Inficon LDS Retrofit Kit Quick guide

Translation of the original operating instructions

LDS Retrofit Kit

Electronic module

jinb10en1-03-(1903)

Catalog No.

560-400

From software version

2.72 (LDS3000) / 2.72 (CU1000)

INFICON GmbH

Bonner Strasse 498

50968 Cologne, Germany

INFICON Table of Contents

LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903) iii

Table of Contents

1 About these instructions ...................................................................................................................................5

1.1 Warnings...................................................................................................................................................5

1.2 Other associated documents ....................................................................................................................5

1.3 Target groups ...........................................................................................................................................6

2 Safety ...............................................................................................................................................................7

2.1 Intended use .............................................................................................................................................7

2.2 Owner requirements .................................................................................................................................7

2.3 Duties of the operator ...............................................................................................................................8

2.4 Dangers ....................................................................................................................................................8

3 Shipment, Transport, Storage ..........................................................................................................................9

4 Description......................................................................................................................................................10

4.1 Function ..................................................................................................................................................10

4.2 Device setup ...........................................................................................................................................10

4.3 Technical data ........................................................................................................................................11

5 Installation ......................................................................................................................................................13

5.1 Setup ......................................................................................................................................................13

5.2 Connect the device with the MSB box of the LDS3000 ..........................................................................14

5.3 Connecting the device with external installation of CU1000 ..................................................................15

5.4 Connect the device when installing the CU1000 in the installation slot of the device ............................16

5.4.1 Install and connect the CU1000.................................................................................................. 17

5.5 Connect the device to the mains power..................................................................................................18

5.6 Setup the compatibility mode..................................................................................................................18

5.7 Set the user defined parameters ............................................................................................................18

5.8 Make the vacuum connection between the device and the existing leak detection system. ..................19

5.8.1 LDS1000 operating modes ......................................................................................................... 19

5.8.2 Vacuum technical specification of the backing pump ................................................................. 19

5.8.3 Recommended system configuration for the operating mode GROSS with pump module ........ 20

5.8.4 Recommended system configuration for the operating mode FINE with pump module ............. 21

5.8.5 LDS3000 operating modes ......................................................................................................... 22

5.8.6 LDS3000 configuration ............................................................................................................... 23

5.8.6.1 Connection LDS3000 .........................................................................................................23

5.8.6.2 LDS3000 specification .......................................................................................................23

Table of Contents INFICON

iv LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903)

5.8.6.3 LDS3000 vacuum configuration for the operating mode GROSS with pump module........24

5.8.6.4 LDS3000 vacuum configuration for the operating mode FINE with pump module ............25

5.8.6.5 LDS3000 vacuum configuration for the operating mode ULTRA with pump module.........26

5.8.6.6 Comparison of the specifications LDS1000 and LDS3000 ................................................27

5.8.7 Vacuum connection transfer from the LDS1000 to the LDS3000 ............................................... 28

5.8.7.1 Vacuum connection transfer for the operating mode GROSS ...........................................28

5.8.7.2 Vacuum transfer for the operating mode FINE ..................................................................29

5.8.7.3 Vacuum connection transfer for the operating mode FINE to ULTRA ...............................29

5.9 Interface protocol LDS1000/LDS2010 ....................................................................................................29

6 Operation........................................................................................................................................................30

7 Error messages ..............................................................................................................................................31

8 Maintenance and repair..................................................................................................................................32

8.1 Cleaning the device ................................................................................................................................32

8.2 Send in for repair ....................................................................................................................................32

9 Decommissioning the device..........................................................................................................................33

9.1 Disposing of the device...........................................................................................................................33

9.2 Sending in the device .............................................................................................................................33

10 Appendix.........................................................................................................................................................34

10.1 CE Declaration of Conformity .................................................................................................................34

INFICON About these instructions | 1

LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903) 5 / 36

1 About these instructions

This document applies to the software version stated on the title page.

Product names may occur in the document, which are added for identification

purposes only and belong to the respective owner of the rights.

1.1 Warnings

DANGER

Imminent hazard resulting in death or serious injuries

WARNING

Hazardous situation resulting in potential death or serious injuries

CAUTION

Hazardous situation resulting in minor injuries

NOTICE

Hazardous situation resulting in damage to property or the environment

1.2 Other associated documents

Name Document number

Operating Instructions LDS3000 MS

module

jiqa54

Operating Manual Control Unit CU1000 jina54

Operating instructions bus module jiqb10

Operating instructions I/O module jiqc10

Operating instructions XL sniffer adapter jinxa54

Interface protocols jira54

1 | About these instructions INFICON

6 / 36 LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903)

1.3 Target groups

These operating instructions are intended for the owner and for technically qualified

personnel with experience in leak detection technology and integration of leak

detection devices in leak detection systems. In addition, the installation and use of the

device require knowledge of electronic interfaces.

INFICON Safety | 2

LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903) 7 / 36

2 Safety

2.1 Intended use

Under certain circumstances the device functions also in the leak detection systems

with LDS2000. When installed with a LDS2000 contact the INFICON Service.

The device forms the interface between the existing leak detection system and the

retrofitted LDS3000. The LDS3000 can then be used without any electrical

adaptations.

• You must install, operate and service the device only in compliance with these

operating instructions.

• Comply with application limits, see "Technical Data".

• Only use the device in connection with the existing leak detection systems, in

which a LDS1000/LDS2010 is being used and retrofitted with a LDS3000.

Improper use Avoid the following, non-intended uses:

• Operation at too high ambient temperature

• Using the device outside of the specific area

The device is an accessory for retrofitting into an existing leak detection systems with

the LDS1000/LDS2010. The device is installed in connection with a LDS3000.

2.2 Owner requirements

The following notes are for companies or any person who is responsible for the safety

and effective use of the product by the user, employee or third party.

Safety conscious operation

• Operate the device only if it is in perfect technical condition and has no damage.

• Only operate the device in accordance with this instruction manual, in a safety and

risk conscious manner.

• Adhere to the following regulations and observe their compliance:

– Intended use

– General applicable safety and accident prevention regulations

– International, national and local standards and guidelines

– Additional device-related provisions and regulations

• Only use original parts or parts approved by the manufacturer.

2 | Safety INFICON

8 / 36 LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903)

• Keep this instruction manual available on site.

Personnel qualifications

• Only instructed personnel should be permitted to work with and on the device. The

instructed personnel must have received training on the device.

• Make sure that authorized personnel have read and understood the operating

instructions and all other applicable documents.

2.3 Duties of the operator

• Read, observe, and follow the information in this manual and in the work

instructions provided by the owner. This concerns in particular the safety

instructions and warnings.

• Always observe the complete operating instructions for all work.

• If you have any questions about operation or maintenance that are not answered

in this manual, please contact Customer Service.

2.4 Dangers

The measuring instrument was built according to the state-of-the-art and the

recognized safety regulations. Nevertheless, improper use may result in risk to life and

limb on the part of the user or third parties, or damage to the measuring instrument or

other property may occur.

Hazards due to liquids

and chemicals

Liquids and chemical substances can damage the instrument.

• Do not suck up liquids with the instrument.

• Never try to find toxic, caustic, microbiological, explosive, radioactive or other

harmful substances with the device.

• Only use the device away from areas with a risk of explosions.

Dangers from electric

power

There is a danger to life from the contact of conductive parts inside the device.

• Disconnect the device from the power supply prior to any installation and

maintenance work. Make sure that the electric power supply cannot reconnected

without authorization.

The device contains electric components that can be damaged from high electric

voltage.

• Before connecting the device to the power supply, make sure that the supply

voltage specified on the device is the same as the local power supply.

INFICON Shipment, Transport, Storage | 3

LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903) 9 / 36

3 Shipment, Transport, Storage

Shipment Item Quantity

LDS retrofit kit 1

Operating instructions 1

Power supply line 24 V, 3 m 1

Power supply line 24V, 5 m 1

EU power supply cord 2.5 m 1

USA power supply cord 2.5 m 1

Table1:

Shipment

Check the scope of delivery of the product for completeness after receipt.

Transport

NOTICE

Damage caused by transport

Transport in unsuitable packaging material can damage the device.

► Retain the original packaging.

► Only transport the device in its original packaging.

Storage Always store the device in compliance with the technical data, see Technical data

[}11].

4 | Description INFICON

10 / 36 LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903)

4 Description

4.1 Function

The device is an accessory for retrofitting into an existing leak detection systems with

the LDS1000/LDS2010. The device is installed in connection with a LDS3000.

Under certain circumstances the device functions also in the leak detection systems

with LDS2000. When installed with a LDS2000 contact the INFICON Service.

The device forms the interface between the existing controller of the leak detection

system and the retrofitted LDS3000. Take the LDS3000 device into operation as a

Plug and Play device.

Make an adaptation to the vacuum equipment depending on the existing leak

detection system.

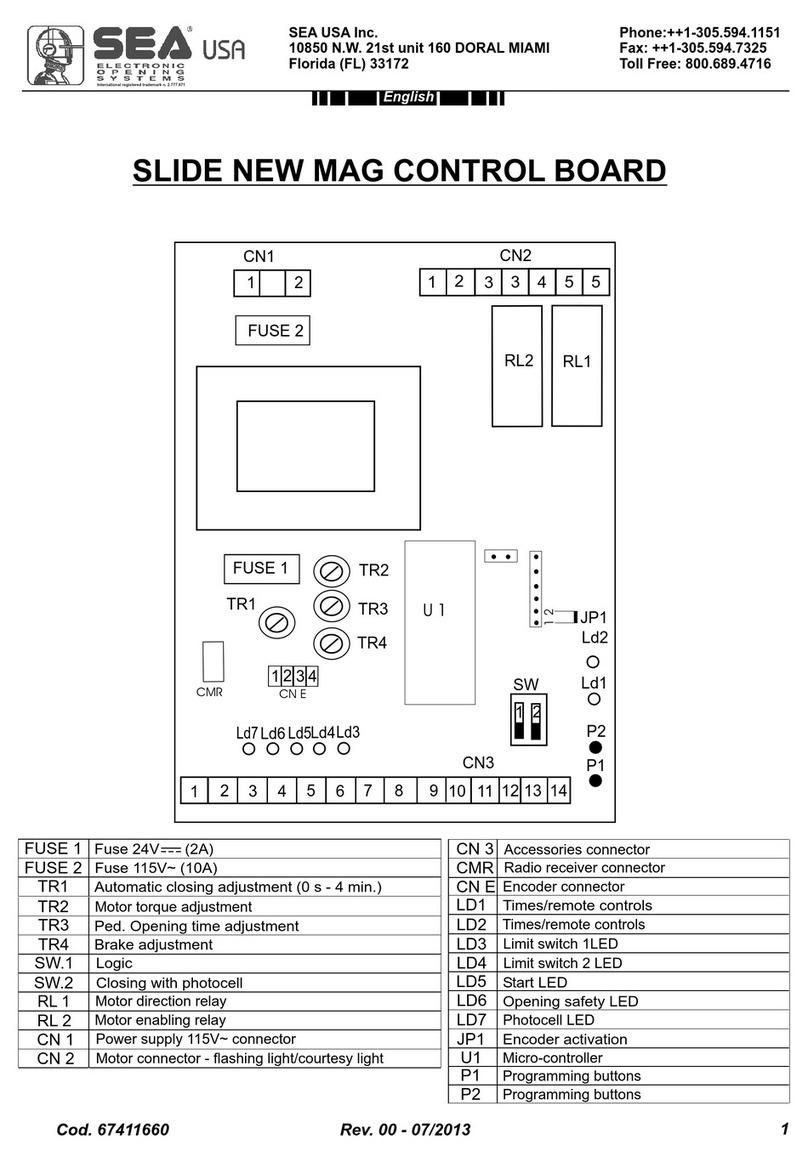

4.2 Device setup

Fig.1:

Front view

1

Front panel handles

3

Cover installation slot CU1000

2

LED operating display

INFICON Description | 4

LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903) 11 / 36

Fig.2:

Rear view

1

Fuse T 0.8 A

7

Digital out, relay output

2

Connection for module IO1000

8

Connection for control unit CU1000

3

Connection multifunction PLC

9

24 V DC Out

4

RS 232 port, sub-D, 9-pin

10

Power cord connector with 2 pcs. fuses T

3.15 A

5

Rating plate

11

On/off switch

6

Analog out, recorder output

For the assignment of the individual interfaces 3, 4, 7 and 6, refer to the operating

instructions for the LDS1000 (jina50) or LDS2010 (jina52).

4.3 Technical data

Basic unit

Dimensions (W x H x D) 483 × 133 × 375 mm

Weight 7.0 kg

Over voltage category (as per DIN EN

61010-1)

II

Table2:

Mechanical data

Permissible ambient temperature (during

operation)

5 °C to 45 °C

4 | Description INFICON

12 / 36 LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903)

Max. relative humidity 80% up to 31 °C

decreasing linearly from 80% to 50% in

the range from 31 °C to 40 °C

50% above 40 °C

Max. altitude above sea level 2000 m

Table3:

Ambient conditions

Power supply 100 V ... 230 V AC

50 Hz ... 60 Hz

280 VA

Protection class IP 20

Table4:

Electrical data

Recorder output analog out 0 - 10 Volt @ max. 1 mA

±15 mV offset, additional ±1% from

measurement (current output voltage)

as linearity error (at 25°C)

Resolution type 2.5 mV

Relay outputs digital out Max. 60 VDC / 25 VAC / 1 A

Control input multifunction

24 V / GND

Type 24 V / 7mA / max. 35 V

Active signal: V = 13 ... 35 V (typical 24

V), I = approx. 7 mA

Inactive signal: U < 7 V (typical 0 V), I = 0

mA

24 V (T 0.8 A)

IO1000 M12

CU1000 M12

RS-232 RS-232 (Sub-D 9-pin)

(1:1 connection, RxD and TxD not

crossed,

no null modem cable)

24 V Out 24 V / 9.2 A / 220 W (Speakon)

Fuses T 0.8 A / T 3.15 A

Table5:

Interfaces

INFICON Installation | 5

LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903) 13 / 36

5 Installation

5.1 Setup

WARNING

Danger from moisture and electricity

Moisture entering the device can lead to personal injury due to electric shocks as well

as damage to property due to short circuiting.

► Only operate the device in a dry environment.

► Operate the device away from sources of liquid and moisture.

NOTICE

Material damage from overheated device

The device heats up during operation and can overheat when located incorrectly.

► Comply with the technical data, see Technical data [}11].

► Keep heat sources away from the device.

► Do not expose the device to direct sunlight.

NOTICE

Material damage due to electrostatic charging

If you are electrostatically charged, you can trigger damage to the equipment via the

multifunction PLC terminals.

► Make sure you take appropriate grounding measures to prevent and dissipate static

charge.

5 | Installation INFICON

14 / 36 LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903)

5.2 Connect the device with the MSB box of the

LDS3000

The connections vary depending on the version of the CU1000. Select one of the two

installation versions for the CU1000 and connect the device according to the selected

installation version:

• In the installation slot CU1000 in the device, see Connect the device when

installing the CU1000 in the installation slot of the device [}16].

• Outside of the device, e.g. as in a control cabinet, see Connecting the device with

external installation of CU1000 [}15].

INFICON Installation | 5

LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903) 15 / 36

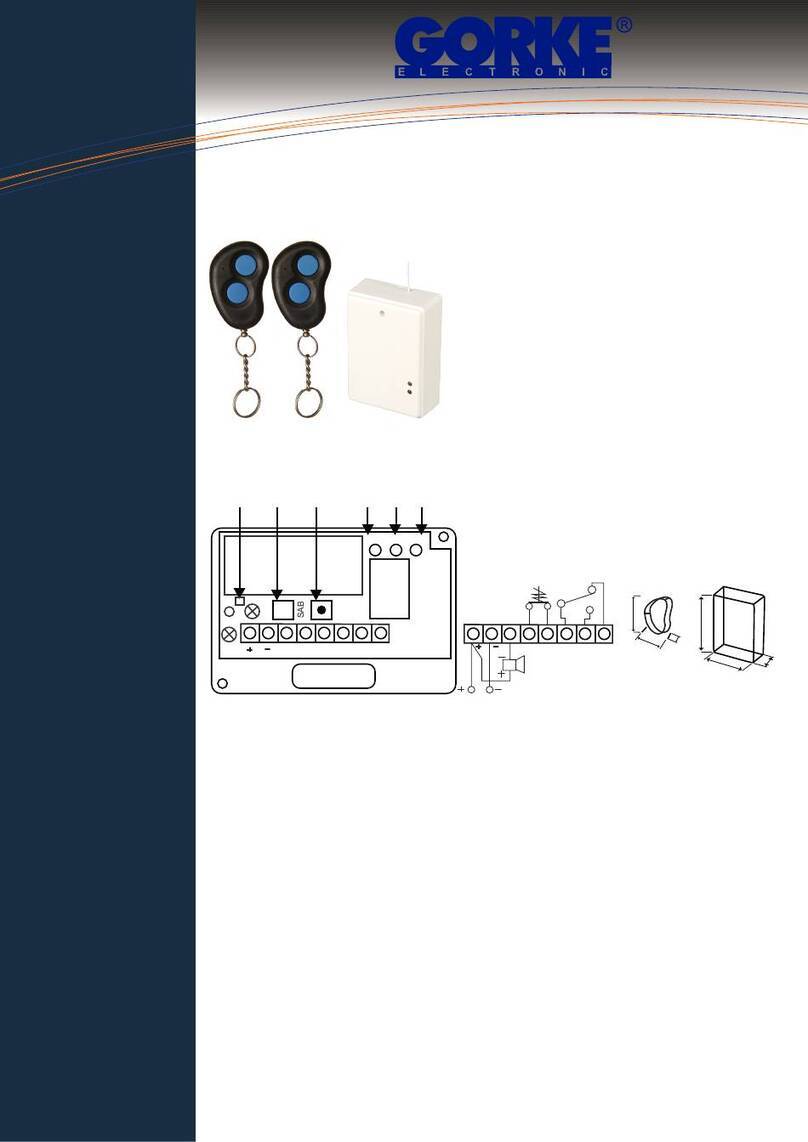

5.3 Connecting the device with external installation

of CU1000

Fig.3:

Connection scheme, CU1000 installed externally

1 LDS retrofit kit 5 Control unit CU1000

2 Power supply line 24V 6 Connection cable IO1000

3 Connection cable CU1000 7 MSB box

4 Customer specific connections

5 | Installation INFICON

16 / 36 LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903)

5.4 Connect the device when installing the CU1000

in the installation slot of the device

DANGER

Life threatening hazard from electric shock

High voltages are inside the device. Touching parts where electrical voltage is present

can result in death.

► Separate the device from the power supply and secure against being switched on

again.

Fig.4:

Connection scheme, CU1000 installed in the installation slot of the device

1 LDS retrofit kit 4 Power supply line 24V

2 Customer specific connections 5 Connection cable CU1000

3 Connection cable IO1000 6 MSB box

INFICON Installation | 5

LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903) 17 / 36

5.4.1 Install and connect the CU1000

DANGER

Life threatening hazard from electric shock

► Switch off the device and disconnect from the mains.

1

To remove the cover of the CU1000 installation slot, loosen the 4 securing

screws.

2

Remove the connection cable from the installation slot and connect it to the

CU1000.

3

Assemble the CU1000 with the 4 securing screws.

5 | Installation INFICON

18 / 36 LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903)

5.5 Connect the device to the mains power

WARNING

Danger from electric shock

Improperly grounded or protected products may be dangerous to life in case of a fault.

The use of the device is not permitted without a connected protective conductor.

► Use only a 3 core power supply cord, as provided with the delivery.

CAUTION

Danger due to incorrect supply voltage

Incorrect supply voltage can destroy the device and injure persons.

► Check whether the supply voltage specified on the rating plate of the device

matches the supply voltage available on site.

5.6 Setup the compatibility mode

To operate the LDS3000 as a replacement for an existing LDS1000/LDS2010, setup

the compatibility mode.

1

Before conversion, note the user defined settings of the existing LDS1000/

LDS2010 for later use.

2

Switch on the LDS retrofit kit.

3

On the touchscreen select the CU1000 "Menu (icon) > Settings > Setup >

Compatibility".

4

Select the setting for the existing system: "LDS1000" or "LDS2010" and confirm

with "OK".

ðThe CU1000 restarts the LDS3000. After restarting, the LDS3000 is in the

compatibility mode with the factory settings of the LDS1000/LDS2010.

5.7 Set the user defined parameters

Use the settings noted with the compatibility mode for the LDS3000 (see Setup the

compatibility mode [}18]). Also refer to the operating manual LDS3000 MS module

jiqa54.

INFICON Installation | 5

LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903) 19 / 36

5.8 Make the vacuum connection between the

device and the existing leak detection system.

The vacuum technical specifications of the LDS3000 are different to that of the

LDS1000. Adapt for the exchange of the vacuum technical configuration.

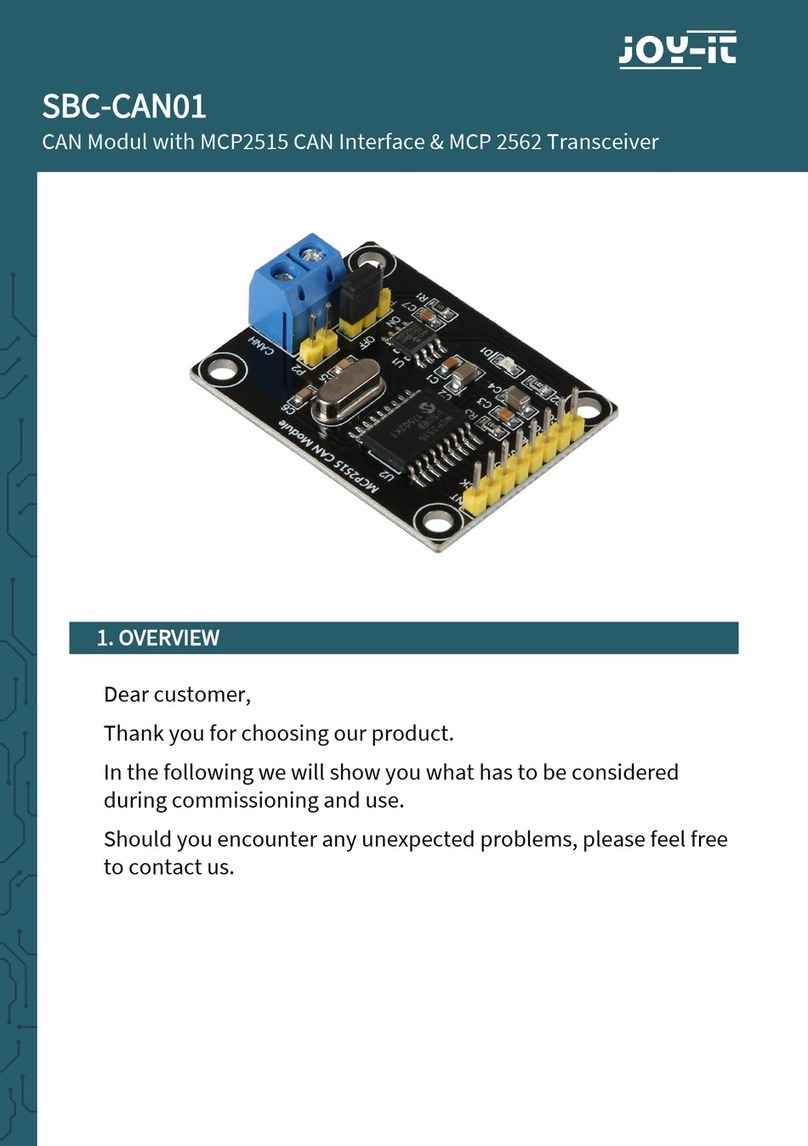

5.8.1 LDS1000 operating modes

The LDS1000 has two operating modes (GROSS, FINE) for vacuum applications and

operates with a fixed turbo pump rotational speed of 1020 Hz.

Operating mode

GROSS

GROSS: The device allows an inlet pressure of 3 mbar. The minimum detectable leak

rate is 3.5·10-10mbar·l/s.

Operating mode FINE FINE: The device allows an inlet pressure of 0.3 mbar. The device has thereby a rapid

response time. The minimum detectable leak rate is 5·10-11mbar·l/s.

Fig.5:

LDS1000

1 GROSS (DN 16 KF) 2 FINE (DN 16 KF)

5.8.2 Vacuum technical specification of the backing pump

The noted specifications for the operating modes GROSS and FINE are reach with the

LDS1000 by using an Oerlikon Leybold Trivac backing pump D4 B. If you use another

backing pump, the following backing pump vacuum technical minimum specifications

must be fulfilled:

• Pumping speed: ≥ 1.6 m3 / h, Total pressure: ≤ 5 ·10-3 mbar

5 | Installation INFICON

20 / 36 LDS-Retrofit-Kit-Operating-Instructions-jinb10en1-03-(1903)

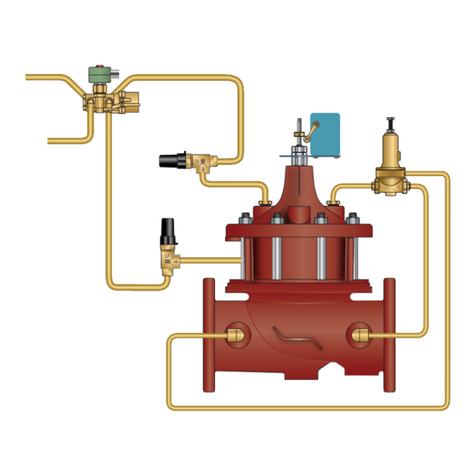

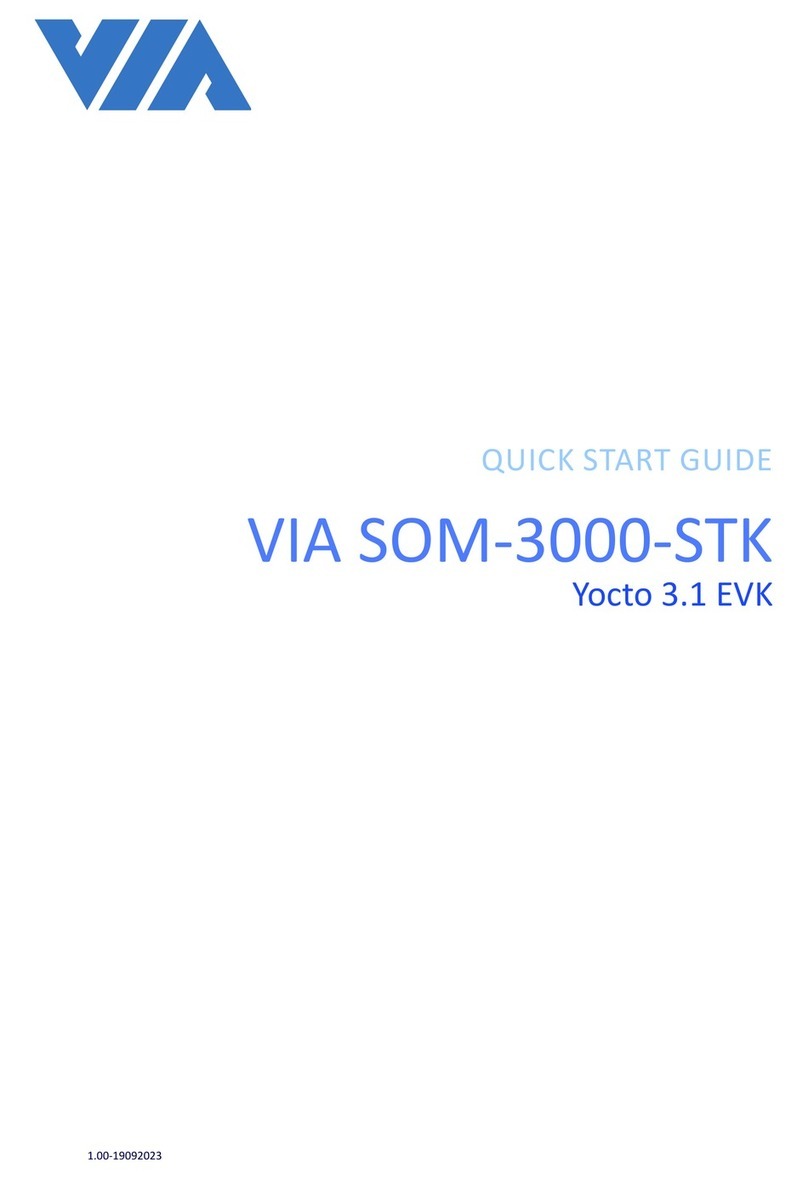

5.8.3 Recommended system configuration for the operating

mode GROSS with pump module

Fig.6:

LDS1000 vacuum configuration for the operating mode GROSS with pump module

1 Mass spectrometer module 11 DUT

2 Pump module (option) 12 Test chamber

3 Coaxial pipe 13 Tracer gas supply

4 Crosspiece 14 Pump valve

5 Turbo molecular pump 15 Vacuum pump stand

6 Mass spectrometer 16 Inlet valve

7 Connection FINE 17 T piece

8 Pressure measuring point pv 18 Connection GROSS

9 Internal calibration leak (option) 19 Pump module connection (option)

10 Test chamber pressure measuring

point

The maximum inlet pressure to the LDS1000 is 3 mbar. The minimum detectable

Helium leak rate is 3.5·10-10mbar·l/s. With an inlet pressure of 3 mbar, the detectable

helium leak rate is 3·10-5mbar·l/s. As long as the pump valve is open, the minimum

detectable Helium leak rate id detected by the ratio of the pumping speed of the pump

module (2) and the vacuum pump stand (15) . If the pump valve (14) is closed, and

the inlet pressure is constant, the configuration for the maximum sensitivity is reached

Table of contents

Other Inficon Control Unit manuals

Popular Control Unit manuals by other brands

Lovato

Lovato T-FAST ie60 Assembling instructions and maintenance

IFM

IFM ECOMAT 100 CR1500 Device manual

Bosch

Bosch CM746B Installer's reference guide

Viking

Viking G-6000 Technical data

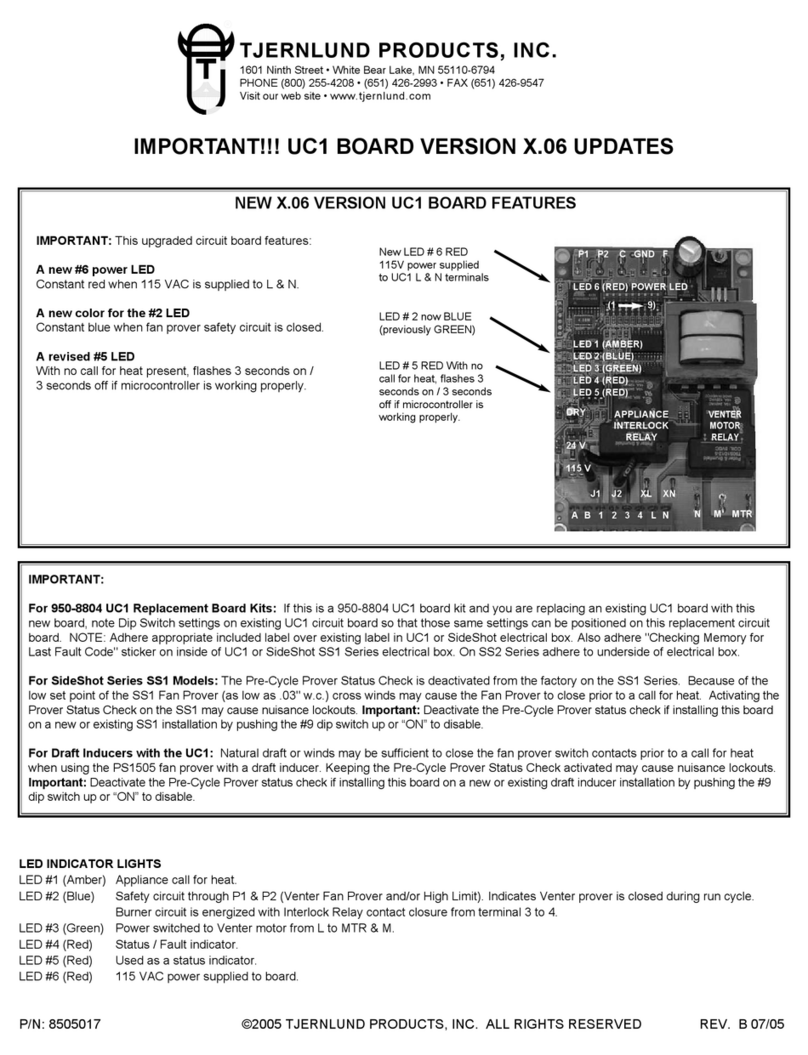

TJERNLUND

TJERNLUND UC1 UNIVERSAL CONTROL (VERSION X.06) ADDENDUM 8505017 REV B... manual

Bticino

Bticino L4488 instruction sheet