E.M.C. - Electromagnetic noise

The user is responsible for installing and using this saw according to the manufacturer’s guidelines outlined in this manual.

This equipment complies with the protection requirements established by the Directives 2006/42/CE, 2004/108/CE,

concerning Electromagnetic Compatibility (EMC). It is in compliance also with the technical guidelines of the Norms EN

55011, EN 50082-2 and it is intended for industrial and not for household use.

Before installing the machine the user must take into account possible electromagnetic problems of the working area. In

particular we suggest to install the equipment away from:

- signalling, control and telephone cables;

- radio-television transmitters and receivers;

The supply cable has to be as short as possible, with no twists. All doors, coverings and frame have to be closed when the

saw is running. Do not make any modifications to the machine except for adjustments and replacements

allowed/recommended by the manufacturer. Follow the maintenance schedule.

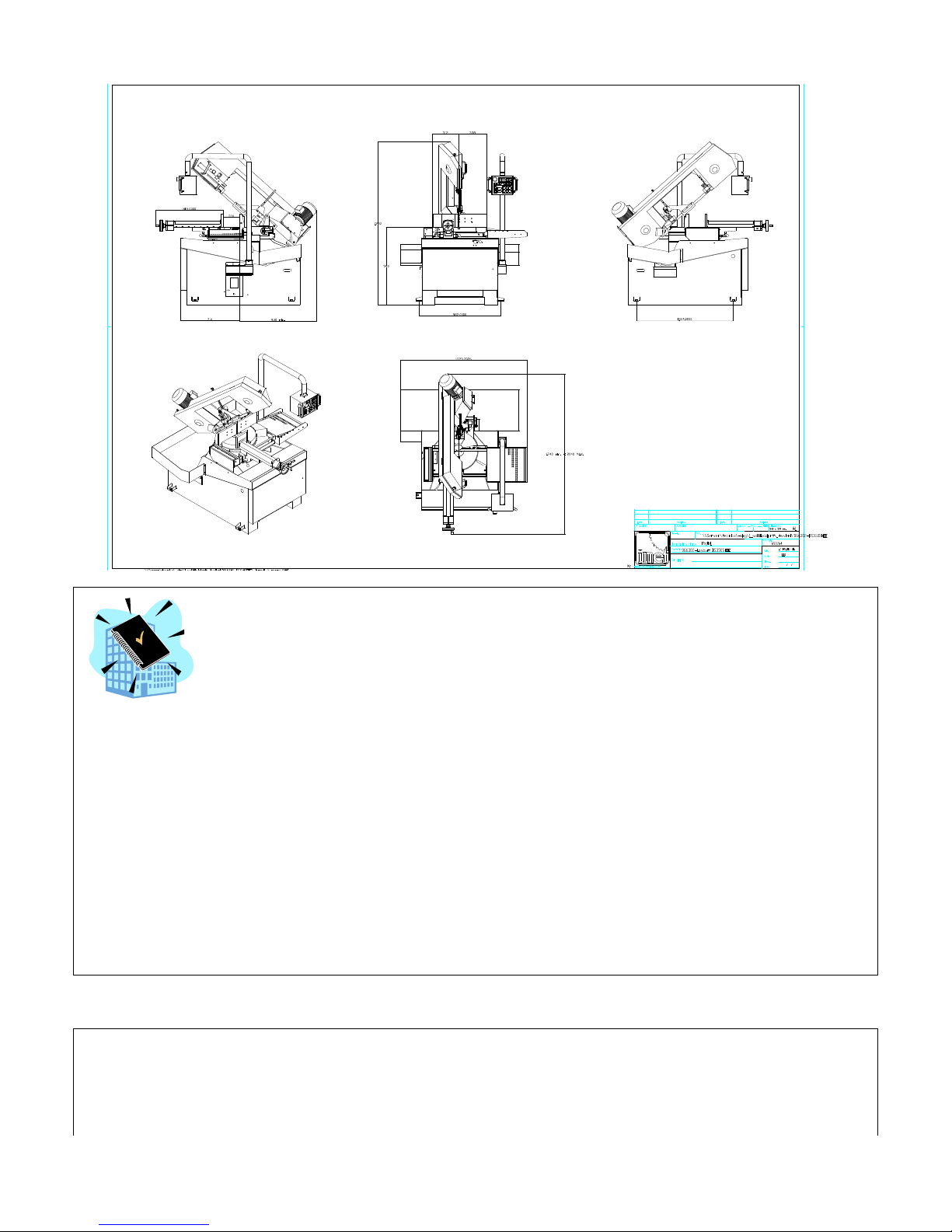

8 –TRANSPORT & LIFTING

To move and transport the saw the procedures described below have to be followed. In any case, make sure that the

lifting equipment and the means of transport have a suited loading capacity (about 700 kg).

WARNING

The use of gloves by the personnel in charge of handling the transport of this equipment is highly recommended.

WARNING

When lifting and moving around the saw, or a part of it, create a safety zone around it, in order to prevent potential risks to

persons and damages to objects located nearby.

Special packing can be supplied upon specific requests by customers.

ALL TRANSPORT AND HANDLING OPERATIONS HAVE TO BE CARRIED OUT WHILE OBSERVING THE

FOLLOWING GUIDELINES:

+ The lifting equipment has to be suited to the size and weight of the machinery to move, with an appropriate loading

capacity.

+ When using equipment such as ropes, chains or lifting belts, special attention has to be paid to their correct use and

positioning in order to not compromise safety and loading capacity.

+ In case lifting belts are in contact with parts of the machine, nylon belts or ropes/chains wrapped with iute or a clean

protection have to be used. When wrapping up and lifting the machine, special care is recommended to prevent

external damages.

+ Handling operations have always to be carried out slowly and carefully, so as to prevent dangerous situations to

persons and things.

+ The personnel in charge of handling operations must observe all local, national and company safety norms

concerning injury prevention and working place.

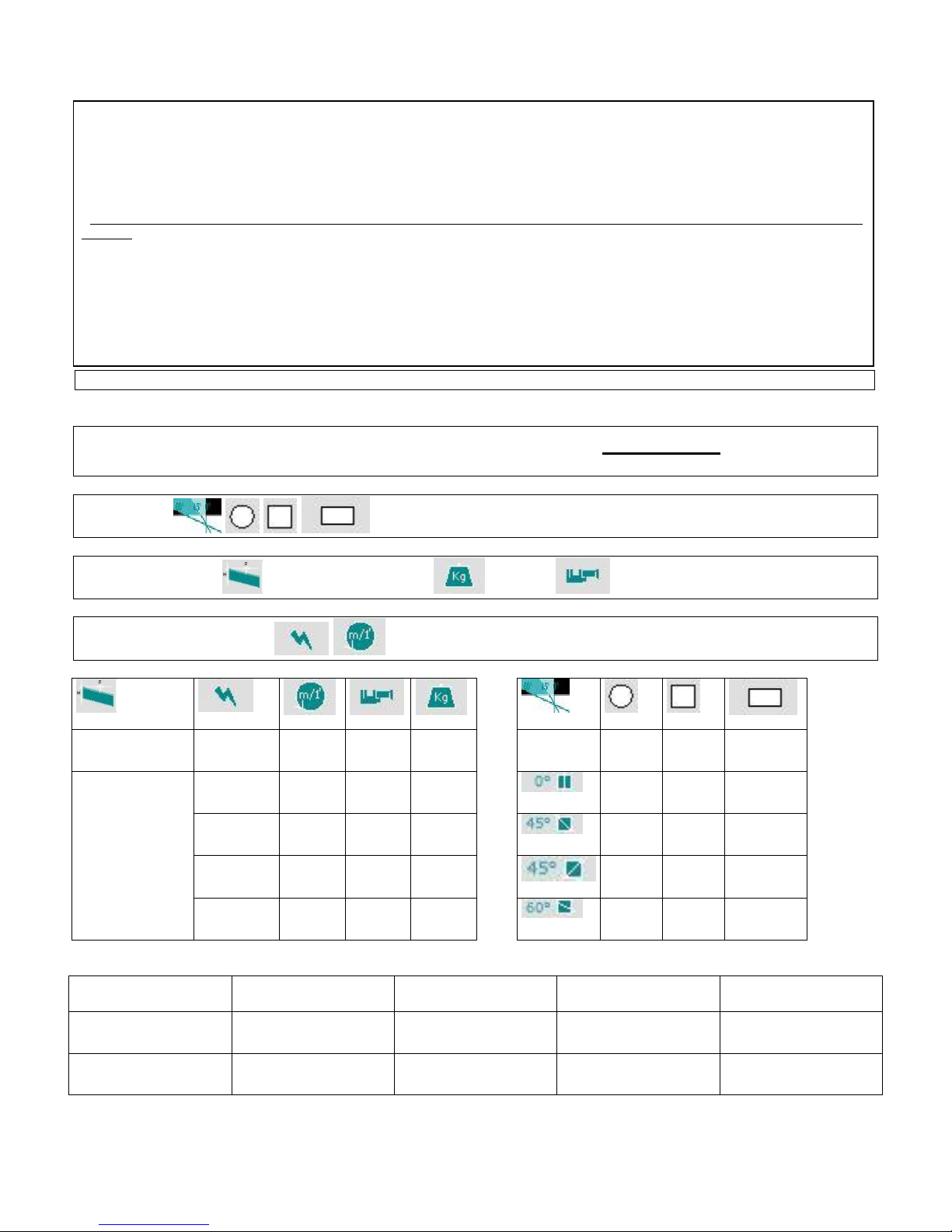

Transporting the machine with packing at sight

Normally the machine is shipped with a packing at sight, if the means of transport is not open. The machinery is fixed to a

wooden base then it is wrapped into thermo-plastic material to protect it. After loading it on a truck, it has to be fixed with

belts to hinder any motions. To move around the machine use a forklift with a fork length of more than 1 meter. It must be

lifted from the front side.

WARNING: cover the machine with a canvas if it’s loaded on an open truck.