BPGS10H PNEUMATIC GRIPPER SYSTEM

User Manual

BIM-BPGS10H-0719 Rev 1 | For Technical Assistance: 800-442-4622

10

CALIBRATING INDIRECT SENSOR

Sensor must be calibrated whenever any part of the gripper is replaced including pads.

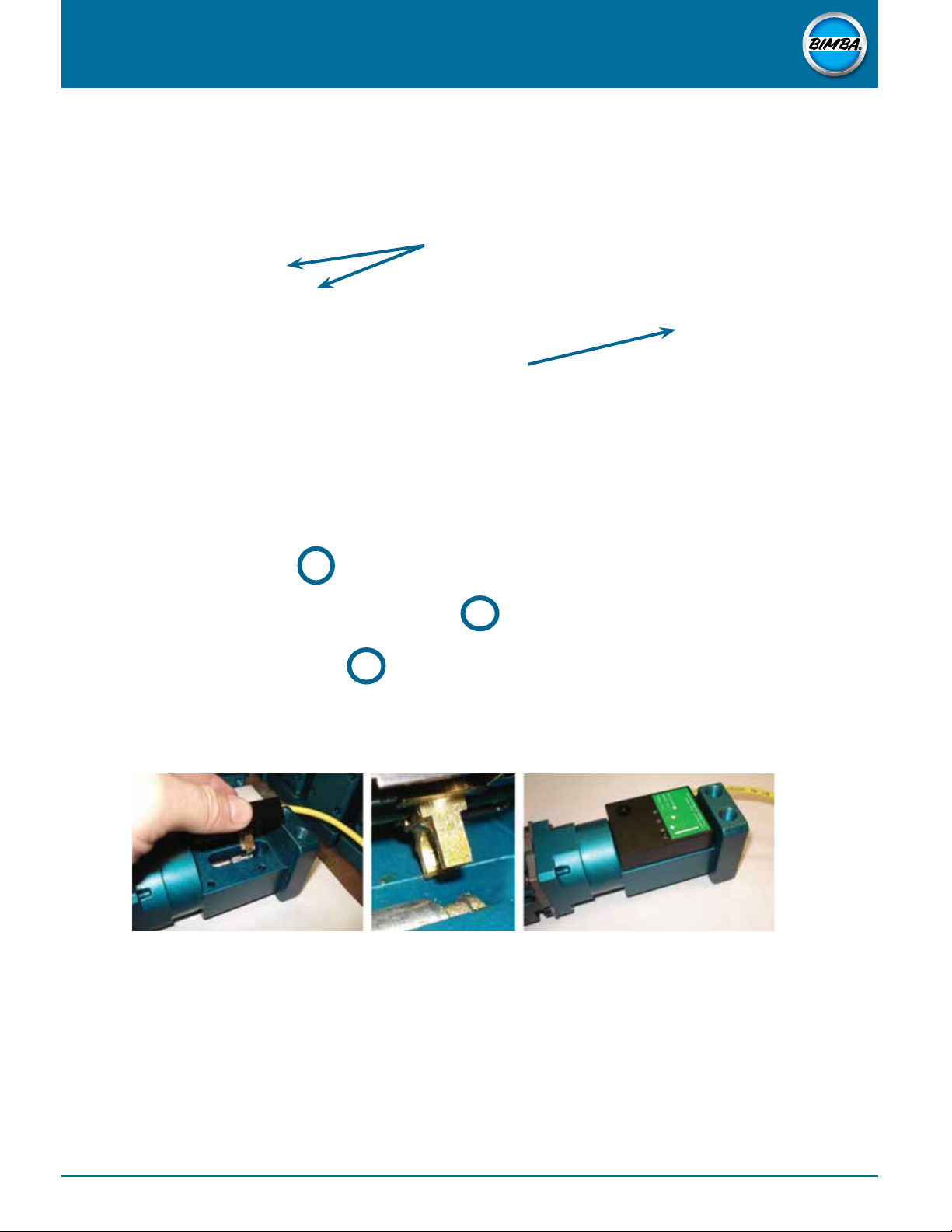

1. Part Present

a) To program the sensor for a particular material thickness, apply air to the gripper and grip on the material

thickness which is to be used for the particular job. With an object such as a small Allen wrench, press the

button until the Red LED corresponding to the material range of the job lights as shown on the label.

b.) Verify calibration:

(1) Close the gripper with no material between the pads. The LED should be o.

(2) Close the gripper on a single blank of material. The Red LED corresponding to your material range

should be on.

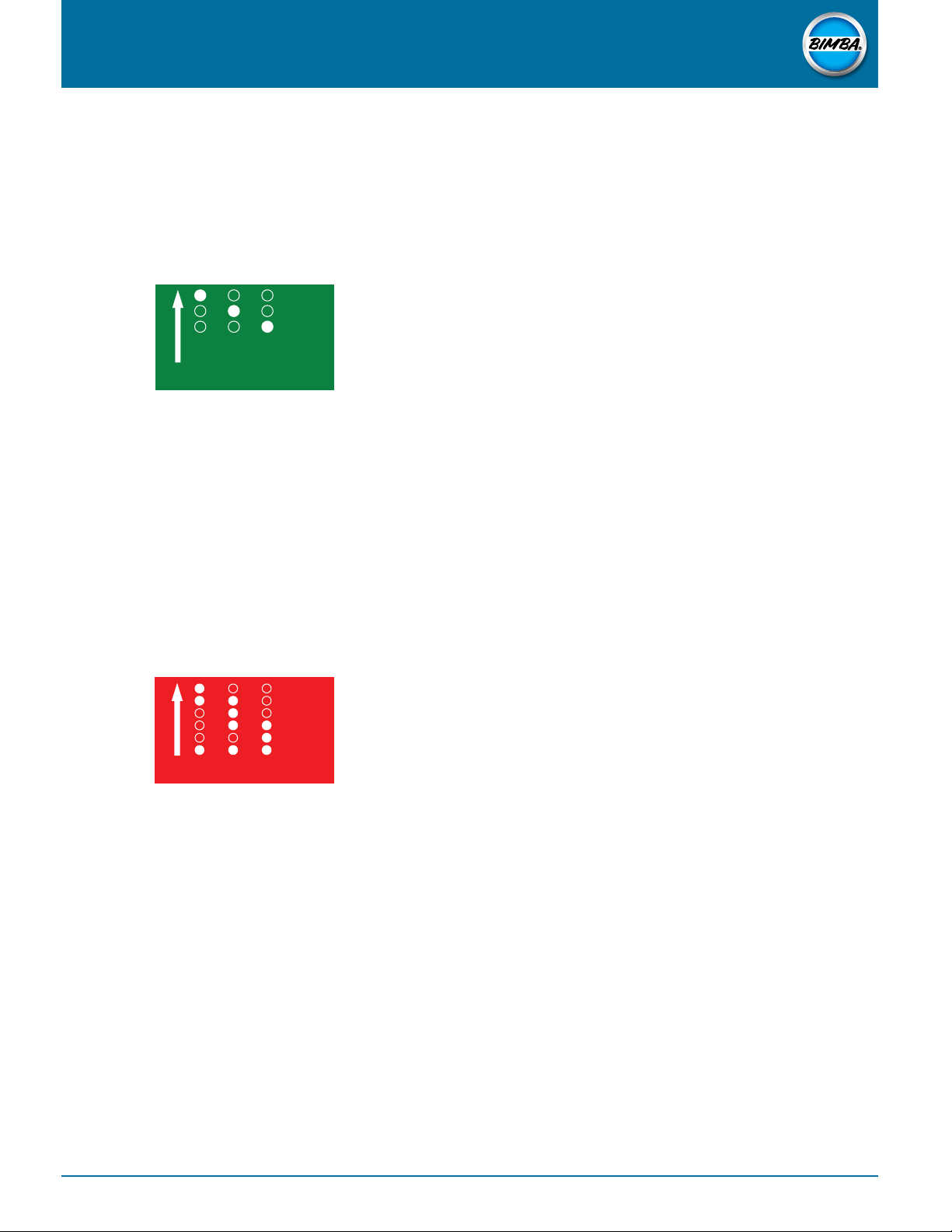

2. Double Blank

a) To program the sensor for a particular material thickness, apply air to the gripper and grip on the material

thickness which is to be used for the particular job. With an object such as a small Allen wrench, press the

button until the Red LED(s) corresponding to the material range of the job lights as shown on the label.

b.) Verify calibration:

(1) Close the gripper with no material between the pads. The LED(s) should be o.

(2) Close the gripper on a single blank of material. The Red LED(s) corresponding to the material range

should be on.

Part Present– Grip 1 Sheet

Press Button for Material range

Double Blank – Grip 1 Sheet

Press Button for Material range

Part Present– Grip 1 Sheet

Press Button for Material range

Double Blank – Grip 1 Sheet

Press Button for Material range