wiHUBB® In-Fixture Module

Installation Instructions

Hubbell Building Automation

9601 Dessau Road Building One Suite 100

Austin, TX 78754

Toll Free: 888-698-3242 Fax: 512-450-1215

www.hubbell-automation.com

DESCRIPTION

Hubbell Building Automation’s wiHUBB In-Fixture

Module (IFM) is a self-contained intelligent wireless

control module. It contains either one or two

independently controlled outputs. The two output

version can be used for Hi/Low or alternate ballast

switching. An optional 0-10 VDC output is also

available for controlling dimmable ballasts and LED

drivers. Each wiHUBB In-Fixture Module can

control one or more fixtures and can be individually

controlled or grouped with other wiHUBB devices.

The wiHUBB IFM communicates securely via 900

MHz radio frequency to other devices within the

wiHUBB wireless self-healing mesh network.

SPECIFICATIONS

Max Load Ratings (-1277 version)

120VAC (SPST): 1200W Tungsten,

Electronic and Standard Ballast

277VAC (SPST): 1200W Electronic and

Standard Ballast

Max Load Ratings (-347 version)

347VAC (SPST): 1500W Electronic and

Standard Ballast

Max Load Ratings (-480 version)

480VAC (DPST): 2400W Electronic and

Standard Ballast

Dimming Output (Optional): 0-10VDC

RF Frequency: 902-928MHz /AES-128 Security

RF Range: Max. Transmission Output: +20 dBm

/ Max Receive Sensitivity: -118 dBm

Operating Temp: -40°C to +90°C

Plenum rated

Conforms with UL916 and Certified to

CAN/CSA C22.2 #61010-1

Patents Pending

Five year limited warranty

PRECAUTIONS

Read and understand all instructions before

beginning installation.

NOTICE: For installation by a licensed

electrician in accordance with National and/or

local Electrical Codes and the following

instructions.

Disconnect switch or a circuit breaker must be

provided and marked as the disconnecting

device.

Disconnect switch / circuit breaker must be

within reach of operator.

CAUTION: RISK OF ELECTRICAL

SHOCK. Turn power off at service panel before

beginning installation. Never wire energized

electrical components.

CAUTION: USE COPPER CONDUCTOR

ONLY.

Confirm device ratings are suitable for

application prior to installation. Use of device in

applications beyond its specified ratings or in

applications other than its intended use may

cause an unsafe condition and will void

manufacturer’s warranty.

Use only approved materials and components

(i.e. wire nuts, electrical box, etc.) as appropriate

for installation.

NOTICE: Do not install if product appears to be

damaged.

INSTALLATION

1. DO NOT DISCARD THE INCLUDED MAC

ADDRESS LABELS. SEE STEP (5) BELOW.

2. Turn power off at the service panel.

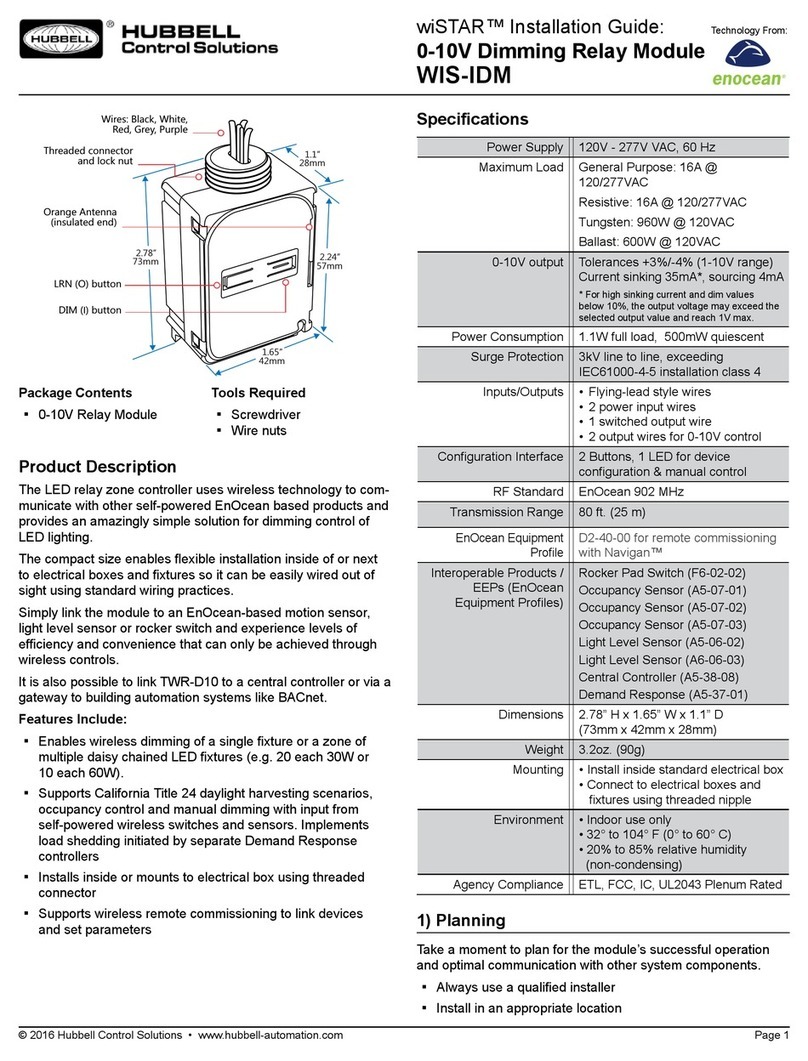

3. Mount the IFM in the installation site. See

Mounting Diagram below. Use 6x32 (or 8x32)

pan head screws to secure the module inside the

lighting fixture ballast cavity. To mount the IFM

to the outside of a junction box, use the J-Box

Mounting Adapter (sold separately – part number

WIH-IM-ADAPTER). Insert the IFM (antenna

side up) into the adapter until a click is heard. To

remove the module from the adapter, insert a

small blade screwdriver between the bottom-side