Imlab IKA VC 10 User manual

29

Source language: German

EN

Page

Device setup 2

Declaration of conformity 29

Explication of warning symbols 29

Warranty 29

Safety instructions 30

Unpacking 31

Correct use 31

Useful information 31

Setting up 33

Commissioning 36

Interfaces and outputs 46

Maintenance and cleaning 47

Error codes 48

Accessories 49

Product contact parts 49

Technical data 50

Contents

We declare under our sole responsibility that this product corresponds to the regulations

2014/35/EG, 2014/30/EG and 2011/65/

EG

and conforms with the standards or standardized documents

EN 61010-1, EN 60529, EN 61326-1 and EN ISO 12100.

Declaration of conformity

Explication of warning symbols

In accordance with IKA®warranty conditions, the warranty period

is 24 months. For claims under the warranty please contact your

local dealer. You may also send the machine direct to our factory,

enclosing the delivery invoice and giving reasons for the claim. You

will be liable for freight costs.

Warranty

The warranty does not cover worn out parts, nor does it apply

to faults resulting from improper use, insucient care or mainte-

nance not carried out in accordance with the instructions in this

operating manual.

DANGER

WARNING

CAUTION

Indicates an (extremely) hazardous situation, which, if not avoided, will result in death, serious injury.

Indicates a potentially hazardous situation, which, if not avoided, can result in death, serious injury.

Indicates a potentially hazardous situation, which, if not avoided, can result in injury.

Indicates practices which, if not avoided, can result in equipment damage.

NOTICE

30

Safety instructions

• The IKA®VC 10 vacuum controller may only be operated

under the conditions described in the “Technical data”

chapter.

• The pressure at the gas inlet and gas outlet must not exceed

1100 mbar. For pressure over 1100 mbar, the total allowab-

le pressure is exceeded and the device no longer displays the

pressure accurately.

• Only use flexible hose lines.

• Flexible elements can be compressed under vacuum.

• In the event of a power failure, the integrated venting valve

automatically aerates the connected recipient.

• Be aware of your emergency measures in the event of a

power failure and ensure that the system is put into a safe

state.

• The safety of the user cannot be guaranteed if the appliance

is operated with accessories that are not supplied or recom-

mended by the manufacturer or if the appliance is operated

improperly, contrary to the manufacturer’s specifications or

if if the instrument or the printed circuit board are modified

by third parties.

For protection of the equipment

CAUTION The voltage stated on the type pla-

te must correspond to the mains-

voltage.

• Covers or parts that can be removed from the device wit-

hout tools must later be refitted to ensure safe operation, so

long as no other connection is made at this point. This will

prevent the infiltration of foreign objects, liquids etc.

• The device must only be operated with the original plug-in

power supply unit supplied.

• The device must only be operated with the original plug-in

power supply unit included in the delivery scope.

• Protect the appliance and accessories from bumps and

impacts.

• The appliance may only be opened by experts (authorized

staff).

• To ensure sufficient cooling of the IKA®VC 10 vacuum

controller, the ventilation slots on the housing must not be

covered.

• Use only original spare parts for repair and maintenance

in order to ensure the reliable operating condition of the

device.

• Pay attention to water condensation inside and outside of

the device. If the device is brought from a cold environment,

allow the device to warm up.

• Never attach the vacuum controller above a heating bath.

• Ensure that no solids and/or liquids enter the IKA®VC 10

vacuum controller via the suction power of the pump. This

will result in damage to the pressure sensor and the valves.

WARNING Check the compatibility of the sub-

stances used with the device with

the materials listed under “Product

contact parts”; see chapter “Pro-

duct contact parts”.

• Place the IKA®VC 10 vacuum controller in an elevated posi-

tion if possible, so that in the event of a fault, no condensa-

te can collect on the pressure sensor.

For your protection

NOTICE

Read the operating instructions in

full before starting up and follow the

safety instructions.

• Keep the operating instructions in a place where it can be

accessed by everyone

• Ensure that only trained staff work with the instrument.

• Follow the safety instructions, guidelines, occupational

health and safety and accident prevention regulations.

DANGER Always wear personal protective

equipment in accordance with the

hazard class of the media being

worked with, otherwise there is a

risk of splashing liquids, release of

toxic or inflammable gases!

• The device and device parts must not be used on humans or

animals.

• Do not expose parts of the human body or animals to the

vacuum.

• Position the device as specified in the “Commissioning”

section and connect the connection cables and interfaces as

described.

• Never work with an incorrectly connected or defective

device.

• Inhalation of or contact with media such as poisonous

liquids, gases, spray mist, vapours, dusts or biological and

microbiological materials can be hazardous to user. Make

sure that all connections are tight and leak-free when wor-

king with such media.

• Prevent the release of the above mentioned substances. The

use of suitable extraction systems e.g. fume cupboards is

recommended in the place of installation. Take protective

measures for personnel and the environment.

• Due to the residual leakage rate of the device, this can result

in the release of medium.

• The IKA®VC 10 vacuum controller is not designed to be

installed in potentially explosive atmospheres

• The IKA®VC 10 vacuum controller is not designed for use

with self inflammable substances, substances which are

inflammable without air or explosive substances.

• Take suitable precautions to prevent any formation of

explosive mixtures. Use inert gas for venting and/or dilution,

if necessary.

• Take into consideration interactions or possible chemical or

physical reactions when working with media under reduced

pressure and elevated temperature.

• Never work with the device under water or underground.

• The device must only be operated with supervision.

• Electrostatic events can occur between the medium and

device and lead to a direct hazard.

• Safe operation is only guaranteed with the accessories

described in the ”Accessories” section.

• The instrument can only be disconnected from the mains

supply by pulling out the mains plug or the connector plug.

• The socket for the mains cord must be easily accessible.

• Do not use the device if the AC adapter is defective.

• Follow the operating instructions of the additional equip-

ment carefully (e.g. a rotary evaporator, vacuum pump) with

which the IKA®VC 10 vacuum controller is operated.

31

Use

Together with the accessories recommended by IKA®, the IKA®

VC 10 vacuum controller is suitable for the controlled evacuation

of air (gas) from laboratory devices and equipment (e.g. rotary

evaporator or laboratory reactors, and also for classical separation

or filtration or drying tasks in the laboratory) in conjunction with a

suitable vacuum source (e.g. IKA®MVP 10 basic/digital membra-

ne vacuum pump).

Correct use

Range of use (indoor use only)

- Laboratories - Schools

- Pharmacies - Universities

This instrument is suitable for use in all areas except:

• residential areas,

• areas that are connected directly to a low-voltage supply

network that also supplies residential areas,

• areas exposed to explosion hazards.

Unpacking

Useful information

In addition to a high-resolution Al2O3pressure sensor, the IKA®

VC 10 vacuum controller has an integrated vacuum valve and a

venting valve. As a result, the IKA®VC 10 vacuum controller can

be used without any additional peripheral devices.

The device provides two basic modes of operation:

Two-position control and analogue speed control.

The change between the two modes is performed automatically

by plugging or unplugging the connector cable at the “MVP 10 di-

gital” interface. Depending on the selection made, some submenu

items may not be available (greyed out on the display).

Unpacking

• Please unpack the device carefully.

• In the case of any damage a detailed report must be sent

immediately (post, rail or forwarder)

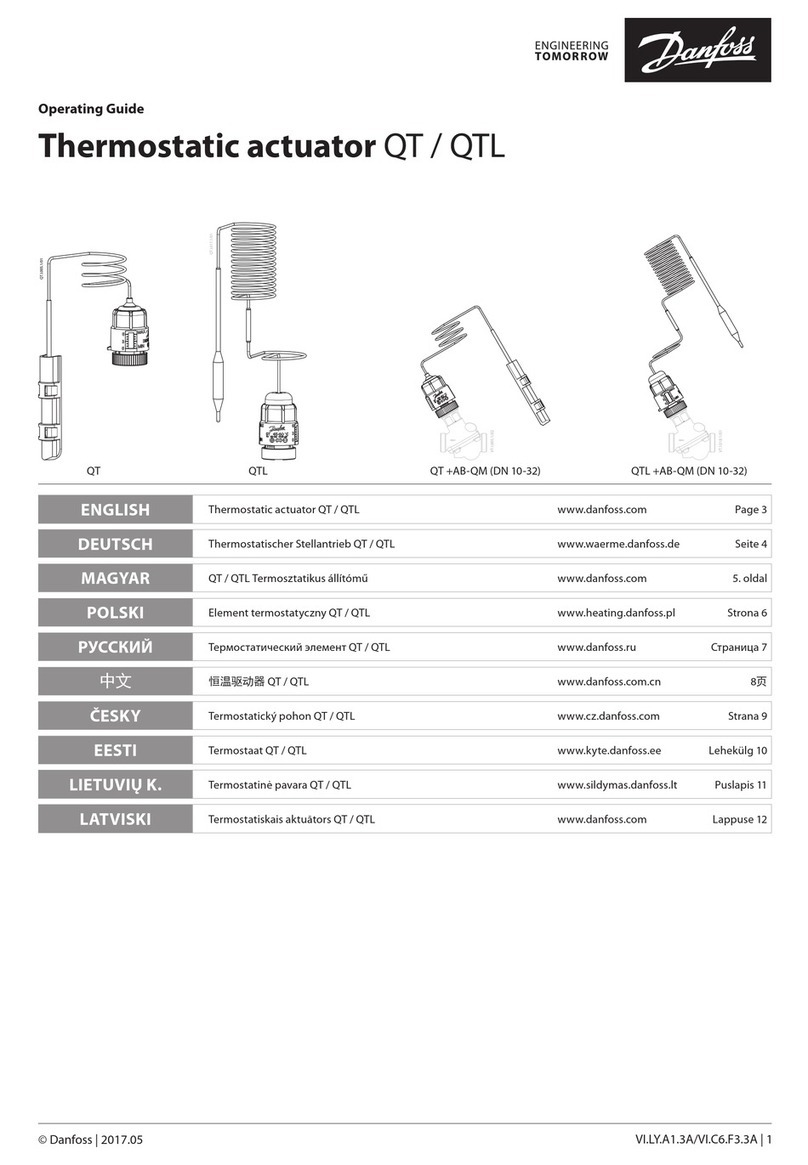

Delivery scope

Vacuum controller IKA®VC 10

Universal plug-in power

supply unit

USB A - micro B cable

A

Fig. 3

Fig. 2

Vacuum hose 1 m

Fig. 4

Y connector

Operating instructions

Warranty card

Fig. 5

The IKA®MVP 10 digital membrane vacuum pump can be opera-

ted automatically with the IKA®VC vacuum controller.

Therefore, it can be used for automatic boiling point recognition,

programmed pressure-time curves or programs from the solvent

library, for example.

Mode of operation: Stand device

WARNING The device must not be used for:

- vacuation of biological biotopes,

- evacuation of explosive, corro-

sive or gas volumes,

- throughput/use of fluids!

With two-position control, parameters from the solvent library can

be applied or target values specified in manual mode.

With analogue speed control, an automatic mode as well as the

setting of the percentage pump speed can also be preset.

Space requirement: To connect all peripheral devices you will need

approximately WxDxH 150 x 200 x 155 mm³ space for the device

with connected plugs.

32

Two-position control

A vacuum is made in the glassware with the help of a vacuum

pump. The vacuum pump operates at constant speed which gene-

rally cannot be adjusted. Once the target value setting is reached,

the integrated vacuum valve interrupts the suction line. If additi-

onal switching on and off of the vacuum pump is desired, please

use the VC 2.4 pump control (accessory).

The device will fall slightly short of the target value setting due to

the time difference in the millisecond range with the vacuum va-

lue, the target value comparison and the switching of the vacuum

valve. Natural leakage from the apparatus now causes another

increase in the pressure value of the system, which in turn is de-

tected by the integrated pressure sensor.

If the target value is exceeded, the vacuum valve is reopened and

the vacuum pump in operation lowers the pressure. The pressure

curve shown on the display fluctuates around the set target value.

The pressure difference between activating/deactivating the valve

can be set using the vacuum hysteresis value.

The quality of the control depends on the suction power of the

Analogue speed control

Imprecision of the two-position control is avoided by using the

analogue speed control.

With this kind of control, the speed of the pump, and therefo-

re its suction power, is reduced the closer the measured pressure

reaches the target value. Once the target value is reached, the

pump only operates according to the leakage rate of the system.

This type of control offers quieter operation, more exact vacuum

control and a long service life of movable pump parts.

Automatic boiling point recognition is possible with this type of

control, i.e. the system reaches and keeps the solvent at its boiling

point in automatic mode.

Analogue speed control with the IKA®MVP 10 digital membrane

vacuum pump:

The MVP 10 digital membrane vacuum pump is automatically

detected as soon as the connection cable is plugged into both

devices. The analogue speed control is enabled, the two-position

control is disabled and cannot be selected.

Menu items such as automatic boiling point recognition, program-

med pressure-time curves or programs from the solvent library can

be used.

Refer to the operating instructions for the MVP 10 digital vacuum

pump.

Schematic view of speed-vacuum control

t

mbar

pump (rotation speed), the tightness of the system and signal de-

lay time of the electronics used.

Automatic boiling point recognition is not possible when using

two-position control.

Schematic view of a two-position vacuum control

t

mbar

An external temperature sensor can be connected to the "PT1000"

temperature sensor interface. When the menu view is enabled,

the temperature value is shown in the display.

Time sequences can be controlled using a timer.

The operating modes A, B, C and D have preset access options for

adjusting and saving target values.

Display settings can be changed using the “Display” menu item.

Access to the device can be restricted by setting up a password in

the “Security” menu item.

Common settings such as language, pressure and temperature

units can be set via the “Settings” menu item. The display back-

ground can also be changed from black to white as well as bright-

ness settings adjusted.

The integrated solvent library calculates the theoretical boiling

point at a specified steam temperature value, or vice versa.

The upper and lower limits or the switching points of the vacuum

control can be set in the submenu items “Limit values" and “Hys-

teresis”.

33

Setting up

NOTICE Observe the general information,

always connect the recipients

(load/vacuum vessel/glass cooler)

at their highest points to the suc-

tion line. This will prevent the risk

of fluid entering into the vacuum

controller or pump.

Install a separator (e.g. Woulff bottle) infront of the intake moun-

ting to protect against the ingress of liquid.

In the case of induced solvent vapours, a vapour condenser (acces-

sory of pump) installed downstream of the pump helps to conden-

se the vapours and prevents release into the atmosphere.

Liquid in the pump chambers deteriorates the pump characteris-

tics.

Attach the IKA®VC 10 vacuum controller to a stand (d=16 mm)

close to the pump.

Secure the controller with the stand locking screw (N).

To do so, use a stand with diameter 16 mm, for example, IKA®

stand VC 10.400, IKA®VSS 1 vacuum safety set, the stand on

IKA®MVP 10 digital vacuum pump or attach the controller to

the IKA®RV 8 rotary evaporator, or at IKA®LR 1000 laboratory

reactor.

d=16 mm

Stand locking screw (N)

Fig. 5

VC 10 to VSS 1 with MVP 10 basic VC 10 to MVP 10 digital VC 10 to RV 8VC 10 at stand

VC 10.400

Fig. 7 Fig. 8 Fig. 9

Fig. 6

34

Connecting the interfaces

Connect the vacuum hoses, pay attention to the following con-

nections (also see Fig. 1):

J: Load

Hose connection d=10 mm to the system to be evacuated (reci-

pient).

K: Pump

Hose connection d=10 mm to the vacuum source (e.g. pump).

I: Vent

Ventilation connection d=10 mm, also suitable for the connection

of inert gas.

Secure the hoses with hose clamps, if necessary.

Lay the vacuum hoses according to your device configuration.

Now connect the connecting cables according to your system

configuration:

L: Mini USB Interface

Connect the VC 10 vacuum controller to a PC using the USB 2.0

cable (A/Micro-B).

Software updates to any existing equipment can be installed using

the IKA®FUT software tool.

M: RS 232 Interface

You can connect the IKA®VC 10 vacuum controller to a PC using

an RS 232 interface cable. The pump can be operated in conjunc-

tion with other devices using IKA®labworldsoft®laboratory soft-

ware. For more information see Chapter “Interfaces and outputs”.

O: VC 2.4 pump control

Connect the control cable of optional VC 2.4 pump control.

Connect the power plug of the vacuum pump to the power outlet

of the VC 2.4 pump control.

The pump is switched on/off in two-point control mode. In con-

junction with the

IKA®MVP 10 digital membrane vacuum pump, please note that

you must operate the pump in operating mode “B”.

Two-position control

Vacuum pump/vacuum source with IKA®VC 10 vacuum control-

ler.

Once the target value is reached, the suction line is closed by the

vacuum valve integrated in the IKA®VC 10 vacuum controller.

The pump speed can be changed by manually adjusting the speed

setting.

For pumps which have the speed setting option, it is recommen-

ded to work at low speed.

When using the optional VC 2.4 pump control (Pos. 6), the pump

is switched off once the target value is reached.

NOTICE When using the IKA®MVP 10 digi-

tal membrane vacuum pump: The

pump must be operated in mode

“B” (restart after voltage drop).

P: PT 1000 temperature sensor

Connect the optional IKA®PT 1000.60, PT 1000.61 or 1000.70 PT

temperature sensor (accessory). The measured temperature (e.g.

tempering bath) is shown on the display.

The value displayed is for information purposes only and is not

processed logically.

Note that the value displayed is dependent on the positioning of

the sensor in the medium, its mixing, as well as the calibration

of the probe and can deviate from other measured temperature

values.

Incorrect or fluctuating measured values can be displayed by using

a heating bath, e.g. by laying the sensor on the heating bath floor,

instead of positioning in the medium.

Q: IKA®MVP 10 digital membrane vacuum pump (Mini DIN)

You can connect the vacuum controller and the IKA®MVP 10

digital membrane vacuum pump to the analogue IKA®

MVP 10.100 connection cable (accessory) for exact speed-cont-

rolled vacuum control. The vacuum controller detects the

pump and switches to speed-vacuum control mode. The two-po-

sition control is disabled. The pump speed is regulated depending

on the measured pressure.

R: Connector for 24 W AC adapter

Connect the universal AC adapter (included) to the socket on the

rear. Observe the country-specific variants of the AC adapter!

Explanation of abbreviations used in the following schema-

tic drawings and configurations:

1 Recipient (load, e.g. rotary evaporator, reactor)

2 Separator (Woulff bottle)

3 Venting valve

4 Pressure sensor

5 Vacuum valve/ball valve

6 VC 2.4 pump control

7 Vapour condenser

8 MVP 10.100 connection cable (analogue)

9 Vacuum source (pump, in-house vacuum)

10 VC 10.300 Check valve

This device configuration is also possible without the IKA®

VC 2.4 pump control.

Once the target value is reached the vacuum valve integrated in

the IKA®VC 10 switches. The pump then starts.

The vacuum source can also be a central in-house vacuum net-

work.

35

Vacuum source with two IKA®VC 10 vacuum controllers.

Once the target value is reached in a recipient, the suction line is

closed by the vacuum valve integrated in the IKA®VC 10 vacuum

controller.

A suciently stable vacuum source (in-house vacuum, pump) can

serve multiple consumers.

For pumps which have the speed setting option, it is recommen-

ded to work at low speed.

A second consumer can be controlled independent of the first

using a second vacuum controller.

Using the optional VC 2.4 pump control is not possible.

Illustration two-position control -vacuum pump/vacuum source with vacuum controller IKA®VC 10

Illustration two-position control - vacuum source with two vacuum controllers IKA®VC 10

36

Speed control

MVP 10 digital vacuum pump with

IKA®

VC 10 vacuum controller

Automatic adjustment of the “analog speed control” mode if the

analogue connection cable (Pos. 8) is connected to the pump with

the vacuum controller.

Once the target value is reached the pump speed is automati

cally reduced to a minimum “0 rpm”. Once the target value is

reached, the pump operates according to the leakage rate of the

vacuum system.

Automatic boiling point recognition is possible.

Commissioning

Check whether the voltage given on the type plate corresponds to

the available mains voltage.

The socket used must be earthed (fit-

ted with earth contact).

If these conditions have been met, the machine is ready for opera-

tion when the mains plug is plugged in.

An information prompt then appears to download the IKA®firm-

ware update tool.

Illustration speed control - vacuum pump IKA®MVP 10 digital with vacuum controller IKA®VC 10

If these conditions are not met, safe operation is not guaranteed

and the machine could be damaged.

Also pay attention to the ambient conditions listed in the “Tech-

nical data”.

Start screen layout at the time of delivery

NOTICE The start screen appears for a few

seconds when the device is swit-

ched using the “Standby ON/OFF”

switch (F) The device name and the

software/firmware versions are

also displayed.

37

The following working screen appears automatically in the display.

Display of two-position control, e.g. with IKA®MVP 10 basic.

Hysteresis display for two-position control

Explanation of symbols on the working screen

The symbols displayed change depending on the status and set-

tings of the vacuum controller:

Lock key

This symbol means that the function of the key and of the

rotating/pressing knob

for controlling the vacuum cont-

roller are disabled. The symbol no longer appears if the

functions are enabled once again by pressing the lock key

a second time (min. 1 sec.).

AOperating mode

This symbol indicates the operating mode currently selec-

ted (A, B, C,D).

USB

This symbol means the vacuum controller is communi-

cating via a USB cable. The symbol no longer appears

if no USB cable is being used for communicating with

the station

Temperature sensor

This symbol appears when the temperature display is ac-

tive in the display.

Display speed control: IKA®VP 10 digital to analogue connection

No hysteresis display for speed control

Timer This symbol appears when the timer display is active

in the display.

PC PC control

This symbol means that the vacuum controller is con-

nected to a computer and the device is being controlled

from the computer.

PR Programm-Steuerung

This symbol means that the vacuum controller is con-

nected to a computer and the device is being controlled

from the selected program.

Continuous mode

This symbol indicates that the vacuum controller is in

continuous mode.

Vent

This symbol indicates that venting is enabled.

Vacuum

This symbol indicates that the current pressure is less

than the existing atmospheric pressure.

Detection

This symbol is displayed during the automatic boiling

point search, the system pressure is reduced further.

Boiling

This symbol indicates that a boiling point has been found

automatically, the system pressure is kept constant.

38

Navigation menu )Press the "Menu" key (C).

)Select the menu by turning the rotating/pressing knob (D) to

the right or left to select the desired menu or sub-menu, which

can then be selected by pressing the rotating/pressing knob

(D).

)

Press or turn the

rotating/pressing knob

(D) again to select the

desired menu option and edit the values or settings, or activate/

deactivate a function.

)

Turn the

rotating/pressing knob

(D) to "OK" and press the "Back"

(B) or "Menu" key (C) to end the procedure and return to the pre-

vious menuor working screen.

NOTICE

The menu option activated is high-

lighted yellow in the display.

Menus which are grayed out are in-

active.

NOTICE If you press the “Menu“ key (C), the system skips directly back to the working

screen.

If you press the “Back“ key (B), the system skips back to the previous display.

Back

Menu

Back Back

Menu

Navigation menu: ÀPress the “Menu“ key (C) and turn the rotating/pressing knob (D)

¿Press the "Back" key (B) or the "Menu" (C)

Fig. 9

39

Menu structure

Menu

Pump

Temperature

Timer

Operating mode

Display

Programs

Safety

Service

Settings

MENU

Sub menu

Modes

Cleaning

Limits

Hysteresis

Solvent library

Actions after stop

Sensor temperature...........................

Display..............................................

Calibration........................................

Timer function

Display..............................................

A......................................................

B......................................................

C......................................................

D......................................................

Timer.................................................

Temperature......................................

Program 01.......................................

... ......................................

Program 10

Last measurement

Password..........................................

Valves

Pump................................................

Languages

Units

Display

Sound

Factory setting

Communication

Information

Option

Automatic............................................

Manual...............................................

Pump %..............................................

Program...............................................

Start after.. .........................................

Duration..............................................

Pump speed.........................................

Clean now...........................................

Manual................................................

Pump %..............................................

Automatic............................................

Manual................................................

Acetonitril............................................

N-Amylalkohol.....................................

n-Pentalon...........................................

Benzol.................................................

... ..............................................

Open venting valve.............................

Cleaning..............................................

...........................................................

...........................................................

...........................................................

Time....................................................

Beep after stop....................................

Activate...............................................

...........................................................

...........................................................

...........................................................

...........................................................

...........................................................

...........................................................

...........................................................

...........................................................

...........................................................

Select...................................................

Edit.....................................................

Delete..................................................

Save as................................................

Edit.....................................................

Delete..................................................

...........................................................

Venting valve.......................................

Vacuum valve......................................

...........................................................

English................................................

German...............................................

...........................................................

Pressure

Temperature

Background

Brightness............................................

Firmware update info..........................

Volume................................................

Key tone..............................................

Menu values........................................

Programs.............................................

Bluetooth...........................................

All.......................................................

Device name........................................

Bluetooth............................................

Firmware update info..........................

Display version.....................................

Logic version........................................

Operating mode .................................

Pressure max. ...................................

Pressure min. ....................................

Pump % max. ....................................

Pump % min. ....................................

Action

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

Minimum.................................................................

Maximum................................................................

Minimum ................................................................

Maximum ...............................................................

...............................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

Edit, insert, delete....................................................

................................................................................

................................................................................

Edit, insert, delete....................................................

................................................................................

................................................................................

Close, open..............................................................

Close, open..............................................................

................................................................................

................................................................................

................................................................................

................................................................................

mbar........................................................................

hPa .........................................................................

mmHg ....................................................................

Torr .........................................................................

°C ...........................................................................

°F ............................................................................

Black.......................................................................

White......................................................................

................................................................................

................................................................................

................................................................................

................................................................................

Reset to factory setting.............................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

................................................................................

Factory setting

Deactivated

Activated

Deactivated

Deactivated

05:00 [mm:ss]

06:00 [mm:ss]

20 %

Deactivated

1 mbar

1100 mbar

0 %

100 %

Activated

Deactivated

-

-

-

-

-

Activated

Deactivated

-

Deactivated

20.0 °C

00:00:01 [hh:mm:ss]

Activated

Deactivated

Deactivated

Deactivated

Activated

Deactivated

Deactivated

Deactivated

Deactivated

-

-

-

-

-

-

-

-

0 0 0

Open

Close

Deactivated

Activated

Deactivated

Deactivated

Activated

Deactivated

Deactivated

Deactivated

Activated

Deactivated

Activated

Deactivated

100 %

Activated

10 %

Deactivated

-

-

-

-

VC 10

Deactivated

-

-

-

B

1100 mbar

1 mbar

100 %

0 %

40

Menu details

Pump

Modes

Automatic:

In the “Modes” menu, the user can enable automatic boiling point

recognition by selecting the “Automatic” menu item. No other pa-

rameters must be set.

The boiling point is detected automatically. For rotary evaporators

with heating bath, it must be ensured that the tempering medium

and solvents have a constant temperature (e.g. 60 °C).

Manual:

In the “Manual” menu item, the target value can be specified (e.g.

in "mbar”). The system is evacuated until the target value.

Pump %

By selecting the “Pump %” menu item, the pump can be operated

continuously with a running performance of between

100 % and 1 %.

Program

Under the “Programs” menu, 10 user-defined pressure-time profi-

les can be created. The last measurement taken can also be view-

ed in this menu and saved as a program.

The target value and the running performance can only be entered

within the set limits (see menu item “Limits”).

Changing to the working screen and pressing the rotating/pres-

sing knob starts the process. Pressing the knob again stops the

process.

NOTICE If no speed-controlled pump with

analogue connection is connected

to the “MVP 10 digital” interface,

the system can only work in manu-

al mode and in “two-position con-

trol" mode. The menu items “Auto”

and “Pump %” are greyed out and

cannot be activated.

Cleaning

The cleaning of the pump ensures that solvent residues are re-

moved in the pump after the measurement. For this purpose, the

pump is operated at a low level while the system is vented. The

air flowing through the pump ensures that the solvent residues

are discharged from the pump. If the cleaning option is selected,

this starts once the measurement has finished (see “Actions after

stop”).

NOTICE The “Cleaning” menu item increa-

ses the service life of the pump,

since solvent residues do not re-

main inside the pump.

You can also clean the pump without using the corresponding

menu item. To do this, remove the hoses and operate the pump

at the end of a working cycle (test, test series, end of the day ...)

at idling speed.

Start after…:

Specifies after which minimum duration of a measurement the

cleaning should take place. The default time is 5 minutes. This

means that a measurement must be run for at least 5 minutes, so

that cleaning is performed at the end of the measurement.

Duration:

Specifies how long the cleaning process should be performed.

Pump speed:

Determines at what power (in %) the pump is operated during

cleaning. If the power is set too high this can lead to a pressure

drop in the system.

Clean now:

If you want to perform a cleaning, you can select it with this set-

ting.

41

Hysteresis

Limits

In this menu, limits for the target value can be set.

Solvent Library

With the “Hysteresis” option, the switching frequency and control

accuracy can be influenced when in a steady state. The hysteresis

value determines the upper and lower limits of the target value

and therefore the closing and opening of the pump and valve

(only for two-position control).

Automatic: Hysteresis is always 10 % of the actual pressure.

Manual: Manual value specification of hysteresis.

NOTICE Limits which are too narrow shor-

ten the service life of the devices.

In the “solvent library”, the most common solvents are assigned a

function to determine the steam temperature at the set pressure

and vice versa. This provides assistance when setting these para-

meters in manual mode, for example, evaporation processes with

a rotary evaporator.

Actions after stop

This menu allows the user to define actions that should be perfor-

med when a test has ended.

42

Temperature

Temperature sensor

In the ”Temperature” menu the user can specify that the tem-pera-

ture sensor is displayed on the display/working screen. A tick (9)

shows that the option is activated.

The precondition for this is that a temperature sensor is connec-

ted to the vacuum controller. If no temperature sensor is con-

nected, or an error is present or the temperature rises above

350 °C, three dashes are shown as the temperature value.

NOTICE Please comply with the tempera-

ture measurement range of the ex-

ternal temperature sensor speci-

fied in the “Technical data” section.

The temperature display can be in

either °C or °F (see the “Settings”

menu).

Calibration

In order to calibrate the external temperature sensor, it must first

be connected to the vacuum controller. The temperature sensor

is then immersed in a vessel with water, for example. The water

temperature is determined using a second, already calibrated tem-

perature measuring device. The measured temperature must then

be entered in the menu under “Temperature calibration”. Once

the entry has been confirmed with “OK”, the external temperature

sensor is calibrated.

Timer

Timer functions

In the ”Timer” menu the user can specify that the timer is dis-

played on the display/working screen. A tick (9) shows that the

option is activated. This setting allows the user to specify the actu-

al time for the evacuation procedure.

A default time can also be set for the timer. This setting allows the

user to start evacuation for a standard time. The device can emit a

signal (beep) after the set target time has elapsed.

NOTICE The user can stop the evacuation

procedure before expiry of the set

time. In this case the countdown

of the timer is interrupted.

43

Operating mode

D

Programs

In the “Display“ menu the user can specify what information will

be displayed on the main screen.

Operating mode A:

In this operating mode, the set target value is not saved when the

current run comes to an end or the device is switched off.

Operating mode B:

In this operating mode, the set target value is saved when the

current run comes to an end or the device is switched off, and the

value can be changed.

Operating mode C:

In this operating mode, the set target value is saved when the

current run comes to an end or the device is switched off, and the

value cannot be changed.

Operating mode D:

In this operating mode, the target value is applied if it does not

change after 3 seconds, or when the yellow background is dis-

played behind the target value. In operating modes A and B, the

target value is applied immediately when the target value is chan-

ged by turning the knob.

In operating mode C, the target value cannot be changed.

Display

Select:

To select a program, use the rotating/pressing knob and press “Se-

lect”. Only programs that have at least one program segment can

be selected.

When a program has been successfully selected, this is indica-

ted by a tick mark (9). The vacuum controller is then in program

mode. In the main screen, the program view can then be selected

by turning the knob to the right. Turning the knob to the left re-

turns the user to the main screen.

Start:

To start a selected program, the push knob must be pressed in the

main screen.

Edit:

Edit the selected program parameters. Start to edit the selected

program parameters by pressing on menu option "Edit" with rota-

ting/pressing knob. The user can edit, delete or insert one selected

program segment in the program.

Delete:

Deletes the selected program. If a selected program is deleted by

pressing on menu option "Delete" with rotating/pressing knob, all

the program parameters will be emptied. The tick (9) disappears.

44

Details for editing the program

Sample for editing the program

In this program, user can define up to 10 segments. The selected

segment is highlighted. Then, the user can edit, delete or

insert a segment in this program. The program is save automa-

tically.

Edit:

If the background of a selected value is yellow, the user can

change the setting of the pressure value or the time value.

Delete:

When a highlighted segment is deleted, the subsequent seg-

ments move upward, closing the gap created by the deleted

segment.

Edit pressure

Edit time

Example of saving the last measurement

When a program is being edited,

following screen appears.

45

Safety

Settings

Languages:

The “Languages“ option allows the user to select the desired lan-

guage by turning and pressing the rotating/pressing knob (D). A

tick (9) indicates the language that is set for the system.

Units:

The “Units” option allows the user to select the desired unit for

displaying the temperature and pressure by turning and pressing

the rotating/pressing knob. For the temperature, the choice is bet-

ween “°C” or “°F”. For the pressure, the choice is “mbar”, “hPa”,

“mmHg” or “Torr”. A tick (9) indicates the unit that is set for the

system.

Display:

The ”Display“ option allows the user to change the background

color and brightness of the working screen.

Sound:

The ”Sound” option allows the user to activate/deactivate the

key-press sound and to set the volume.

Factory settings:

Select the “Factory settings” option by turning and pressing the

rotating/pressing knob. The system requests confirmation to re-

create the factory settings. You can choose if you want to reset

only the “Menu values”, or only the “Programs”. Alternatively, you

can reset all by selecting “All”. Pressing the “OK” key resets the

system settings to the original standard values set at dispatch from

the factory (see “Menu structure” illustration).

Communication:

The “Device name” option allows the user to input a device name.

The device name appears on the opening screen when the device

is switched on.

This can be useful when using multiple devices with different set-

tings. This also facilitates the identification of each device when

communicating with a PC via USB, RS232 and Bluetooth, for ex-

ample.

Information:

The ”Information” option offers the user an overview of the most

important system settings of the vacuum controller IKA®VC 10.

Service

In the “Password“ menu, the user can protect the vacuum cont-

roller settings using a password.

(factory setting: 000)

In the “Service” menu, the valves and the pump can be operated

individually and also checked to ensure that they are operating

correctly. If no IKA®MVP 10 digital is connected, the menu item

“Pump” is greyed out and not active.

46

Interfaces and outputs

The device can be operated in “Remote” mode via an RS 232 or

USB interface using the laboratory software labworldsoft®.

The RS 232 interface at the back of the device is fitted with a

9-pole SUB-D port which can be connected to a PC. The pins are

assigned serial signals.

NOTICE Please comply with the system re-

quirements together with the ope-

rating instructions and help sec-

tion included with the software.

USB interface

The Universal Serial Bus (USB) is a serial bus for connecting the

device to the PC. Equipped with USB devices can be connected to

a PC during operation (hot plugging). Connected devices and their

properties are automatically recognized.

Use the USB interface in conjunction with labworldsoft®for opera-

tion in “Remote” mode and also to update the firmware.

Installation

First, download the latest driver for IKA®devices with USB in-

terface from http://www.ika.com/ika/lws/download/usb-driver.zip

and install the driver by running the setup file. Then connect the

IKA®device through the USB data cable to the PC.

Serial interface RS 232 (V 24)

Configuration:

• The functions of the interface connections between the de-

vice and the automation system are chosen from the signals

speci-fied in EIA standard RS 232 in accordance with DIN 66

020 Part 1.

• For the electrical characteristics of the interface and the allo-

cation of signal status, standard RS 232 applies in accordance

with DIN 66 259 Part 1.

• Transmission procedure: asynchronous character transmissi-

on in start-stop mode.

• Type of transmission: full duplex.

• Character format: character representation in accordance

with data format in DIN 66 022 for start-stop mode. 1 start

bit; 7 character bits; 1 parity bit (even); 1 stop bit.

• Transmission speed: 9600 bit/s

• Data flow control: none

• Access procedure: data transfer from the device to the com-

puter takes place only at the computer’s request

Command syntax and format

The following applies to the command set:

• Commands are generally sent from the computer (Master) to

the stirrer machine (Slave).

• The stirrer machine sends only at the computer’s request.

Even fault indications cannot be sent spontaneously from the

device to the computer (automation system).

• Commands are transmitted in capital letters.

• Commands and parameters including successive parameters

are separated by at least one space (Code: hex 0x20).

• Each individual command (incl. parameters and data) and

each response are terminated with Blank CR LF (Code: hex

0x20 hex 0x0d hex 0x20 hex 0x0A) and have a maximum

length of 50 characters.

• The decimal separator in a number is a dot (Code: hex 0x2E).

The above details correspond as far as possible to the recommen-

dations of the NAMUR working party (NAMUR recommendations

for the design of electrical plug connections for analogue and

digital signal transmission on individual items of laboratory control

equipment, rev. 1.1).

The NAMUR commands and the additional specific IKA®com-

mands serve only as low level commands for communication bet-

ween the stirrer machine and the PC. With a suitable terminal or

communications programme these commands can be transmitted

directly to the stirrer equipment.

The IKA®software package, labworldsoft®, provides a convenient

tool for controlling the equipment and collecting data under MS

Windows, and includes graphical entry features, for motor speed

ramps for example.

The following table summarises the (NAMUR) commands under

-stood by the IKA®control equipment.

NAMUR Commands Function

IN_NAME Read device name

IN_PV_3 Read PT 1000 value

IN_PV_66 Read current pressure value

IN_SP_66 Read pressure target value

IN_SP_70 Read hysteresis target value

IN_MODE_66 Read current evacuation mode

IN_ERROR Read error status

OUT_SP_66 Set pressure target value

OUT_SP_70 Set hysteresis value

OUT_MODE_66 Set evacuation mode

START_66 Start evacuation

STOP_66 Stop evacuation

RESET Switch to normal operating mode

47

PC 1.1 Cable (Device to PC)

Required for connecting the 9-pin socket to a PC.

1

2 RxD

3 TxD

4

5 GND

6

7 RTS

8 CTS

9

1

RxD 2

TxD 3

4

GND 5

6

RTS 7

CTS 8

9

PC

1

2

3

4

5

6

7

8

9

9

8

7

6

5

4

3

2

1

Connection cable MVP 10.100

This cable is required to connect the VC 10 to the IKA®MVP 10 digital membrane vacuum pump (speed mode).

Fig. 10

Fig. 12

Maintenance and cleaning

The instrument is maintenance-free. It is only subject to the natu-

ral wear and tear of components and their statistical failure rate.

For cleaning disconnect the main plug!

Use only cleaning agents which have been approved by IKA®to

clean IKA®instruments.

Dirt Cleaning agent

Dyes isopropyl alcohol

Construction materials water containing tenside, isopro-

pyl alcohol

Cosmetics water containing tenside,

isopropyl alcohol

Foodstuffs water containing tenside

Fuel water containing tenside

Not listed materials please request information from

IKA®application suppor

•Wear protective gloves during cleaning the instruments.

• Electrical instruments may not be placed in the cleansing

agent for the purpose of cleaning.

9-pin RS 232 9-pin RS 232

Mikro B

Connection VC 10 - PC

A

USB Mikro B USB A

or

USB A

Fig. 11

• Do not allow moisture to get into the instrument when

cleaning.

•Before using another than the recommended method for

cleaning or decontamination, the user must ascertain with

IKA®that this method does not destroy the instrument.

Spare parts order

When ordering spare parts, please give:

• machine type,

•manufacturing number, see type plate,

•item and designation of the spare part see www.ika.com,

spare parts diagram and spare parts list.

• software version

Repair

Please send in instrument for repair only after it has been

cleaned and is free from any materials which may consti-

tute a health hazard.

For this, you should request the “Decontamination Certifica-

te” from IKA®, or use the download printout of it from the IKA®

website www.ika.com.

If you require servicing, return the instrument in its original pa-

ckaging. Storage packaging is not sucient. Please also use suita-

ble transport packaging.

Table of contents

Popular Controllers manuals by other brands

Newport

Newport New Focus Picomotor 8743-CL user manual

Dynamatic

Dynamatic 4000 instruction sheet

Martin Audio

Martin Audio MICT3B - 7-1996 manual

Yaesu

Yaesu G-800DXA user manual

Arbor Technology

Arbor Technology ARES-1980 Series user manual

Franklin Fueling Systems

Franklin Fueling Systems STP-SCIIIC installation guide