BPGS PNEUMATIC GRIPPER SYSTEM

User Manual

BIM-BPGSM-0519 Rev 1 | For Technical Assistance: 800-442-4622

10

Gripper Throat Depth

Inch (mm)

Flange Height

Inch (mm)

Working Pressure Double Sided Grip

Force Up To

Actuation Time

BPGS10C .76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

100 psi (689 kPa) Max.

450lbs (200kgf) @ 80

psi (551kPa)

.050±.010 sec close /

<.090 sec open

BPGS10D .76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

100 psi (689 kPa) Max.

450lbs (200kgf) @ 80

psi (551kPa)

.050±.010 sec close /

<.090 sec open

BPGS10E .76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

100 psi (689 kPa) Max.

450lbs (200kgf) @ 80

psi (551kPa))

.050±.010 sec close /

<.090 sec open

BPGS10F .92 23.4 1.21 (30.6mm) 60 psi (413kPa) Min. –

100 psi (689 kPa) Max.

450lbs (200kgf) @ 80

psi (551kPa)

.050±.010 sec close /

<.090 sec open

BPGS10R .75 19 1.03 (26.3mm) 60 psi (413kPa) Min. –

100 psi (689 kPa) Max.

450lbs (200kgf) @ 80

psi (551kPa)

.050±.010 sec close /

<.090 sec open

BPGS10S .76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

100 psi (689 kPa) Max.

450lbs (200kgf) @ 80

psi (551kPa)

050±.010 sec close /

<.090 sec open

BPGS10T .76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

100 psi (689 kPa) Max.

450lbs (200kgf) @ 80

psi (551kPa)

.050±.010 sec close /

<.090 sec open

BPGS10U .76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

100 psi (689 kPa) Max.

450lbs (200kgf) @ 80

psi (551kPa)

.050±.010 sec close /

<.090 sec open

BPGS10V .76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

100 psi (689 kPa) Max.

450lbs (200kgf) @ 80

psi (551kPa)

.050±.010 sec close /

<.090 sec open

BPGS10W .76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

100 psi (689 kPa) Max.

450lbs (200kgf) @ 80

psi (551kPa)

.050±.010 sec close /

<.090 sec open

BPGS10Y .76 19.3 1.27 (32.3) 60 psi (413kPa) Min. –

100 psi (689 kPa) Max.

450lbs (200kgf) @ 80

psi (551kPa)

.050±.010 sec close /

<.090 sec open

CLEANING AND MAINTENANCE

1) Remove excess grease from outer surfaces of gripper.

2) No required maintenance.

QUALITY ASSURANCE REQUIREMENTS

1) Verify that jaws shall open freely. Look for any irregular movement, binding, or interference.

SPECIFICATIONS

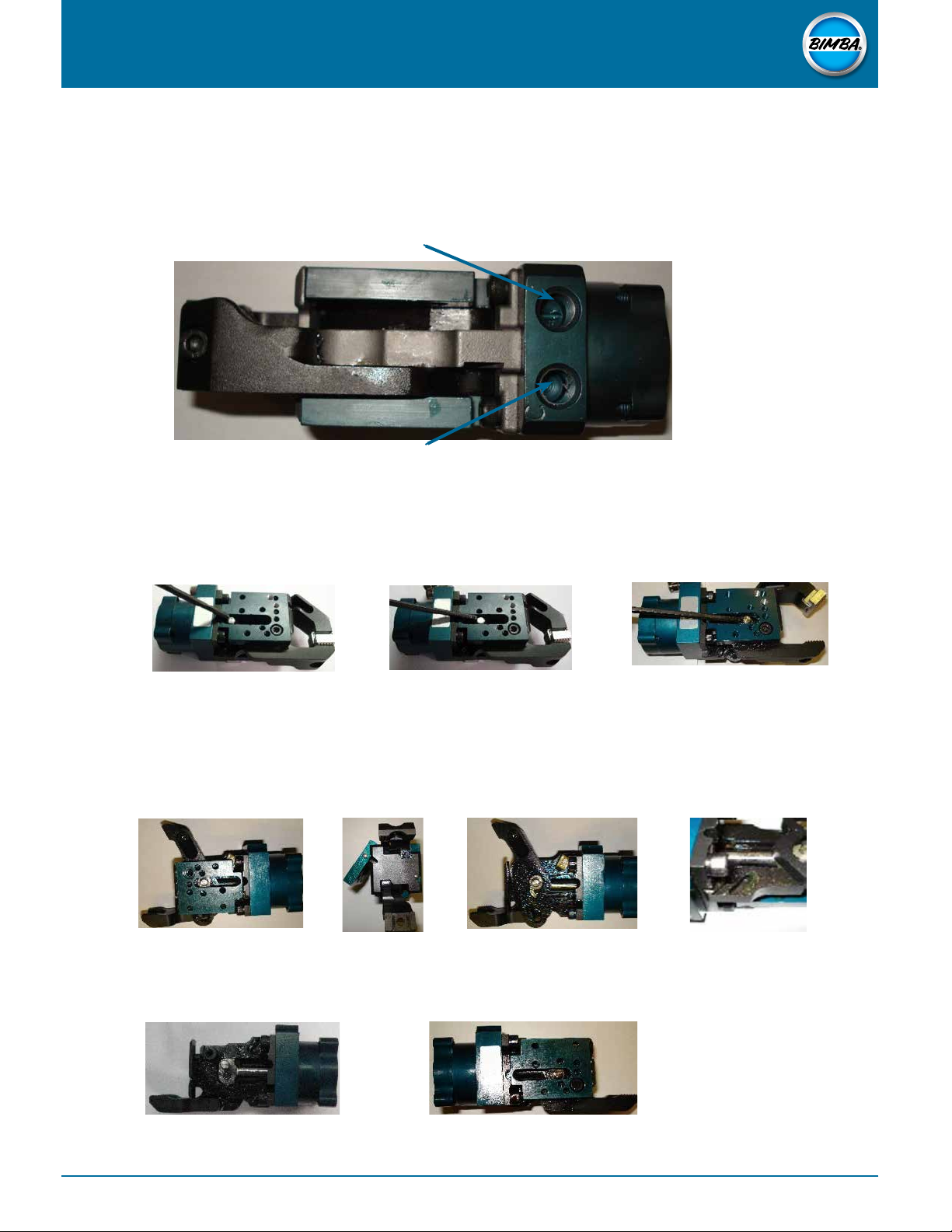

3. Apply Red Loctite 262 or equivalent to sensor stud, place thru jaw and tighten sensor nut to 72in-lb.

Cable should follow

the contour of the

gripper jaw

Cable storage loop

can be adjusted with

a push/pull motion to

provide more or less

cable slack in gripper

jaw area