ILX Lightwave LDC-3916338 User manual

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Find the Newport / ILX Lightwave LDC-3916376 at our website: Click HERE

User’s Guide

3.0 Amp Laser Diode

Current Source Module

LDC-3916338

ILX Lightwave Corporation P. O.Box 6310 Bozeman, MT, U.S.A. 59771 :· · · 1-800-459-9459 · ·

www.ilxlightwave.com

U.S. & Canada International Inquiries: 406-586-1244 Fax 406-586-9405

E-mail: [email protected]

70031502_7/01

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Safety and Warranty Information

! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! !

S

AFETY

AND

W

ARRANTY

I

NFORMATION

The Safety and Warranty Information section provides details about cautionary symbols used in the

manual, safety markings used on the instrument, and information about the Warranty including

Customer Service contact information.

Safety Information and the Manual

Throughout this manual, you will see the words Caution and Warning indicating potentially

dangerous or hazardous situations which, if not avoided, could result in death, serious or minor

injury, or damage to the product. Specifically:

!

CAUTION

Caution indicates a potentially hazardous situation which can result in minor or

moderate injury or damage to the product or equipment.

WARNING

Warning indicates a potentially dangerous situation which can result in serious injury or

death.

WARNING

Visible and/or invisible laser radiation. Avoid direct exposure to the beam.

General Safety Considerations

If any of the following conditions exist, or are even suspected, do not use the instrument until safe

operation can be verified by trained service personnel:

•Visible damage

•Severe transport stress

•Prolonged storage under adverse conditions

•Failure to perform intended measurements or functions

If necessary, return the instrument to ILX Lightwave, or authorized local ILX Lightwave distributor,

for service or repair to ensure that safety features are maintained (see the contact information on

page vi).

All instruments returned to ILX Lightwave are required to have a Return Authorization Number

assigned by an official representative of ILX Lightwave Corporation. See Returning an Instrument on

page v for more information.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Safety and Warranty Information

S

AFETY

S

YMBOLS

This section describes the safety symbols and classifications.

Technical specifications including electrical ratings and weight are included within the manual. See

the Table of Contents to locate the specifications and other product information. The following

classifications are standard across all ILX Lightwave products:

•Indoor use only

•Ordinary Protection: This product is NOT protected against the harmful ingress of moisture.

•Class I Equipment (grounded type)

•Mains supply voltage fluctuations are not to exceed ±10% of the nominal supply voltage.

•Pollution Degree II

•Installation (overvoltage) Category II for transient overvoltages

•Maximum Relative Humidity: <80% RH, non−condensing

•Operating temperature range of 0 °C to 40 °C

•Storage and transportation temperature of ˘40 °C to 70 °C

•Maximum altitude: 3000 m (9843 ft)

•This equipment is suitable for continuous operation.

Safety Marking Symbols

This section provides a description of the safety marking symbols that appear on the instrument.

These symbols provide information about potentially dangerous situations which can result in death,

injury, or damage to the instrument and other components.

Caution,

refer to

manual

Earth

ground

Terminal

Alternating

current

Visible and/or

invisible laser

radiation

Caution, risk

of electric

shock

Protective

Conductor

Terminal

Caution, hot

surface

Frame or

chassis

Terminal

On: In position of a bistable push control. The

slash (I) only denotes that mains are on.

Off: Out position of a bistable push control.

The circle (O) only denotes that mains are off.

or

(I) or

(O)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Safety and Warranty Information

W

ARRANTY

ILX LIGHTWAVE CORPORATION warrants this instrument to be free from defects in material and

workmanship for a period of one year from date of shipment. During the warranty period, ILX will

repair or replace the unit, at our option, without charge.

Limitations

This warranty does not apply to fuses, lamps, defects caused by abuse, modifications, or to use of

the product for which it was not intended.

This warranty is in lieu of all other warranties, expressed or implied, including any implied warranty

of merchantability or fitness for any particular purpose. ILX Lightwave Corporation shall not be liable

for any incidental, special, or consequential damages.

If a problem occurs, please contact ILX Lightwave Corporation with the instrument’s serial number,

and thoroughly describe the nature of the problem.

Returning an Instrument

If an instrument is to be shipped to ILX Lightwave for repair or service, be sure to:

1Obtain a Return Authorization number (RA) from ILX Customer Service.

2Attach a tag to the instrument identifying the owner and indicating the required service or

repair. Include the instrument serial number from the rear panel of the instrument.

3Attach the anti−static protective caps that were shipped with the instrument and place the

instrument in a protective anti−static bag.

4Place the instrument in the original packing container with at least 3 inches (7. 5 cm) of

compressible packaging material. Shipping damage is not covered by this warranty.

5Secure the packing box with fiber reinforced strapping tape or metal bands.

6Send the instrument, transportation pre−paid, to ILX Lightwave. Clearly write the return

authorization number on the outside of the box and on the shipping paperwork. ILX

Lightwave recommends you insure the shipment.

If the original shipping container is not available, place your instrument in a container with at least 3

inches (7.5 cm) of compressible packaging material on all sides.

Repairs are made and the instrument returned transportation pre−paid. Repairs are warranted for the

remainder of the original warranty or for 90 days, whichever is greater.

Claims for Shipping Damage

When you receive the instrument, inspect it immediately for any damage or shortages on the

packing list. If the instrument is damaged, file a claim with the carrier. The factory will supply you

with a quotation for estimated costs of repair. You must negotiate and settle with the carrier for the

amount of damage.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Safety and Warranty Information

Comments, Suggestions, and Problems

To ensure that you get the most out of your ILX Lightwave product, we ask that you direct any

product operation or service related questions or comments to ILX Lightwave Customer Support.

You may contact us in whatever way is most convenient:

Phone . . . . . . . . . . . . . . . . . . . . . . . . . . . (800) 459−9459 or (406) 586−1244

Fax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (406) 586−9405

Email. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .support@ilxlightwave.com

Or mail to:

ILX Lightwave Corporation

P. O. Box 6310

Bozeman, Montana, U.S.A 59771

www.ilxlightwave.com

When you contact us, please have the following information:

If ILX Lightwave determines that a return to the factory is necessary, you are issued a Return

Authorization (RA) number. Please mark this number on the outside of the shipping box.

You or your shipping service are responsible for any shipping damage when returning the

instrument to ILX Lightwave; ILX recommends you insure the shipment. If the original shipping

container is not available, place your instrument in a container with at least 3 inches (7.5cm) of

compressible packaging material on all sides.

We look forward to serving you even better in the future!

Model Number:

Serial Number:

End−user Name:

Company:

Phone:

Fax:

Description or sketch of what

is connected to the ILX

Lightwave instrument:

Description of the problem:

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of Contents

Module Instruction Manual

Chapter 1 Introduction to the LDC-3916338 3.0 Amp Laser Diode Current Source

Module

Introduction ...............................................................................................................................................................1

Safety Symbols and Terms..............................................................................................................................................1

Product Overview............................................................................................................................................................2

Installing your LDC-3916338 Laser Diode Current Source Module...............................................................................2

How to Contact Customer Service..................................................................................................................................3

LDC-3916338 3.0 Amp Current Source Module Specifications.....................................................................................5

Chapter 2 How to Operate Your LDC-3916338 Laser Diode Current Source Module

Introduction ...............................................................................................................................................................1

Connecting to the Laser Controller..................................................................................................................................2

Operating the Laser Current Source from the Front Panel..............................................................................................5

Operating a Laser in Constant Current Mode.................................................................................................................5

Operating a Laser in Constant Power Mode...................................................................................................................8

Conditions which will Automatically Shut Off the Laser Output ................................................................................12

Chapter 3 Operating in Remote Control

Introduction ...............................................................................................................................................................1

Remote Configuration......................................................................................................................................................1

LDC-3916338 Laser Diode Current Source Command Set .............................................................................................1

Status Reporting..............................................................................................................................................................4

Chapter 4 Command Reference

Introduction ...............................................................................................................................................................1

LDC-3916338 Device-Dependent Commands................................................................................................................3

LDC-3916338 Device-Command Reference....................................................................................................................3

Chapter 5 Calibration and Troubleshooting Guide

Introduction ...............................................................................................................................................................1

Calibration Overview.......................................................................................................................................................1

Local Calibration of the Laser Current Source.................................................................................................................3

Remote Calibration of the 3916338 Current Source Module..........................................................................................6

Troubleshooting Guide..................................................................................................................................................10

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

INTRODUCTION TO THE LDC-3916338 3.0 AMP CURRENT SOURCE MODULE CHPT 1

CHAPTER 1 1

INTRODUCTION TO THE LDC-3916338 3.0 AMP LASER DIODE CURRENT SOURCE MODULE 1

INTRODUCTION 1

SAFETY SYMBOLS AND TERMS 1

PRODUCT OVERVIEW 2

INSTALLING YOUR LDC-3916338 LASER DIODE CURRENT SOURCE MODULE 2

Installation into LDC-3916 or LDC-3908 Laser Diode Controller Mainframe 2

HOW TO CONTACT CUSTOMER SERVICE 3

Calibration and Repair Services 3

General Shipping Instructions 3

LDC-3916338 3.0 AMP CURRENT SOURCE MODULE SPECIFICATIONSERROR! BOOKMARK NOT

DEFINED.

Laser Current Source Specifications 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

INTRODUCTION TO THE LDC-3916338 3.0 AMP CURRENT SOURCE MODULE CHPT 1

PAGE 1

CHAPTER 1

INTRODUCTION TO THE LDC-3916338 3.0 AMP LASER DIODE CURRENT

SOURCE MODULE

INTRODUCTION

This chapter is an introduction to the LDC-3916338 3.0 Amp Laser Diode Current Source Module for the LDC-3916 or

LDC-3908 LD Controller Mainframes. Contained in Chapter 1 is unpacking information, instructions on how to install

and apply power, and safety considerations and instructions. It also contains some maintenance information, and

specifications.

WARNING

If any of the following symptoms exist, or are even suspected, remove the LDC-3916338

Module from service. Do not use LDC-3916xxx modules until safe operation can be verified

by trained service personnel.

1. Visible damage

2. Severe transport stress

3. Prolonged storage under adverse conditions

4. Failure to perform intended measurements or functions

If necessary, return the LDC-3916338 modules to ILX Lightwave for service and repair to ensure

that safety features are maintained.

SAFETY SYMBOLS AND TERMS

The following safety terms are used in this manual:

•The WARNING heading explains dangers that could result in personal injury or death.

•The CAUTION heading explains hazards that could damage your instrument.

•The NOTES heading gives information to the user that may be beneficial in the use of the instrument and to the

devices being tested.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

INTRODUCTION TO THE LDC-3916338 3.0 AMP CURRENT SOURCE MODULE CHPT 1

PAGE 2

The following symbols are used in this manual and on the instrument:

Earth Ground and/or Protective Conductor Terminal

Caution: Refer to accompanying documents

Caution: Risk of Electrical Shock

Instrument Power Off

Instrument Power On

PRODUCT OVERVIEW

The LDC-3916338 Laser Diode Current Source Module contains one fully independent current source. The current

sources provide high stability output up to a maximum drive current of 3.0 Amps, with fully redundant current limits

and multiple laser protection features such as contact bounce detection, compliance voltage limit adjust, and 4-wire

voltage measurement for precise laser diode forward voltage measurement.

INSTALLING YOUR LDC-3916338 LASER DIODE CURRENT SOURCE MODULE

Installation into LDC-3916 or LDC-3908 Laser Diode Controller Mainframe

If you are receiving this new module for installation into a previously purchased LDC-3916 or LDC-3908 mainframe,

follow the instructions below. If your system was configured at the factory with your desired modules skip this

section.

CAUTION

Static discharge can damage your new Laser Diode Current Source Module. Be certain you use

proper grounding procedures before you unpack and install your controller module(s) into the

LDC-3916 or LDC-3908 Mainframe.

Inspect the module for any visible shipping damage that may have occurred before inserting the

module into the mainframe. Pay special attention to the copper shielding material on the back

edge of the module.

Be sure that the LDC-3916 or LDC-3908 Mainframe power is off before inserting your new laser

diode controller module.

Unwrap the module from the anti-static bag it was packaged in.

Insert the module into the desired slot from the rear of the LDC-3916 or LDC-3908 Mainframe. Each module is

supported by two plastic card guides inside of the mainframe. Insert the module, 40-pin connector first, by lining up

the edges of the module frame with the appropriate card guides (one on the top and one on the bottom). Carefully

slide the module into the mainframe slot until the connector is seated. You will have to push a little harder to seat the

module. The rear panel of the module should be flush with the mainframe when properly inserted. Fasten the

module to the mainframe with the two screws located at the top and bottom of the module rear panel.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

INTRODUCTION TO THE LDC-3916338 3.0 AMP CURRENT SOURCE MODULE CHPT 1

PAGE 3

HOW TO CONTACT CUSTOMER SERVICE

If you have any questions or comments related to product operation or service, please contact Customer Support at

1-800-459-9459 (USA and Canada) or 406-586-1244 (International); by fax at 406-586-9405; or E-mail us at

Please have the following information available (if applicable):

NOTE: All ILX Lightwave modules are identified byan seven-digit serial number located on the rear

panel. The first three digits are the model number; the last four identify your module specifically.

1) Product Model: ________________________________________________

2) Unit Serial Number: ________________________________________________

3) End user name and telephone/fax

Name: ________________________________________________

Company: ________________________________________________

Phone: ________________________________________________

Fax: ________________________________________________

4) Description/sketch of what is connected to the ILX Lightwave instrument.

5) Description of the problem.

Calibration and Repair Services

You may have to return your current source module to an ILX Lightwave facility at some time for repair, calibration or

service whether it is under warranty or not. There is a charge for repairs after the warranty period has expired.

Contact an ILX Lightwave service representative for shipping instructions prior to returning the instrument. Have

the above information available when you call. A return authorization number will be given to you at the time of your

request for repair or service. Please use this number in all communications concerning your instrument.

General Shipping Instructions

If you need to ship your LDC-3916338 Laser Diode Current Source Module back to the factory for repair, be sure that

the module is packaged in an anti-static bag and an enclosure with cushioning material to prevent damage to the

module during shipment (use the original shipping containers and accessories if possible). Re-install the ESD

protective caps on the rear panel over the 9-pin connector. Shipping damage is not covered under warranty.

Attach to the module a copy of the completed service form above. We suggest that you insure the shipment.

Ship the module to:

UNITED STATES

ILX LIGHTWAVE CORP.

31950 E. Frontage Rd.

Bozeman, Montana 59715

PH: 406-586-1244

FAX: 406-586-9405

OUTSIDE THE UNITED STATES

Contact the local distributor.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

INTRODUCTION TO THE LDC-3916338 3.0 AMP CURRENT SOURCE MODULE CHPT 1

PAGE 4

Laser Current Source Specifications1

MODEL NUMBER 3916338 Single 3.0A

DRIVE CURRENT OUTPUT

Output Current Range: 0 to 3000mA

Setpoint Resolution: 80 µA

Setpoint Accuracy:2±0.1% of full scale

Compliance Voltage: 4.5 V (adjustable voltage limit)

Temperature Coefficient: ≤100ppm/°C

Short Term Stability (1 hr.):3≤50 ppm

Long Term Stability (24 hr.):4≤75 ppm

Noise and Ripple:5

High Bandwidth Mode: < 36µA rms

Low Bandwidth Mode: < 24µA rms

Transients:

Operational: 6< 5mA

1kV EFT / Surge:7< 5 mA / < 10mA

LASER DRIVE LIMIT SETTINGS

Current Limit Range: 0 to 3000mA

Current Limit Resolution: 1.025 mA

Current Limit Accuracy: ±9 mA

Voltage Limit Range: 0 to 7.5V

Voltage Limit Resolution: 0.2V

PHOTODIODE FEEDBACK

Type: Differential 10ΩInput,

Selectable Zero Bias or 5V Reverse Bias

PD Current Range: 0 to 5000µA

Output Stability:8±0.01%

Accuracy, Setpoint (% of FS): ± 0.1%

EXTERNAL ANALOG MODULATION

Input :90 to 8.0 V, 50Ω

Transfer Function: 375 mA / V ±10 %

High Bandwidth Mode, Small Signal Bandwidth:10 DC to 0.6 MHz

High Bandwidth Mode, Large Signal Bandwidth:11 DC to 0.6 MHz

Low Bandwidth Mode: DC to 30 kHz

DRIVE CURRENT MEASUREMENT

(DISPLAY)

Output Current Range: 0 to 3000.0mA

Output Current Resolution: 0.01 mA

Output Current Accuracy (@25°C): ± 0.07% of Full Scale

Photodiode Current Range: 0 to 5000µA

PD Current Resolution: 0.1 µA

PD Current Accuracy (@25°C): ± 2µA

PD Responsivity Range:12 0.00 to 1000.00µA/ mW

PD Responsivity Resolution: 0.01 µA/ mW

Optical Power Range: 0.00 to 5000.0mW

Optical Power Resolution: 100 µW

Forward Voltage Range: 0.00 to 7.5 V

Forward Voltage Resolution: 10 mV (1 mV GPIB)

Forward Voltage Accuracy:13 ±7 mV (± 2 mV GPIB)

CURRENT SOURCE NOTES:

1. All values relate to a one-hour warm-up period.

2. Accuracy is 0.15% above 2.5 Amps after 1hr warm-up period.

3. Over any 1-hour period, half-scale output.

4. Over any 24-hour period, half-scale output.

5. Measured optically, evaluating noise intensity of a laser diode into a photodetector with 150kHz Bandwidth.

6. Maximum output current transient resulting from normal operational situations (e.g., power on-off, current on-off), as well as accidental situations (e.g., power

line plug removal).

7. Maximum output current transient resulting from a 1000V power-line transient spike.

8. Maximum monitor photodiode current drift over any 30 minute period. Assumes zero drift inresponsivity of photodiode.

9. Modulation input is 50Ωterminated inside the mainframe.

10. 250 mA Setpoint, 50mA modulation current, 1Ωload. High bandwidth mode.

11. 50% modulation at mid-scale output, 1Ωload. High bandwidth mode.

12. Responsivity value is user-defined and is used to calculate the optical power.

13. Four-wire voltage measurement while driving calibration load. Specification valid for values above 10 mV.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HOW TO OPERATE YOUR LDC-3916338 3.0 AMP CURRENT SOURCE MODULE CHPT 2

CHAPTER 2 1

HOW TO OPERATE YOUR LDC-3916338 LASER DIODE CURRENT SOURCE MODULE 1

INTRODUCTION 1

CONNECTING TO THE LASER CURRENT SOURCE 2

Interlock Connections 4

Four-Wire Voltage Sense 4

Photodiode Connections 4

Grounding considerations 4

OPERATING THE LASER CURRENT SOURCE FROM THE FRONT PANEL 5

OPERATING A LASER IN CONSTANT CURRENT MODE 5

Entering the Laser Channel Setup Menu 5

Selecting the Mode of Control 6

Setting the Current Limit 6

Setting the Constant Current Value 6

Setting the Voltage Limit 6

Enabling the Modulation Input 7

Setting Photodiode Bias Voltage 7

Turning the Laser Current Source On 7

OPERATING A LASER IN CONSTANT POWER (P) MODE 8

Calculating Photodiode Responsivity Values 8

Entering the Laser Channel Setup Menu 8

Selecting the Mode of Control 8

Setting the Current Limit 9

Setting the Voltage Limit 9

Setting the Power Limit 10

Adjusting the Constant Power Setting 10

Setting the Responsivity Value (CalPD) 10

Setting the Photodiode Bias Voltage 11

Enabling the Modulation Input 11

Constant Power Mode If CalPD is Unknown 11

Turning the Laser Current Source On 11

CONDITIONS WHICH WILL AUTOMATICALLY SHUT OFF THE LASER OUTPUT 12

Laser Error Indicators 13

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HOW TO OPERATE YOUR LDC-3916338 3.0 AMP CURRENT SOURCE MODULE CHPT 2

PAGE 1

CHAPTER 2

HOW TO OPERATE YOUR LDC-3916338 LASER DIODE CURRENT SOURCE

MODULE

INTRODUCTION

This chapter introduces you to the operation of the LDC-3916338 LD Current Source's control functions. It offers

instructions for connecting your lasers to the current sources. This chapter also contains step by step procedures

that teach you how to operate your module in Constant Current Mode or Constant Power Mode. We recommend

that you review the contents of this chapter at a minimum before operating your new LDC-3916338 Laser Diode

Current Source.

LDC-3916338 SERIES CURRENT SOURCE DEFAULT CONFIGURATION

LASER CONTROLLER

LASER output off

LAS current set point (LDI or Iset) = 50 mA

LAS current limit (LIM:I or Ilim) = 150 mA

LAS voltage limit (LIM:V or Vlim) = 5.0 V

LAS Mode = Constant Current, low bandwidth mode (MODE:ILBW or Ilbw)

Modulation off

Optical power set point (MDP or Pset) = 3.0 mW

Monitor responsivity (CALPD or CalPD) = 0.0µA/mW

Optical power limit (LIM:MDP or Plim) = 500 mW

Monitor PD Bias off

LASER STEP value = 0.1mA

Monitor PD current set point (MDI or Ipdset) = 100µA

Table 2.1 LDC-3916338 Series Current Source Default Settings

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HOW TO OPERATE YOUR LDC-3916338 3.0 AMP CURRENT SOURCE MODULE CHPT 2

PAGE 2

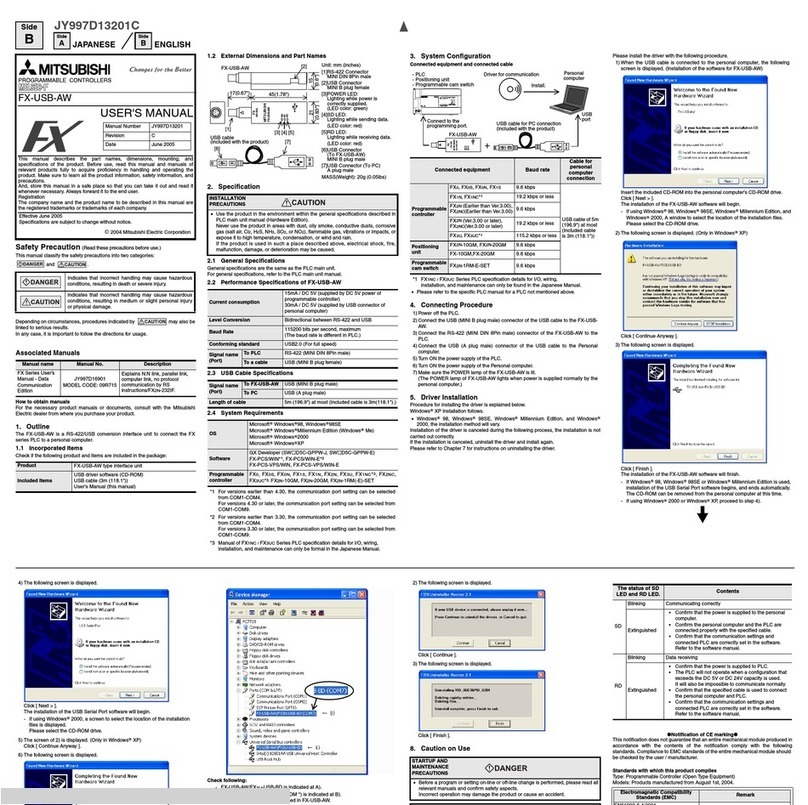

CONNECTING TO THE LASER CURRENT SOURCE

When connecting your laser diode or any other sensitive devices to the LDC-3916338 Laser Diode Current Source

Modules, we recommend that the instrument be powered up and the LASER output be off. In this condition, a low

impedance shunt is active across the output terminals. When disconnecting devices, it is only necessary to turn the

LASER Output off.

It is also recommended that the connections to the LDC-3916338 Laser Diode Controller module output be made

using twisted wire pairs with an earth-grounded shield (see Figures 2.1 A - D). We recommend using our CC-305S or

shorter CC-315S Shielded Laser Cable which are unique twisted-pair cables with braided outer shield designed to

provide the best possible rejection of most transient noise signals. The output terminals of the instrument are left

floating relative to earth ground to suppress AC power-on/power-off transients that may occur through an earth-

ground path. If the output circuit is earth-grounded at some point (such as through the laser package and mount),

the user must be careful to avoid multiple earth grounds in the circuit. Multiple earth grounds may provide circuit

paths that induce spurious currents in the photodiode feedback circuit and output leads.

NOTE

Experience indicates that should an inadvertent open circuit occur during laser operation

(while the LASER is ON), your laser may be damaged by a momentary circuit break-and-remake

before the final circuit break. Your new LDC-3916338 Controller Module has circuitry designed

to detect open circuits and will shut the output off under most conditions. However, we

recommend that cable connections to the laser be secure enough that they won't open-circuit,

should they be jostled or bumped.

Use appropriately shielded cabling to reduce coupling of potentially laser damaging transients.

Do not “bundle” the current source cables with other cables in your system or laboratory. See

Application Note #3, “Laser Diode Protection Strategies” for more detailed discussions on

connecting to your laser.

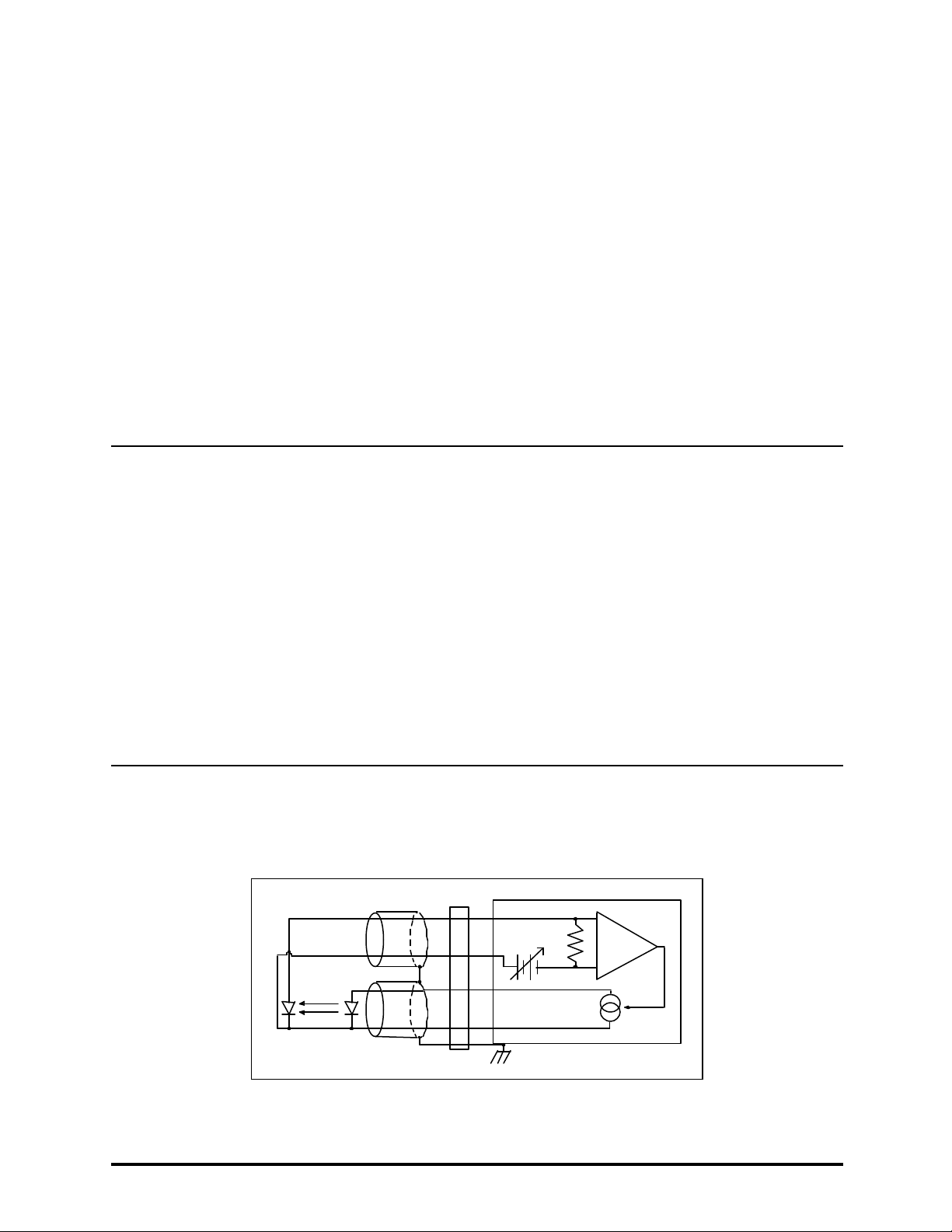

Figures 2.1 A - D show the possible configurations of connecting laser diodes and photodiodes with the

LDC-3916338 Module.

+

-

+Bias

Module

OUTPUT

7

6

9

5

3

P. D. L. D.

Earth Ground

Figure 2.1 A Common Laser Cathode - Photodiode Cathode

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

HOW TO OPERATE YOUR LDC-3916338 3.0 AMP CURRENT SOURCE MODULE CHPT 2

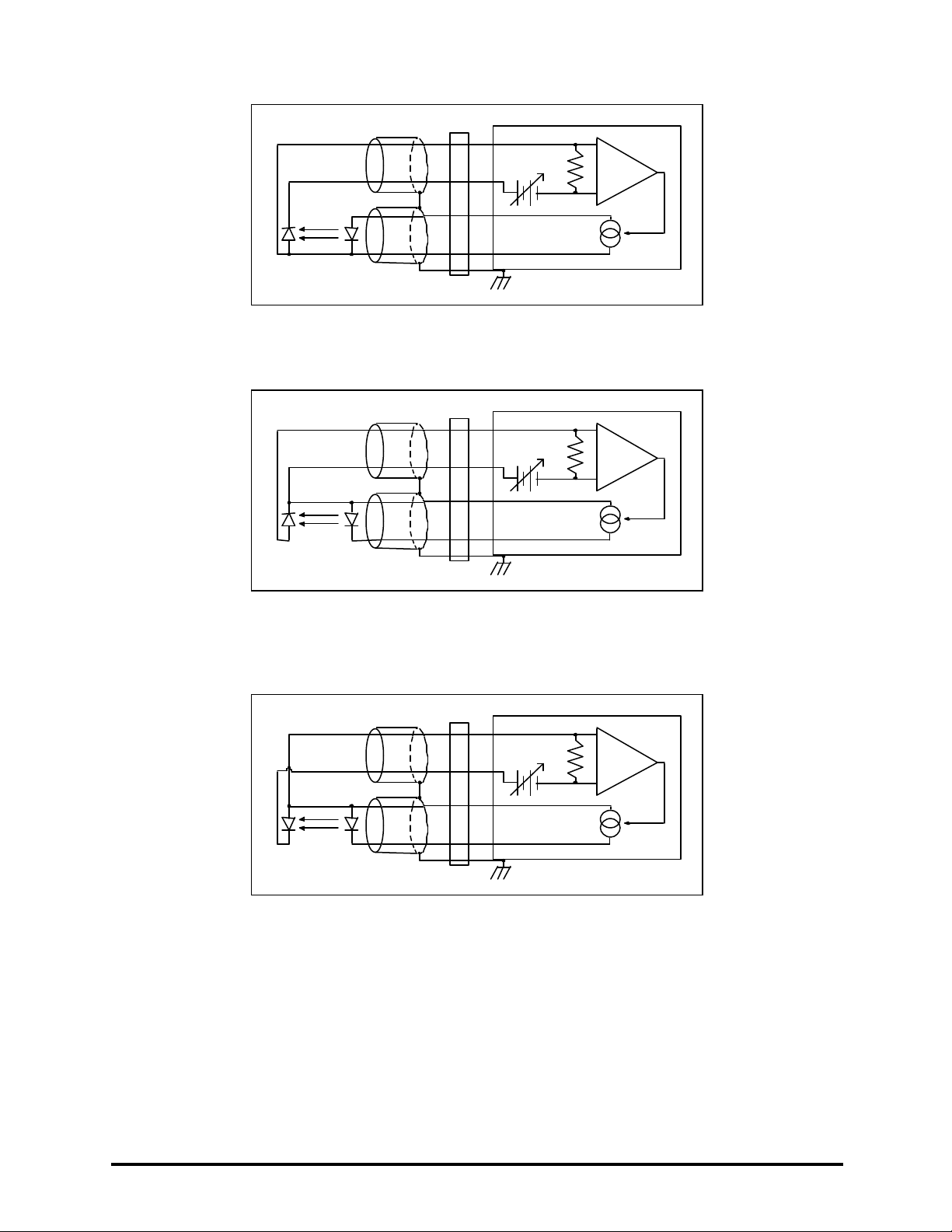

PAGE 3

+

-

+Bias

Module

OUTPUT

7

6

9

5

3

P. D. L. D.

Earth Ground

Figure 2.1 B Common Laser Cathode - Photodiode Anode

+

-

+Bias

Module

OUTPUT

7

6

9

5

3

P. D. L. D.

Earth Ground

Figure 2.1 C Common Laser Anode - Photodiode Cathode

+

-

+Bias

Module

OUTPUT

7

6

9

5

3

P. D. L. D.

Earth Ground

Figure 2.1 D Common Laser Anode - Photodiode Anode

The 9-pin connector on the rear panel (bottom connector) of your Current Source Module is used to connect your

laser diode to the current source. There are connections provided for laser cathode and anode, photodiode cathode

and anode, chassis ground, interlock, and laser forward voltage. The pin-out diagram for this connector is shown in

Figure 2.2.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of contents

Other ILX Lightwave Control Unit manuals

Popular Control Unit manuals by other brands

ANTUMBRA

ANTUMBRA BANK Building instructions

Radwin

Radwin AP0127730 reference guide

Wiesner Hager

Wiesner Hager furniloop Assembly instructions/Operating instructions

Tescom

Tescom SG 1 Series Instructions for use

FireAngel

FireAngel WTSL-SN-1 Installation and user guide

Bentel Security

Bentel Security Absoluta ABS-IP Installer manual