Imesa TANDEM Quick start guide

E170701X.01_ENG 16/04/18

1

TANDEM

INSTALLATION,

USE AND MAINTENANCE

INSTRUCTIONS

PRESERVE FOR FUTURE

CONSULTATION

IMESA S.p.A.

via degli Olmi 22

31040 Cessalto (TV)

ITALY

E170701X.01_ENG 16/04/18

2

INDEX

INDEX............................................................................................................................................................... 2

1. INTRODUCTION........................................................................................................................................ 4

2. SAFETY RULES........................................................................................................................................ 5

3. MANUFACTURER LIABILITY................................................................................................................. 6

4. UNPACKING .............................................................................................................................................. 6

5. MACHINE IDENTIFICATION................................................................................................................... 7

6. INSTALLATION AND POSITIONING .................................................................................................... 8

7. INSTALLATION: GAS HEATED MACHINES SPECIFICATIONS.................................................... 9

8. NOISE LEVEL............................................................................................................................................ 9

9. ELECTRIC CONNECTION..................................................................................................................... 10

10. EMERGENCY STOP IN SELF SERVICE CONFIGURATION....................................................... 11

11. GAS CONNECTION.............................................................................................................................. 11

12. GAS CONNECTION: TIGHTNESS TEST ......................................................................................... 11

13. GAS CONNECTION: THERMAL POWER........................................................................................ 12

14. GAS CONNECTION: GAS INLET PRESSURE CONTROL.......................................................... 12

15. GAS CONNECTION: FINAL TEST .................................................................................................... 12

16. HUMID AIR AND BURN GAS EXAUST............................................................................................ 12

17. STEAM CONNECTION ........................................................................................................................ 13

18. COMPRESSED AIR CONNECTION.................................................................................................. 14

19. HYDRAULIC CONNECTION: LOAD ................................................................................................. 14

20. HYDRAULIC CONNECTION: DRAIN................................................................................................ 15

21. MACHINE DESCRIPTION .................................................................................................................. 15

22. MASCHINE START AND FINAL TEST............................................................................................. 15

23. LANGUAGE CHANGE......................................................................................................................... 15

24. REMOTE ASSISTANCE SERVICE ACTIVATION .......................................................................... 16

25. HOW TO PREPARE THE LINEN: WASHING MACHINE.............................................................. 17

26. HOW TO LOAD THE MACHINE AND CLOSE THE DOOR.......................................................... 17

27. DOOR MANUAL OPENING................................................................................................................. 17

28. HOW TO SWITCH ON THE MACHINE............................................................................................. 20

29. HOW TO SELECT A PROGRAM....................................................................................................... 20

30. PREFERED PROGRAMS.................................................................................................................... 21

31. DELAYED START................................................................................................................................. 21

32. RUNNING THE PROGRAM................................................................................................................. 22

E170701X.01_ENG 16/04/18

3

33. PROGRAM PAUSE............................................................................................................................... 22

34. RAPID ADVANCE................................................................................................................................. 22

35. PROGRAM END.................................................................................................................................... 23

36. END OF THE WORKING DAY: WASHING MACHINE .................................................................. 23

37. PROGRAMMING................................................................................................................................... 23

38. PROGRAM MODIFICATION............................................................................................................... 23

39. EASY PROG FUNCTION..................................................................................................................... 26

40. SELF DIAGNOSTICS ........................................................................................................................... 29

40. FACTORY PROGRAMS: WASHING MACHINE............................................................................. 33

42. OTHER FUNCTION............................................................................................................................... 34

43. WASHING MACHINE MAINTENANCE............................................................................................. 34

44. WASHING DEFECTS ........................................................................................................................... 35

45. SAFETY DEVICES CONTROL........................................................................................................... 35

46. PREPARE THE LINEN FOR DRYING............................................................................................... 35

47. START A PROGRAM: DRYER........................................................................................................... 36

48. PROGRAM START DELAYED........................................................................................................... 38

49. PROGRAM PAUSE............................................................................................................................... 38

50. PROGRAM STOP.................................................................................................................................. 38

51. PROGRAM STEPS OF DRYING........................................................................................................ 39

52. END OF A WORKING DAY: DRYER................................................................................................. 39

53. PARAMETERS MODIFICATIONS DURING THE CYCLE............................................................. 39

54. MANUAL CONFIGURATION .............................................................................................................. 39

55. SAVED PROGRAMS............................................................................................................................ 40

56. COIN OP DRYER: HOW IT WORKS................................................................................................. 41

57. HOW TO ACCES TO THE PROGRAM AREA................................................................................. 42

58. PROGRAMS........................................................................................................................................... 42

59. PROGRAM: LANGUAGE SELECTION ............................................................................................ 43

60. PROGRAM: DATE/TIME...................................................................................................................... 43

61. PROGRAM: ENERGY CONSUMPTION........................................................................................... 43

62. PROGRAM: NO WRINKLE ................................................................................................................. 43

63. PROGRAM: INITIAL COOLING ......................................................................................................... 44

64. PROGRAM: PAYMENT SYSTEM...................................................................................................... 44

65. PROGRAM: COIN BOX MENU........................................................................................................... 44

66. EMERGENCY STOP BUTTON........................................................................................................... 44

67. BLACK OUT........................................................................................................................................... 44

68. WHAT MUST BE DONE IN CASE OF GAS SMELL ...................................................................... 44

E170701X.01_ENG 16/04/18

4

69. DISPLAYED WARNING....................................................................................................................... 45

70. DRYER MAINTENANCE...................................................................................................................... 46

71. DRYING PROBLEMS........................................................................................................................... 47

72. SAFETY DEVICE CONTROL.............................................................................................................. 48

73. SCRAPPING........................................................................................................................................... 48

74. WARRANTY CONDITION.................................................................................................................... 49

75. GAS PRESSURE................................................................................................................................... 49

TRANSLATION OF ORIGINAL INSTRUCTIONS

In the event of any disputes, the reference text will be the Italian version.

1. INTRODUCTION

This manual refers to industrial tumble dryers and

washing machines. installation, use and

maintenance.

It is written in compliance with the European

Community rules in force. The information here

written are addressed to the installer and the user,

who must be sure to fully understand them before

use of the machine.

This manual must always be available for

consultancy. In case it should be lost or damaged,

ask for a new copy from the manufacturer.

The producer is not responsible for any

consequences coming from incorrect dryer use

due to incomplete or misreading of this manual.

The manufacturer reserves itself the right to

modify the specifications written in this manual or

the characteristics of each machine. Some

pictures in this manual may differ from reality.

Diagrams and technical data may be changed

without previous notice.

This manual is integrated by the following

attachments : UE declaration of conformity

technical data sheet and wiring diagram. All these

documents are contained in a envelope you’ll find

inside the machine.

The manual and its attachments are part of the

machine itself, so they must be kept together

and follow the machine when it is sold to

another user.

The manual Attachments and exploded views with

spare parts list can be retrieved in the technical

area of the manufacturer’s website.

Dryer serial number must be available when

entering in the web site.

ATTENTION!

Manufacturer is not responsible for any possible

incorrect information here written, when the errors

are due to a printing or translation error.

The manufacturer reserves themselves the right

to modify the product, when necessary or useful,

without changing the main characteristics. Without

any previous authorization of the manufacturer, to

copy completely or partially the next and the

pictures of this manual is forbidden.

E170701X.01_ENG 16/04/18

5

2. SAFETY RULES

ATTENTION!

Chocking, injury and permanent invalidate

risks!

Not respecting the following instruction, may

cause damages to people, things and animals.

Installations and maintenance of the here

described machines must be trained by

authorized personnel, which knows the product

and respecting the European Rules in matter of

industrial machines installation.

Reparation made in a not correct way may

seriously compromise the user safety.

Instruction must be read in detail before the

machine is put in use. Instruction must be

available to all the people working with the dryer.

Here described machines must be used for

professionally drying clothing and linen: any other

use is forbidden if not before authorized by the

manufacturer.

Before removing linen from the dryer, be sure that

the drum has stopped. Never put your hands

inside the drum, if it is still rotating.

Do not dry in the machine any dissimilar items; do

not dry linen, which has entered in contact with

dangerous materials like explosives, detonating

explosives or inflammables.

Follow always very carefully the cleaning

instruction of each linen.

To avoid risks off fire or explosion, do not

approach the machine with combustible or

inflammable substances.

The use of this machine is forbidden to people

under 16 years of age.

Children must not play or be close to this

equipment.

Packing materials must be kept out of the reach of

children.

Detergents must be kept out of the reach of

children. Children and pets must be kept away

from the equipment door when it is open.

External supplementary connection to the

machine releases the manufacturer from any

responsibility if they are not properly done.

WARNINGS

Working with opened sides is forbidden!

In order to avoid burns or accidents it is

forbidden to remove, even temporarily, the

protection panels and the safety system!

It is forbidden to introduce bars, sticks or

metallic objects inside the drum. In case of

emergency, please follow always the here

described procedures.

Each time the dryer is started, check always

the safety device is correctly working!

To know the machine and its safety device

working is compulsory!

BURNS DANGERS

The dryer, because of its nature, presents

burns danger.

Burns may be caused by:

-The contact with the linen taken out from

the dryer;

-The contact with the door inside, following

its opening;

-The contact with the heating batteries

during the maintenance;

-The contact with the fluxing steam parts.

Following labels are fixed on the machine. If

one of them would be damaged, the user must

replace it with a new identical one.

Stuck near dried linen exit.

External panels can reach high temperatures

E170701X.01_ENG 16/04/18

6

when the machine is working.

Dryer must always be used by trained

personnel and with at least two operators in

the room!

READ CAREFULLY THE INSTRUCTION FOR

OPERATING IN CASE OF BLACK OUT, AND

INFORM ALL THE USERs ABOUT THEM.

ELECTROCUTION DANGER

Only qualified personnel must operate any

service of the electrical parts. Before working

on the machine, cut off the electrical supply.

Only manufacturer personnel can modify

power and controlled circuits, on the contrary

the warranty conditions expire.

On the electric board, the here below warning

label was stuck. If this label should be damaged

or unstuck, an identical one must replace it.

OPERATOR PSYCHOPHYSICAL

CONDITIONS

User must be in perfect psychophysical condition;

during the working cycle, the user must always

assume a vertical posture in front of the machine.

Sudden or not controlled movement must be

avoided because of the risks of dangerous knocks

against the dryer chassis, i.e.: during the dryer

unloading.

The other people present on the laundry room

must not distract the operator, who is working on

the dryer.

While working, the operator must not be distracted

by TV, radio or any other source of distraction.

LIGHTING

In the room where the machine is installed,

lighting must be at least of 300-500 lux intensity;

unpleasant flashing must be avoided.

ATTENTION!

These instructions do not cover all possible risks.

User must always pay high attention and respect

carefully the rules.

The machine in not previewed to be used by

persons with reduced phisical or mental capacities

or with missing or reduced experience and

knowledge.

3. MANUFACTURER LIABILITY

The instructions written in this manual are not

replacing, but completing the duties deriving from

the safety and accident prevention laws.

With reference to what is written in this manual,

the manufacture is not responsible when:

- The machine user does not respect safety and

accident prevention laws in force;

- The machine was not correctly installed;

- Periodical and/or programmed maintenance is

missing;

- Manual instruction was not respected;

- Defects occur in the power supply;

- Non authorized modification made on the

machine;

- Non-authorized personnel use the machine.

4. UNPACKING

During tranportation or storage the machine must

stay within the following conditions:

- temperature: -15°C÷50°C

- humidity: 0%÷90% (without condensation)

The machine must be inspected at the delivery

moment, any external or internal damage due to

the transport, must be reported immediately to the

forwarder.

Machine must be completely unpacked next to the

installation place. Straps must be cut and the

covering packing material must be taken off.

Packing materials must be disposed following the

rules in subject of environment protection.

Using a key, take away the fixings on the machine

base which are attaching the dryer to the pallet

(frontal and back).

ATTENTION!

Check the machine net and gross weight on the

technical data sheet sent with the machine: it

must comply with the available lifting means.

ATTENTION!

Pallet cannot be used as normal dryer support!

The machine must always be installed without

E170701X.01_ENG 16/04/18

7

pallet and positioned as described in the relative

paragraph.

ATTENTION!

Move the machine only when it is fixed on its

pallet: only trained and competent personnel must

do the machine handling.

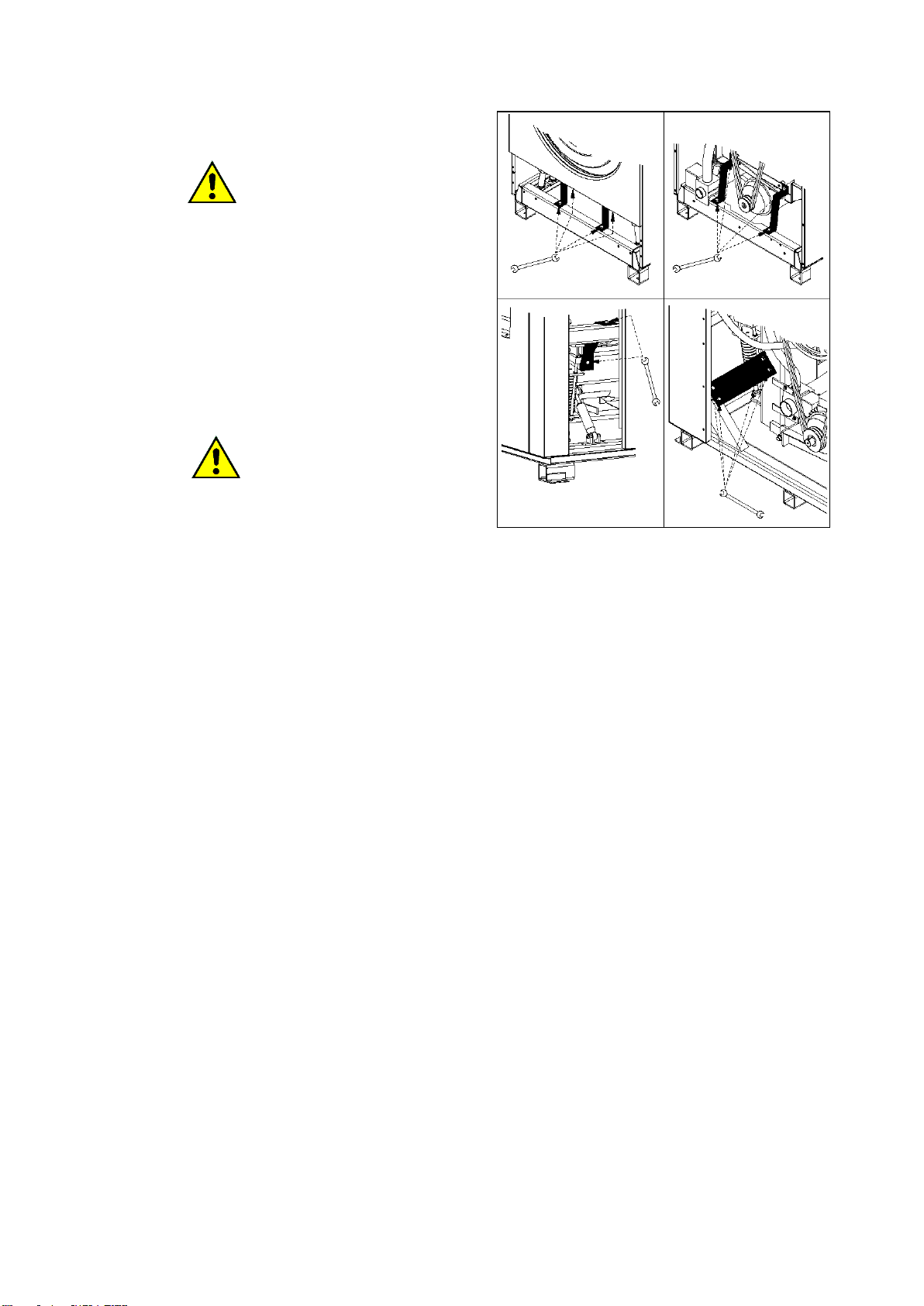

During the transport, the high spin washing

machines basement and cradle are blocked with

locks in order to avoid shock absorber stress.

ATTENTION!

Transport locks need to be removed once the

machine is positioned and before it is supplied.

To take off the transport locks, follow the next

instructions. Pictures indicate the lock type, not

the machine.

- Remove frontal and rear panels.

- Unscrew the bolts fixing the

transport locks.

- Remove the transport locks

- Mount again the panels in the original

position.

Each panel must be mounted again in the original

position before the machine is switched on.

When removed, the locks need to be kept and

used again each time the machine needs to be

moved.

5. MACHINE IDENTIFICATION

The sticker reporting the machine serial number,

model, power and technical characteristics

identifies the dryer. Be sure that the electrical,

hydraulic, steam, gas, compressed air

connections are complying with the sticker data.

Spare parts and/or services require the correct

model identification.

E170701X.01_ENG 16/04/18

8

If the sticker with serial number is tampered,

missed, removed or damaged in a way that does

not allow correct machine identification, the dryer

installation and service can be difficult and the

warranty automatically expires.

6. INSTALLATION AND POSITIONING

Installation must be by trained, qualified

personnel. Machine must be positioned on a flat

surface horizontally and in a stable way using the

adjustable feet at the dryer base. Feet can be

adjusted from outside, screwing and unscrewing

them until the dryer is correctly levelled.

In equipped models, the feet can be adjusted from

inside using a 5mm hexagonal key after the filter

door and the back panel have been opened.

Always check if the floor can bear the machine

weight written in the technical data sheet. The

machine load can be considered very static. To

calculate the dryer static load, the weight of the

wet linen to be loaded must be added to the dryer

net weight. Be sure the floor is clean and high

temperature resistant. For correct machine use,

working and service, leave at least 500 mm free

surface around the dryer.

The room temperature must be between +5ºC and

+40ºC.

Protection class is IPX4.

Relative humidity must be within 5% and 90%

(without condensation)

The room where the machine installed must have

enough incoming air ventilation. Please note: the

machine takes air from the room where it is

installed and expels the humid air from the drying

cycle to the outside.

Sizing the air intakes: refer to national normatives.

Consider a minimum of 9cm2/kW witha a minimum

surface of 150cm2. Remember that grates and

curtains reduce the flow of air.

The dryer must not be installed behind a door,

which can be closed with a key, a sliding door, or

a door with hinges mounted on the opposite side

to the tumble dryer.

Do not install or use a machine if it is damaged.

Do not install a machine in a position where the

door cannot be completely opened (a suitable kit

can be provided to change the door hinge from

left to right opening and vice versa)

ATTENTION!

Clean air must be assured to the machine; air

combined with chlorine, fluorine or other

solvent vapors must be avoided.

Do not use or stock near the machine

benzene, petroleum or other inflammable

stuffs otherwise fire or explosion may be

caused.

Keep near the machine a foam extinguisher,

which is periodically controlled in compliance

with the rules in force.

ATTENTION!

Machine CAN’T be installed on open air,

but in a CLOSED room, specifically built

and adhibited as a laundry.

E170701X.01_ENG 16/04/18

9

ATTENTION!

Check the cleaning of the drum.

Processing residues may be found in the

internal side of the drum.

ATTENTION!

In case of tilting machines foresee

necessary spaces to avoid the risk of

crush between the machine and the

elements in the installation room: other

machines, walls, roofs, doors and

windows (opened and closede) etc.

The amount of movement during the

phase of tilting can be founf in the

technical data sheet.

7. INSTALLATION: GAS HEATED MACHINES

SPECIFICATIONS

Independently from the capacity, every gas-

heated machine must be considered as a gas

equipment.

During the installation must be respected the

following rules:

-Territorial building and fire-prevention rules;

-Accident prevention rules;

-CENELEC rules /electric system);

-Rules about the combustible gas use

-Rules about gas system supplied by public

net or LPG gas

-Rules coming from the gas company

-Rules coming from the electricity company

-Other possible local rules.

Air inlet and ventilation openings can be closed

only if the opening condition is controlled and if

the flame of the gas-heated equipment has

opened air inlet and ventilation.

The room must be correctly ventilated, even when

the gas exhaust is mechanically operated, if the

nominal thermal pollution of this gas equipment

does not cause depression in the room. In this

way, a regular gas combustion and the complete

exhaust of the burn gas are guaranteed.

To dimension the air grating, please refer to the

data written on the machine technical sheet and to

the rules in force. In this way, a regular gas

combustion and the complete gas exhaust are

guaranteed.

Air inlet dimensions must comply with the

technical sheet requirements and with the subject

rules in force.

In case the dryer is supplied with liquid gas and is

installed in a basement, forced ventilation system

must be provided.

Data of gas are in paragraph 49.

ATTENTION!

Never install a gas-heated machine in the

same room where there are machines that use

solvents (example: dry cleaning machine).

This combination could produce dangerous

substances for the operator and it can cause

steel corrosion.

If a gas-heated machine and a machine using

solvents are installed in two separate rooms,

be sure that there is no possibility of air

exchange between these two rooms.

ATTENTION!

In case of machine equipped with a tilting

system, the machine must be fixed to the floor

using some screw anchors.

Machine must be installed perfectly

horizontally on a floor without elastic reaction.

ATTENTION!

In case of tilting machines, there are external

parts that move during the linen loading and

unloading steps.

For machine dimensions and machine-

required space during the movement, please

refer to the technical data sheet.

8. NOISE LEVEL

The air noise produced by the machine is

producing a continuous and weighted acoustic

pressure lower than 70 dB.

E170701X.01_ENG 16/04/18

10

9. ELECTRIC CONNECTION

Electric connections must be carried out by

qualified technicians and must comply with

local and National rules in force. Check if the

supply data corresponds to the data written on

the machine plate. (voltage tollerance ±10%,

frequency tollerance ±1Hz).

To connect the machine use a H05 VV –F cable

or superior and follow the data label and in the

technical data sheet to dimension it correctly.

Install before the machine an omni-polar

disconnecting device with interlocked padlock

(i.e.: a circuit breaker) which has a contact

opening that allows the complete disconnection in

case one of the conditions of the over tension III

category is verified. This device must comply with

the subject regulation in force.

Check the main switch; it must be in position “0”.

Open the electric supply door.

Pass the electric supply cable through the cable

holder supplied with the machine.

Before inserting the supply cable, verifiy that it

makes a dead neck lower than the entrance: in

this way eventual condensation drops, cannot get

in touch with electrical connections.

Electric supply cable connection must be done on

a series of marked terminal.

Following the kind of heating indicated on the

serial number plate, connect the cable to the

terminals, as indicated:

: Ground, color: yellow/green

L1, L2, L3: phase, color: brown

N: neutral, color: blue

In case of installation or replacement of the

supplying cable, the ground cable must be at least

5cm longer than the other cables. The electric

diagram is contained in an envelope, inside the

electric board.

On the back panel there’s an equipotential

born for the connection to be done according

to law,

ATTENTION!

Check the fan rotation direction: it must rotate in

the direction that allows the exhaust air discharge;

it means that the fan motor rotated in the direction

indicated by the arrow marked on the motor cover.

Check the correct connecting sequence of

phases.

The machine must be connected to an efficient

ground system: the supplier is not responsible in

case this connection is not operated in

compliance with the subject rules in force. Before

any maintenance, cut the electricity supply to the

machine: for the maintenance refer to the

machine electric diagram, which is inside the

machine; anyway, it can be retrieved at any

moment on manufacturer web site.

The minimum section for the electric cable is

indicated in the attached technical data sheet and

are expressed in mm2.

ATTENTION!

The technical data minimum sections can change

according to the connection length. In case the

cable is longer than 5 meters, the cable diameter

must be proportionally increased.

ATTENTION!

The machine connection must always be made

respecting the data written in the serial number

plate (power, supply tension, frequency).

For a different voltage from the one provided, ask

for more information to the manufacturer.

ATTENTION!

For a machine equipped with drum or fan speed

control, it means for machine equipped with

inverter, a protection by RCD type B device must

be provided (sensible to the current medium

value).

ATTENTION!

In case the machine is equipped with a supply

cable, and the cable is damaged, the

manufacturer must replace it or by the authorized

technical service; anyway only qualified personnel

can service the machine, in order to prevent any

E170701X.01_ENG 16/04/18

11

risk.

ATTENTION!

Before turning on the power supply of a

machine that suffered a therma rus, wait for

the evaporation of condensed humidity to

avoid damages to electronics.

10. EMERGENCY STOP IN SELF SERVICE

CONFIGURATION

Machines in a self service don’t have an

emergency button. The installer must supply an

emergency device connected to all the machines.

11. GAS CONNECTION

If the machine is gas heated, the necessary

connection with the distribution system must be

made: check the machine serial number plate

data, especially check supply gas pressure.

ATTENTION!

The maximum gas pressure admitted is

50mbar. To supply the gas with a higher

pressure, even for short time, may damage the

valve.

The gas distribution system must be realized in

compliance with the rules in force and it must

respect the sections and the pressure suitable for

the installed equipment, as per tables at the end

of this manual.

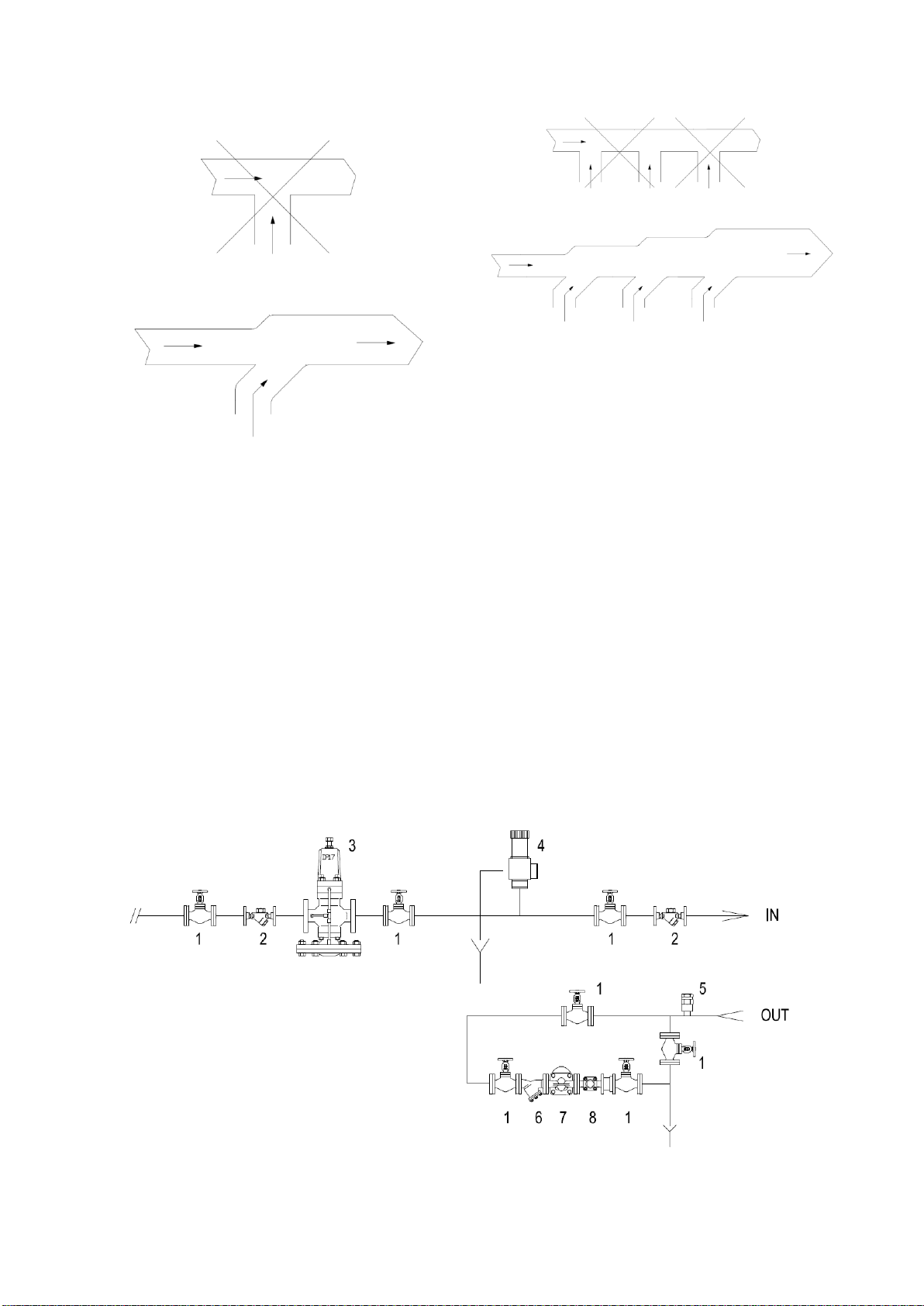

Look to the following picture: back to the machine

must be installed a rapid gas interceptor valve (1):

the gas cock must be near the dryer and in an

easily reachable position. The cock must comply

with the rules in force and must be an approved

model.

A low point pressure switch must be provided (2).

The connection to the gas system must be made

using a no-vibration joint (3); if flexible tubes are

used, these must be in stainless steel DIN 3384 or

DIN 3383.

The gas system must be realized in compliance

with the rules in force. Respect dimension of the

dryer gas-connection written in the technical data

sheet; this dimension must not be reduced.

The next picture shows how the machine should

be connected in case of gas cylinder with high

pressure. In this case, a two-step reduction

system is necessary; it must be realised in

compliance with the rules in force.

At first 1.5mbar governor must be connected after

the high pressure gas cylinder (1), after that a

safety valve with the appropriate dimension must

be installed (2).

The high pressure tube (3) is interrupted by an

interceptor cock (4) and then it follows protected

(5) below the compartments division area border.

Before entering the room where the machine is

installed, a second interceptor valve must be

provided and then a filter (6) and a second

governor (7) which brings the pressure to the

correct working value.

12. GAS CONNECTION: TIGHTNESS TEST

All the joints between system and dryer must be

tightness tested.

To make this test, use a leak finder spray;

otherwise, the joints can be covered with foamy

substances, which must not be corrosive. In both

cases, bubbles must not appear.

E170701X.01_ENG 16/04/18

12

ATTENTION!

It is forbidden to use free flame for tightness

test!

13. GAS CONNECTION: THERMAL POWER

Each dryer tested in the factory is prepared for a

kind of gas that is written in the sticker near the

serial number plate.

If the machine is predisposed for a gas that does

not correspond to the kind available in the

installation place, then it is compulsory to make

the dryer adaptation. In this case, the authorized

after sales center must be informed.

A dryer that is working with the expected thermal

power depends on the inlet pressure and the gas

calorific power, but also depends on the nozzle,

the gas pressure arriving to the nozzle and from a

correct supply of primary air.

The pressure of the gas arriving to the machine

must be included in the limits written on the gas

type tables. If the pressure is not included in the

limits written in this manual, the dryer cannot be

started.

If the verified gas pressure is different from the

table values, please contact the gas company or

the company that realized the gas system.

The GAS Lower Calorific Power, which must be

asked to the gas company, must correspond to

the one indicated in the technical data table.

14. GAS CONNECTION: GAS INLET

PRESSURE CONTROL

The inlet gas pressure must be controlled using a

digital or liquid measuring tool (resolution of 0.1

mbar at least).

- Close the interception device.

- Open the sealing screw on the pressure tube

gas valve connection indicated as “Pin”.

- Connect the manometer

- Open the interceptor device

- Start the dryer following the user instruction

- Check the inlet pressure, with the burner

working.

- Switch off the dryer.

- Close the interception device.

- Take off the monometre.

- Close the screw of the gas valve pressure

tube and control the tightness.

- Open the interceptor device and control test

the tightness.

The dryer must not be used if the gas pressure is

out of the limit shown in the reference table.

15. GAS CONNECTION: FINAL TEST

Once the connection works are completed, the

equipment and the installation must be tested. It is

necessary to test:

-That the connection are made respecting the

instructions written in this manual;

-That the safety rules and the laws about this

subject are respected;

-That gas connections are tightness tested.

Switch on the machine following the user manual

instructions controlling the burner lighting on and

the flame aspect.

Do a gas test with the volumetric method. Using

the gas regulator, control how much gas was used

in a fixed time unit: this value must be compared

with the values in the tables.

16. HUMID AIR AND BURN GAS EXAUST

The humid air and burns gas exhaust system

must be realized following the rules in force.

To avoid lack of humid air and noise, the exhaust

joints to the outside must be made tight with high

temperature resistant material (filler, putty,

silicone preparation).

To avoid leakage, don’t use spiral ducts: use

straight metallic and rigid tubes therefore. The

material used must be compatible with the

exhaust temperatures of the machine. Gas heated

tumble dryer are B22 equipment, it means they

are gas equipment which depend on an aired

room without any wind protection device with

blower behind the burning room.

Dryer burned gas must be brought outside

through a chimney.

Burnt gas and humid air pipe must be the shortest

possible one and it must be rising to the exhaust

chimney. To reduce load losses, don’t use curves

at 90 °, preferring two 45 ° curves.

A condenser drain must be provided in the lowest

point. This drain derivation must observe local

rules of water drain connection.

Te duct must resist to any crush. In case of a

manifold, don’t use "T" connections and consider

the correct value of the manifold section. If

necessary, increase the manifold section.

E170701X.01_ENG 16/04/18

13

The manifold for multiple machines can’t be done

for gas machines.

For machines with electric or steam heating it is

possible to foresee a collector: do not perform "T"

connections and consider the correct value of the

manifold section. If necessary, increase the

manifold section.

The dryer is equipped with a suction fan that

produces its typical noise while working.

To reduce the noise level, a muffler can be

installed on the drain (it can be found in a

specialized shop).

17. STEAM CONNECTION

Only for steam-heated fryers, personnel in

compliance with the national and local rules in

force must perform a connection. Steam must

satisfy the minimum requirement written in the

technical data sheet; all component in the system

must be certified. The steam system must be

realized following the below diagram:

E170701X.01_ENG 16/04/18

14

Elements are identified in the system as below:

1On –Off Valve;

2Filter;

3Pressure reducing valve (if necessary);

4Safety valve

IN) Machine steam exchanger inlet

ATTENTION!

In order to be efficient, the safety valve must

be of an adequate size to provide to the

maximum steam system rate.

5Vacuum breaker valves

6Filter

7Inverted bucket steam trap

8Flow indicator

OUT) Machine steam heater outlet

ATTENTION!

Drying productivity depends on the steam

heater efficiency.

Dryer can work within the steam pressure

range referred in the technical data sheet,

anyway lower is the pressure, poorer are the

machines performance. In order to avoid too

much longer drying time, the pressure should

be at least 5bar.

ATTENTION!

Open slowly the shut-off valve (1) to minimize

pressure shocks effects.

ATTENTION!

Electric valves MUST NOT intercept steam line

nor pneumatics for temperature adjust.

Machine damper already does the

thermoregulation. The use of valves shorten

the life of the exchanger and the warranty

automatically lapse.

ATTENTION!

Don’t touch steam inlet or outlet tube when

they are hot!

18. COMPRESSED AIR CONNECTION

Connection to a compressed air system is

necessary for some dryer models: check the

equipment data sheet.

Qualified personnel in compliance with national

and local rules in force must perform system.

Connections between system and dryer must be

tested tightly; it is suggested to use a leak finder

spray. In case of leaks, stop them.

19. HYDRAULIC CONNECTION: LOAD

The washing machines are equipped with

electrovalve for the cold and hot water loading (in

case it is requested, the machine is equipped with

a third electrovalve for hard water). Each water

inlet is identified, for connection quotes refer to

technical data sheet.

At the beginning of each hydraulic supply a gate

valve must be provided to cut the water supply to

the machine at any moment, in case of

emergency or in case of service.

At the beginning of each water inlet an inspect

filter must be provided. It is necessary, also, to

control the machine inlet valve filter after a short

time of use, overall the hydraulic system is old or

not used from a long time.

ATTENTION!

All the inlet valve must always be connected!

If in the supply system it is not available the

hot water, connect cold water also to the inlet

valve called “HOT WATER”.

When more washing machine are connected to

the same water line, the water line must have a

diameter sufficient to grand a water flow enough

to supply all the machine in case all of them are

loading water.

A minimum pressure of 0,4 atm is necessary to

load the water: if the supplied pressure is lower,

the water loading time are longer.

Maximum water loading pressure is 8 Atm (the

minimum and maximum values are taking in

E170701X.01_ENG 16/04/18

15

consideration all the kind of valve mounted on the

different machine size).

20. HYDRAULIC CONNECTION: DRAIN

The electric drain valve used are a normally open

kind, it means that the water is drained in case of

black out.

In case of more washing machines connected to

the same drain line, it must be enough to allow the

correct water flow in case all the machines are

draining water at the same time.

Drain collector must avoid that the water drained

by one machine enter in the next one.

The washing machine drain is for gravity, the

drain tube must not present sinking or counter

slope. A 2% slope must be provided to allow a

correct water flow.

The drain system must satisfy the local or national

laws and regulation in force.

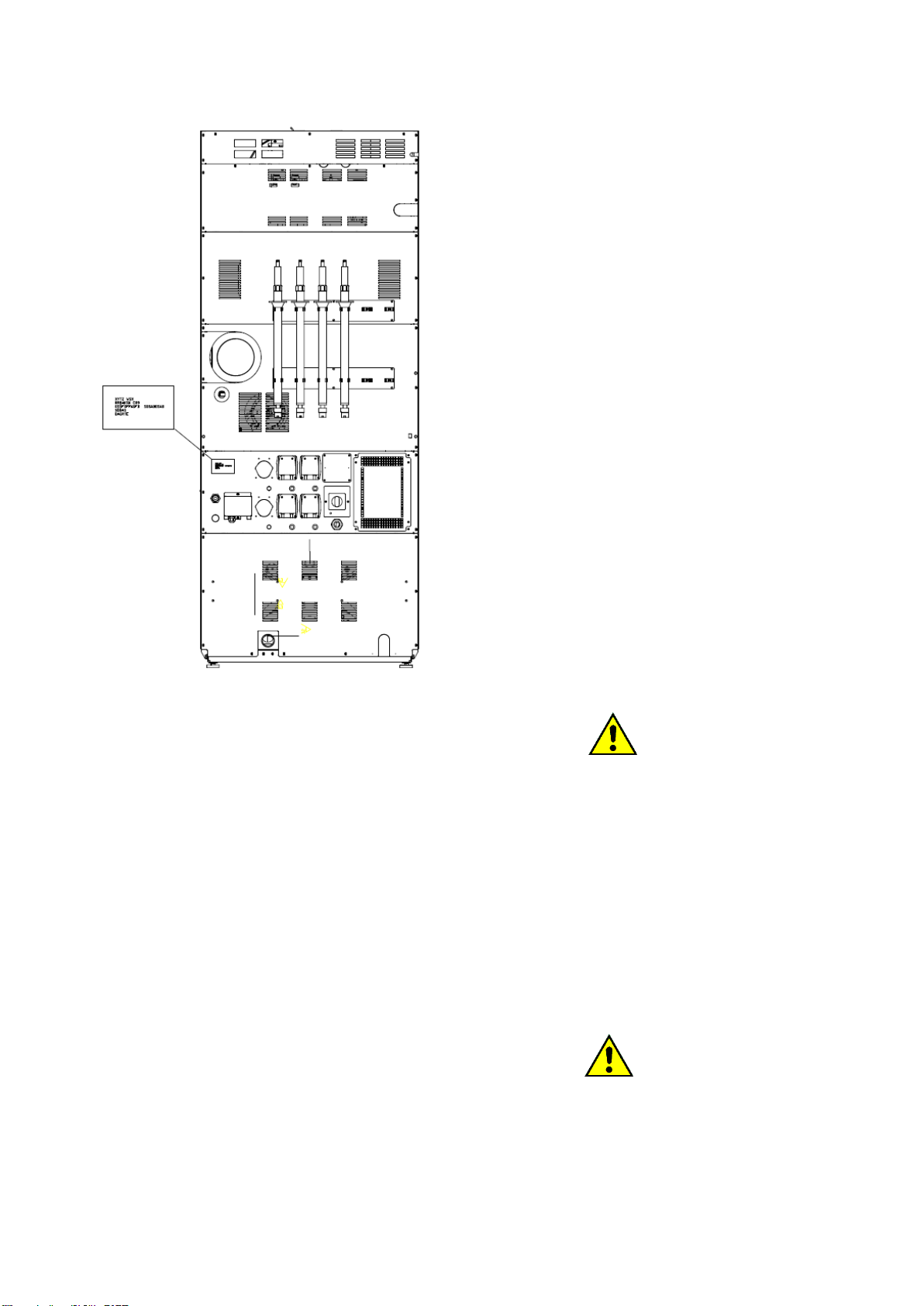

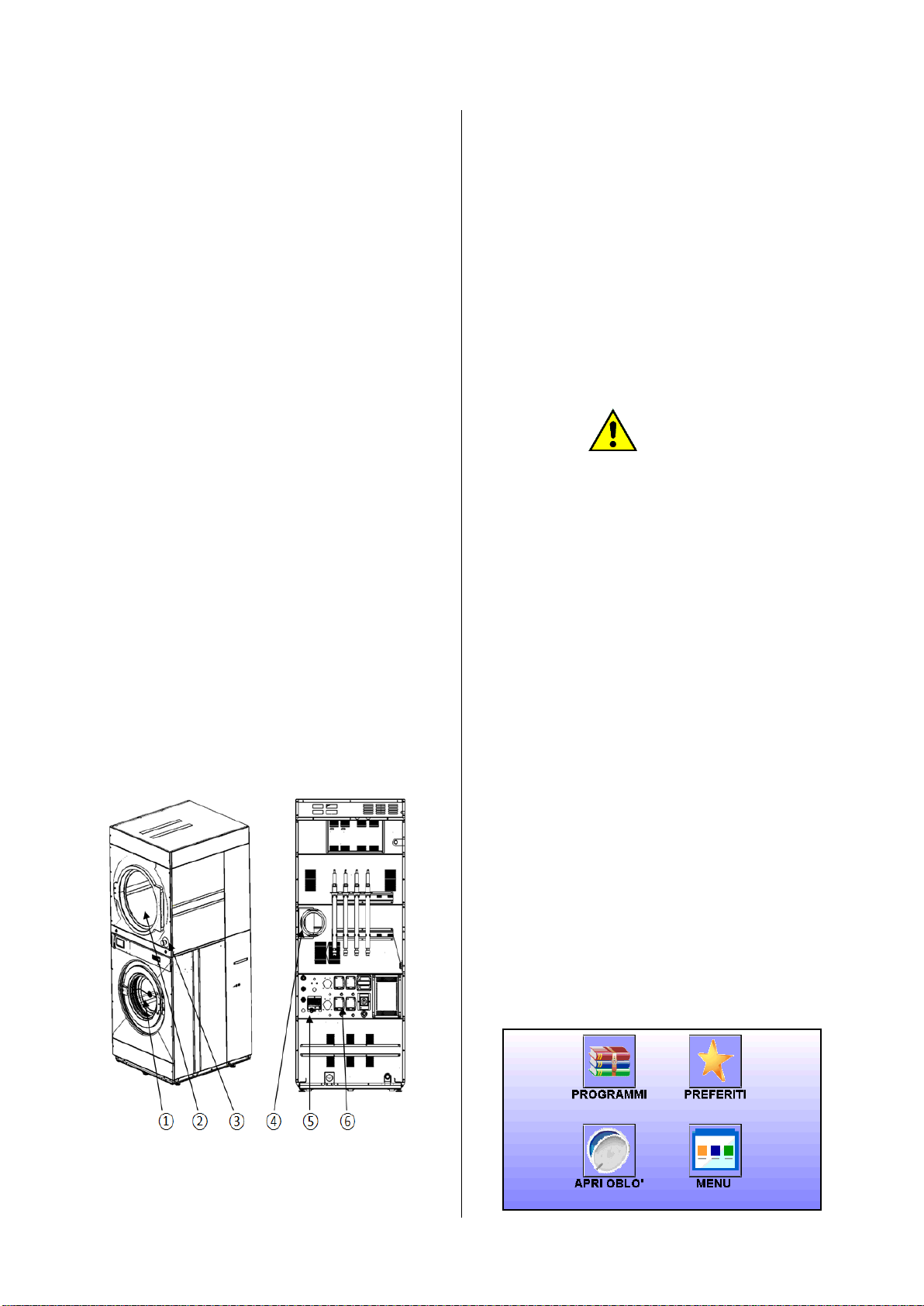

21. MACHINE DESCRIPTION

The dryer is characterized by some elements that

must be known before using the machine.

The point no. 1 identifies the door of the washing

machine..

The point no. 2 identifies the door of the dryer.

The point no. 3 identifies emergency mushroom (if

present).

The point no. 4 identifies the humid air exhaust

(always) and the burn gas exhaust (in case of

gas-heated machines).

The point no. 5 identifies the electronic connection

box and apart of the electric system. Only

competent and specialized personnel are allowed

to access to the electric board.

The point no. 6 identifies the peristaltic pumps.

ATTENTION!

Air intakes on the machine back must be

always free. The air passage must not be

limited in any way.

22. MASCHINE START AND FINAL TEST

Once the machine is installed, and all connections

are made, it must be started following the

provided instructions. Each machine part must be

tested: start a program and check at least one

complete program. The machine must be fully

loaded and, in case of high spin machines, the

unbalance end switch position must be controlled.

23. LANGUAGE CHANGE

When the machine is switched on for the first

time, interface language could be different from

the one wished by the user.

The following procedure explains how to change

the interface language.

Touch the icon “MENU” of the home page.

E170701X.01_ENG 16/04/18

16

The display shows:

Touch the icon “PARAMETERS”, the display

shows:

Digit the code “111111” and the display shows:

Touch the icon MODIFICA and scroll the menu of

the available languages using the keys “<<” and

“>>”. When the whished language appears on the

screen, confirm touching the icon “OK”.

Exit the configuration menu touching the icon

“HOME” as many time as necessary to reach the

home page.

24. REMOTE ASSISTANCE SERVICE

ACTIVATION

In case of models equipped with the remote

assistance system, the connection to the service

server must be activated. In order to do it, check

the instructions sent with the machine.

E170701X.01_ENG 16/04/18

17

25. HOW TO PREPARE THE LINEN: WASHING

MACHINE

Machine must be loaded on the base of the serial

number plate: it must not be loaded with a weight

higher than the one written in the technical data

sheet or in the serial number plate.

Before to choose the most suitable program, the

linen need to be sorted into groups homogeneous

for fibers and fabrics, in order to have a uniform

washing for the whole load.

Before to put the linen into the washing machine,

be sure that the linen label is authorizing the

machine washing; always stick to linen

manufacturer indication.

Here below the meaning of the most common

International symbols:

Maximum temperature: 70°;

Mechanical action: midle.

Maximum temperature: 60°C;

Mechanical action: soft

Maximum temperature: 40°C;

Mechanical action: very soft

Only hand washing

Do not clean with water

26. HOW TO LOAD THE MACHINE AND CLOSE

THE DOOR

The machine must be loaded following the

indication given in the serial number plate.

The label is stuck on the machine back.

ATTENTION!

Machine must be loaded with linen, which is the

most homogeneous possible. The weight of the

loaded linen must not be higher than the one

indicated in the technical data sheet and in the

serial number sticker.

Before to load the linen, be sure that the drum is

completely empty. When the machine is loaded,

close the door.

ATTENTION!

Be sure that no linen parts are taken between the

door and the machine front panel, while the door

is going to be closed.

In case of machine without door handle, just press

the door against the machine until it is locked.

In case of machine with handle or motorized door

lock, the door must just set ajar the machine front,

in this way the closing pin enters in the correct

position on the machine front.

When the machine is started the computer will

give the command to lock the door.

ATTENTION!

In case of barrier washer (double door): before to

close the external door, be sure that the drum

door was correctly closed as explained in the

notice supplied with the machine.

In case the inside door was not correctly

closed, the program MUST NOT be started.

Be sure that the operators perfectly

understood how to close the inside door!

27. DOOR MANUAL OPENING

While the cycle is running, it could be necessary

to open the door manually, without using the

unlock function of the touch screen.

ATTENTION!

Before to open manually the door, cut the

electricity supply to the machine using the

main switch.

E170701X.01_ENG 16/04/18

18

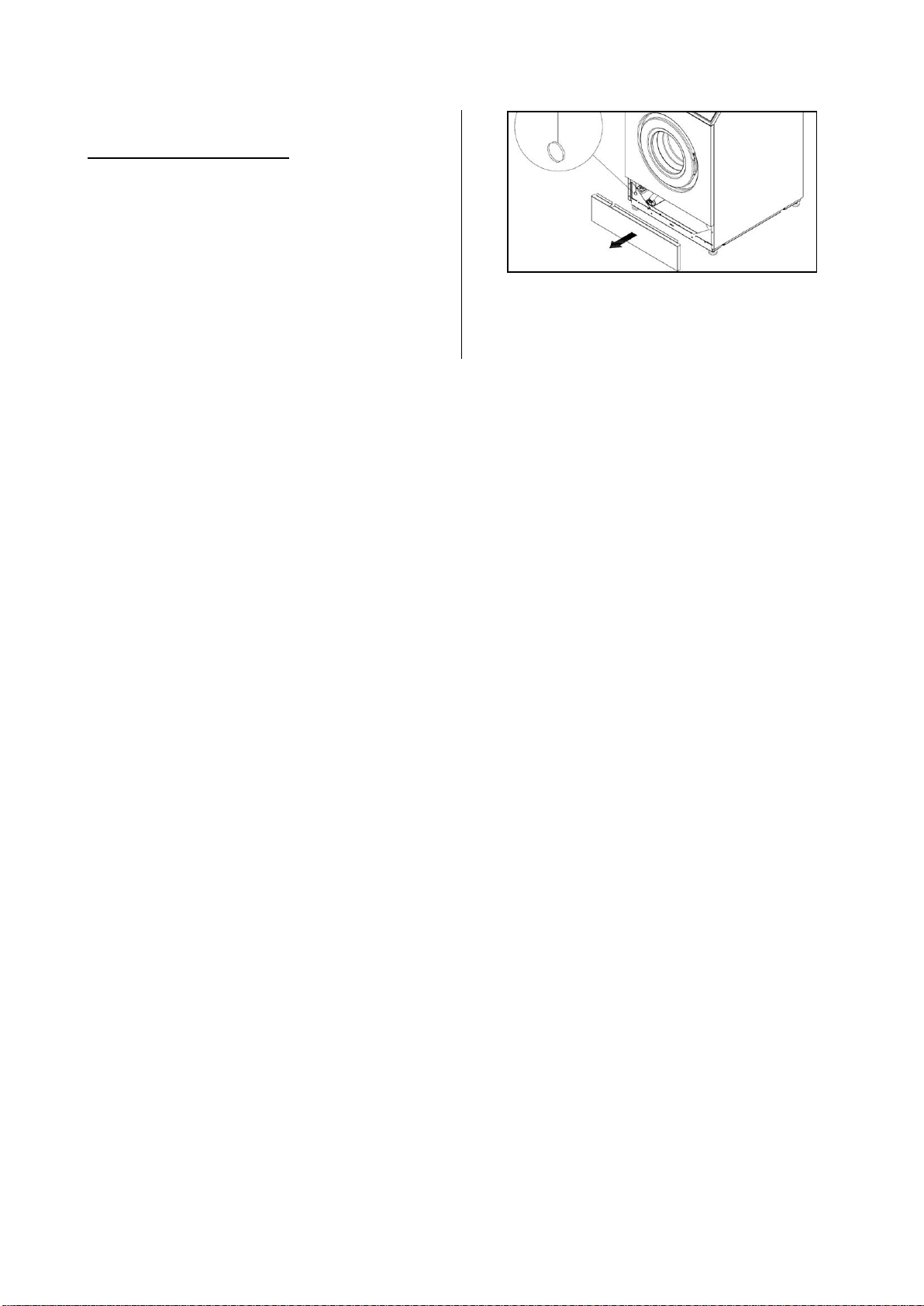

Machine with impulse closing

Open the below panel (the one shown in the

picture). To unlock the door, pull the lanyard with

the small ring.

E170701X.01_ENG 16/04/18

19

Machines with motorized door lock

Remove the small plug (1) and insert the unlocking lever (2) in the door lock as show in the picture (on the

above edge). The lever must be correctly positioned!

Turn the lever upward until the mechanism clicks.

When the motorize door locking is manually opened, the mechanism alignment procedure must be done as

soon as the electricity is came back.

Touch “MENU”

Touch “PARAMETERS”

Touch: “111111”

Touch “<<”

Touch “MODIFY”

confirme with “OK”

1

2

RIPOSIZIONAMENTO

BLOCCO PORTA

RIPOSIZIONAMENTO

BLOCCO PORTA

E170701X.01_ENG 16/04/18

20

ATTENTION!

Before to supply again energy to the machine, all the protection must be placed again in the original

position.

28. HOW TO SWITCH ON THE MACHINE

Switch on the main switch, which supply the

machine.

In case of steam heated machines: open the

steam gate valve to allow the steam to enter.

To limit water hammering cases, the valve must

be open slowly passing from the close position to

open position in 1 minute time.

The emergency stop button must be in rest

position; control that the emergency stop was not

activated during the transport or before the

machine was switched off last time.

Before to start the machine always check the

safety system (refer to the related paragraph).

When the machine is switched on, the software

version, as well as its release date, appear on the

screen for a while.

The software loading could take a minute time,

more or less.

The display shows:

Load the machine and close the door following the

instruction given in the previous paragraphs.

29. HOW TO SELECT A PROGRAM

When the machine is loaded and the door is

closed, the touch screen shows:

Touch the icon “PROGRAMS” to display the

program list.

Table of contents

Other Imesa Industrial Equipment manuals