2

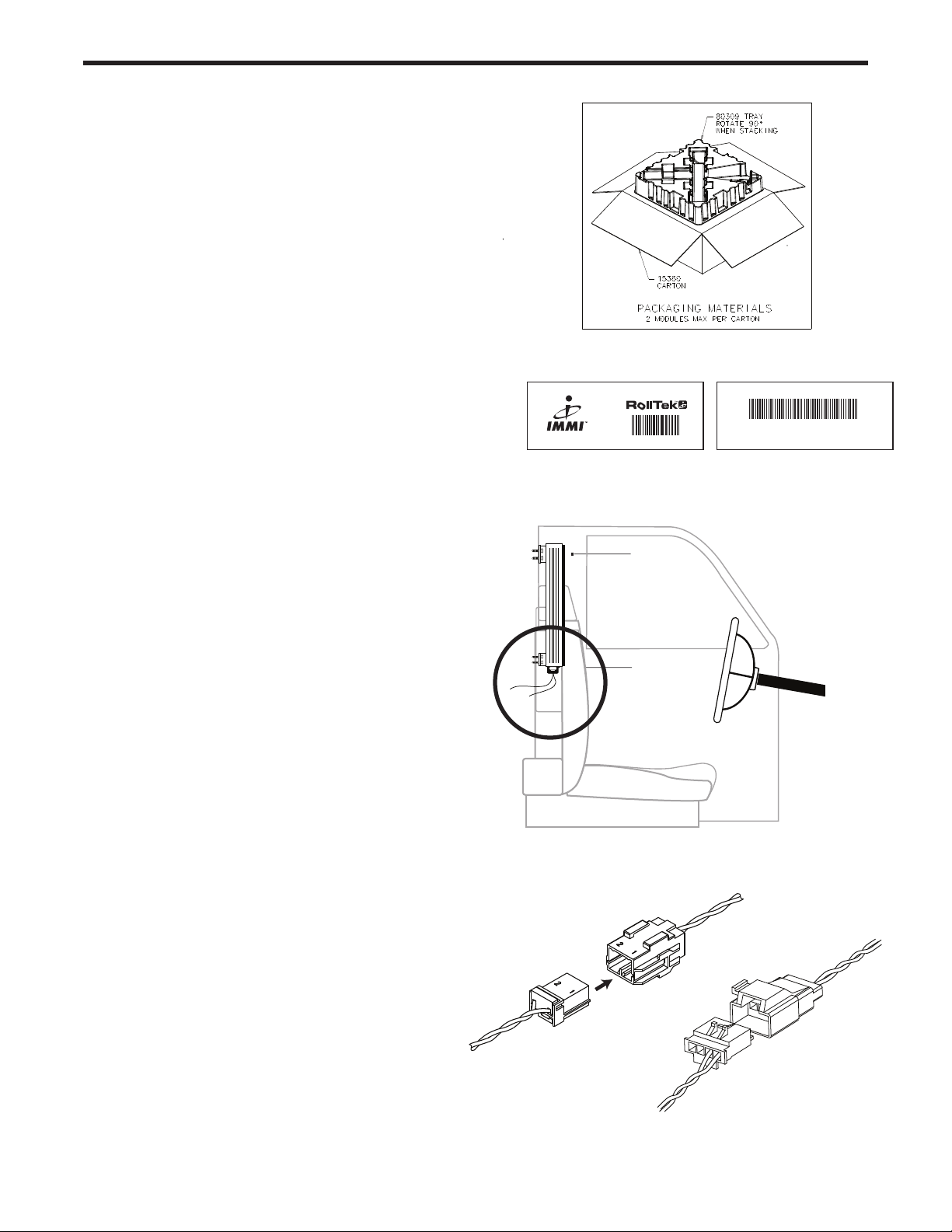

Unpacking the IHC

1. Remove unit from main carton. There can be up to 2 units of same

part number. See FIGURE 1

2. If parts need to be returned, they must be returned in the original

packaging, assuring conformance to all applicable regulations for

transportation of Class 9 Dangerous Goods.

Product Identification

1. Locate the product identification labels, located on the back

side of the unit. See FIGURE 2.

2. Verify your unit is the proper system for your configuration.

3. Scan or manually record unit S/N. Retain this record for 20 years.

Mounting IHC to Vehicle Wall

1. The module is fastened to a structural member of the vehicle or to a

seat-mounted bracket via four (4) #10 - 32 captive studs. See

FIGURE 3. If studs are not supplied with module, installer must use

equivalent Grade 8 fasteners.

2. Metal to metal contact is preferred on all mounting points.

Mounting over trim panels is not recommended.

3. Position unit in place and route harness. Make sure wiring harness

is free and not pinched under unit. See FIGURE 3.

4. DO NOT MAKE WIRING HARNESS CONNECTION TO UNIT AT

THIS TIME.

5. If mounting studs are provided, use Grade 2 locknuts (or

equivalent.) Hand start nuts onto studs.

6. Torque nuts on the studs to 5.7 - 6.2 N-m.

Electrical Connection and Test

1. Ensure battery switch is OFF.

2. Make connection between cab wiring harness and IHC.

See FIGURE 4.

3. Verify that both plugs and connectors are latched together.

IHC

Figure 2

Figure 3

Figure 1

Top

Bottom

or

Figure 4

PN80275 Rev 01 12/17 2376P

©2017 IMMI All rights reserved.