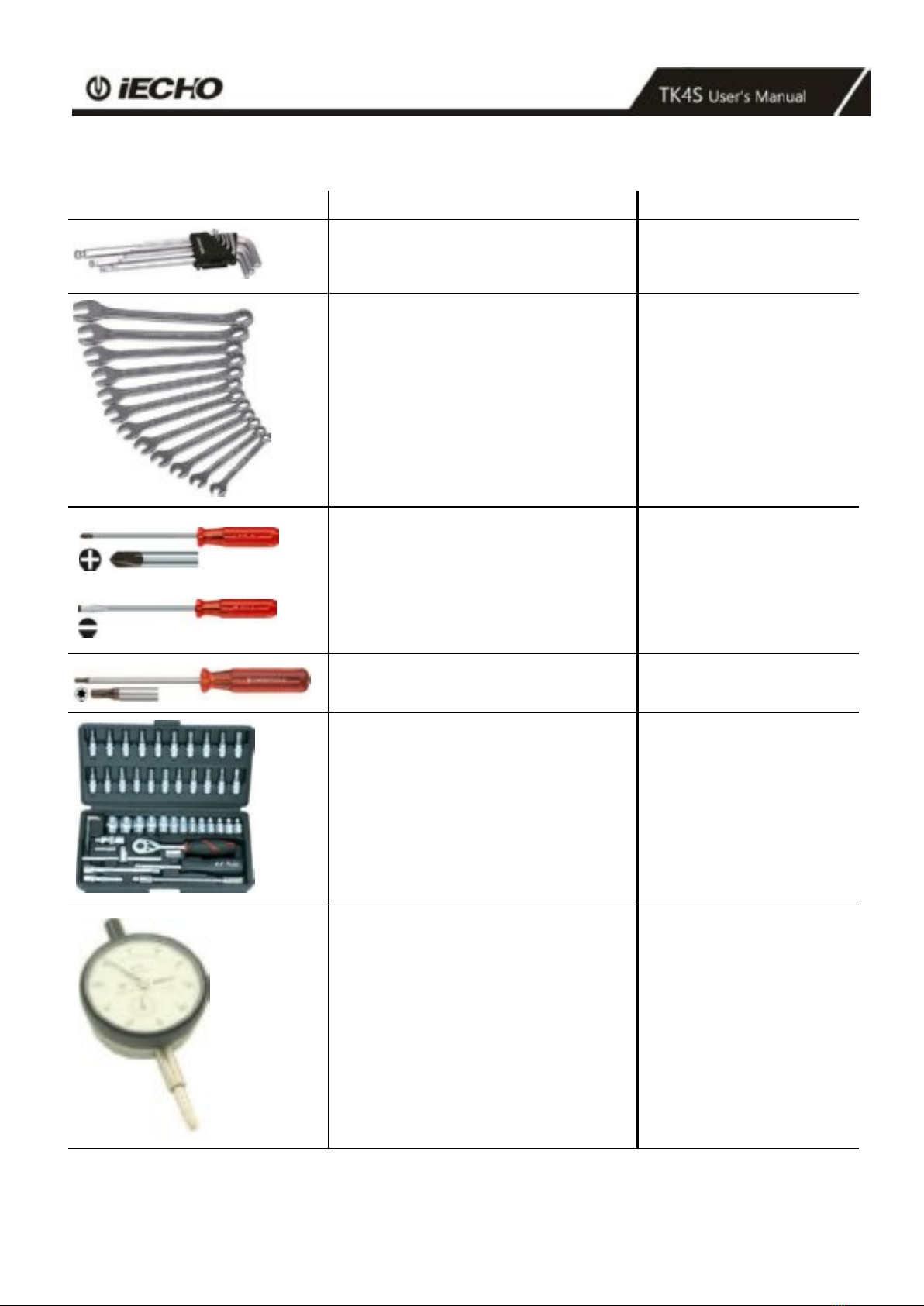

1.8 List of Tools

Illustration

Description

Function

A set of Allen keys (SW 1.5 to 8)

Various open-ended spanners (SW

5.5-19.2x10)

various Phillips and slotted screwdrivers

screwdriver

Ratchet set with bolt nuts and Allen inserts

Dial gauge (resolution of 0.1 mm)

To align the table plate

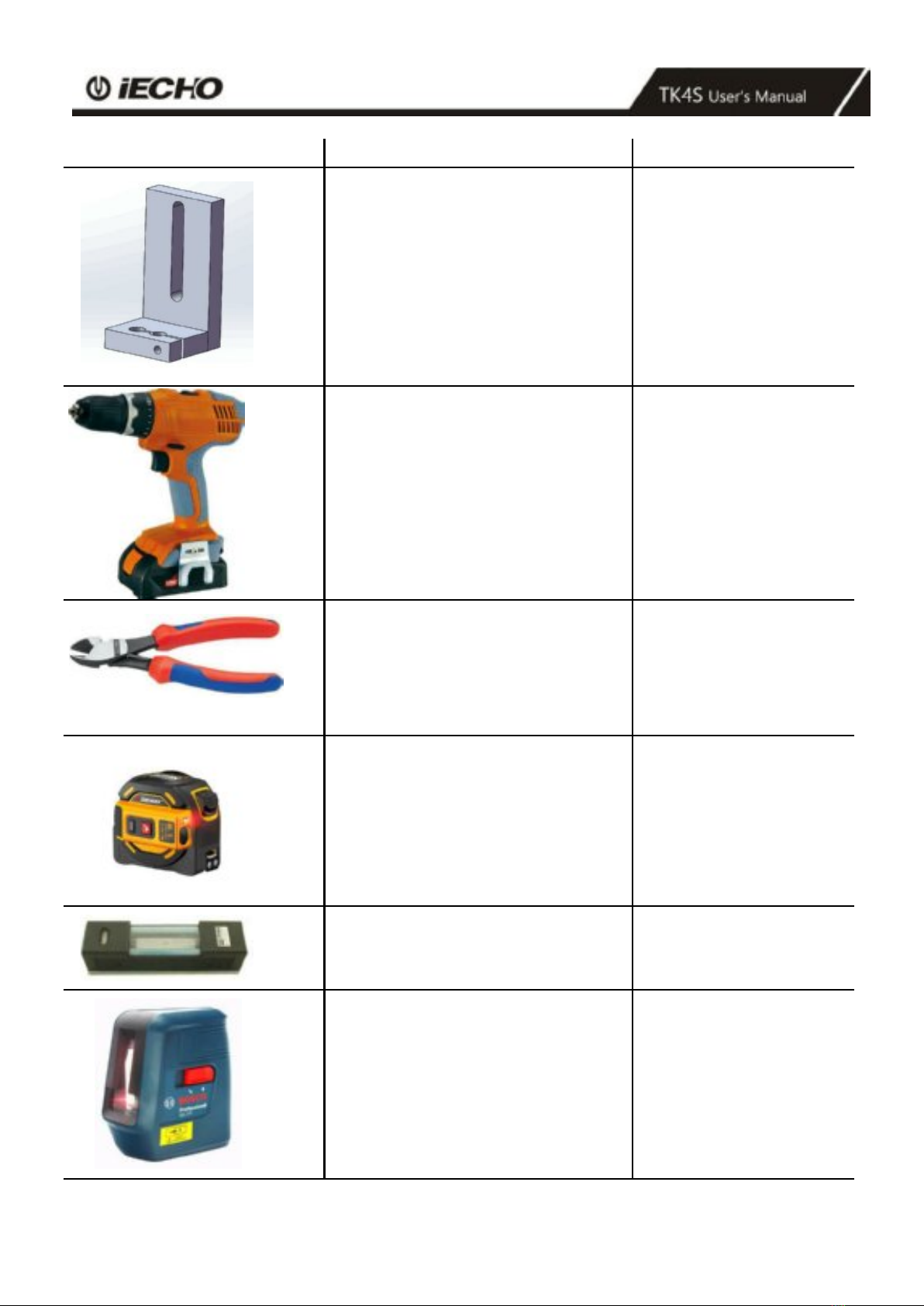

9

Illustration

Description

Function

Holder for supporting dial gauge

Table plate: set height

Electric drill

Side cutters

to open the transport locking

devices

Measuring tape

Precision spirit level (recommended value

0.05 mm/m)

To level the machine

Precision spirit level

To level the machine foot

10

2. Preparation

2.1 Installation Location

Make sure that the following requirements are met:

•the installation location is level and can withstand the floor loads.

•the transportation routes to the installation location do not include steps or staircases.

•the shipping crates can be deposited close to the installation location and their presence does not

prevent the machine from being assembled.

•the aisle width from the unloading location to the installation location is at a minimum the width

required for the dimensions of the packing crates.

•the electrical and air connections meet the requirements listed in the technical data.

•the installation location is well-lit.

•At least 1 meter of space is available all around the cutting system for service and daily operation.

2.2 Personnel

Make sure that the following requirements are met:

•the support personnel wear safety clothing and work gloves.

•the support personnel are familiar with the hazards associated during machine installation and have

read and understood the mounting instructions.

2.3 Power Requirement

Three

-phase

Vacuum

Pump

Voltage

Electric

Current

Air

Circuit

Breaker

Wire

Size

Wiring System

5.5KW

380V

8.3A

20A

6mm²

L1、L2、L3、N、G

7.5KW

380V

12A

20A

6mm²

L1、L2、L3、N、G

Three

-phase

Vacuum

Pump

Voltage

Electric

Current

Air

Circuit

Breaker

Wire

Size

Wiring System

5.5KW

220V

14.5A

30A

6mm²

L1、L2、L3、G

7.5KW

220V

20A

50A

8mm²

L1、L2、L3、G

11

2.4 Environmental Conditions

2.5 Basic Device Compressed Air

2.6 Flooring Space Requirement

Machine Dimension Length X Width (with router, the height of regular route holder is 2.8meter)

2.7 Operation Space Requirement

Machine Dimension: Length X Width (with router, the height of regular route holder is 2.8meter)

Value

Unit

Operating temperature

+ 10 to + 35

°C

Storage temperature

- 20 to + 55

°C

Relative humidity

10 - 80, non-

condensing

%

Conveyor feeding clamps

Value

Units

Operating pressure

0.6

MPA

Min. air flow

0.4

m³/min

Control of POT tool, supply of 1kw,1.8KW

Router

Value

Units

Operating pressure

0.85

MPA

Min. air flow

0.6

m³/min

Material loader

Length / width

TK4S

With

Length

Length+1.9m

Width

Width+0.9m

Without

Length

Length+0.9m

Width

Width+0.9m

Feeding Frame

Length / width

TK4S

With

Length

Length+3.4m

Width

Width+2.4m

Without

Length

Length+2.4m

Width

Width+2.4m

12

3. Installation

3.1 Opening and Inspecting Packing Crates

Note:

Prevent the crate cover from warping when placed at an

angle. Place the packing crate level.

Note:

•Only complete the installation if all parts are present and undamaged.

•Inform IECHO customer service if any parts are missing or damaged.

•Replenish or replace missing or damaged parts.

ARemove all screws on the upper side of the packing crate.

BRemove the cover and place it to one side.

CRemove the screws from the upper crossbars

DRemove the crossbars and place them to one side

ELoosen the screws of the side cover.

FRemove the side cover.

GMake sure the contents are complete and without damage.

13

3.2 Setting Up the Base Frame Structure

3.2.1 Framework

The components consists of the left beam, right beam and under frame.

1. Front foot (including pause cable)

2. Middle foot

3. Rear foot Left / Right

Note:

Assemble the left and right beam under frame as below, fasten tightly T-bolts(M8x25mm) with glue, set up the

framework, meet the following requirements:

1. Both side of the end surface distance:200±2mm,adjust the distance between each legs component:1180±2mm。

2. Make sure the diagonal dimensions are less than 2 mm.

TK4S frame

work 1

14

3.2.2 Initial leveling of the base frame

ALift each side support end to keep the balance by precision spirit level.

BDetermine the lowest position of the foot and use the setscrews to adjust it upwards.

CUse the setscrew to raise the position of the lowest foot.

15

3.2.3 Connecting the Pause cables

16

3.3 Assemble the Cutting Beam

Beam Block slider

Pay attention:

Keep balance from rear side when assembling the cutting beam, carefully take out the plug in the slider,

put the cutting beam onto the side beams, make sure that the pen holder faces to the photoelectric plate.

After assembly, put the block slider back and then tighten the screws.

Table of contents

Other IECHO Cutter manuals