6.2.1 Overview of Limiting Factors ....................................................................... 30

6.2.2 Calculating the Effective Mass..................................................................... 31

6.2.3 Calculating the Maximum Operating Frequency of the Loaded Piezo

Actuator....................................................................................................... 31

6.2.4 Calculating the Forces that Occur During Dynamic Operation.................... 32

6.2.5 Calculating the Power Requirement for Sinusoidal Operation ................... 32

6.3 Operating the P-2x5 ................................................................................................. 33

6.4 Discharging the P-2x5............................................................................................... 34

7Maintenance 35

7.1 General Notes on Maintenance ............................................................................... 35

7.2 Cleaning the P-2x5.................................................................................................... 35

8Troubleshooting 37

9Customer Service 39

10 Technical Data 41

10.1 Specifications............................................................................................................ 41

10.1.1 Data Table.................................................................................................... 41

10.1.2 Maximum Ratings........................................................................................ 43

10.1.3 Ambient Conditions and Classifications ...................................................... 44

10.2 Dimensions ............................................................................................................... 45

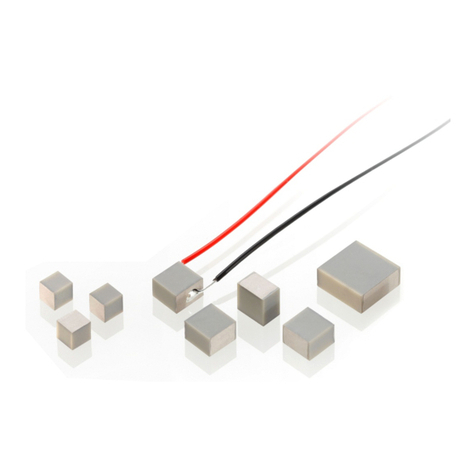

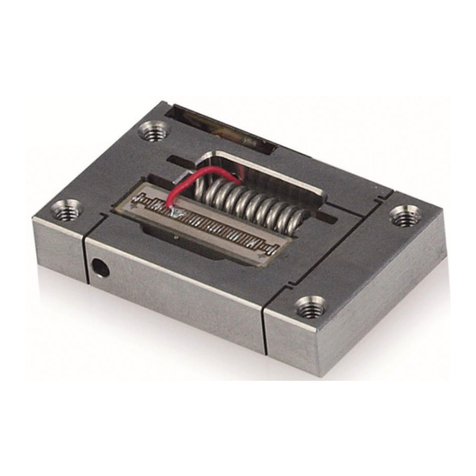

10.2.1 P-2x5 Piezo Actuator ................................................................................... 45

10.2.2 P-2x5 with P-177.50 Option (Temperature Sensor and Purge Air

Connector)................................................................................................... 46

10.2.3 P-2x5 with the P-706.00 Option (Water-Resistant Housing)....................... 46

10.2.4 Ball Tip P-176.B25........................................................................................ 46

10.2.5 Flat Tips P-176.F25 and P-176.F35 .............................................................. 47

10.2.6 Vacuum Feedthrough for High-Voltage Piezo Actuators ............................ 48

10.2.7 Vacuum Feedthroughs for Sensors ............................................................. 49

10.3 Pin Assignment ......................................................................................................... 50

10.3.1 Voltage Connection ..................................................................................... 50

10.3.2 Connection of the Position Sensor .............................................................. 50

10.3.3 Connection of the Temperature Sensor...................................................... 50

11 Old Equipment Disposal 51

12 European Declarations of Conformity 53