7 - INSTALLATION

The machine can work according to the parameters provided by the manufacturer if it is rightly installed and the

minimum requirements are observed, as follows :

- Machine must be used indoor and with temperatures from +5 to + 40 ° C.

- The relative humidity of the environment must not go over 95%.

- The nominal value of the voltage of electric energy must be between + - 10 and the frequency of the nominal value

must be between + - 2%.

The floor has to be leveled and have good characteristiques of capacity.

The machine can be placed on any working table ( if the structure guarantees a good stability and safety during the use)

or can be mounted on a stand, purposely designed for the professional use.

In this last case the floor space , the distances and the sources of energy are indicated in the included drawing RI0047.

It is recommended to level the work table also in a roughly way. This avoids that the material to cut could move, or the

machine could loose the stability.If the use in a definite place is foreseen ( fixed installation ).By using the screws and

nuts (NOT SUPPLIED) we suggest put in the little feet holes to FIX the machine to the floor .

The included electrical schemes reproduces the necessary details to arrange the connections, to be

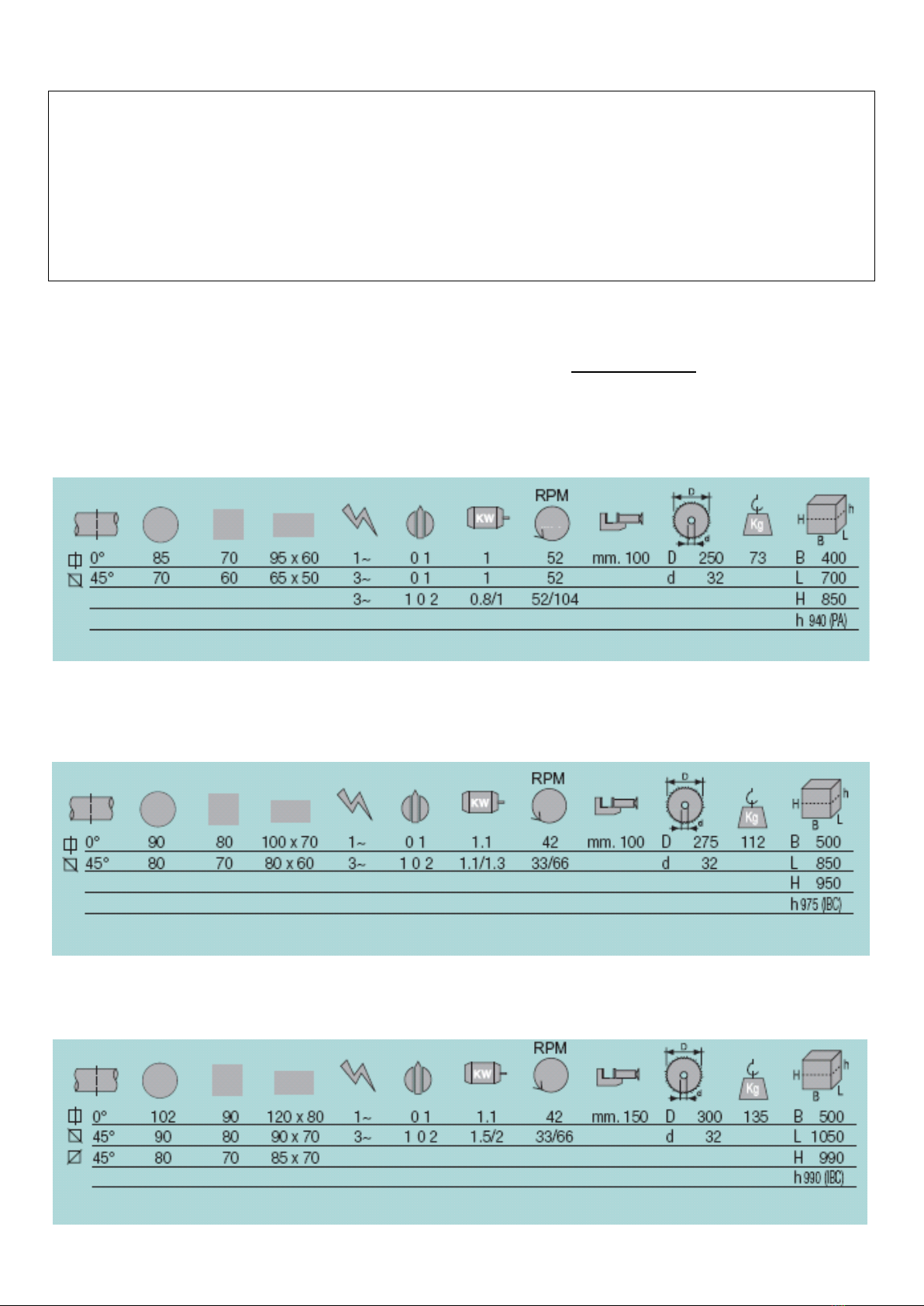

predisposed for 2 Kw power request, (Perfect 300 and 275) or 1,5 Kw for Perfect 250..

At the top of the supplying cables it is necessary to set up a sectionalizing device provided with a protection .

. Earthing of all the electric parts with a dedicated GREEN/YELLOW wire, connected with a TN system to the supply

cable. A supplementary earthing point –indicated with PE –can be located on the metallic structure of the machine

E.M.C. Electromagnetic noise

This machine has been foreseen for industrial and not for household use. In the event that should be electromagnetic

interferences the user is responsable for solving the problem together with the technical assistance of the manufacturer.

Before installing the machine the user must take into account possible electromagnetic problems of the working area. In

particular we suggest to install the plant away from:

- signalling, control and telephone cables;

- radiotelevision transmitters and receivers;

- computers or controlling and measuring instruments;

- safety and protection devices.

The electric supply cable must be kept as short as possible, well right and

without wires.

The covers, the door and the frame must be suitably closed when the plant is operating.

Under no circumstances the plant must be modified except for adjusting and

changing established by the manifacturer. Follow the maintenance schedule.

8 –TRANSPORT & LIFTING

For the transport of the machine only the methods indicated below are possible. However, be sure that the means of

transport snd lifting are able to stand the machine's weight and its packing (about 150 Kg):

WARNING

The personnel in charge of loading, unloading and moving the machines should use protective gloves.

WARNING

When lifting or moving the machine, or a part of it, take care of clearing the operations area of the people, considering

also an appropriate safety area around it, so as to avoid any risks of injuring people or damaging things located nearly.

Special packings –wooden crate , wooden case –may be predisposed on request, by charge.

ALL THE OPERATIONS THAT INVOLVE MOVING THE MACHINE MUST BE CONDUCTED WHILE RESPECTING

THE FOLLOWING BASIC RULES: