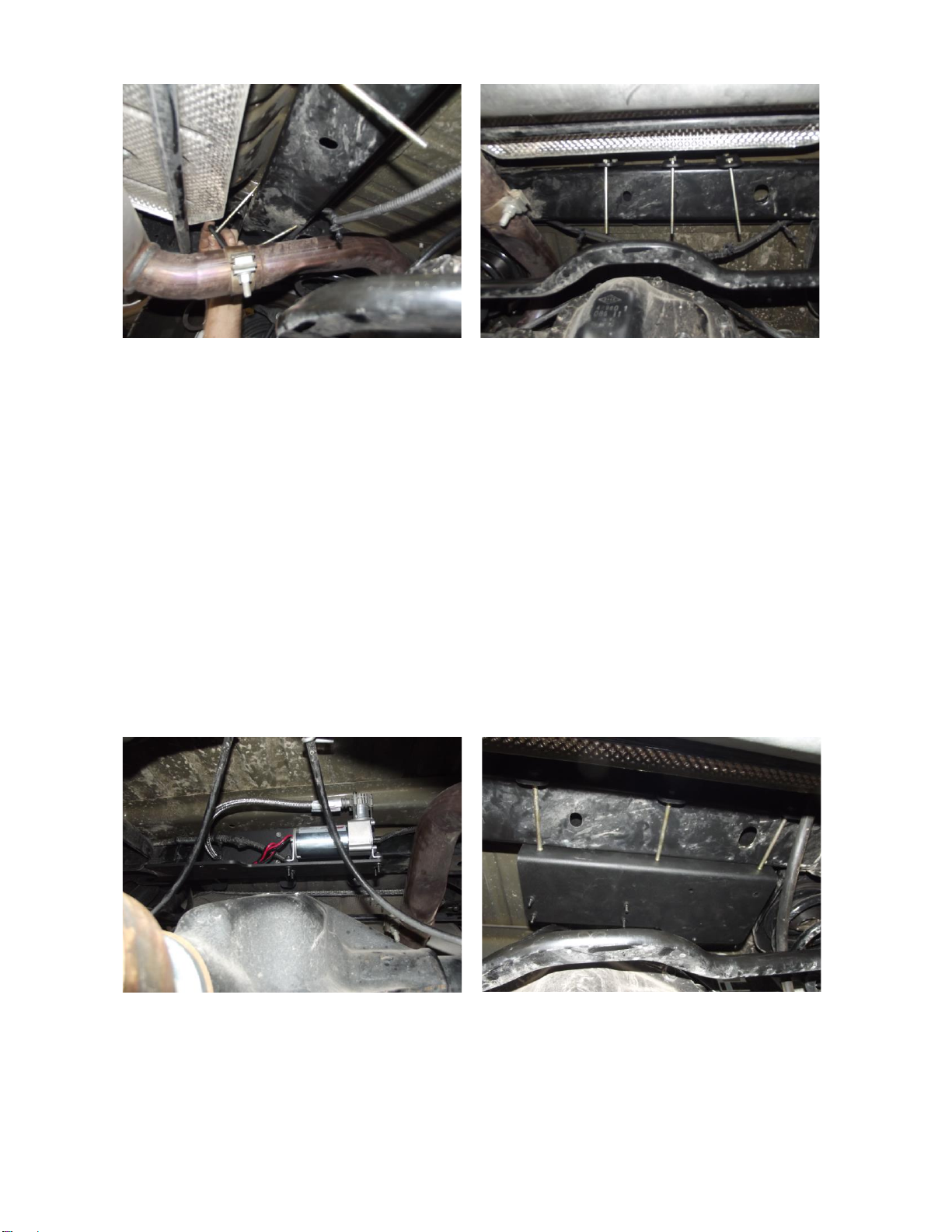

8. Use the supplied wire ties to secure the factory wiring harness that was detached earlier to

the holes on the compressor mounting bracket.

Mounting the air tank

1. After all electrical connections have been completed, pressure test the tank before bolting

it to the bracket. To pressure test the tank, complete your wiring and turn on the ignition

to run the compressor. Once the pressure switch shuts the compressor off, spray soapy

water on all the air connections at the tank. If you see bubbles, tighten the connection

slightly or add more Teflon tape.

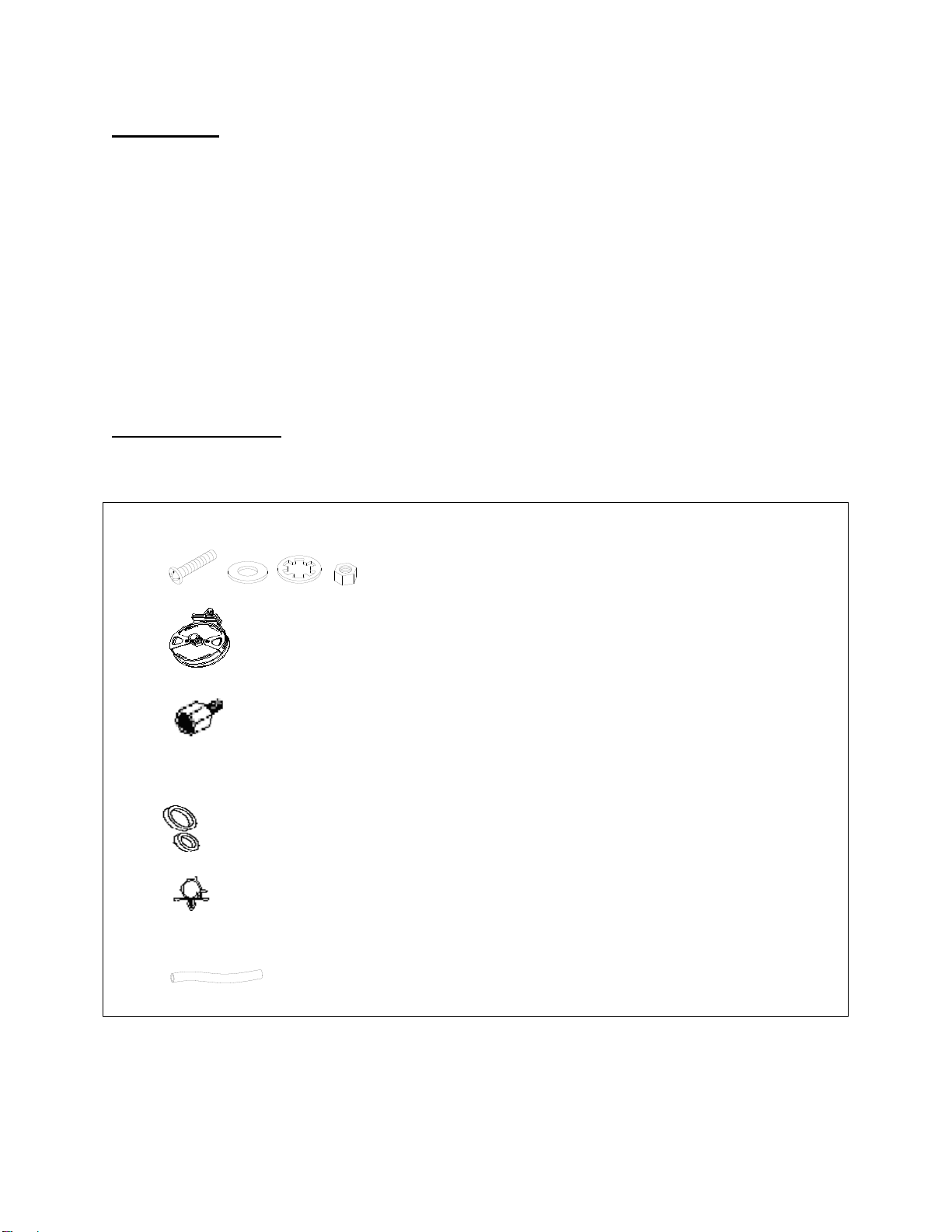

2. Once you have pressure tested the system, the tank can be mounted to the bracket. Use

the four nuts, bolts and washers included in hardware package #1. Install the bolts from

the top downward. Helpful Tip: The passenger side rear bolt will be difficult to access.

Use a piece of electrical tape to temporarily hold the bolt into the tank’s foot when doing

your final positioning of the tank on the bracket.

COMPRESSOR OPERATING INSTRUCTIONS

IMPORTANT: The compressor has a maximum working pressure of 120 PSI and is capable of

9% duty cycle. It is designed for use with air horns, air bags and other accessories that utilize the

compressed air stored in the tank. Always operate the compressor at or below the MAXIMUM

PRESSURE RATING of the compressor. Operation exceeding maximum pressure ratings and or

duty cycle will result in damage to air compressor.

1. Your air compressor is equipped with an AUTOMATIC THERMAL OVERLOAD

PROTECTOR. This feature is designed to protect the air compressor from overheating and

causing permanent damage to your air compressor. The thermal overload protector will

automatically cut off power to your air compressor should the internal operating temperature

of the air compressor rise above safe levels during excessive use.

2. Should your air compressor automatically shut off while in use; do not attempt to restart the

air compressor. Turn power switch to the air compressor to the OFF position. The automatic

thermal overload protector will automatically reset when internal temperature of the air

compressor drops below safe level. After allowing air compressor to cool off for about 30

minutes, you can safely resume use of the air compressor by turning on the air compressor.

3. To prevent discharge of your vehicle’s battery and to provide peak performance, we strongly

recommend that you keep the vehicle’s engine running while using the air compressor.

4. ONLY OPERATE THE AIR COMPRESSOR IN WELL-VENTILATED AREAS.

Compressor Maintenance & Repairs

1. Periodically check all electrical and fitting connections. Clean and tighten as needed.

2. Periodically check all mounting screws. Tighten as needed.

3. Replace air filter element periodically. Replacement frequency depends on operating

frequency and operating environment. For frequent use in dusty environment, you should

replace air filter element more often.

4. Regularly clean dust and dirt from compressor.