1

STHCkW ed 04/09 HERCULES Condensing Export

Technical Documentation Technical Documentation

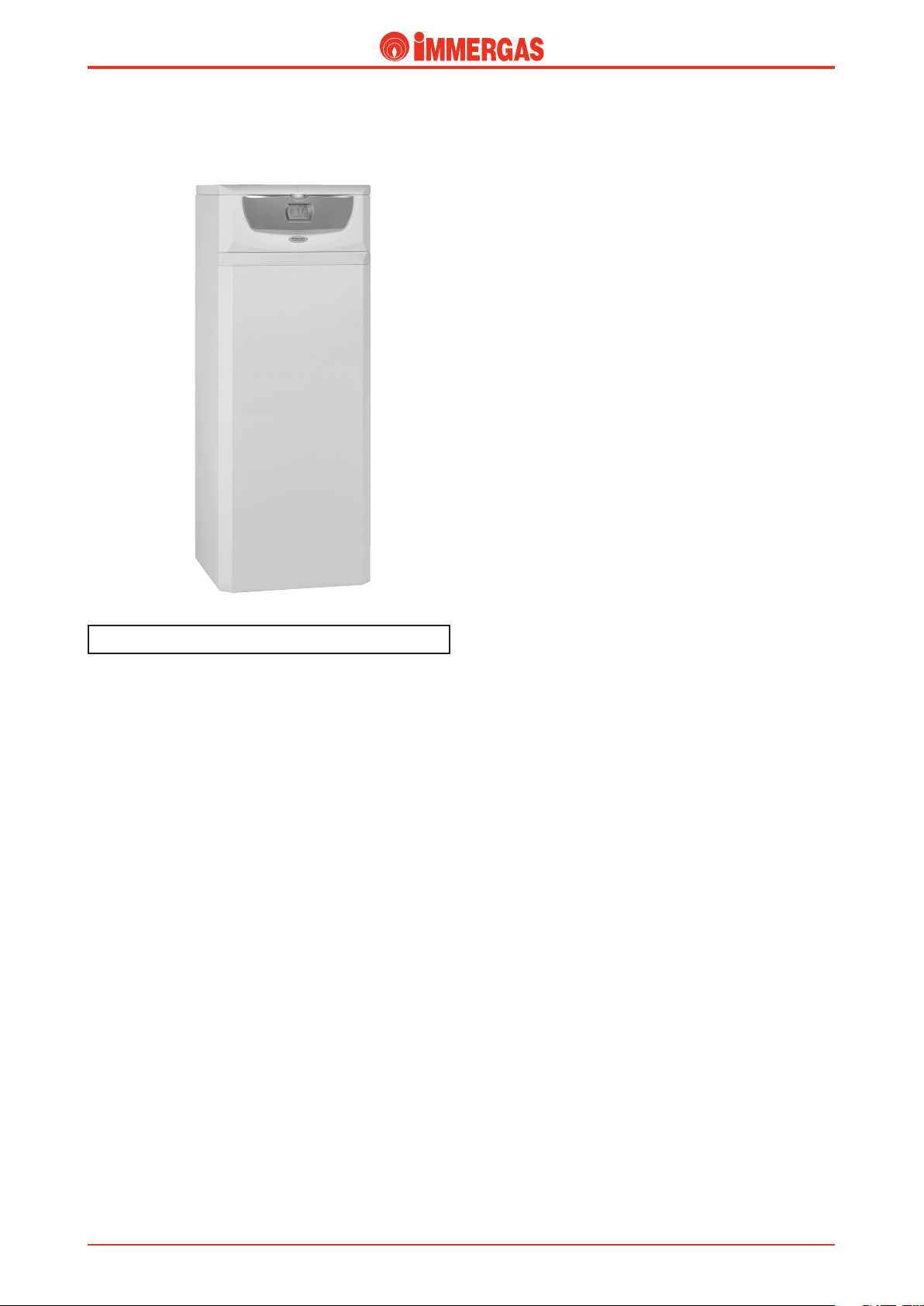

HERCULES Condensing

Ecological oor-standing condensing

boiler with 120 litre storage tank

HERCULES Condensing 26 2 E

HERCULES Condensing 32 2 I

HERCULES Condensing ABT 32 2 I

HERCULES Condensing combines the advantages of an

ecological condensing boiler with VICTRIX Superior type mi-

croprocessor with those of a oor standing boiler with storage

tank. e range envisions two versions with useful heat outputs

of 23.9 kW (20554 kcal/h) and 32.0 kW (27520 kcal/h). Both

models are equipped with a total premix combustion system,

which guarantees particularly low pollutant emissions and

allows functioning with methane or LPG. anks to condensa-

tion technology, it is characterised for its high eciency and

for the large modulating eld (20÷100% of the nominal heat

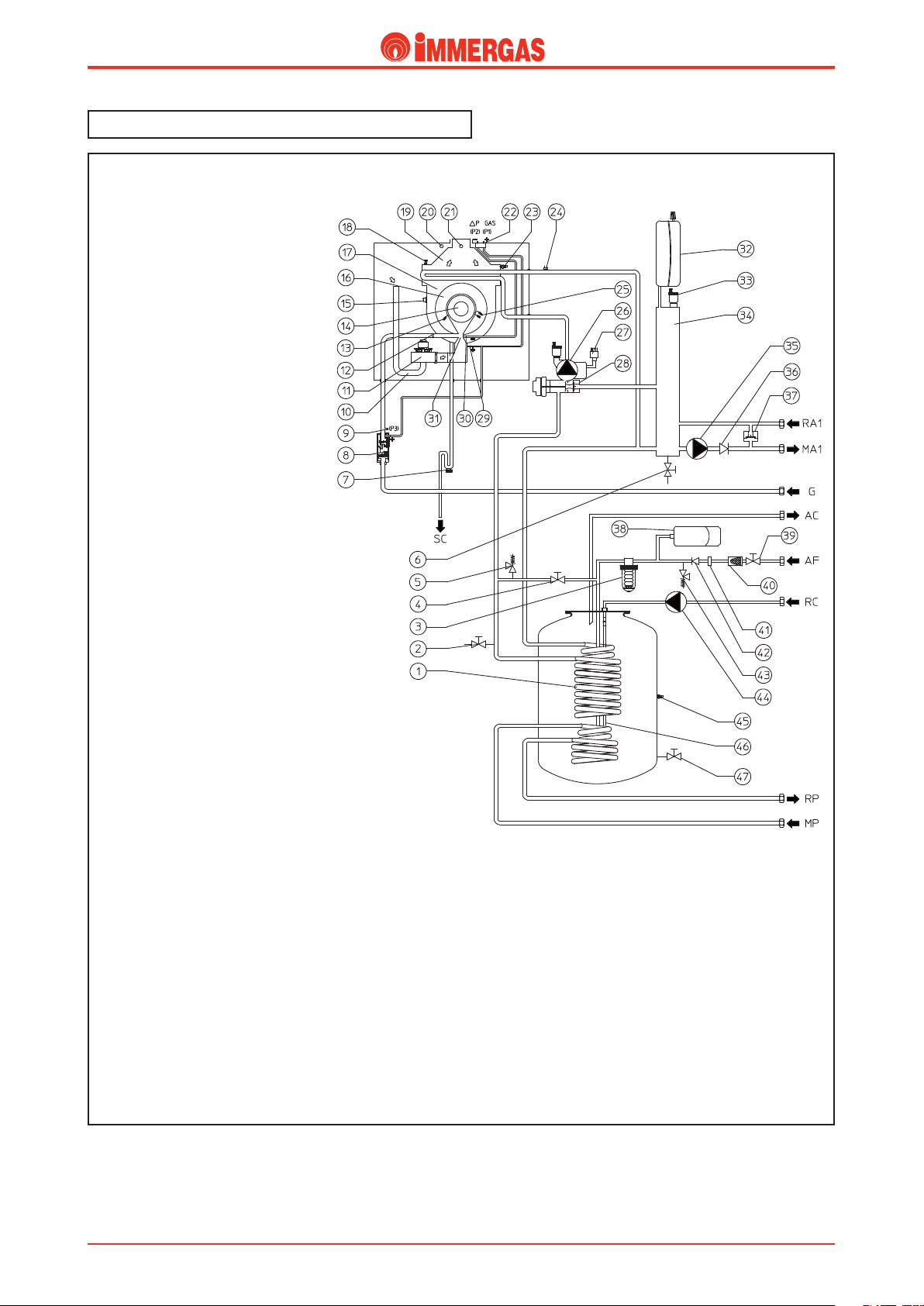

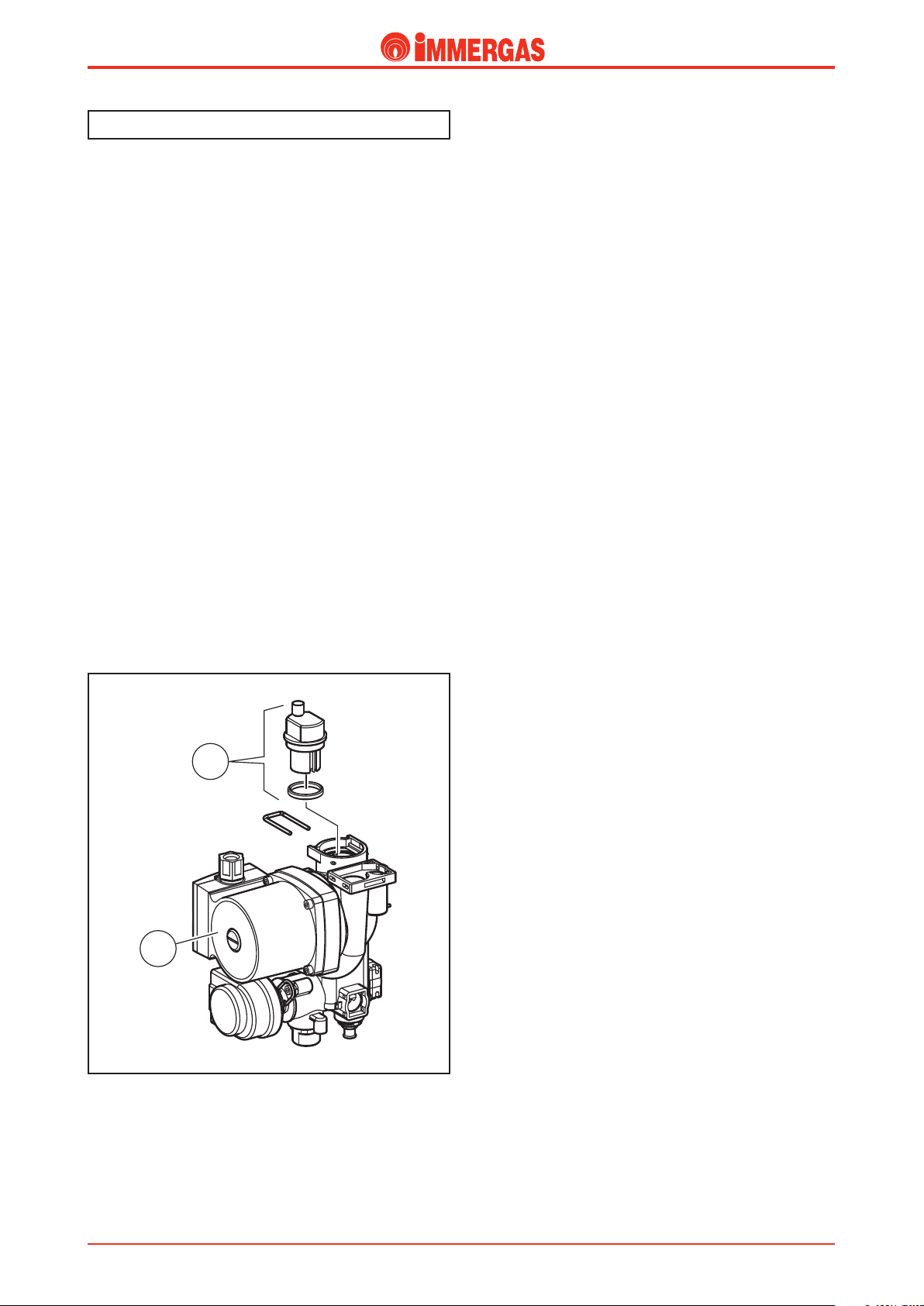

output). e hydraulic circuit, made up from one stainless steel

water-gas coil exchanger, a hydraulic manifold inserted as per

standard and two pumps, means that the boiler is suitable for

the heating systems that require high ow rate.

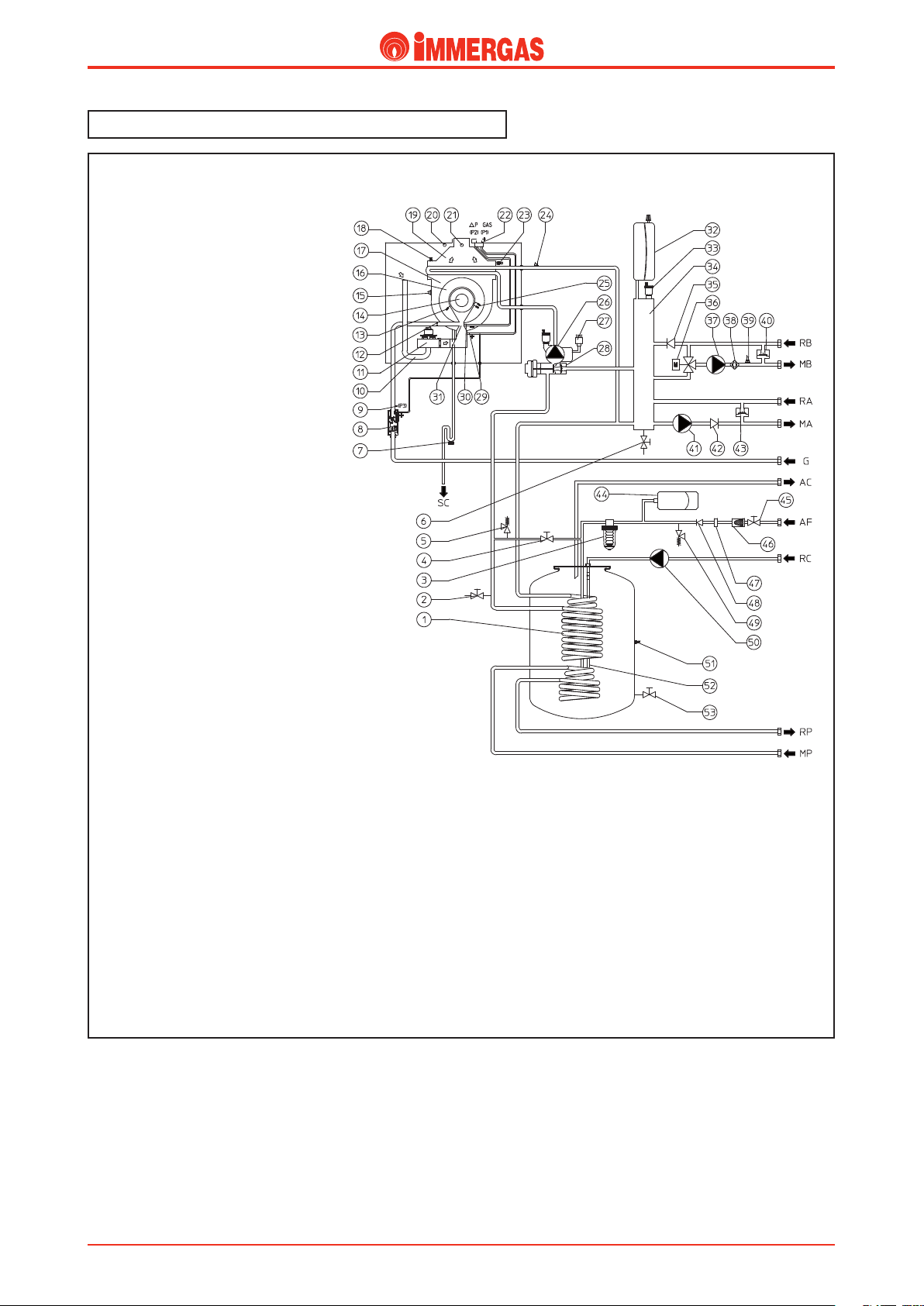

HERCULES Condensing can function in zone systems con-

trolled by pumps: it is, in fact, prepared to house the pumps

necessary to control up to 3 zones on the heating system inside

the casing. It is also prepared for the realisation of mixed sys-

tems: one high temperature zone (e.g. radiators) and two low

temperature zones (e.g. oor radiating panels) by inserting the

optional kit inside the casing (including pumps, mixer valves

and zone management board). e new zone management board

allows to use the Remote Control (optional) to control that

considered to be the main zone.

N.B.: e HERCULES Condensing ABT boiler is equipped

to manage a high temperature zone (example radiators) and a

low temperature zone (example oor radiating panels). e tem-

perature of the ow water onto the low temperature zones can

be adjusted on the boiler control panel (whenever functioning

General features.

with variable temperature is not envisioned) from 25 to 50°C.

All models are prepared for coupling and connection of the

storage tank to solar panel systems (optional).

e new electronics allow the connection of the appliance

to the Comando Amico Remoto and to the Super Comando

Amico Remoto remote control; both allow to manage and

control the boiler at a distance with great ease. Using the Super

CAR it is possible to indierently vary some settings from the

boiler control panel and from the Super CAR control panel,

such as: selection of Summer Winter, DHW set point, DHW

comfort status, Reset.

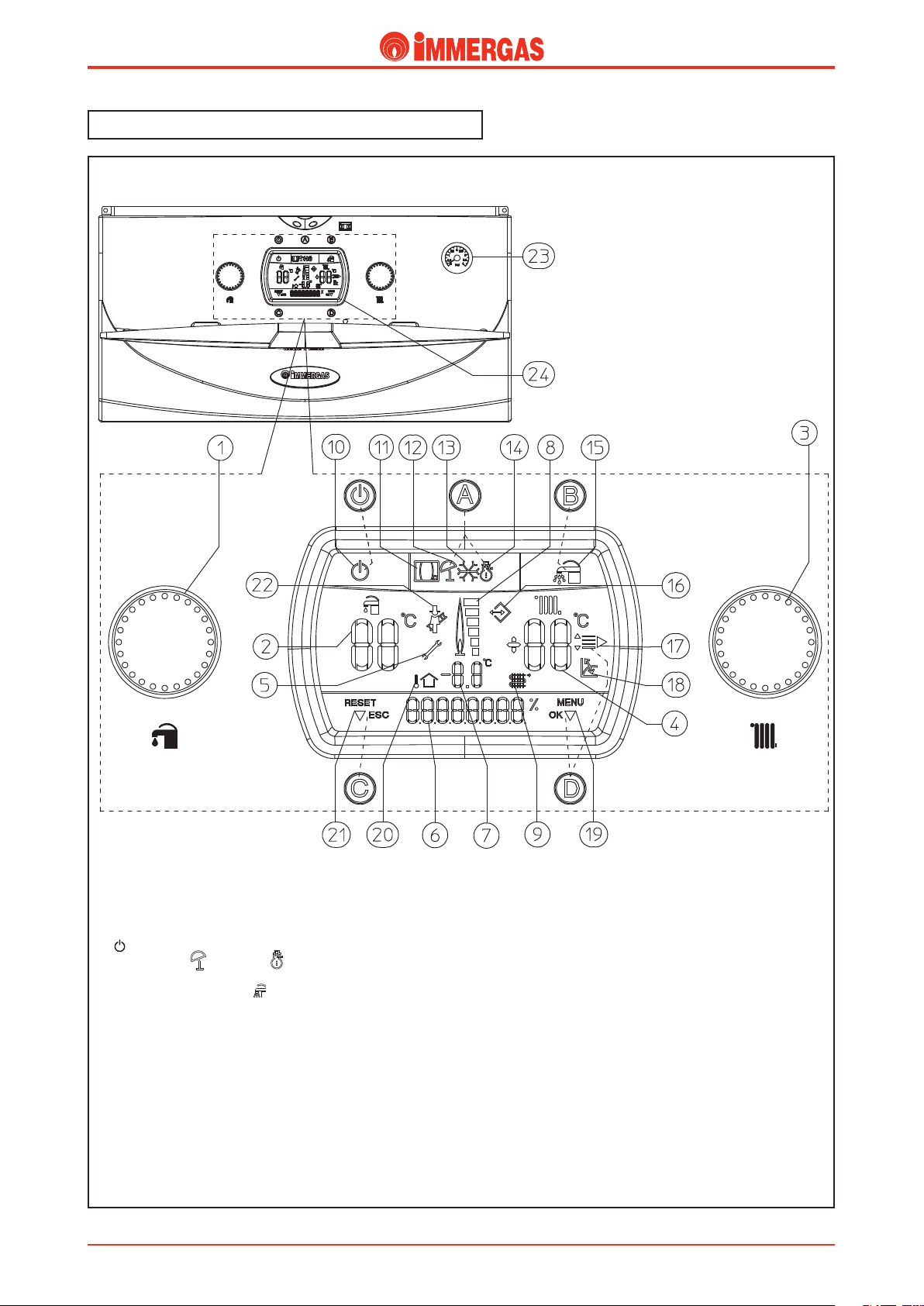

e adjustment and the control of the appliance are entrusted

to a P.C.B. with continuous ame modulation. e boiler

functioning parameters are set using the buttons and knobs

while display of the status, functioning mode and anomalies

takes place on the back-lit digital display.

e DHW circuit is equipped with a 5 litre expansion vessel

and a120 litre stainless steel storage tank which, as well as the

advantages of storage, guarantees the instantaneous produc-

tion of hot water.

HERCULES Condensing must be installed using the intake/

exhaust kits or the ducting systems (Ø 60 mm rigid, Ø 80 mm

rigid and Ø 80 mm exible) realised in plastic and designed

expressly for Immergas condensing boilers.