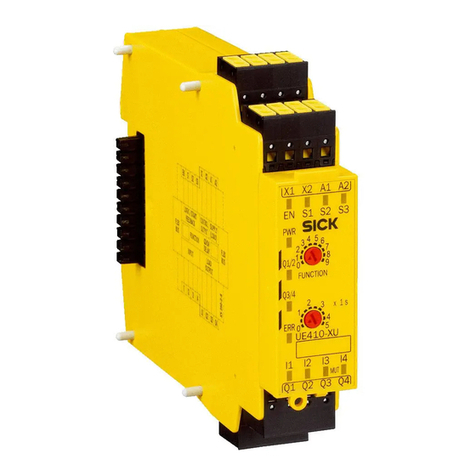

SICK UE 440 User manual

&

Safety Controller

UE 440/UE 470

OPERATING INSTRUCTIONS

Operating Instructions

UE 440/470

2© SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 010 432/P097/14-03-05

This document is protected by copyright. The SICK AG company retains this right. Reproducing this document in

whole or part is only permissible within the limits of the statutory regulations of copyright law. Modifying or

abridging this document is impermissible without express written permission from the SICK AG company.

Operating Instructions

UE 440/470

8 010 432/P097/14-03-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 3

Contents

Contents

1 About this document....................................................................................................................... 6

1.1 Function of this document ........................................................................................6

1.2 Target group...............................................................................................................6

1.3 Scope .........................................................................................................................6

1.4 Depth of information .................................................................................................7

1.5 Abbreviations .............................................................................................................7

1.6 Symbols used.............................................................................................................8

2 On safety............................................................................................................................................. 9

2.1 Specialist personnel..................................................................................................9

2.2 Applications of the device.........................................................................................9

2.3 Correct use.............................................................................................................. 10

2.4 General protective notes and protective measures ............................................. 10

2.5 Environmental protection....................................................................................... 11

2.5.1 Disposal ...................................................................................................... 11

2.5.2 Material separation.................................................................................... 11

3 Product description .......................................................................................................................12

3.1 Special features...................................................................................................... 12

3.2 Operating principle of the device........................................................................... 13

3.2.1 Principle of the device................................................................................ 13

3.2.2 Connectable devices.................................................................................. 14

3.3 Display elements .................................................................................................... 15

3.3.1 LEDs and 7-segment display ..................................................................... 15

4 Configurable functions .................................................................................................................17

4.1 Base settings with the configuration wizard ......................................................... 17

4.1.1 Configuration name ................................................................................... 17

4.1.2 Operating modes and operating mode selector switch ........................... 18

4.1.3 Automatic reconfiguration ......................................................................... 20

4.2 Protective operation ............................................................................................... 20

4.2.1 Electro-sensitive protective equipment..................................................... 22

4.2.2 OSSDs of the UE 440/470 ........................................................................ 23

4.2.3 Signal output (ADO).................................................................................... 23

4.2.4 Devices and sensors.................................................................................. 24

4.2.5 Two-hand control........................................................................................ 25

4.2.6 Emergency stop.......................................................................................... 25

4.2.7 External device monitoring (EDM) ............................................................. 27

4.2.8 Reset interlock ........................................................................................... 28

4.2.9 Bypass......................................................................................................... 30

4.2.10 Shutdown delay of output Out2................................................................. 32

4.2.11 Linking the input elements to logic modules............................................ 32

4.2.12 Release of the application with a release module................................... 33

4.2.13 Application name ....................................................................................... 33

4.3 PSDI mode with safety controller UE 470............................................................. 33

4.3.1 Principle of PSDI mode .............................................................................. 34

4.3.2 PSDI time monitoring ................................................................................. 35

4.3.3 Significance of the machine cycle contacts for PSDI mode operation ... 35

4.3.4 Start sequence (PSDI mode initiation)...................................................... 37

4.3.5 Releasing the PSDI control ........................................................................ 38

4.3.6 Overrun monitoring .................................................................................... 38

Operating Instructions

UE 440/470

4© SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 010 432/P097/14-03-05

Contents

4.3.7 Deactivation of the restart interlock during upward movement.............. 38

4.3.8 Eccentric presses........................................................................................39

4.3.9 PSDI signal lamp.........................................................................................39

4.4 Evaluation of device-specific EFI status bits..........................................................39

4.5 Teach-in for C 4000 ................................................................................................ 40

4.5.1 Teach-in key-operated switch for C 4000.................................................. 41

4.6 Settings for overlapping functions .........................................................................41

4.6.1 Complementary or equivalent input evaluation........................................41

4.6.2 Testing of the connected input devices and sensors ...............................42

4.6.3 Input delay................................................................................................... 42

4.6.4 Discrepancy time ........................................................................................ 43

5 Installation........................................................................................................................................44

6 Electrical installation ....................................................................................................................45

6.1 Connections of the UE 440/470............................................................................46

6.1.1 System connection .....................................................................................46

6.1.2 Configuration connection ...........................................................................48

6.2 Connection of contact-based safety sensors ........................................................49

6.2.1 Single channel input devices and sensors................................................ 49

6.2.2 Dual channel input devices and sensors ..................................................49

6.2.3 Two-hand control ........................................................................................50

6.2.4 Single channel emergency stop.................................................................50

6.2.5 Dual channel emergency stop ................................................................... 51

6.2.6 Key-operated switch for bypass ................................................................. 51

6.2.7 Reset button ............................................................................................... 51

6.2.8 Machine-cycle contacts .............................................................................. 52

6.2.9 Teach-in key-operated switch for C 4000.................................................. 53

6.2.10 Operating mode selector switch ................................................................53

6.2.11 External device monitoring (EDM)..............................................................54

6.3 Connection of active sensors .................................................................................55

6.3.1 Electro-sensitive protective equipment .....................................................55

6.4 Connection to the outputs......................................................................................56

6.4.1 "Reset required" signal lamp...................................................................... 56

6.4.2 Bypass signal lamp..................................................................................... 56

6.4.3 PSDI signal lamp.........................................................................................56

6.4.4 Signal output (ADO) .................................................................................... 56

6.4.5 Test outputs ................................................................................................57

7 Application and switching examples .......................................................................................58

7.1 Access protection....................................................................................................58

7.1.1 Access protection for two robot cells......................................................... 58

7.1.2 Access protection with point-of-operation protection ...............................60

7.2 Hazardous area protection..................................................................................... 62

7.2.1 Simultaneous hazardous area protection.................................................62

7.3 Hazardous point protection .................................................................................... 65

7.3.1 Hazardous point protection with PSDI mode ............................................65

7.3.2 Hazardous point protection with interior area protection ........................68

7.3.3 Hazardous point protection with hazardous area protection................... 70

Operating Instructions

UE 440/470

8 010 432/P097/14-03-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 5

Contents

8 Commissioning ...............................................................................................................................73

8.1 Sequence for commissioning ................................................................................ 73

8.1.1 System self-check after switching on........................................................ 74

8.1.2 Switch-on sequence ................................................................................... 75

8.2 Full approval of the application ............................................................................. 76

8.3 Test notes ............................................................................................................... 76

8.3.1 Tests before the first commissioning........................................................ 76

8.3.2 Regular inspection of the protective device by qualified personnel ....... 76

8.3.3 Daily functional checks of the protective device...................................... 76

9 Configuration ...................................................................................................................................77

9.1 Default delivery status............................................................................................ 78

9.2 Offline configuration............................................................................................... 78

9.3 Online configuration ............................................................................................... 78

9.4 Configuration memory............................................................................................ 79

10 Fault diagnosis................................................................................................................................80

10.1 In the event of faults or errors ............................................................................... 80

10.2 SICK support........................................................................................................... 80

10.3 LED displays............................................................................................................ 81

10.4 Displays of the 7-segment display......................................................................... 81

10.5 Extended diagnostics ............................................................................................. 85

11 Technical data.................................................................................................................................86

11.1 Response times of OSSDs A and B ....................................................................... 86

11.1.1 Examples .................................................................................................... 88

11.2 Data sheet............................................................................................................... 90

11.3 Dimensional drawing.............................................................................................. 94

12 Ordering information .....................................................................................................................95

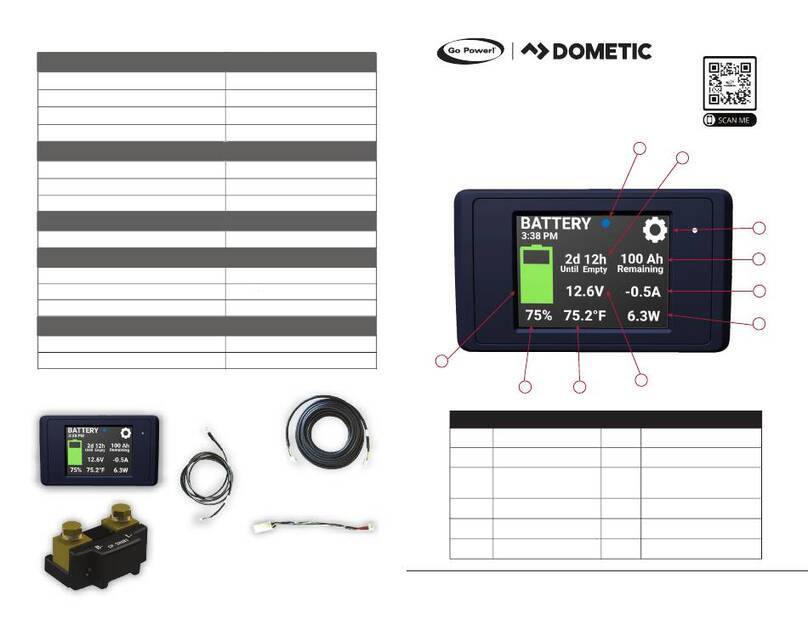

12.1 Scope of delivery .................................................................................................... 95

12.2 Available systems ................................................................................................... 95

12.3 Accessories/Spare parts........................................................................................ 95

12.3.1 System plug ................................................................................................ 95

12.3.2 CDS and connection cable ........................................................................ 95

12.3.3 Connection cable for self-made cables..................................................... 95

13 Annex .................................................................................................................................................96

13.1 Declaration of conformity....................................................................................... 96

13.2 Checklist for the manufacturer.............................................................................. 97

13.3 List of tables ........................................................................................................... 98

13.4 List of illustrations .................................................................................................. 99

Chapter 1Operating Instructions

UE 440/470

6© SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 010 432/P097/14-03-05

About this document

1About this document

Please read this chapter carefully before working with the documentation and a safety

controller UE 440/470.

1.1 Function of this document

These operating instructions are designed to address the technical personnel of the

machine manufacturer or the machine operator in regards to safe mounting, installation,

configuration, electrical installation, commissioning, operation and maintenance of the

safety controller UE 440/470 in connection with other protective devices (e.g. safety light

curtain C 4000 or safety laser scanner S 3000).

These operating instructions do not provide instructions for operating machines on which a

safety controller is, or will be, integrated.

1.2 Target group

These operating instructions are addressed to planning engineers, machine designers and

the operators of systems which are to be protected by one or more SICK protective devices

in connection with a safety controller UE 440/470. It also addresses people who integrate

a UE 440/470 into a machine, initialise its use, or who are in charge of servicing and

maintaining the unit.

1.3 Scope

These operating instructions apply for the safety controllers UE 440 and UE 470 with the

following type label entry in the Operating Instructions field: 8 010 426.

Only C4000 Receivers with the following type label entry are to be used: Software Version

3.28 or higher.

Only S3000s with the following type label entry are to be used: Software Version 2.26 or

higher.

This document is part of SICK part number 8 010 426 (operating instructions

"Configurable Safety Controller UE 440/470" in all available languages).

You will require a CDS (Configuration & Diagnostic Software) version 2.31 or greater for the

configuration and diagnostics of these devices. To check the software version, select the

Module info item from the ?menu in the menu bar.

Note

Operating Instructions Chapter 1

UE 440/470

8 010 432/P097/14-03-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 7

About this document

1.4 Depth of information

These operating instructions contain the following information on the safety controller

UE 440/470:

$Mounting

$Electrical installation

$Putting into operation and configuration

$Operation

$Error diagnositcs and remedying

$Part numbers

$Conformity and approval

Planning and using SICK protective devices also require specific technical skills which are

not detailed in this documentation.

When operating a UE 440/470, the national, local and statutory rules and regulations

must be observed.

General information on health and safety using opto-electronic protective devices is

contained in the brochure "Safe Machines with Opto-Electronic Protective Devices".

We also refer you to the SICK homepage on the Internet at

www.sick.com

Here you will find:

$Sample applications

$A list of common questions on safety controller UE 440/470

$These operating instructions in different languages for viewing and printing

1.5 Abbreviations

Application diagnostic output = configurable signal output that indicates a specific status

Bottom dead centre = machine cycle contact. Indicates that the bottom dead centre has

been reached on a press

Electro-sensitive protective equipment (e.g. C 4000 or S 3000)

C 4000 safety light curtain

SICK Configuration & Diagnostic Software = software for configuring your UE 440/470 and

devices connected via EFI

External device monitoring

Enhanced function interface = secure SICK device communication

Error-proof programmable logic controller

Output signal switching device = switching output which operates the safety circuit

Probability of failure on demand

Presence sensing device initiation = PSDI mode

S 3000 safety laser scanner

Stop control contact = Overrun monitoring. Indicates the end of the expected stopping

path on a press

Safety data link = SICK safety interface (connection for OSSD and EFI of ESPE)

Safety integrity level

Top dead centre = machine cycle contact. Indicates that the top dead centre has been

reached on a press

Note

ADO

BDC

ESPE

C 4000

CDS

EDM

EFI

EPLC

OSSD

PFD

PSDI

S 3000

SCC

SDL

SIL

TDC

Chapter 1Operating Instructions

UE 440/470

8© SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 010 432/P097/14-03-05

About this document

1.6 Symbols used

Recommendations are designed to give you some assistance in your decision-making

process with respect to a certain function or a technical measure.

Notes provide special information on the device.

Display indicators show the status of the 7-segment display:

/Constant display of characters, e.g. 8

Flashing display of characters, e.g. 8

2O*Changing display of characters, e.g. A and 3

LED symbols describe the state of a diagnostics LED. Examples:

,The LED is illuminated constantly.

+The LED is flashing.

-The LED is off.

Instructions for taking action are shown by an arrow. Read carefully and follow the

instructions for action.

Warning!

A warning indicates concrete or potential dangers. They save you from harm.

Read warnings carefully and abide by them!

Software notes show the location in the CDS (Configuration & Diagnostic Software) where

you can make the appropriate settings and adjustments.

The term "dangerous state"

In the figures in this document, the dangerous state of the machine is always represented

as a movement of a machine part. In practical operation, there may be a number of

different dangerous states, e.g.:

$Machine movements

$Electrical conductors

$Visible or invisible radiation

$A combination of several risks and hazards

Recommendation

Note

/, , 2O*

,, +, -

Take action …

%

ATTENTION

!

Operating Instructions Chapter 2

UE 440/470

8 010 432/P097/14-03-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 9

On safety

2On safety

This chapter deals with your own safety and the safety of the equipment operators.

Please read this chapter carefully before working with a UE 440/470 or with the

machine protected by the UE 440/470.

2.1 Specialist personnel

The safety controller UE 440/470 must be installed, commissioned and serviced only by

specialist personnel. Specialist personnel are defined as persons who…

$have undergone the appropriate technical training

and

$who have been instructed by the responsible machine operator in the operation of the

machine and the current valid safety guidelines

and

$have access to the operating instructions of the UE 440/470 and have read and

familiarised themselves with them

and

$have access to the operating instructions for the protective devices (e.g. C 4000)

connected to the safety controller and have read and familiarised themselves with them.

2.2 Applications of the device

The safety controller UE 440/470 is a configurable controller for comprehensive

implementation of safety applications.

The device corresponds to category 4 according to EN 954-1; applications can reach SIL3

according to IEC 61508. The emergency stop function in the device corresponds to stop

category 0 or 1 in accordance with EN 418.

Opto-electronic and tactile safety sensors (e.g. light curtains, laser scanners, reset devices,

sensors, emergency-stop devices and machine cycle contacts) are connected to the safety

controller and are linked logically. The accompanying actuators of connected machines or

systems are switched off safely via the switching outputs of the safety controller.

Connected pick-ups or safety sensors and the subsequent control, wiring and installation

must correspond to the required category in accordance with EN 954-1.

Suitability UE 440 UE 470

Logical link of safety signals

Connection/integration of safety sensors and

actuators

PSDI mode

Tab. 1: Suitability of the

device variants

Chapter 2Operating Instructions

UE 440/470

10 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 010 432/P097/14-03-05

On safety

2.3 Correct use

The safety controller UE 440/470 may only be used as intended in Section 2.2

"Applications of the device". It may only be used by specialist personnel and only at the

machine at which it was mounted and initially commissioned by specialist personnel in

accordance with these operating instructions.

SICK AG accepts no claims for liability if the equipment is used in any other way or if

modifications are made to the device, even in the context of mounting and installation.

2.4 General protective notes and protective measures

Observe the protective notes and measures!

Please observe the following items in order to ensure proper use of the safety controller

UE 440/470.

$When mounting, installing and using the UE 440/470, observe the standards and

directives applicable in your country.

$The national/international rules and regulations apply to the installation, use and

periodic technical inspection of the safety controller UE 440/470, in particular:

–Machinery Directive 98/37/EC.

–Provision and use of Directive 89/655/EEC.

–Low-Voltage Directive 73/23/EEC.

–Work safety regulations/safety rules.

–Other relevant health and safety regulations.

$Manufacturers and owners of the machine on which a UE 440/470 is used are

responsible for obtaining and observing all applicable safety regulations and rules.

$The notes, in particular the test notes (see Chapter 8 "Commissioning" on Page 73) of

these operating instructions (e.g. on use, mounting, installation or integration into the

existing machine controller) must be observed.

$The tests must be carried out by specialist personnel or specially qualified and

authorised personnel and must be recorded and documented to ensure that the tests

can be reconstructed and retraced at any time by third parties.

$The operating instructions must be made available to the user of the machine where the

UE 440/470 is fitted. The machine operator is to be instructed in the use of the device

by specialist personnel and must be instructed to read the operating instructions.

$The external voltage supply of the devices must be capable of buffering brief mains

voltage failures of 20 ms as specified in EN 60 204. Suitable power supplies are

available as accessories from SICK (Siemens type series 6 EP 1).

%

ATTENTION

Operating Instructions Chapter 2

UE 440/470

8 010 432/P097/14-03-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 11

On safety

2.5 Environmental protection

The safety controller UE 440/470 has been designed to minimise environmental impact. It

uses only a minimum of power and natural resources.

At work, always act in an environmentally responsible manner.

2.5.1 Disposal

Disposal of unusable or irreparable devices should always occur in accordance with the

applicable country-specific waste-disposal regulations

(e.g. European Waste Code 16 02 14).

$We would be pleased to be of assistance on the disposal of this device. Contact your

local SICK representative.

2.5.2 Material separation

Material separation may only be performed by specialist personnel!

Exercise care when disassembling the devices. The danger of injury is present.

Before you can turn over the devices for environmentally-friendly recycling, you must

separate the different materials of the UE 440/470 from one another.

Separate the housing from the remaining components (especially the PCB).

Turn over the separated components to their respective recycling centres (see Tab. 2).

Components Disposal

Product

Housing Metal recycling (steel sheeting)

PCBs, cables, plugs and electrical

connection pieces

Electronics recycling

Packaging

Cardboard, paper Paper/cardboard recycling

Polyethylene packaging Plastic recycling

Notes

%

ATTENTION

Tab. 2: Overview of disposal

by component type

Chapter 3Operating Instructions

UE 440/470

12 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 010 432/P097/14-03-05

Product description

3Product description

This chapter provides information on the special features and properties of the

UE 440/470. It describes the structure and operating principle of the device.

It is imperative that you read this chapter before you mount, install and commission the

device.

3.1 Special features

Properties of UE 440/470

$2 EFI connections for the attachment of corresponding SICK protective devices

(e.g. C 4000 Standard/Advanced or S 3000)

$Saving of the configuration of a device connected via EFI, e.g. C 4000 in the

UE 440/470. automatic device identification after replacement of such a device and

transfer of the saved configuration to the device. This makes easy replacement of a C

4000 possible.

$15 inputs for the connection…

–of single or dual channel standard sensors and input devices such as reset and EDM.

–of single or dual channel safety sensors and input devices such as emergency stop,

two-hand control, bypass etc.

–of an operating mode selector switch for switching between up to five operating

modes.

$8 outputs, which can be used...

–as single channel control or signal outputs for downstream controllers (e.g. EPLC or

others).

–as dual channel OSSDs (for the connection of e.g. actuators or EPLC).

–for the connection of signal lamps.

–as outputs for test signals for single or dual channel sensors or input devices, such as

emergency stop.

$Configurable logic modules, e.g. logical AND/OR/NAND/NOT gates for linking of input

signals

$Configurable release modules for evaluation of release criteria e.g. reset, external device

monitoring (EDM) and two-hand control

$Configurable software function module for protective operation for simple configuration

of safety applications, e.g. with emergency stop or bypass

$Diagnostics via 7-segment display and LEDs

$RS-232 interface for configuration and diagnostics with the Configuration & Diagnostic

Software (CDS)

Special features of safety controller UE 470 for PSDI applications

$Configurable PSDI mode software function modules for 1 or 2 PSDI (also hydraulic or

eccentric presses) with and without overrun monitoring

$Configurable software function module for protective operation with evaluation of

machine cycle contacts

$Inputs for machine cycle contacts (TDC, BDC, SCC)

Operating Instructions Chapter 3

UE 440/470

8 010 432/P097/14-03-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 13

Product description

3.2 Operating principle of the device

3.2.1 Principle of the device

The safety controller UE 440/470 enables easy integration of several safety and standard

sensors or input devices, other input devices or actuators in a safety application. With this,

you can...

$implement individual safety applications.

$implement two independent safety applications.

$implement two safety applications bound to one another.

Within a safety application, the safety controller processes specific signals of optical and

tactile sensors.

The safety controller also expands the functions of connected systems, such as C 4000 or

S 3000 (PSDI mode, simultaneous protective field monitoring).

Using the Configuration & Diagnostics Software (CDS), you can link the connected

components to one another. Predefined software function modules used to implement

your safety application are available in the CDS for this purpose.

Fig. 1: Principle of the device

Opto-electronic protective devices, such

as S 3000 or C 4000

Tactile or opto-electrical

sensors

Hazardous area or hazardous point

protection

PSDI applications

UE 440/470

Input devices, operatin

g

mode selector switches,

signal lamps

A

ccess protection

or or

Chapter 3Operating Instructions

UE 440/470

14 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 010 432/P097/14-03-05

Product description

Available software function modules are e.g.:

$Logical link of input signals

$Pre-configured input elements for the connection of all devices specified by SICK

$Pre-configured output elements, e.g. for the connection of signal lamps or downstream

controllers or actuators

$Function modules for protective operation

$Function modules for PSDI mode, overrun monitoring (UE 470)

3.2.2 Connectable devices

$Contact-based sensors and input devices e.g.:

–Single or dual channel emergency stop input device

–Single or dual channel input devices

–Two-hand input device, dual channel

–Key-operated switch for bypass

–Reset button

–External device monitoring

–Switch for switching monitoring fields at S 3000 and for blanking field switching at

C 4000

–Teach-in key-operated switch for teaching in blanked areas with C 4000

–Machine cycle contacts TDC, BDC, SCC (with UE 470)

Sensors must be active HIGH.

Fig. 2: Linking of inputs and

outputs

Note

EFI1 and EFI2

e.g.. C 4000/S 3000)

Digital inputs, e.g.

for 1 or dual channel input

devices and sensors (e.g.

for the OSSDs of ESPE,

emergency stop,

safety switches, reset

buttons, operating mode

selector switches,

machine cycle contacts)

Logic modules

Function modules

(Standard, PSDI)

Outputs:

signal outputs,

signal lamps,

test signals, OSSDs

RS-232 (for CDS)

Display elements:

LEDs,

7-segment display

Release modules

Operating Instructions Chapter 3

UE 440/470

8 010 432/P097/14-03-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 15

Product description

$ESPE e.g.:

–S 3000 safety laser scanner

–PLS safety laser scanner

–C 4000 safety light curtain

–FGS safety light curtain

–C 2000 safety light grid

–M 2000 or MSL multi-beam safety light barriers

$Signal lamps e.g.:

–for "Waiting for PSDI interruption"

–for "Reset required"

3.3 Display elements

3.3.1 LEDs and 7-segment display

The LEDs and 7-segment display indicate the operational status of the UE 440/470. They

are found on the front of the safety controller.

The LEDs are grouped into two blocks. The left block indicates the conditions of outputs

02.0 and 02.1, and the right block deals with outputs 02.2 and 02.3. If the dual channel

outputs are used as OSSDs, they have the following meaning:

Display Meaning

,red OSSD (02.0 AND 02.1) switched off

,green OSSD (02.0 AND 02.1) switched on

+yellow Reset of the application configured above in the CDS required

Display Meaning

,red OSSD (02.2 AND 02.3) switched off

,green OSSD (02.2 AND 02.3) switched on

+yellow Reset of the application configured below in the CDS required

Fig. 3: Status indicators of

the UE 440/470

Tab. 3: Meaning of the LEDs

of the left block (A)

Tab. 4: Meaning of the LEDs

of the right block (B)

(O2.0, O2.1) (O2.2, O2.3)

7-segment displa

y

Chapter 3Operating Instructions

UE 440/470

16 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 010 432/P097/14-03-05

Product description

Avoid confusion by using the appropriate configuration!

Ensure that you configure the applications in the CDS in such a way that the respective

yellow LED is assigned to the corresponding OSSDs and that confusion cannot occur

during a reset.

If the outputs are used as control or signal outputs in a single channel mode, they have the

following meaning:

Display Meaning

,green 02.0 AND 02.1 = HIGH

,red With all other conditions of outputs 02.0 and 02.1

+yellow Reset of the application configured above in the CDS required

Display Meaning

,green 02.2 AND 02.3 = HIGH

,red With all other conditions of outputs 02.2 and 02.3

+yellow Reset of the application configured below in the CDS required

Display Meaning

&System ready for operation

*System initialisation

-Configuration mode

ZEmergency-stop was actuated

3Bypass active

Other

displays

For all other displays, refer to the meanings in Chapter 10.4 "Displays of

the 7-segment display" on Page 81.

%

ATTENTION

Tab. 5: Meaning of the LEDs

of the left block (A)

Tab. 6: Meaning of the LEDs

of the right block (B)

Tab. 7: Meaning of the

7-segment display

Operating Instructions Chapter 4

UE 440/470

8 010 432/P097/14-03-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 17

Configurable functions

4Configurable functions

Plan and carry out configuration carefully!

Incorrect configuration can lead to ineffectiveness of the safety function!

$The configuration of safety applications must be carried out with the greatest accuracy

and must match the status and the condition of the machine or system to be monitored.

Check whether the configured safety application monitors the machine or system as

planned and whether the safety of a configured application is ensured at all times. This

must be ensured in each operating mode and partial application. Document the result of

this check.

$Each safety application must be checked at a specific interval. The interval is to be

defined to suit the specific case dependant on the application.

$In each case, observe the instructions for commissioning and daily checking in the

operating instructions of the protective devices integrated into the safety application!

$Note the warnings and function descriptions of protective devices connected to the

safety controller! Contact the respective manufacturer of the protective device if in

doubt!

$Functions such as the restart interlock, PSDI etc. can be configured in both the

UE 440/470 and in a device connected via EFI. The UE 440/470 does not check

whether or not these functions were configured with the connected devices. You must

therefore check whether the configured safety application monitors the machine or

system as planned.

The configurable functions of the UE 440/470 are described in the following sections.

Examples for typical safety applications are found in Chapter 7 "Application and switching

examples" from Page 58 and on the Internet at www.sick.com.

4.1 Base settings with the configuration wizard

The functions which you can configure using the configuration wizard are described in this

section.

4.1.1 Configuration name

You can save a configuration name with max. 22 characters in the device. Use this

function as a reminder.

Context menu device symbol UE 440/470, command Edit configuration draft… in Edit

configuration draft window, menu Tools, command Configuration wizard….

%

ATTENTION

!

Chapter 4Operating Instructions

UE 440/470

18 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 010 432/P097/14-03-05

Configurable functions

4.1.2 Operating modes and operating mode selector switch

You can configure up to five operating modes for your safety application with the

UE 440/470. In each operating mode, you can configure different links between the

connected sensors and actuators and integrate the protective devices connected via EFI

into the application(s). This gives you the option of matching the application(s) to the

operating modes of the machine or system to be secured.

You can save a name for each operating mode during configuration in the CDS. Use this

function as a reminder, e.g. to describe the operating mode.

Check the protective device in every operating mode and after every change to an

operating mode!

If you configure several operating modes, you must especially check the operation of the

protective device in each of these operating modes. Please observe the test notes in the

operating instructions of the connected protective device.

Observe EN 963 when executing the BDC.

Up to two safety applications can be adapted and configured to the requirements of the

respective operating mode.

$Input and output elements are configured once for this and remain the same in each

operating mode.

$Logic module, release module and function module can be configured individually for

each operating mode.

$Connections between input and output elements and between logic module, release

module and function module can be configured individually for each operating mode.

A configured input element should generally be used in all operating modes and

connected to other elements for this reason. The CDS checks whether this is the case

when saving the application. If the CDS determines that an input element is not used in all

operating modes, you are notified of this and must confirm this explicitly.

If you do not wish to use a configured input element in one or more operating modes,

check whether this is permissible with the application!

Ensure that all connected elements are integrated in the safety application. This is

especially important when it is an element critical for safety (e.g. an emergency stop or

ESPE)!

$An electrical connection may only be made for operating modes that are in use.

$If the operating mode is switched with activated bypass (e.g. when switching from

operating mode 1 to operating mode 3) (see Section 4.2.9 "Bypass" on Page 30), bypass

is deactivated and the UE 440/470 switches to the new operating mode. If the bypass is

to be reactivated, the key-operated switch for bypass must be actuated again.

$If the operating mode is switched while teach-in via a Teach-in key-activated switch

connected to the UE 440/470 is active, the UE 440/470 first remains in the previous

operating mode (see Section 4.5 “Teach-in for C 4000" on Page 40). Only after the teach-

in is complete does the UE 440/470 switch to the selected operating mode and forward

the information on the new operating mode e.g. to the C 4000 Standard/Advanced, if

such forwarding is configured via EFI in the CDS.

This applies only if operating mode switching is configured simultaneously at the

UE 440/470 and at a protective device connected to EFI (for example S 3000 or

C 4000).

%

ATTENTION

Note

Notes

Operating Instructions Chapter 4

UE 440/470

8 010 432/P097/14-03-05 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 19

Configurable functions

Switching operating modes for devices connected via EFI

The status of the operating mode selector switch of the UE 440/470 can be transferred to

a protective device connected via EFI. The operating mode selector switch can be

configured so that operating mode switching of the EFI device …

$takes places simultaneously with operating mode switching of the UE 440/470.

$takes places independently of operating mode switching of the UE 440/470.

In the case of simultaneous operating mode switching the status of the operating mode

selector switch of the UE 440/470 is transferred to a EFI device. In this case, both the

UE 440/470 and the connected protective device switch to another operating mode when

switching occurs.

In the case of independent operating mode switching the status is transferred from local

inputs to an EFI device.

Operating mode switching of the UE 440/470 by means of the operating mode selector

switch corresponds to a switching of programs and always leads via a RED state of the

safety outputs at the UE 440/470.

$When transferring the status of an operating mode selector switch to a device connected

via EFI, the same number of operating modes must be configured there. Ensure that

when a C 4000 or S 3000 is connected, the same number of operating modes are

configured in both it and the UE 440/470.

$If the status of the operating mode selector switch is transferred via EFI to a safety laser

scanner S 3000, then there is a switching between the monitoring cases. The OSSD of

the S 3000 can remain switched on during this switch, depending on the protective field

status. The OSSDs of the safety controller are switched off, however.

$Only C4000 Receivers with the following type label entry are to be used: Software

Version 3.28 or higher.

Operating mode selector switch

The operator can switch between the operating modes by means of an operating mode

selector switch.

$When switching to another operating mode, the OSSDs of the safety controller are

switched off.

$After switching, the condition of the OSSDs depends on the configured application and

the input signals at their inputs.

Examples: With the internal restart interlock activated, the OSSDs remain switched off

and a reset is required. If an internal restart interlock was not configured, and if no

switch-off conditions (emergency stop, ESPE interrupted etc.) are active at the inputs, the

OSSDs switch on again after the switch to the new operating mode.

As soon as you configure several operating modes in the CDS, the operating mode selector

switch automatically appears in the pin assignment of the safety application. It has as

many inputs as configured operating modes.

The operating mode selector switch must be a (1-of-n) key-operated switch.

You configure whether the operating mode selector switch is actuated with or without

testing (see Section 4.6.2 "Testing of the connected input devices and sensors" on

Page 42).

Context menu device symbol UE 440/470, command Edit configuration draft… in Edit

configuration draft window, menu Tools, command Configuration wizard….

The electrical connection of the operating mode selector switch is described in Chapter 6

"Electrical installation" on Page 45.

Notes

Note

!

Chapter 4Operating Instructions

UE 440/470

20 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8 010 432/P097/14-03-05

Configurable functions

4.1.3 Automatic reconfiguration

The configuration of a protective device (e.g. C 4000) connected via EFI can be saved in

the safety controller. After exchanging a protective device (e.g. due to a defect), device

detection occurs, and the saved configuration is transferred to the protective device.

$For the safety controller to reconfigure a protective device, the type code of the new

device must match that of the original device.

$Commissioning (see Chapter 8 on Page 73) and full approval of the application (see

Chapter 8.2 on Page 76) must occur both after the replacement of a protective device

connected via EFI and after the replacement of the safety controller UE 440/470. After

replacement of a UE 440/470 with a new UE 440/470 with active automatic

reconfiguration, the configuration of a C 4000 connected via EFI may be overwritten by

the new UE 440/470 in certain circumstances. This is the case if the configuration

saved in the UE 440/470 contains the same type code as the connected C 4000.

Context menu device symbol UE 440/470, command Edit configuration draft… in Edit

configuration draft window, menu Tools, command Configuration wizard….

4.2 Protective operation

To configure the functions described below, you must position a function module for

protective operation in the CDS. Two function modules are available for protective

operation:

$Standard function module

$Standard function module with machine cycle contact evaluation (UE 470)

The function module for protective operation can have the following inputs:

Input Effect

ESPE/Switch If an ESPE connected to this input or a switch connected to the

input switches off, the outputs Out1 and Out2 are switched off.

For information on evaluating the machine cycle contacts please

refer to Section 4.3.3 "Significance of the machine cycle contacts

for PSDI mode operation" on page 35 and Section 6.2.8

"Machine-cycle contacts" on page 52.

Logic If a logic module connected to this input supplies the link result

logical 0, the outputs Out1 and Out2 are switched off.

For information on evaluating the machine cycle contacts please

refer to Section 4.3.3 "Significance of the machine cycle contacts

for PSDI mode operation" on page 35 and Section 6.2.8

"Machine-cycle contacts" on page 52.

Bypass If a key-operated switch for bypass connected to this input is

actuated, the outputs Out1 and Out2 are forced high connected.

This is not the case if an emergency stop input device connected

to the Emergency stop input is actuated.

Emergency Stop If an emergency stop input device connected to this input is

actuated, the outputs Out1 and Out2 are switched off. The input

overrides all other input signals.

Notes

!

Tab. 8: Possible inputs of the

function module for

protective operation

Other manuals for UE 440

1

This manual suits for next models

1

Table of contents

Other SICK Controllers manuals

SICK

SICK Flexi Classic User manual

SICK

SICK Flexi Soft User manual

SICK

SICK Flexi Classic User manual

SICK

SICK RMS1000 User manual

SICK

SICK Flexi Classic series User manual

SICK

SICK Flexi Compact User manual

SICK

SICK RFH6 Series Manual

SICK

SICK MITSUBISHI ELECTRIC MELSEC iQ-F Series User manual

SICK

SICK MSC800 User manual

SICK

SICK Flexi Soft User manual