IMR 1100F User manual

IMR Environmental Equipment, Inc.

IMR 1100F

2

INTRODUCTION 3

SAFETY INSTRUCTIONS 3

1GENERAL 3

1.1 IMPORTANT NOTES ON OPERATION OF THE METER 3

2DESCRRIPTION 4

2.1 OVERVIEW WITH TECHNICAL DATA 4

2.2

CONNECTORS

5

2.2.1

GASNipple(Gas sampling probe) 5

2.3 POWER SUPPLY / BATTERY 5

2.4 CONTROLS 6

3OPERATION 7

3.1 TURNING 7

3.2 MEASURE 7

3.3 PRINT 8

3.3.1

IR-Printer A740 (optional) 9

3.4 SAVE 10

3.5 STORED MEASUREMENTS 11

3.6 LIGHTING 11

3.7 DATE / TIME 12

3.8 OFF 12

4 BRIEF SUMMARY OF OPERATIONS 13

5 ERROR MESSAGES 14

6 SPARE PARTS & SUPPLIES 14

7 WARRANTY 15

8 DISPOSAL OF WASTE EQUIPMENT 16

9 IMR USA 16

IMR Environmental Equipment, Inc.

IMR 1100F

3

INTRODUCTION

Thank you for purchasing the flue gas analysis computer in IMR 1100F.

Please read the manual before using the appliance and observe the following safety tips

SAFETY INSTRUCTIONS

Please observe all instructions that are printed on the product.

The analyzer may only be opened and serviced by qualified personnel. When servicing,

make sure that the instrument is never repaired standing under pressure.

During the warranty period, do not open the device as this would invalidate the warranty.

Do not place anything on the unit, in particular, no objects filled with liquids. Liquid must

not penetrate into the device; otherwise there is a risk of a short circuit or electric shock.

The device must not be used in water.

1 GENERAL

The IMR 1100F is a sophisticated flue gas analyzer, which for CO measurement on trucks

with LPG - combustion engine according to §§ 33 and 37 UVV "Use of Liquid" (BGV D34)

can be used.

1.1 IMPORTANT NOTES ON OPERATION OF THE METER

A pump sucks the gas through the gas sampling probe and the condensate trap and feeds it to

sensor. In the condensate trap is condensed water and deposited in the dust filter fine dust

particles.

The electrochemical CO sensor is a highly sensitive and selective gas transmitter, which could

get damaged by improper handling. For this reason, must never be measured without filter.

Drain the condensate trap after each measurement and rinse the device after each measurement

with fresh air to the CO sensor indicates less than 15ppm.

Also look in the winter time that the machine is warming up before a measurement, so there is

no condensation inside the unit. This would result in an incorrect measurement and in damage

of the sensor.

The device should not be used for a long time, make sure it is stored in a dry place.

IMPORTANT INSTRUCTIONS!

Annual calibration and maintenance

Operating Temperature 10°C to 40°C

Storage temperature -20°C to 50°C

Never take measurements without filter / condensate trap

Empty the condensate trap after each measurement

Ventilate the meter with fresh air after each measurement

Replacement of the dust filter

For defects on the sensor due to condensation or improper handling, no guarantee can be given.

IMR Environmental Equipment, Inc.

IMR 1100F

4

2 DESCRIPTION

2.1 OVERVIEW WITH TECHNICAL DATA

The flue gas analyzer is equipped

IMR 1100F follows.

The adjacent picture shows the

IMR 1100F the case with infrared

printer, gas sampling probe and

condensate trap.

STANDARD EQUIPMENT

IMR 1100F Meter in soft case with carrying case

Gas sampling probe, curved flexible Rohr 300mm, probe tube 2m

Condensate trap with integrated filter

Thermal printer ( optional)

3 AA batteries

Memory

User manual

Calibration

OPTIONAL ACCESSORIES

Hose Extensions

CD100

–Gas leak detector for gas-powered trucks

SPT1 –Smoke tester

IMR900 –Soot Meter with decimal place

INF155 –Infrared Thermometer

RLD10

–Refrigerant Leak Detector

DTH51

–Hygrometer with IR-Thermometer

TECHNICAL SPECIFICATIONS

Power Supply

3 x AA Batteries

LCD

Illuminated

Gas sampling probe

Flexible Pipe, 300mm

Operating

-10°C to 50°C

Storage Temperature

-20°C to 50°C

IMR reserves the right to change technical reserves.

FEATURES

Data memory for 50 measurements

GAS SENSOR

CO Carbon Monoxide 0-10.000 Vol. %

IMR Environmental Equipment, Inc.

IMR 1100F

5

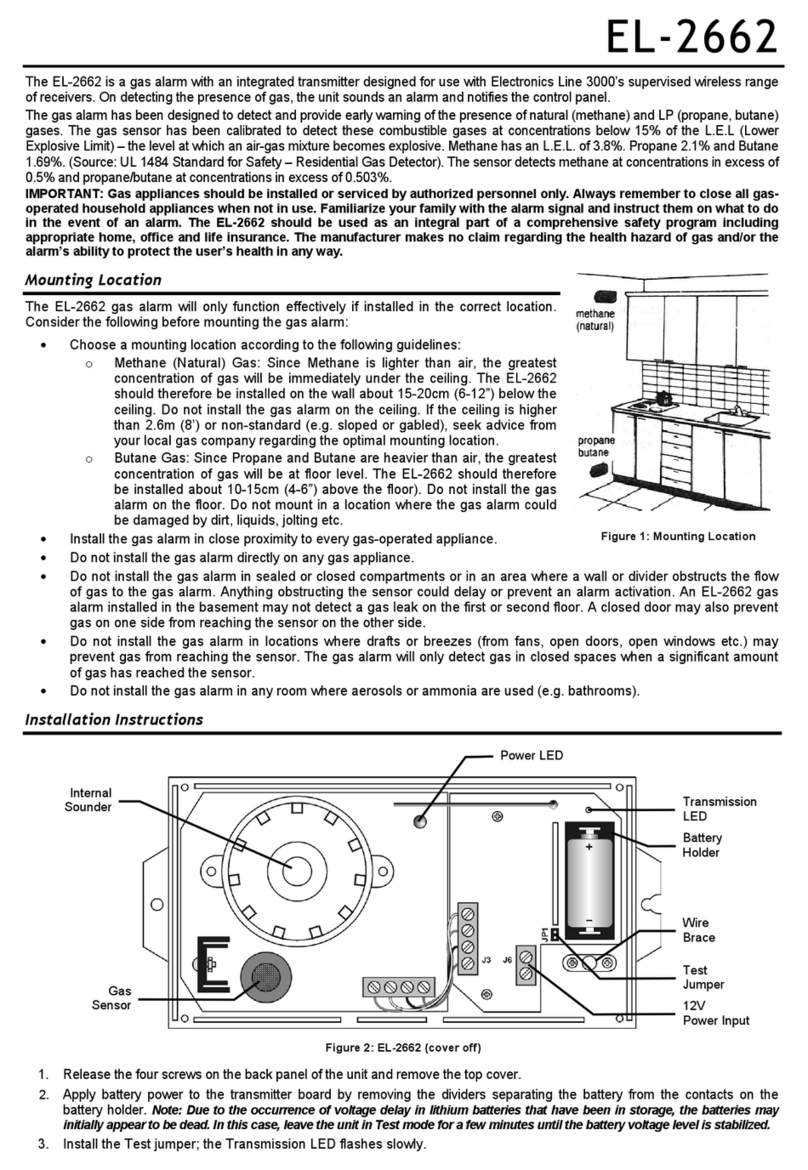

2.2 CONNECTORS

GAS –Gas inlet nipple (probe tube)

2.2.1 GAS Nipple (Gas sampling probe)

Before the device can be put into operation, the gas

sampling probe must be connected to the analyzer.

For this purpose, the tube of the probe is placed on

the bag filter and this is then placed on the “GAS”

nipple plugged.

The gas sampling probe must not be introduced into the

flue gas duct during zeroing.

2.3 POWER SUPPLY / BATTERY

The IMR 1100F is equipped with 3 x AA cell batteries. These batteries must be charged in a

separate charging station. The batteries can be used more than 6 hours.

The battery compartment is located on the back. To remove the batteries, first a screw must be

loosened to open the flap.

Please make sure that changing the batteries in the correct polarity.

Rear Battery Compartment

IMR Environmental Equipment, Inc.

IMR 1100F

6

▲

2.4 CONTROLS

IR-transmission-

LED

GAS-ENTRANCE

GAS-EXIT

Upon turning on 2 seconds –on / off switch

SWITCHING –from the current CO value to Max value and vice versa

ENTER –Confirmation key

Up Arrow –is as requires at date / time

Down Arrow –is as requires at date / time

Store –call the stored measurement or the last calibration date

Save –Saves the current reading in one of the 50 memory locations

Function –switch the current measurement for the date / time display

Lighting –press for 2 seconds to turn on the lights

Print –prints the current measured value, the stored value or the last calibration

measurement

▲

RECALL

IMR Environmental Equipment, Inc.

IMR 1100F

7

3 OPERATION

3.1 TURNING ON

IMPORTANT NOTE

-Before the exhaust gas measurement of motor of the truck must be warm!

-There should be no measurement done on a cold engine, as this would distort the

measurements and adjustments.

3.2 MEASURE

MAXIMUM CO-VALUE (Peak)

Connect as described above, first the gas sampling probe and the

small bag filter with the IMR 1100F and then turn on the device.

For the ON/OFF button for 2 seconds must be pressed. The unit

starts with a zero point calibration, and these must be carried out

in fresh air.

The zero point calibration takes 30 seconds. The meter examines

the sensor at this time and all other components. If an error occurs

a message is displayed. After a successful zero calibration will take

you directly to measure.

Now run the gas sampling probe into the exhaust one, while the

probe is fixed to the bracket in the exhaust. Immediately thereafter,

the CO value of the burn process appears. IF the readings are stable,

it takes about 3 minutes, can be printed or saved measurement.

IMPORTANT NOTE

-

The flue gas analysis should be carried out in partial load (neutral).

-

In accordance with §§ 33 to 37 UVV “Use of Liquid” (BGV D34) may the CO

value when the engine is warm no greater than 0.1 Vol.%(=1000ppm).

-

If the measured value exceed 0.1 Vol.%, an alarm will sound.

IMR Environmental Equipment, Inc.

IMR 1100F

8

3.3 PRINT

The measured values can also be printed on the optional printer.

The IR transmitting LED of the meter, which is located on the left side.

-------------------------------------------------------------------------------------------------------------------------------------------

IMR Environmental Equipment, Inc.

IMR 1100F

9

IMR Environmental Equipment, Inc.

IMR 1100F

1

0

3.3.1 -Printer A740 (optional)

Operation

Taste 1: On/Off switch –Red LED is on when the printer is turned on

Taste 2: Contrast –yellow = low; Green = normal; Red = high

Taste 3: Paper feed

Paper exchange

Ensure that the paper is loaded properly (Thermal coating!)

-Opening the cover

-Cut the paper pointed to and run it into the sheet feeder and press the paper feed

button while.

-Close cover

Batteries

-4 x AA Mignon cells

-Optional AC-Adapter charges the batteries.

Technical specifications

Maximum Transmission Distance 45cm

Horizontal Transmission Angle +/- 30°

Vertical Transmission Angle -10° to +20°

Batteries 4 x AA Mignon Cells

AC Adapter DC 7V / 1500mA

Thermal Paper b = 57mm

Operating Conditions 0 –50°C / 5-80% RH

Storage Temperature -10°C to 60°C

IMR Environmental Equipment, Inc.

IMR 1100F

11

3.4 SAVE

IMR Environmental Equipment, Inc.

IMR 1100F

10

3.5 STORED MEASUREMENTS

3.6 BACKLIGHT

To turn on the backlight, the "FUNC" button for 2 seconds must be pressed. The backlight

is switched on and is automatically switched off again after 20 seconds. A small icon also

appears on the display.

IMR Environmental Equipment, Inc.

IMR 1100F

12

3.7 DATE / TIME

To display the time and date, the “FUNC” button must be pressed. To make changes,

follow these steps:

3.8 OFF

IMPORTANT NOTE

-Please when removing the probe, make sure that the probe tip can still be hot!

-Please empty the condensate trap after each measurement and replace if necessary the

dust filter!

-Please ventilate the instrument before switching off with fresh air.

-The meter can only be turned off if the CO value is less than 15ppm.

To turn off the on/off switch and a ventilate cycle begins

and the meter turns off automatically after this countdown

from.

The IMR 1100F also turns off automatically after 10 minutes, if the CO value is

below 15ppm and no key is pressed in the last 10 minutes.

IMR Environmental Equipment, Inc.

IMR 1100F

13

4 BRIEF SUMMARY OF OPERATIONS

CONDENSATE TRAP BEFORE TURNING INSPECT AND EMPTY!

Switching on:

DANGER:

–

TASTE 2 Hold seconds

STE

30sCal

Reading

CO

-

But gas sampling probe connect not introduce into the exhaust!

-

Truck must only be measured in operating temperature!

-

The flue gas analysis should be carried out in partial load / idle!

-

The CO limit amounts to according to §§ 33 und 37 UVV

“Use of Liquid"(BGVD34)0.1Vol.%= 1000ppm!

CO-MAX-WORTH

ENTER

ENTER Display

Of Max-Worth

PRINT

↑, ↓

ENTER

↑, ↓

ENTER

PRINT

Select of

“rEAL“ Mode

(should flash)

Confirmation

of expression

of “rEAL“

Mode

Break up-

“YES“

Select

(should flash)

SAVE

ENTER

↑, ↓

ENTER

↑, ↓

ENTER

STORE

Confirm

Selection of stored

Confirm

Break up –“YES”

Confirmation

the storing

Measurement

(number flashes)

number

select

(should be flashing)

and back to

measuring menu

MORE KEYS:

General selecting numbers: ↑, ↓- TASTE

Calling stored measurements:

RECALL-KEY (see INSTRUCTIONS)

Changing the display of the measured value to date-time: FUNC-TASTE

Lighting switched On:

FUNC-BUTTON

2 illumination and hold

2 seconds goes out automatically

after 20 seconds.

I

-

Button

OFF

Please ventilate the instrument before switching off with fresh air!

The instrument can only be turned off when theCO-level is below 15ppm!

The unit automatically turns off after 10 Minutes if no key is pressed –but only if the CO level

is below 15ppm.

DANGER:

When removing the gas sampling probe, make sure that the probe tip is still hot!

CONDENSATE TRAP AND FILTER AFTER SWITCHING OFF AND IF NECESSARY. DRAIN OR

SWAP!

Confirmation

and back to

measuring

menu

Confirmation

and back to

measuring

menu

IMR 1100F

I

–

TA

IMR Environmental Equipment, Inc.

IMR 1100F

14

5 ERROR MESSAGES

The IMR 1100F is equipped with a number of Self check to ensure trouble-free operation.

If an error is detected, it is displayed. Thereafter, no further measurements should be

performed, but the cause of the error will be corrected as soon as possible.

ERROR

DECLARATION

POSSIBLE ERRORS

SHOOTING

Flo

Err

Flow Rate

Incorrectly

Blocked probe tube

Check and fix

Contaminated dust fine filters

Replace filters

Defective Pump

Back to Service

InIt

CO

Err

CO Sensor could

not calibrated

become

Probe during

Zeroing in exhaust gas

flow

Abgasstrom

Disconnect the

probe and recalibrate

Unit has not flushed at last

switch

Ventilate the machine for

20 minutes with fresh air

CO Sensor malfunction

Back to Service

Lo

Batt

Battery voltage

too low

Battery empty

Replace batteries

oFl

CO overflow

Measured CO value is too

high

Remove the probe and

ventilate the device with

fresh air

6 SPARE PARTS & SUPPLIES

Please enter the model and serial number known if you want to order spare parts.

DESCRIPTION

ARTICLE NO.

10 Filter in a Box

72550

Bag house

11763

Condensate trap

91101

Flexible probe

11785

CO-Sensor 0-100,000ppm

11792

Soft case

11765

Suitcase

115533

IR-Printer (A740)

11740

Printer paper w=58mm

71250

Soot filter

70350

Comparative scale

90300

Gas output jack

11764

IMR Environmental Equipment, Inc.

IMR 1100F

15

Warranty

IMR Environmental Equipment, Inc. states the following:

IMR hereby grants the following worldwide IMR warranty for an IMR analyzer purchased from

an authorized dealer.

1. The IMR warranty shall entitle every IMR customer to demand a free replacement or repair

of the defective parts from any IMR dealer authorized for the respective IMR unit.

2. The IMR warranty shall be granted on the factory new unit and shall commence on the date

of the delivery of the original IMR unit to the customer. It shall last for a period of twelve

months regardless of the type and the intensity of use and regardless of any change of

owner, which may occur during this warranty period.

3. The IMR warranty shall refer to absence of faults with respect to the state of the art nature

of the sold unit in terms of material and finish. The warranty for all parts fitted during the

twelve-month warranty period shall end with the unit warranty.

4. After the establishment of a material or production fault by IMR or the authorized IMR

dealer, the faults will be eliminated by means of free repair or replacement. Replaced parts

shall become the property of IMR.

5. No warranty claims may be made for maintenance and setting work, cleaning or other utility

materials required for the function of the unit and other wear parts unless they have a direct

bearing on work performed under the warranty.

6. The terms and conditions for the acknowledgement of this warranty shall be the

presentation of the fully completed warranty card, which must contain the confirmation from

the authorized IMR dealer on its delivery and, if applicable, the prescribed maintenance work.

7. The IMR warranty shall only be applicable if

a. The analyzer has been maintained in accordance with the instructions issued by the

manufacturers and the operating instructions by an authorized IMR dealer.

b. Only original IMR spare parts have been used for any repairs.

c. The unit has been used properly, the operating instructions observed and the unit has not

been used for a purpose other than the one for which it has been designed.

d. The IMR unit has been left in its original design and meets the original IMR specifications.

e. The fault is not due to external influences or use for a purpose other than the one for which

it has been designed.

f. Exclusively authorized IMR dealers have made repairs to the IMR unit.

g. The IMR unit has been sent to an authorized IMR dealer immediately after the fault was

discovered.

8. Warranty time for the analyzer, including electrochemical sensors is 12 months.

IMR Environmental Equipment, Inc.

3634 Central Ave.

USA –St. Petersburg, FL 33711

Ph: +1-727-328-2818

Fax: +1-727-328-2826

Email: info@imrusa.com

Web: www.imrusa.com

Table of contents

Other IMR Gas Detector manuals