8

1-5

A

A

A

UB INOX 80 ErP

UB INOX 200 ErP

UB INOX 120 ErP

INSTALLERUSER

MAINTENANCE TECHNICIAN

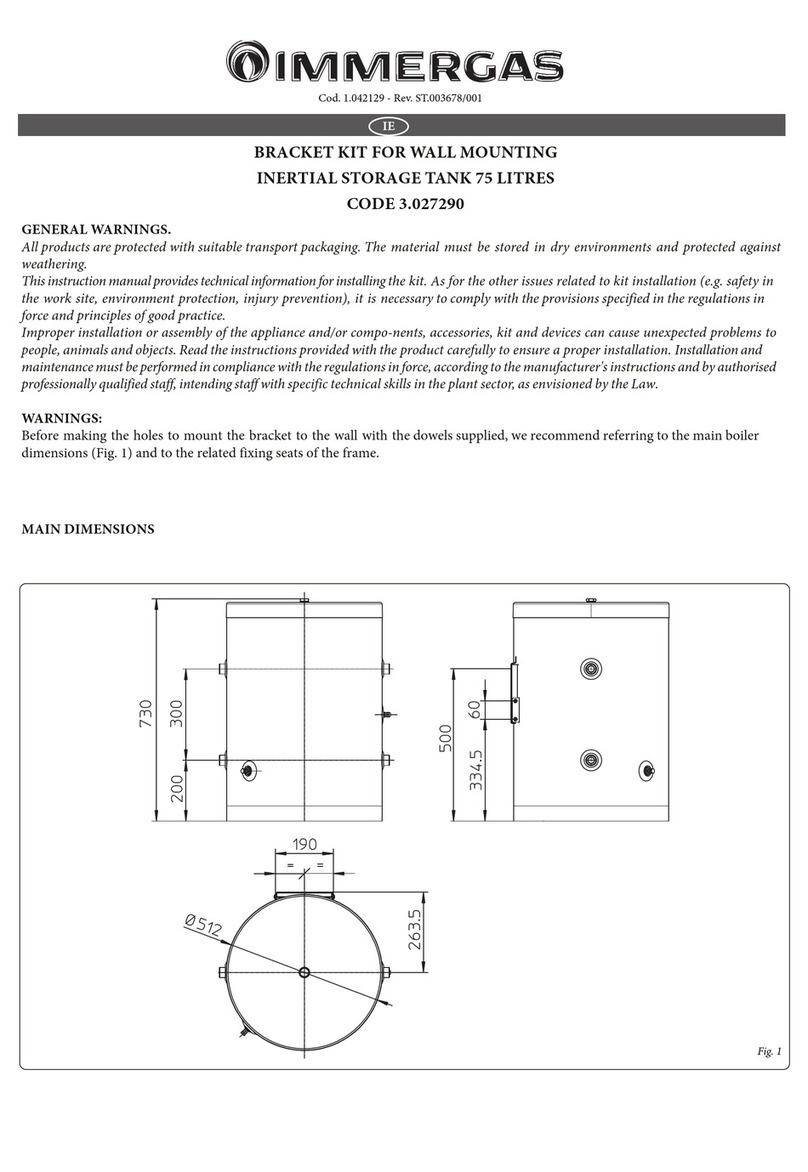

Hydraulic circuit resistance.

A - Storage tank unit

hydraulic circuit resistance

1.7 HYDRAULIC CIRCUIT RESISTANCE.

In order to guarantee sucient DHW ow rate,

it is important to consider the resistance of the

storage tank hydraulic circuit to be coupled to

the boiler. (Fig. 1-5). For correct connection of

the storage tank unit to Immergas boilers, see the

boiler instruction book.

1.8 KITS AVAILABLE ON REQUEST.

• Pump kit (on request). e storage tank unit

is prepared for application of the pump kit.

Immergas supplies a series of fittings and

attachments that allow connection between

the storage tank unit and domestic hot water

system. The pump kit attachment is also

envisioned on the template.

• Column attachment kit (on request for UB

INOX 200 ErP) A vertical connection kit is

envisioned for the connection of the storage

tank unit to the column, which allows to

connect the storage tank unit directly to the

boiler without having to insert the connection

pipes into the wall.

• Solar collectors kit (on request for UB INOX

120-200 ErP) On request Immergas supplies

complete packs for set-up, if solar collectors

are to be used for the production of domestic

hot water.

• Double storage tank kit in parallel (on request

for UB INOX 200 ErP) A connection kit is

envisioned for the connection of two storage

tank units in parallel, which allows connection

of the two storage tank units directly to the

boiler without having to insert the connection

pipes into the wall.

• Solar panels kit in parallel (on request for UB

INOX 200 ErP) For the connection of two

storage tank units to the solar panels without

having to insert the connection pipes into the

wall.

• Storage tanks pump kit in parallel (on request

for UB INOX 200 ErP) For the connection

of two storage tank units to the recirculation

pump pipes without having to insert the

connection pipes into the wall.

• Electronic anode kit (on request).

(Not available for UB INOX 80 ErP).

Direct current is made to circulate between the

device and the tank to be protected via a special

titanium anode.

Use the tting present on the storage tank upper

ange for installation of the anode (Free tting

for UB INOX 200 ErP, or replacing the anode

present in the UB INOX 120 ErP).

e above-mentioned kits are supplied complete

with instructions for assembly and use.

Head (kPa) Head (kPa) Head (kPa)

Flow rate (l/h)

Flow rate (l/h)

Flow rate (l/h)

Head (m H2O) Head (m H2O) Head (m H2O)