10

There are two other conditions for which the LED will be out besides the drive being set for zero

speed or running wide open above the regulating range. These are whenever the “E” relay is

deenergized (the drive is stopped), or due to a wiring error, ground or some malfunction of the

controller itself.

Max Speed/volts R21, Alternate Methods

a. To set maximum rated speed with a tach or stroboscope: turn the Run Speed potentiometer

R5 to 100% (full CW) Allow the drive to accelerate to full speed, turn the Max Speed/Volts pot

CW until the rated speed indicated is the same as the speed listed on the nameplate of the

mechanical unit.

b. To set approximate maximum speed with a voltmeter, connect a voltmeter (60 Vac scale

across terminals G1 and G2. Turn the Run Speed pot R5 to 100% (Full CW) Allow the drive to

accelerate to full speed. With the drive at full speed, turn the Max Speed/Volts pot CW until

the meter reading ceases to rise. Back off the adjustment (CCW) until the meter reading just

begins to drop. This is the point of maximum speed.

c. To set a maximum speed that is less than rated maximum speed requires the use of a

tachometer or stroboscope indicator. This cannot be accomplished with the LED status

monitor. Turn the Run Speed potentiometer to 100% (Full CW). Allow the drive to accelerate

to full speed, slowly increase Max Speed/Volts potentiometer setting CW until the desired

speed is indicated.

5. Since there may be some interaction between the Zero Adjust and the Max Speed/Volts,

particularly if the minimum speed is other than zero, repeat steps 3 and 4 until the desired speeds

are obtained for both the zero and max positions of the Run Speed pot.

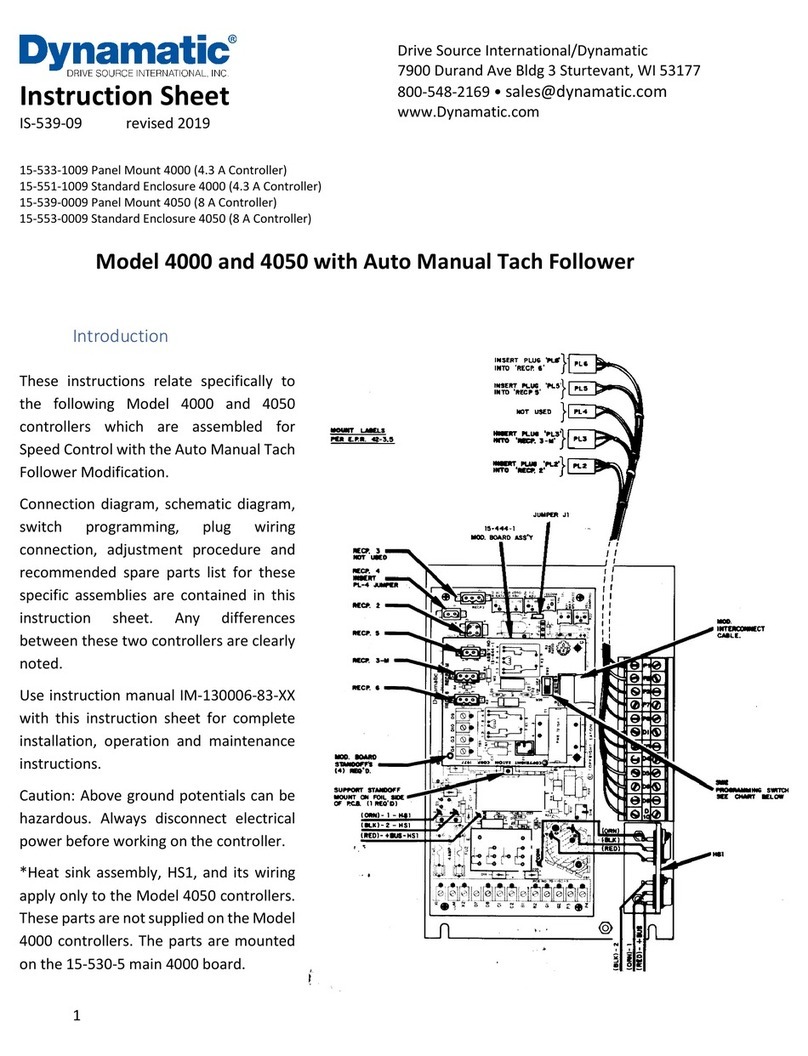

6. Time Constant (TC) Adjust R26- The TC adjust is used to set current feedback by using coil

voltage and a variable RC combination to simulate the different coil time constants of various size

drives. A trimpot illustration is provided to facilitate the setting of this control. Sufficient range

has been provided for drive size from fractional through 20 hp for the 4000 controller and up to

125 hp for the 4050 controller. Set you TC control appropriately for your individual drive size as

shown in Preliminary Adjustments.

Setting are not critical and so may be ‘tuned” for each drive. High inertia applications can benefit

from a higher than normal setting.

7. Current Feedback R20*-Normal operation will not require use f this potentiometer. Certain

applications are best met with a negative current feedback response which is slower in settling

and less likely to overshoot at low rpms. There are some low inertia, light load, linear acceleration

applications that may also benefit from improved low-end linearity with current feedback

damping. If you have one of these applications, remove jumper J1 from the Normal position and

place it in the increased position. Adjust Current Feedback R20 as required to obtain desired drive

response.

*See Basic 4000/4050 manual for a more detailed description of this adjustment.