Table of Contents INFICON

iv ILS500 F_FHP-Operation-manual-ninp69en1-02-(2201)

5 Setup..............................................................................................................................................................30

5.1 Placement of the ILS500 F/FHP .............................................................................................................30

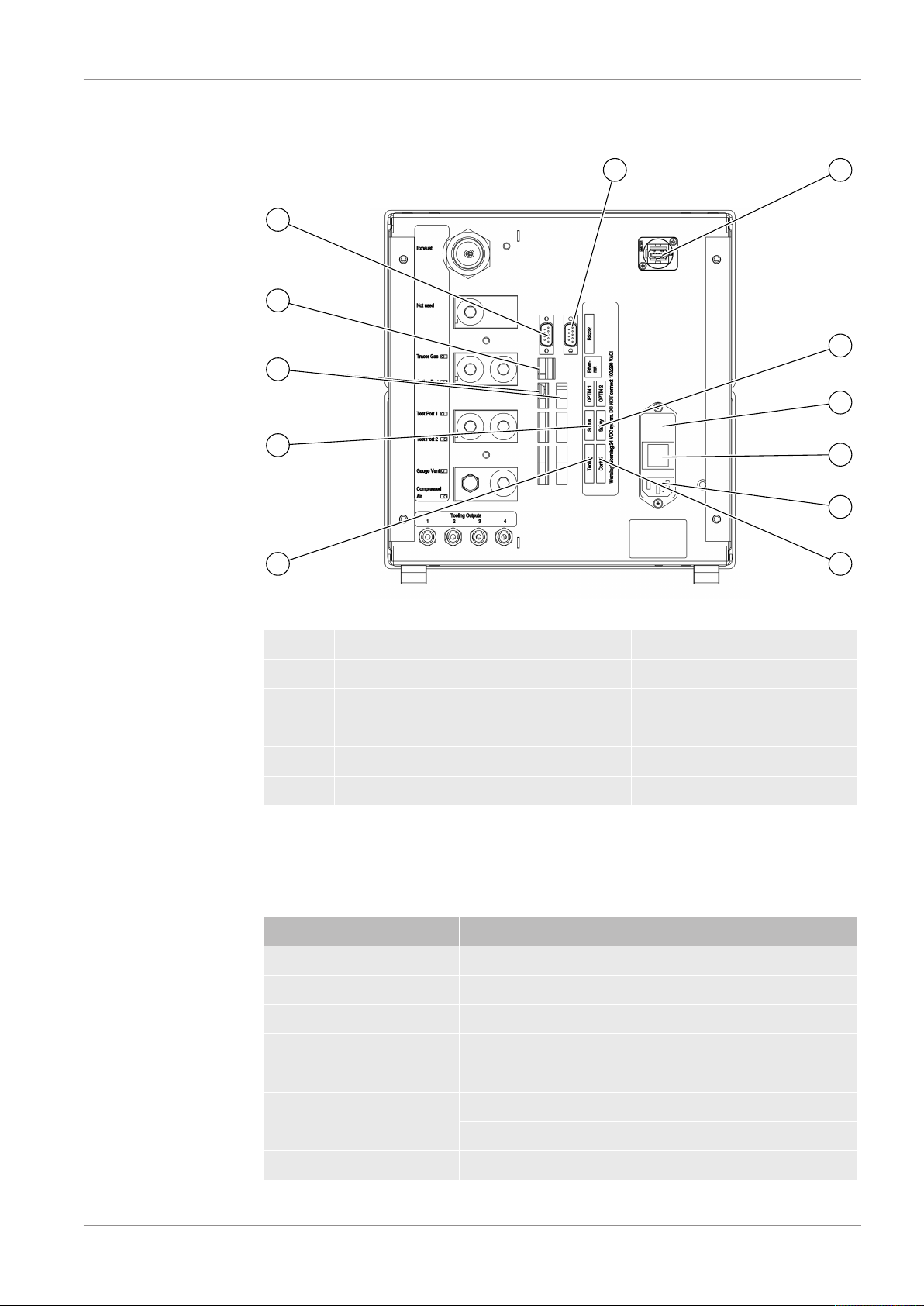

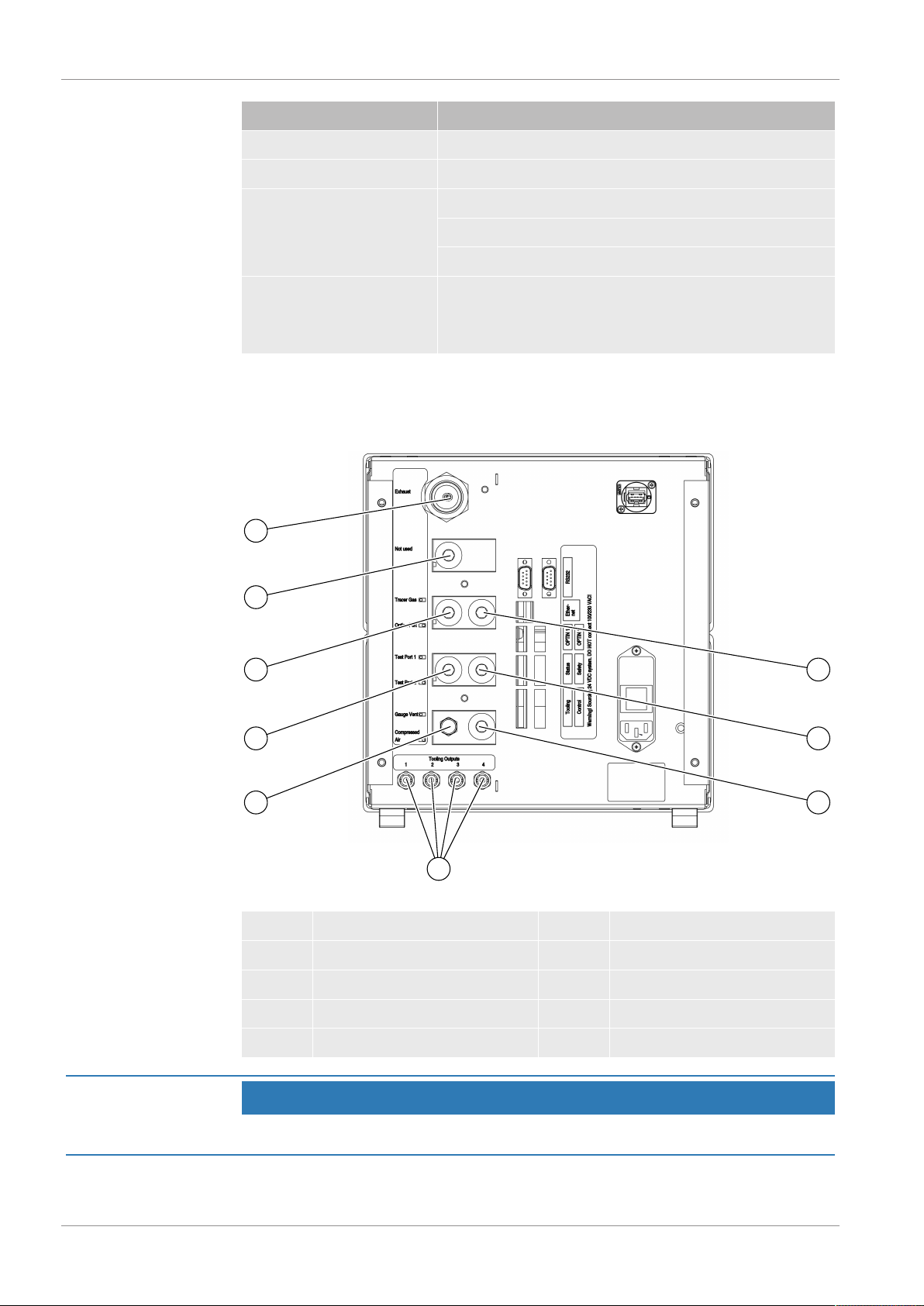

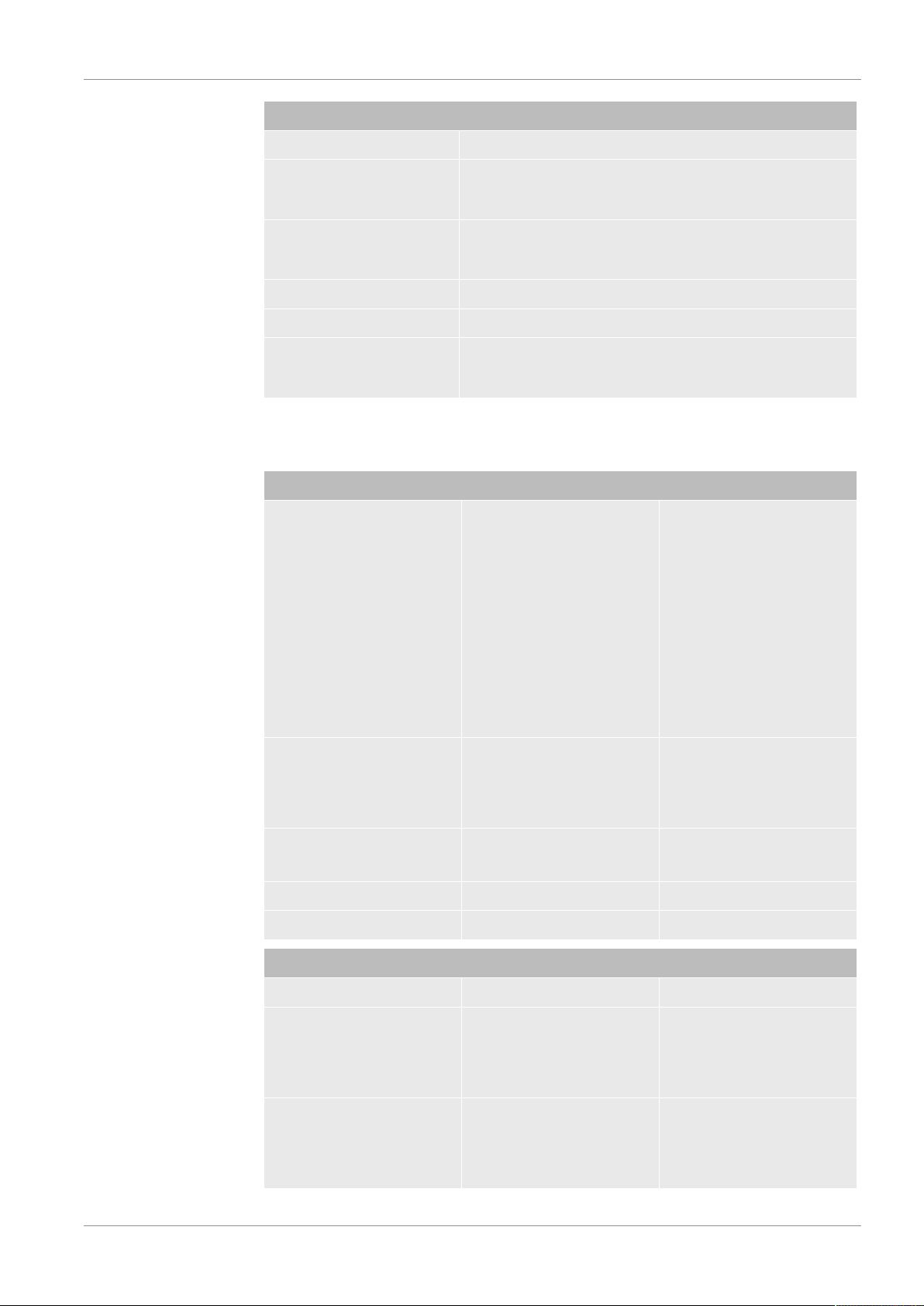

5.2 Electrical Connections ............................................................................................................................31

5.2.1 Setting Up an Emergency Stop................................................................................................... 31

5.2.2 Connecting to Mains ................................................................................................................... 31

5.2.3 Connecting Extra Features ......................................................................................................... 32

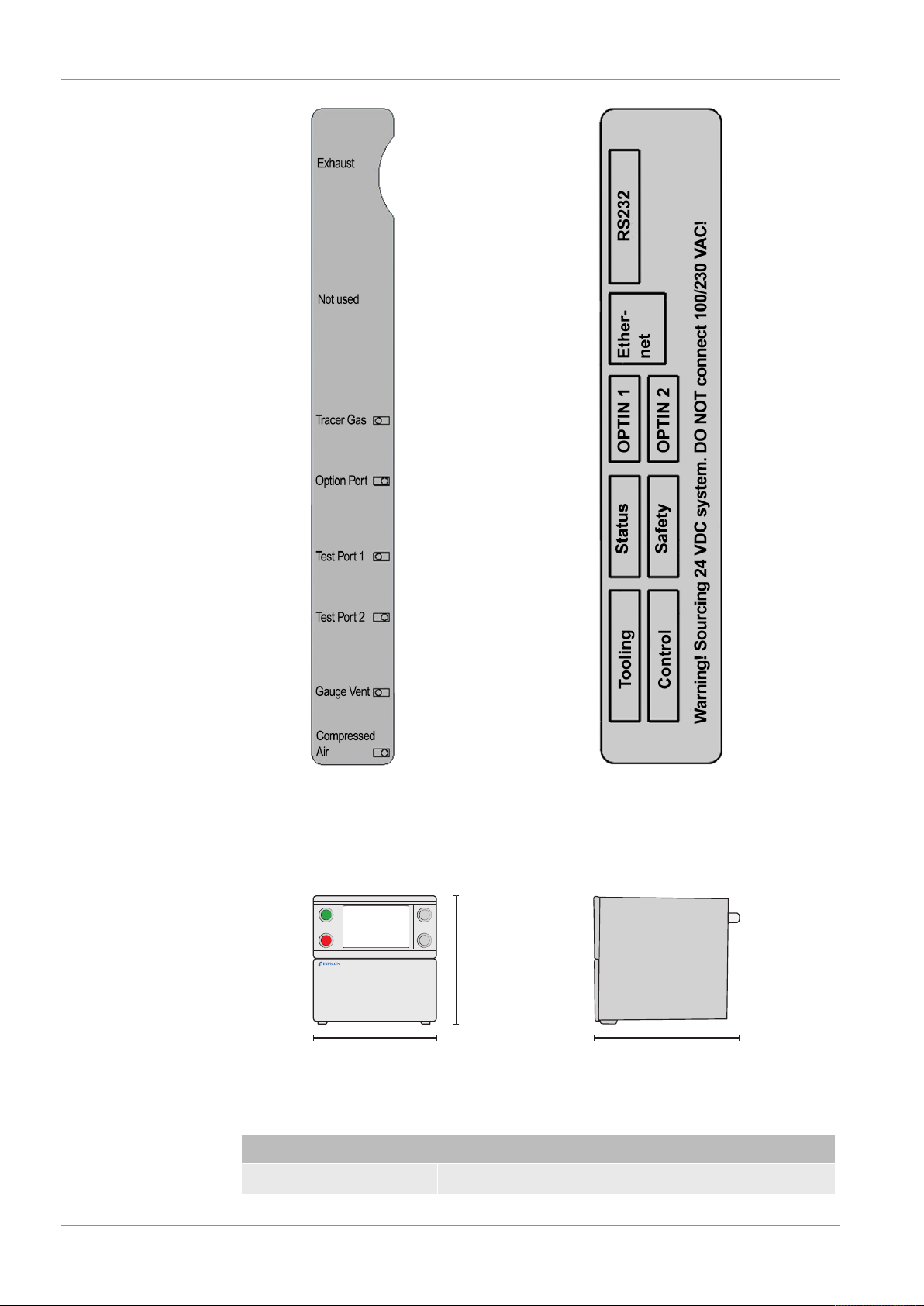

5.3 Pneumatic Connections..........................................................................................................................32

5.3.1 Connecting Compressed Air ....................................................................................................... 32

5.3.2 Connecting Tracer Gas............................................................................................................... 33

5.3.3 Connecting Exhaust to Air Vent .................................................................................................. 35

5.3.4 Connecting to Test Port 1 and 2 ................................................................................................. 36

5.3.5 Connecting Tooling ..................................................................................................................... 36

5.4 Set Up Test Area ....................................................................................................................................37

6 Menu System ................................................................................................................................................39

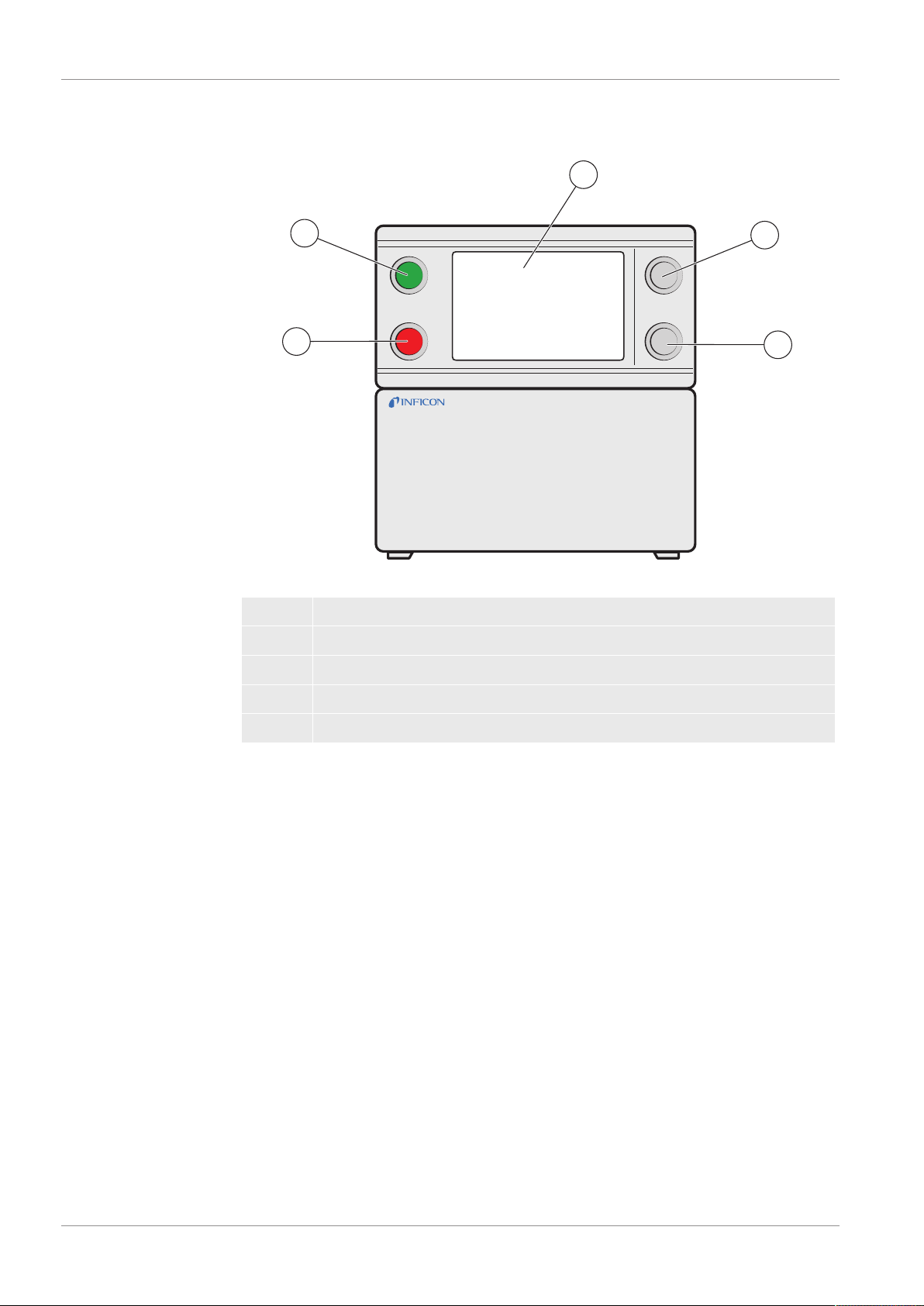

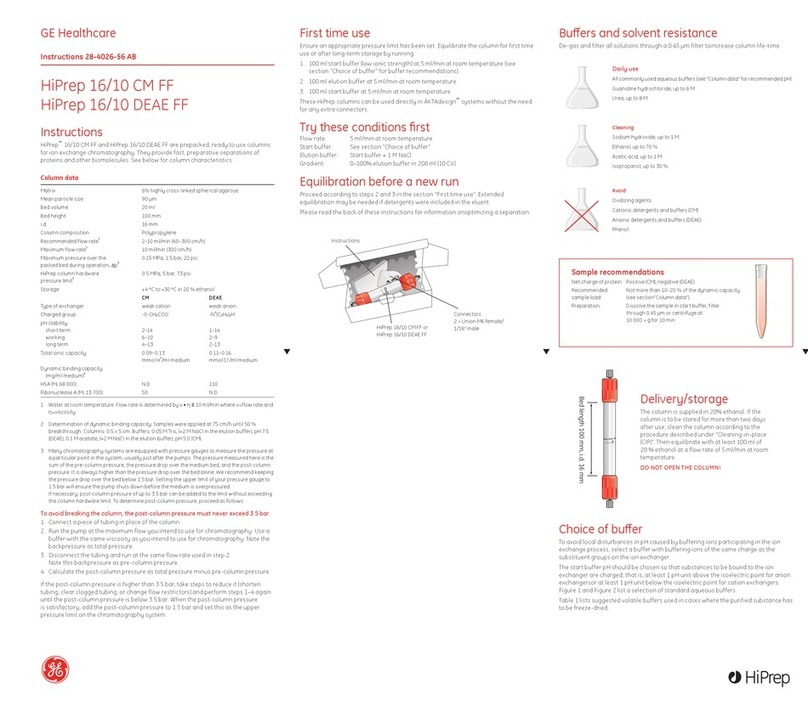

6.1 ILS500 F/FHP Display ............................................................................................................................39

6.1.1 Menu Buttons.............................................................................................................................. 39

6.1.2 Navigation and Other Buttons..................................................................................................... 39

6.1.3 Entering Numbers and Text ........................................................................................................ 40

6.1.4 Screen Saver .............................................................................................................................. 40

6.2 Passwords ..............................................................................................................................................41

6.2.1 Set Up New User ........................................................................................................................ 41

6.3 Menu Overview.......................................................................................................................................41

7 Using the ILS500 F/FHP ...............................................................................................................................47

7.1 Test Sequence........................................................................................................................................47

7.2 Run a Test ..............................................................................................................................................48

7.2.1 Start Up....................................................................................................................................... 48

7.2.2 Place the Test Object.................................................................................................................. 48

7.2.3 Perform Tracer Gas Filling.......................................................................................................... 48

8 Recipes..........................................................................................................................................................50

8.1 Recipe Overview.....................................................................................................................................50

8.2 Create a Recipe......................................................................................................................................51

8.2.1 New Recipe................................................................................................................................. 51

8.2.2 Modify a Recipe .......................................................................................................................... 52

8.3 Test Settings...........................................................................................................................................52

8.3.1 Tooling Connection ..................................................................................................................... 53