REFRIGERATION LTD

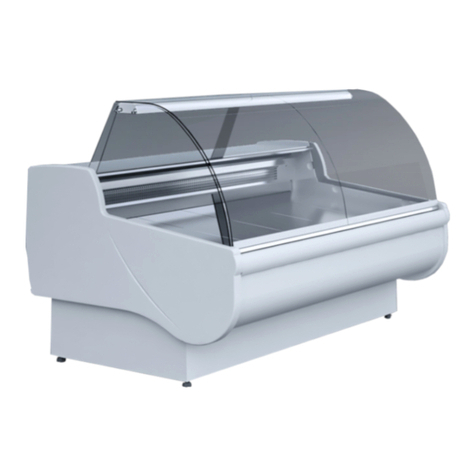

Refrigerated Pastry Display Case | www.igloorefrigeration.com

Contents

1 UNLOADING ..................................................................................................................................................... 3

2 PROPERTIES OF THE UNIT.................................................................................................................................. 3

2.1. Purpose .................................................................................................................................................... 3

2.2. Description of the unit............................................................................................................................... 3

2.3. Technical data........................................................................................................................................... 4

3. PREPARING THE DEVICE FOR START UP ............................................................................................................ 5

3.1. Installation requirements .......................................................................................................................... 5

3.2. Unit Location ............................................................................................................................................ 5

3.3. Connection and start-up............................................................................................................................ 6

4. UNIT START UP ............................................................................................................................................... 9

4.1. Temperature regulation ............................................................................................................................ 9

5. MAINTENANCE .............................................................................................................................................. 10

5.1 Cleaning and maintenance ....................................................................................................................... 10

6. SERVICE......................................................................................................................................................... 15

6.1. Faults identification and repair................................................................................................................ 15

6.2 Service..................................................................................................................................................... 16

List of Figures

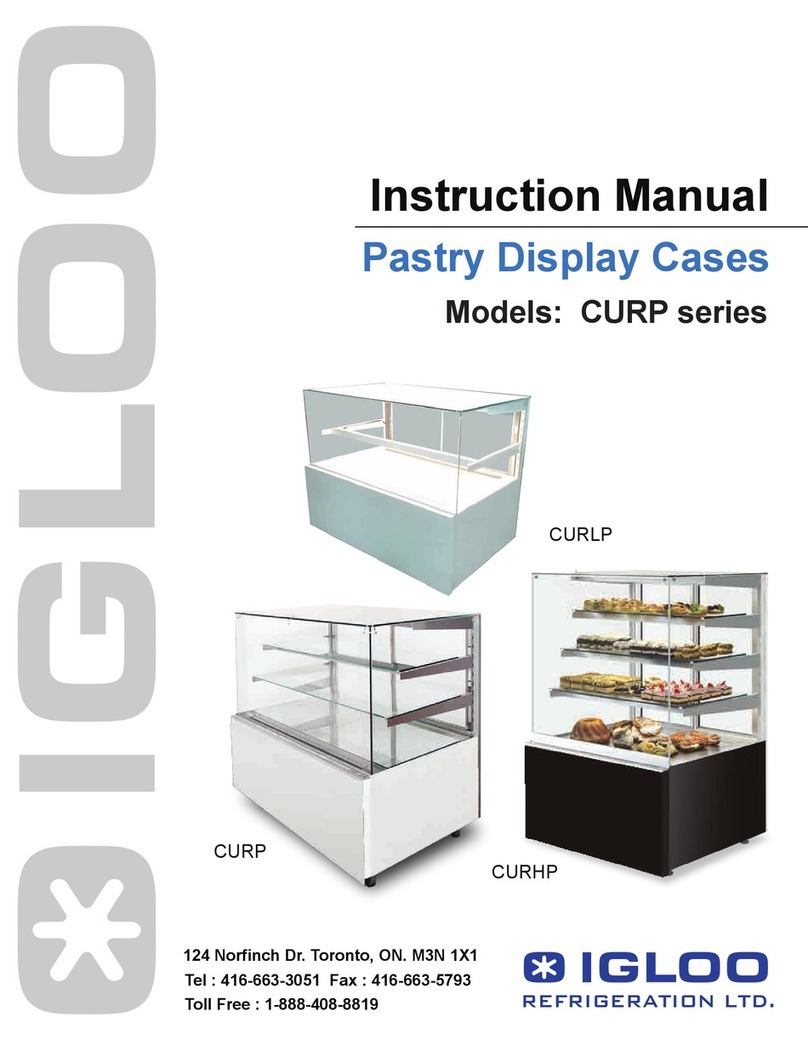

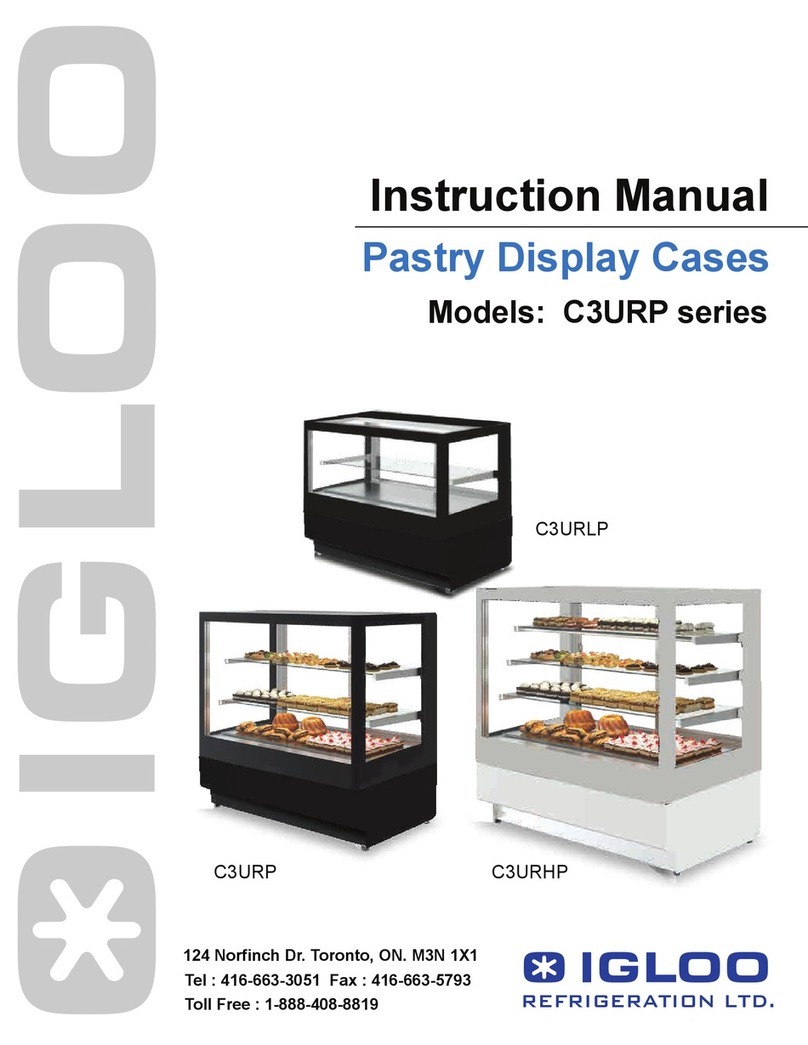

Figure 1 "JOR" series overview ............................................................................................................................ 4

Figure 2 Caster wheels........................................................................................................................................ 5

Figure 3 Mounting glass shelves........................................................................................................................... 7

Figure 4 Install the door handle ........................................................................................................................... 7

Figure 5 Control panel ......................................................................................................................................... 7

Figure 6 Ventilation holes of the device................................................................................................................ 8

Figure 7 “Carel” thermostat control panel.......................................................................................................... 10

Figure 8 Cleaning the condenser ........................................................................................................................ 14

List of Tables

Table 1 Technical data ......................................................................................................................................... 4

Table 2 Table of alarms and signals .................................................................................................................... 11

Table 3 Table of easy compact parameters......................................................................................................... 12