INDCO FGM 5 Gal Series User manual

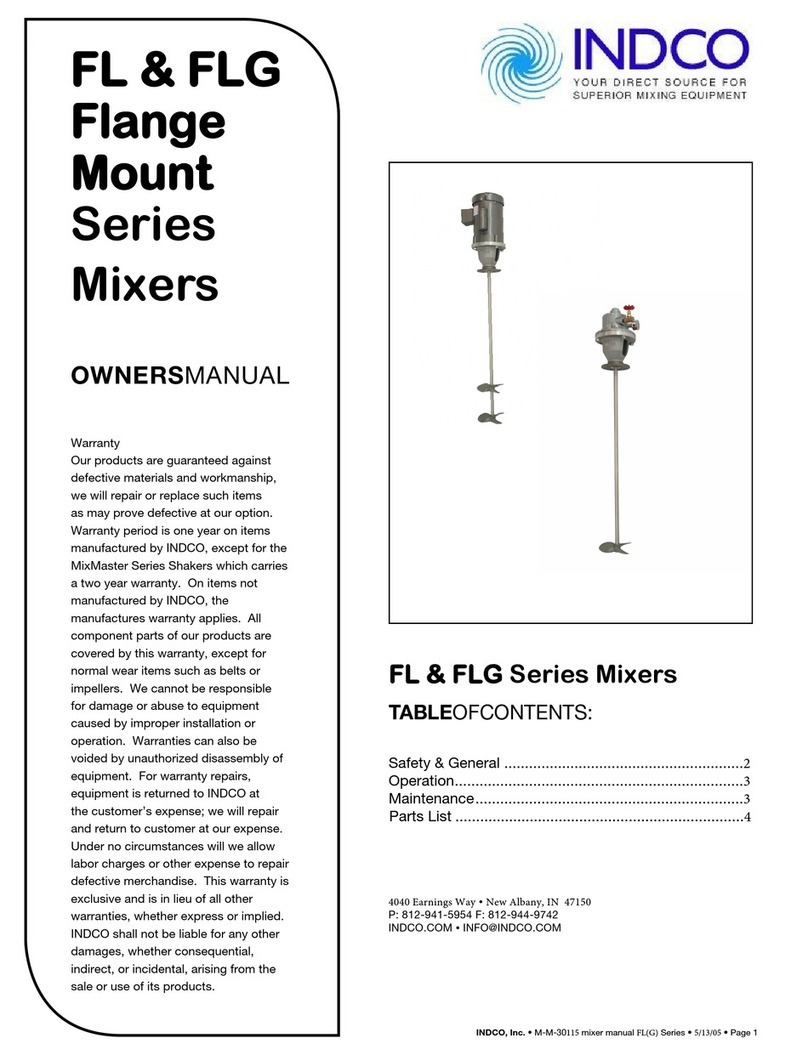

FGM Series Mixers

tablEOFCONTENTS:

Safety & General ..........................................................2

Operation......................................................................3

Parts List ......................................................................4

4040 Earnings Way •New Albany, IN 47150

P: 812-941-5954 F: 812-944-9742

INDCO, Inc. • M-M-30114 mixer manual FGM Series • 5/13/05 • Page 1

FGM

5 Gal

Series

Mixers

OWNERSMANUAL

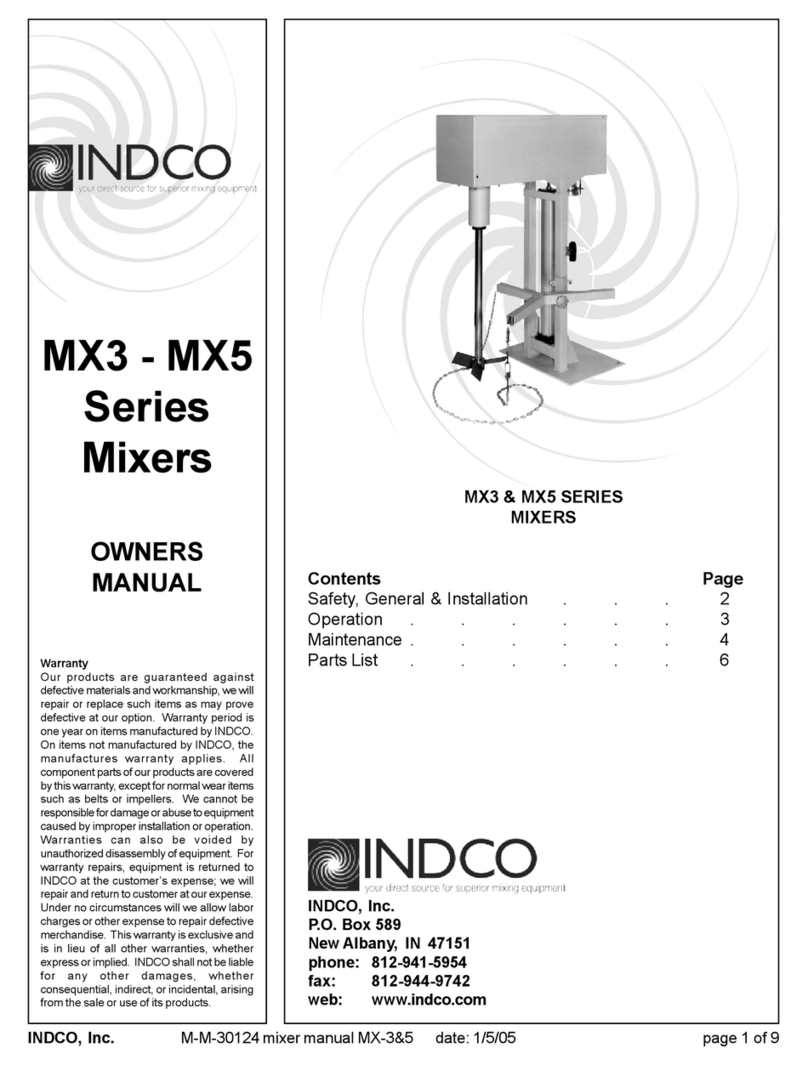

Warranty

Our products are guaranteed against

defective materials and workmanship,

we will repair or replace such items

as may prove defective at our option.

Warranty period is one year on items

manufactured by INDCO, except for the

MixMaster Series Shakers which carries

a two year warranty. On items not

manufactured by INDCO, the

manufactures warranty applies. All

component parts of our products are

covered by this warranty, except for

normal wear items such as belts or

impellers. We cannot be responsible

for damage or abuse to equipment

caused by improper installation or

operation. Warranties can also be

voided by unauthorized disassembly of

equipment. For warranty repairs,

equipment is returned to INDCO at

the customer’s expense; we will repair

and return to customer at our expense.

Under no circumstances will we allow

labor charges or other expense to repair

defective merchandise. This warranty is

exclusive and is in lieu of all other

warranties, whether express or implied.

INDCO shall not be liable for any other

damages, whether consequential,

indirect, or incidental, arising from the

sale or use of its products.

INDCO, Inc. M-M-30114 mixer manual FGM date: 5/13/05

General

The ring mount provides steady, worry-free mixing. Ideal for

mixing colorants into paint, remixing settled material or

blending powders into liquids. All models are supplied with

5/8” diameter stainless steel shafts equipped with “Quic-

Change Couplers”, which eliminates the bother of fumbling

with set-screws when changing or cleaning mixing shafts.

Shafts twist on and off without tools. Fits 5-gallon pails with

lids up to 12-1/4” outside diameter.

Standard Features:

• 5/8” diameter x 15” long shaft - 316 stainless steel.

• Quic-Change Coupler for easy shaft removal.

• 9” diameter, 2-blade Propellers - 319 aluminum.

• Electric models have cord, plug & switch.

• Air models have speed control valve & exhaust muffler.

Receiving

Before removing any packing, visually inspect the exterior of

the shipment for any sign of damage. Should there be any

damage, bring it to the attention of the delivering UPS or

truck line and note the same on the receiving ticket. Should

there be damage you must place a claim with the truck line.

They are the only ones who will pay for the damage done and

you are the only one who can place that claim.

Safety

Please read this complete manual before trying to operate

your mixer. Failure to follow these instructions could result

in serious bodily injury or death.

• Do not touch moving parts while mixer is operating.

Do not wear loose-fitting clothes or jewelry around an

operating mixer. Keep all hands, feet, clothes, neckties,

necklaces and other objects clear of moving parts.

• Never run the unit in open air.

Electric Motor Safety:

Not all rotating parts are guarded. Keep hands and clothing

away from moving parts.

Trained, qualified personnel should make electrical repairs

and non-standard connections.

If environment has hazardous combustible fumes present,

use only explosion-proof electric motors.

Air Motor Safety:

The air motor is designed to be driven by compressed air and

under no circumstances be driven with any other gases.

Fluids, particles, solids or any substance mixed with air,

particularly combustible substances likely to cause

explosions, must not drive air motor.

• Do not drive with flammable or explosive gases or operate

unit in an atmosphere containing them.

• Air motor is designed for air only. Do not allow corrosive

gases or particulate material to enter motor. Water vapor,

oil-based contaminants, or other liquids must be filtered

out.

• Do not use a hammer or force coupling or drive pulley

onto shaft when installing drive onto air motor. This

causes end thrust that could damage air motor.

• Ambient temperature should not exceed 250°F.

• Beware of any exposed and/or movable parts. Proper

guards should be in place to prevent personal and/or

property damage.

• Solid or liquid material exiting unit can cause eye or skin

damage. Keep away from air stream.

• Always disconnect air supply before servicing.

• Do not allow air motor to “run free” at high speeds with no

loads. Excessive internal heat build-up, loss of internal

clearances and rapid motor damage will result.

• Some models may exceed 85dB(A) sound level. Hearing

protection should be worn when in close proximity to

these models.

page 2 of 6

INDCO, Inc. M-M-30114 mixer manual FGM date: 5/13/05

Operation

CAUTION:

9Never run the shaft~impeller in open air.

9Never run shaft~impeller outside the pail.

Your new mixer requires some assembly. Ensure ALL set-

screws and fasteners on the unit have been tightened

completley before operating the equipment. The impeller(s)

and impeller-shaft have to be fitted to the machine before it’s

operational.

Shaft & Coupler

The FGM Series mixers have a Quic-Change Coupler that

allows easy installation and removal of the Mixing Shaft.

A Pin is installed in the Mixing Shaft, which fits into a slot in

the Quic-Change Coupler.

Mounting

The FGM Series Mixer will work with open 5-gallon pails only.

1. Loosen Thumb Screw and place the unit on top of the pail

with the Mixing Shaft and Impellers attached.

2. Make adjustments, if necessary, to the position by rotating

the Ring Base on the pail.

3. Tighten Thumb Screw.

4. Check shaft rotation:

Electric Power: Check rotation to be sure the mixer

shaft is rotating in a counter clock-wise direction,

looking downward into the container.

Air Power: Ensure the air valve is in the closed

position, then connect air supply. Check rotation to

be sure the mixer shaft is rotating in a counter clock-

wise direction, looking downward into the container.

5. Mixer is ready to operate.

Quic-Change Coupler

set screws

shaft

pin

slot

Quic-Change

Coupler

Thumb

Screw

Ring Base

Mixing Shaft

& Impellers

page 3 of 6

INDCO, Inc. M-M-30114 mixer manual FGM date: 5/13/05

Parts List

Ring Base

- end view -

Ring Base

- side view -

300

3/8”-16 Hex Nut

welded to

ring base

Air Motor Model Shown

400

500

600

601

602603

700

701 700 202

201

200

150160

100

110

120

page 4 of 6

INDCO, Inc. M-M-30114 mixer manual FGM date: 5/13/05

Item Qty. Part No. Description

FGM-5T

100. 1 MTR-1/2-56C-1-TEFC Electric Motor, 1/2-HP, 56C, 115-volt, 1-phase, TEFC

110. 4 N-HARDWARE Bolt, 3/8”-16 x 1”

120. 4 N-HARDWARE Lock washer, 3/8”

130. 1 CPG-INLINE-18/3 Power cord, plug & in-line switch

200. 1 HDW-GB-56C Gear Box, 5:1 ratio, 56C face in/out

201. 4 N-HARDWARE Bolt, 3/8”-16 x 1”

202. 4 N-HARDWARE Lock washer, 3/8”

300. 1 C-DEV-C Coupler, quic-change, 5/8” x 5/8”

400. 1 C-DEV-S Shaft, 15” long, 5/8” dia., with quic-change pin

500. 2 AP958 Propeller, 9” diameter w/ 5/8” bore, 2-blade - aluminum

600. 1 MNT-FGM Motor base with handles, 56C face mount

601. 2 N-HARDWARE Bolt, 5/16”-18 x 1” long

602. 2 N-HARDWARE Lockwasher, 5/16”

603. 2 N-HARDWARE Nut, 5/16”

700. 1 HDW-RTM Ring base

701. 1 N-HARDWARE Thumb screw, 3/8”-16 x 1-1/4”

FGM-7T

100. 1 MTR-3/4-56C-1-TEFC Electric Motor, 3/4-HP, 56C, 115-volt, 1-phase, TEFC

110. 4 N-HARDWARE Bolt, 3/8”-16 x 1”

120. 4 N-HARDWARE Lock washer, 3/8”

130. 1 CPG-14/3 Power cord with plug

140. 1 SWT-GUARD Switch guard

150. 1 SWT-TOGGLE Switch (on-off)

200. 1 HDW-GB-56C Gear Box, 5:1 ratio, 56C face in/out

201. 4 N-HARDWARE Bolt, 3/8”-16 x 1”

202. 4 N-HARDWARE Lock washer, 3/8”

300. 1 C-DEV-C Coupler, quic-change, 5/8” x 5/8”

400. 1 C-DEV-S Shaft, 15” long, 5/8” dia., with quic-change pin

500. 3 AP958 Propeller, 9” diameter w/ 5/8” bore, 2-blade - aluminum

600. 1 MNT-FGM Motor base with handles, 56C face mount

601. 2 N-HARDWARE Bolt, 5/16”-18 x 1” long

602. 2 N-HARDWARE Lockwasher, 5/16”

603. 2 N-HARDWARE Nut, 5/16”

700. 1 HDW-RTM Ring base

701. 1 N-HARDWARE Thumb screw, 3/8”-16 x 1-1/4”

FGM-1T

100. 1 MTR-1-56C-1-TEFC Electric Motor, 1 HP, 56C, 115-volt, 1-phase, TEFC

110. 4 N-HARDWARE Bolt, 3/8”-16 x 1”

120. 4 N-HARDWARE Lock washer, 3/8”

130. 1 CPG-14/3 Power cord with plug

140. 1 SWT-GUARD Switch guard

150. 1 SWT-TOGGLE Switch (on-off)

200. 1 HDW-GB-56C Gear Box, 5:1 ratio, 56C face in/out

201. 4 N-HARDWARE Bolt, 3/8”-16 x 1”

202. 4 N-HARDWARE Lock washer, 3/8”

300. 1 C-DEV-C Coupler, quic-change, 5/8” x 5/8”

400. 1 C-DEV-S Shaft, 15” long, 5/8” dia., with quic-change pin

500. 3 AP958 Propeller, 9” diameter w/ 5/8” bore, 2-blade - aluminum

600. 1 MNT-FGM Motor base with handles, 56C face mount

601. 2 N-HARDWARE Bolt, 5/16”-18 x 1” long

602. 2 N-HARDWARE Lockwasher, 5/16”

603. 2 N-HARDWARE Nut, 5/16”

700. 1 HDW-RTM Ring base

701. 1 N-HARDWARE Thumb screw, 3/8”-16 x 1-1/4”

FGM-5V

100. 1 MTR-098000 Electric Motor, DC Variable-Speed, ½ HP, 56C, TEFC

101. 1 MTR-DC-CONTROL Variable-Speed controller, 115-volt, 1-phase input

102. 2 MET-VSO-BRACKET Mounting brackets, controller to electric motor

110. 4 N-HARDWARE Bolt, 3/8”-16 x 1”

120. 4 N-HARDWARE Lock washer, 3/8”

130. 1 CPG-18/3 Power cord with plug

200. 1 HDW-GB-56C Gear Box, 5:1 ratio, 56C face in/out

201. 4 N-HARDWARE Bolt, 3/8”-16 x 1”

202. 4 N-HARDWARE Lock washer, 3/8”

300. 1 C-DEV-C Coupler, quic-change, 5/8” x 5/8”

400. 1 C-DEV-S Shaft, 15” long, 5/8” dia., with quic-change pin

500. 2 AP958 Propeller, 9” diameter w/ 5/8” bore, 2-blade - aluminum

600. 1 MNT-FGM Motor base with handles, 56C face mount

601. 2 N-HARDWARE Bolt, 5/16”-18 x 1” long

602. 2 N-HARDWARE Lockwasher, 5/16”

603. 2 N-HARDWARE Nut, 5/16”

700. 1 HDW-RTM Ring base

701. 1 N-HARDWARE Thumb screw, 3/8”-16 x 1-1/4”

Parts List (continued)

page 5 of 6

INDCO, Inc. M-M-30114 mixer manual FGM date: 5/13/05

Parts List (continued)

Item Qty. Part No. Description

FGM-7V

100. 1 MTR-108018 Electric Motor, DC Variable-Speed, 3/4-HP, 56C, TEFC

101. 1 MTR-DC-CONTROL Variable-Speed controller, 115-volt, 1-phase input

102. 2 MET-VSO-BRACKET Mounting brackets, controller to electric motor

110. 4 N-HARDWARE Bolt, 3/8”-16 x 1”

120. 4 N-HARDWARE Lock washer, 3/8”

130. 1 CPG-14/3 Power cord with plug

200. 1 HDW-GB-56C Gear Box, 5:1 ratio, 56C face in/out

201. 4 N-HARDWARE Bolt, 3/8”-16 x 1”

202. 4 N-HARDWARE Lock washer, 3/8”

300. 1 C-DEV-C Coupler, quic-change, 5/8” x 5/8”

400. 1 C-DEV-S Shaft, 15” long, 5/8” dia., with quic-change pin

500. 3 AP958 Propeller, 9” diameter w/ 5/8” bore, 2-blade - aluminum

600. 1 MNT-FGM Motor base with handles, 56C face mount

601. 2 N-HARDWARE Bolt, 5/16”-18 x 1” long

602. 2 N-HARDWARE Lockwasher, 5/16”

603. 2 N-HARDWARE Nut, 5/16”

700. 1 HDW-RTM Ring base

701. 1 N-HARDWARE Thumb screw, 3/8”-16 x 1-1/4”

FGM-1V

100. 1 MTR-108022 Electric Motor, DC Variable-Speed, 1 HP, 56C, TEFC

101. 1 MTR-DC-CONTROL Variable-Speed controller, 115-volt, 1-phase input

102. 2 MET-VSO-BRACKET Mounting brackets, controller to electric motor

110. 4 N-HARDWARE Bolt, 3/8”-16 x 1”

120. 4 N-HARDWARE Lock washer, 3/8”

130. 1 CPG-14/3 Power cord with plug

200. 1 HDW-GB-56C Gear Box, 5:1 ratio, 56C face in/out

201. 4 N-HARDWARE Bolt, 3/8”-16 x 1”

202. 4 N-HARDWARE Lock washer, 3/8”

300. 1 C-DEV-C Coupler, quic-change, 5/8” x 5/8”

400. 1 C-DEV-S Shaft, 15” long, 5/8” dia., with quic-change pin

500. 3 AP958 Propeller, 9” diameter w/ 5/8” bore, 2-blade - aluminum

600. 1 MNT-FGM Motor base with handles, 56C face mount

601. 2 N-HARDWARE Bolt, 5/16”-18 x 1” long

602. 2 N-HARDWARE Lockwasher, 5/16”

603. 2 N-HARDWARE Nut, 5/16”

700. 1 HDW-RTM Ring base

701. 1 N-HARDWARE Thumb screw, 3/8”-16 x 1-1/4”

FGM-5A

100. 1 MTR-3/4-56C-AIR Air Motor, 3/4-HP, 56C

110. 1 N-HARDWARE Bolt, 3/8”-16 x 1”

120. 1 N-HARDWARE Lock washer, 3/8”

150. 1 HDW-25-CNG Pipe nipple, steel - 1/4” x 7/8”

160. 1 HDW-1/4-VALVE Needle valve, brass, 1/4”

200. 1 HDW-GB-56C Gear Box, 5:1 ratio, 56C face in/out

201. 4 N-HARDWARE Bolt, 3/8”-16 x 1”

202. 4 N-HARDWARE Lock washer, 3/8”

300. 1 C-DEV-C Coupler, quic-change, 5/8” x 5/8”

400. 1 C-DEV-S Shaft, 15” long, 5/8” dia., with quic-change pin

500. 2 AP958 Propeller, 9” diameter w/ 5/8” bore, 2-blade - aluminum

600. 1 MNT-FGM Motor base with handles, 56C face mount

601. 2 N-HARDWARE Bolt, 5/16”-18 x 1” long

602. 2 N-HARDWARE Lockwasher, 5/16”

603. 2 N-HARDWARE Nut, 5/16”

700. 1 HDW-RTM Ring base

701. 1 N-HARDWARE Thumb screw, 3/8”-16 x 1-1/4”

FGM-1A

100. 1 MTR-1.5-56C-AIR Air Motor, 1.5-HP, 56C

110. 1 N-HARDWARE Bolt, 3/8”-16 x 1”

120. 1 N-HARDWARE Lock washer, 3/8”

150. 1 HDW-25-CNG Pipe nipple, steel - 1/4” x 7/8”

160. 1 HDW-1/4-VALVE Needle valve, brass, 1/4”

200. 1 HDW-GB-56C Gear Box, 5:1 ratio, 56C face in/out

201. 4 N-HARDWARE Bolt, 3/8”-16 x 1”

202. 4 N-HARDWARE Lock washer, 3/8”

300. 1 C-DEV-C Coupler, quic-change, 5/8” x 5/8”

400. 1 C-DEV-S Shaft, 15” long, 5/8” dia., with quic-change pin

500. 3 AP958 Propeller, 9” diameter w/ 5/8” bore, 2-blade - aluminum

600. 1 MNT-FGM Motor base with handles, 56C face mount

601. 2 N-HARDWARE Bolt, 5/16”-18 x 1” long

602. 2 N-HARDWARE Lockwasher, 5/16”

603. 2 N-HARDWARE Nut, 5/16”

700. 1 HDW-RTM Ring base

701. 1 N-HARDWARE Thumb screw, 3/8”-16 x 1-1/4”

page 6 of 6

Table of contents

Other INDCO Mixer manuals

INDCO

INDCO CL Series User manual

INDCO

INDCO MX3 Series User manual

INDCO

INDCO TL Series User manual

INDCO

INDCO TMD Series User manual

INDCO

INDCO BM Series User manual

INDCO

INDCO TM Series User manual

INDCO

INDCO BT Series User manual

INDCO

INDCO DL Series User manual

INDCO

INDCO CB Series User manual

INDCO

INDCO FL Series User manual