INDCO, Inc. M-M-30128 mixer manual TMD date: 1/5/05

Safety

Please follow the below safety precautions. If there are any

questions, please call INDCO at 800-942-4383.

Please read this complete manual before trying to operate

your mixer. Failure to follow these instructions could result

in serious bodily injury or death.

• Do not touch moving parts while mixer is operating.

Do not wear loose-fitting clothes or jewelry around an

operating mixer. Keep all hands, feet, clothes, neckties,

necklaces and other objects clear of moving parts.

• Never move the unit without a suitable lifting device.

• Have a qualified individual bring power to your unit.

• Always ground the unit. Never use an extension cord.

• Never run the unit in open air.

• Never adjust the speed without the unit running.

• Always lockout the power when working on the unit.

Electric Motor Safety:

Motors should be installed, protected and fused in accordance

with latest issue of National Electrical Code, NEMA Standard

Publication No. MG 2 and local codes.

Not all rotating parts are guarded. Keep hands and clothing

away from moving parts.

Trained, qualified personnel should make electrical repairs

and non-standard connections.

If environment has hazardous combustible fumes present,

use only explosion-proof electric motors.

Air Motor Safety:

The air motor is designed to be driven by compressed air and

under no circumstances be driven with any other gases.

Fluids, particles, solids or any substance mixed with air,

particularly combustible substances likely to cause

explosions, must not drive air motor.

• Do not drive with flammable or explosive gases.

• Air motor is designed for air only. Do not allow corrosive

gases or particulate material to enter motor. Water

vapor, oil-based contaminants, or other liquids must

be filtered out.

• Do not use a hammer or force coupling or drive pulley

onto shaft when installing drive onto air motor. This

causes end thrust that could damage air motor.

• Ambient temperature should not exceed 250°F.

• Beware of any exposed and/or movable parts. Proper

guards should be in place to prevent personal and/or

property damage.

General

• Single-phase TEFC models include cord, plug and switch.

• Three-phase models must be wired in the field by user.

• Ex-Proof models must be wired in the field by user.

• DC-Variable-Speed electric models have a controller

mounted to the mixer and they are pre-wired.

• Air motors include exhaust muffler & speed control valve.

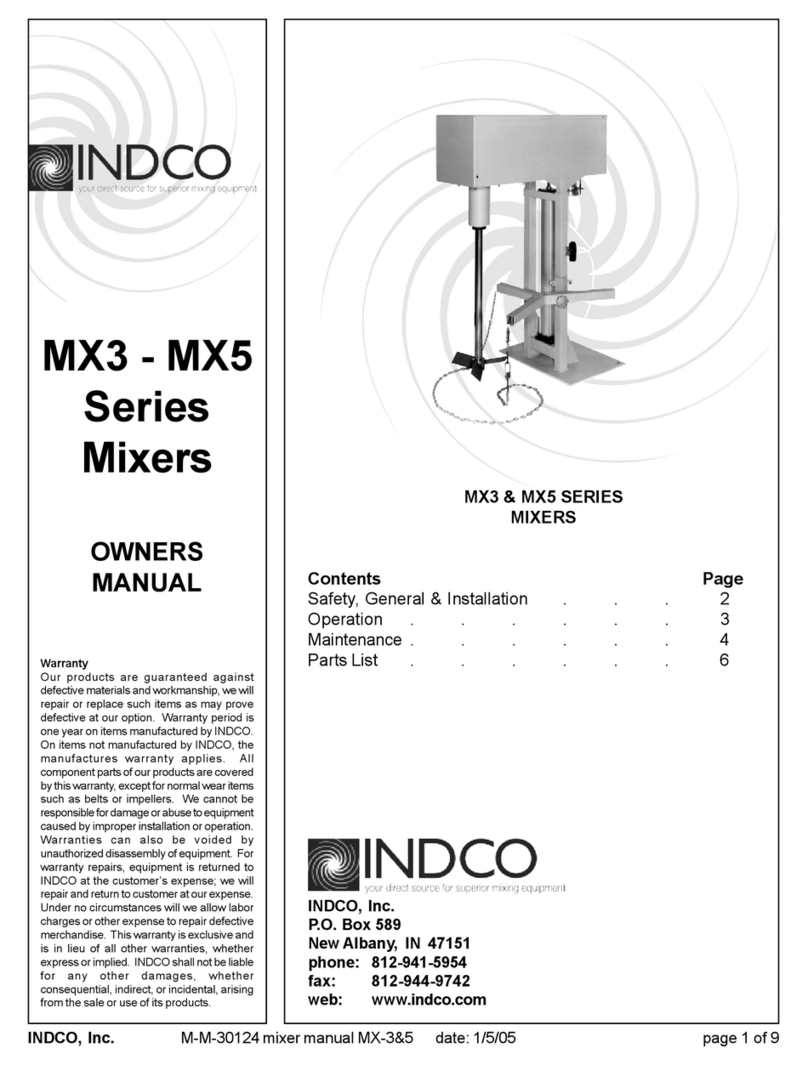

TMD - Plate Mount Series

These top entry tank mixers can be channel or beam

mounted on open tanks, or mounted on closed tanks which

are operated under atmospheric conditions. (non-sealed)

Mounting is on a rugged flat steel plate supplied as standard

equipment with predrilled holes. Carrier bearing offers

maximum shaft support, reducing motor and gearbox wear

and minimizing shaft wobble.

Receiving

Before removing any packing, visually inspect the exterior

of the shipment for any sign of damage. Should there be

any damage, bring it to the attention of the delivering UPS

or truck line and note the same on the receiving ticket.

Should there be damage you must place a claim with the

truck line. They are the only ones who will pay for the

damage done and you are the only one who can place that

claim.

page 3 of 9