5

INSTALLERUSER

MAINTENANCE TECHNICIAN

1STORAGE TANK

UNIT INSTALLATION

1.1 INSTALLATION

RECOMMENDATIONS.

Only professionally enabled companies are au-

thorised to install Immergas appliances.

e place of installation of the appliance and

relative Immergas accessories must have suitable

features (technical and structural) such to allow

(always in safety, efficiency and comfortable

conditions):

- installation (according to the provisions of the

technical legislation and technical regulations);

- maintenance operations (including scheduled,

periodic, routine and special maintenance);

- removal (to outdoors in the place for loading

and transporting the appliances and compo-

nents) as well as their eventual replacement

with appliances and/or equivalent components.

Installation must be carried out according to

regulation standards, current legislation and

in compliance with local technical regulations

and the required technical procedures. Before

installing the storage tank unit, ensure that it is

delivered in perfect condition; if in doubt, contact

the supplier immediately. Packing materials (sta-

ples, nails, plastic bags, polystyrene foam, etc.)

constitute a hazard and must be kept out of the

reach of children.

If the storage tank unit is installed inside or

between cabinets, ensure there is sucient space

for normal servicing. It is advisable to leave an

adequate gap between the storage tank casing

and the sides of the cabinet.

In the event of malfunctions, faults or incorrect

operation, turn the storage tank o and contact

an authorised company (e.g. the Authorised

Technical Assistance centre, which has specical-

ly trained sta and original spare parts). Do not

attempt to modify or repair the appliance alone.

Failure to comply with the above implies personal

responsibility and invalidates the warranty.

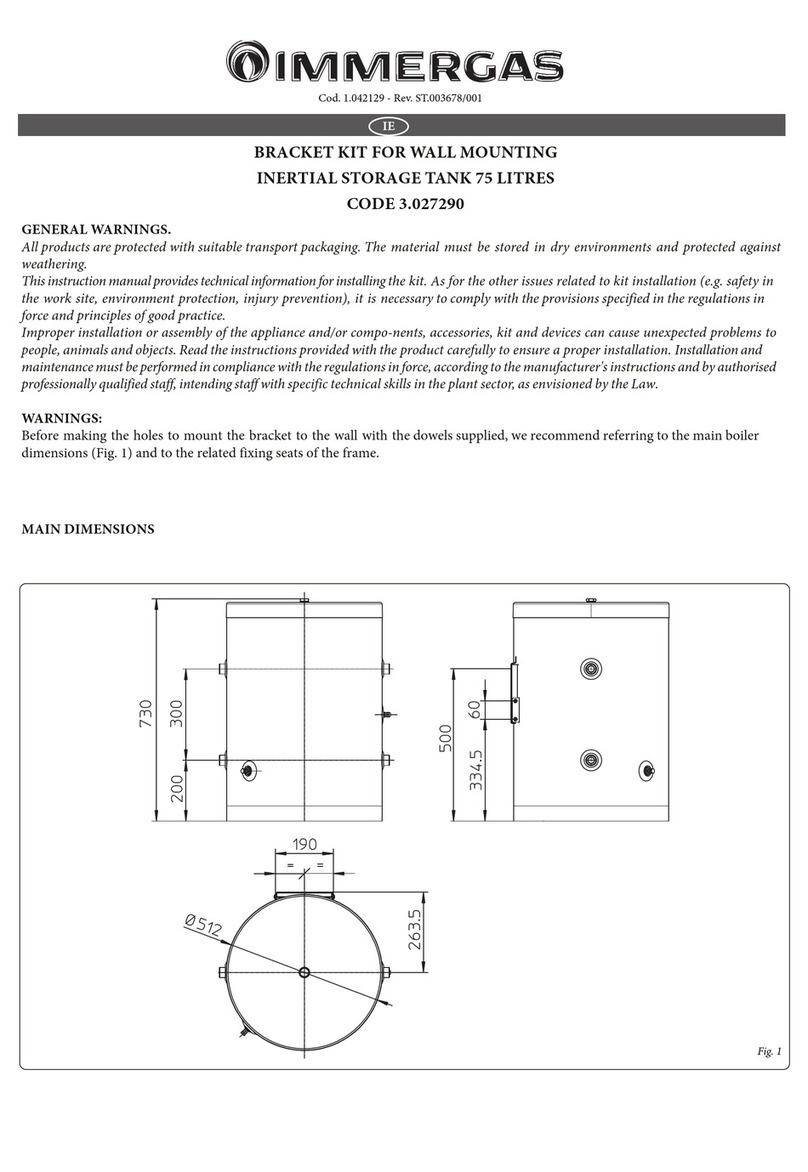

• Installation standards: check the features of the

installation area in advance, in terms of overall

dimensions and weight of the cylinder, setting

up a supporting surface under the storage tank

if necessary, to optimise weight distribution.

ese storage tanks have been designed for

oor installation only; they must be used for

the storage of domestic hot water and similar

purposes. ey have not be designed for wall-

installation. Ensure that the useful heat output

of the generator is at least 15% higher than the

heat output that can be absorbed by the stor-

age tank, and that the volume and factory-set

pressure of the expansion tank of the secondary

circuit are suitable for the system;

Attention: this storage tank unit is designed to

produce and store hot water, it must therefore

be connected to a heating system, to a domestic

hot water distribution network and to the water

system, compatibly with its specications and

heat output. e materials used for installation

and connection must be fully compatible with the

minimum characteristics required for solar use.

It must also be installed in rooms where the

temperature cannot fall below 0°C. It must not

be exposed to the eects of the weather.