Biobase BK-HS32 User manual

Automatic Nucleic Acid Extraction System

BK-HS32

User Manual

BIOBASE GROUP

Version 2020.09

1

Preface

Thank you for purchasing Automatic Nucleic acid extraction system (BK-HS32).

Before using the instrument, please read the contents of this operation manual carefully to ensure

proper operation.

Please keep this manual well for reference when needed.

Product name:Automatic Nucleic acid extraction system

Model:BK-HS32

Scope of application:Used for the extraction and purification of nucleic acids in clinical samples.

Registrant/Manufacturer: Biobase Biodustry(Shandong) Co., Ltd.

Intellectual property

The intellectual property rights of this operation manual and its corresponding instrument belong to

Biobase Biodustry(Shandong) Co., Ltd.

Without the written consent of Biobase Biodustry(Shandong) Co., Ltd. no individual or organization

may copy, modify or translate any part of this manual.

Statements

The contents of this operation manual are consistent with the situation of this product.

Biobase Biodustry(Shandong) Co., Ltd. reserves the final right to interpret this operation manual.

Biobase Biodustry(Shandong) Co., Ltd. assumes responsibility for the safety and reliability of the

product only if it meets all of the following requirements:

Assembly, commissioning and maintenance of the instrument are performed by Biobase

Biodustry(Shandong) Co., Ltd. after-sales service engineers or other authorized professionals by

Biobase Biodustry(Shandong) Co., Ltd.;

All the parts and consumables used for replacement and maintenance are provided or accepted by

Biobase Biodustry(Shandong) Co., Ltd.;

Relevant electrical equipment complies with national standards and the requirements of this

operation manual;

The operation of this instrument is in accordance with this operation manual.

After-sales service

The standard warranty period of this product is 1 year. Within this warranty period, the products are

entitled to receive free after-sales service; however, the product needs to be repaired due to the

following reasons, which does not fall into the free after-sales range. You need to pay for

maintenance and accessories:

2

Improper use and man-made damage.

Grid voltage or electromagnetic interference does not conform to the product specified range.

Irresistible natural disasters.

Replace or use non-Biobase Biodustry(Shandong) Co., Ltd. original (original) or non-Biobase

Biodustry(Shandong) Co., Ltd. approved parts, accessories, consumables or repairied by

non-Biobase Biodustry(Shandong) Co., Ltd. authorized personnel.

After the warranty period expires, Biobase Biodustry(Shandong) Co., Ltd. can continue to

provide repair services for fees.

Disassemble the instrument by yourself.

Failures caused by other than the product itself.

User qualification

This system should only be operated by professionals, doctors, or experimenters trained by Biobase

Biodustry (Shandong) Co., Ltd. or agents of Biobase Biodustry (Shandong) Co., Ltd., and the

operator must be systematically trained in Automatic Nucleic acid extraction system (BK-HS32)to

meet the corresponding requirements, and have the following qualifications:

You must have read and understood this operation manual.

You must know computer operation to a certain level,and have a good command of the

instrument and software system operation .

You must be familiar with corresponding laboratory requirements and local laws and regulations.

About

This manual provides description about main structure, function, performance, installation, use,

operation, maintenance, repair, storage and safety precautions to protect the operator and the

instrument related with the BK-HS32, please see the corresponding chapter for details. Before using

this instrument, users should read this manual carefully for better understanding and command of the

operation knowledge.

Warning:

Personnel without professional training are forbidden to operate this

instrument.

3

Note:

The readers of this Operation Manual are the following professionals:

daily operation personnel;

Maintenance and troubleshooting personnel;

People who learn to operate.

The "extractors, instruments, and systems" mentioned in this article all refer to

"BK-HS32Automatic Nucleic acid extraction system".

4

Content

Preface.................................................................................................................................................... 1

1.Foreword............................................................................................................................................. 6

1.1 Symbols.....................................................................................................................................6

1.2 Security precautions.................................................................................................................. 7

1.2.1 Work environment requirements..................................................................................... 7

1.2.2 Electricity safety..............................................................................................................8

1.2.3 Electrical danger..............................................................................................................9

1.2.4 Mechanical danger.......................................................................................................... 9

1.2.5 Electromagnetic interference prevention.........................................................................9

1.2.6 Biological risk protection.............................................................................................. 10

1.2.7 Other precautions.......................................................................................................... 10

1.3 Accessories list........................................................................................................................ 10

1.4 Consumable service life.......................................................................................................... 10

2. Module function introduction...........................................................................................................11

2.1 Performance parameters.......................................................................................................... 11

2.2 Module structure and function................................................................................................ 12

2.2.1 Structure of magnetic rod and rod sleeve......................................................................12

2.2.2 Function of plate positions............................................................................................ 12

2.2.3 Function of floodlight....................................................................................................12

2.2.4 Function of HEPA......................................................................................................... 13

3.Operation guidance............................................................................................................................15

3.1 Boot......................................................................................................................................... 15

3.2 Program running......................................................................................................................15

3.2.1 Program viewing........................................................................................................... 16

3.2.2 Program running............................................................................................................16

3.2.3 Alarming........................................................................................................................17

3.3 Program management..............................................................................................................18

3.3.1 Add................................................................................................................................ 19

5

3.3.2 Edit................................................................................................................................ 20

3.3.3 System default program.................................................................................................21

3.4 Program management..............................................................................................................22

3.4.1 Language settings.......................................................................................................... 23

3.4.2 Instrument Debug.......................................................................................................... 23

3.4.3 Import/Export................................................................................................................ 23

3.4.4 Software upgrade...........................................................................................................23

3.5 UV disinfection....................................................................................................................... 24

3.6 About....................................................................................................................................... 25

3.7 Exit.......................................................................................................................................... 26

4.Maintenance...................................................................................................................................... 27

6

1.Foreword

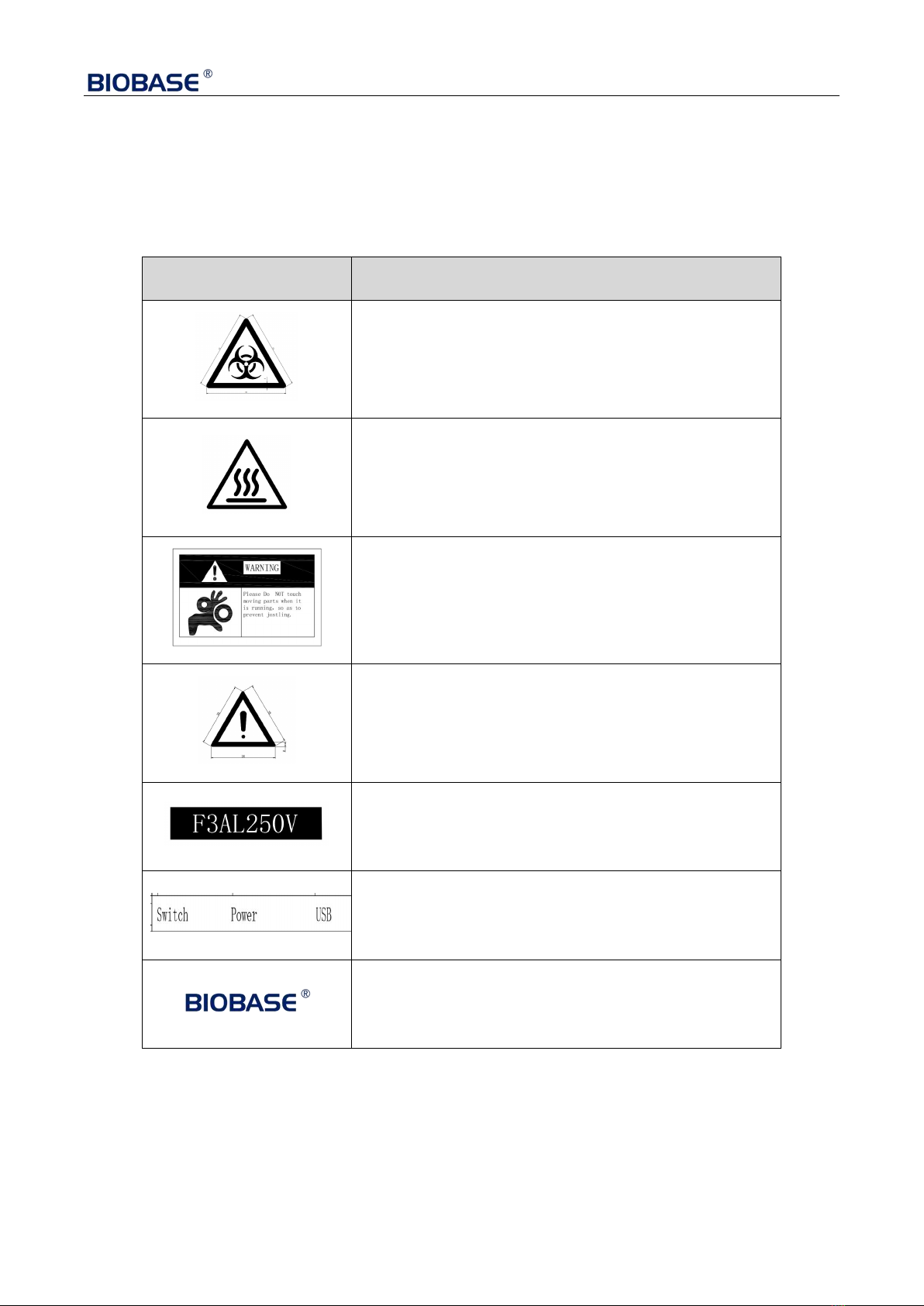

1.1 Symbols

You may see these signs, labels and symbols used with text on the BK-HS32 to remind operators of

the warnings and potential dangers, please understand the meaning of the symbols before use.

Symbols

Description

Biological risk:

This mark appears on the instrument as a warning of

the risk of contamination associated with biological or

chemical materials.

Heat warning label.

When this mark appears on the instrument, it is a

warning for high temperature parts, be careful of hot

hands.

Anti-squeeze sign.

When this mark appears on the instrument, it is a

warning for moving parts. Be careful of squeezing

hands.

Safety warning label.

When this mark appears on the instrument, attention

should be paid to safety to prevent collision or

entrainment!

Fuse specification label.

Interface and switch identification on the rear of the

instrument.

The company logo.

7

Text description in the manual.

Text

Description

Notice

Used to illustrate important information in the action steps or other

things that need to be brought to the user's attention.

Warning

Remind the user to follow the instructions, otherwise it may result in

personal injury.

1.2 Security precautions

In order to use the system safely and effectively, please read the following safety precautions

carefully. Any operation that violates the following safety precautions may result in system damage

or personal injury. If operating the instrument without following the instructions, the protective

measures provided by the system may fail.

1.2.1 Work environment requirements

Considering the safety and performance of the instrument, the

environment in which the Automatic Nucleic acid extraction system is

installed and the working environment of the instrument shall satisfy

the following scientific conditions:

environmental temperature:10℃~40℃.

Relative humidity:≤80%.

Atmospheric pressure:76kPa~106.0kPa.

No strong magnetic field interference and mechanical vibration, no

corrosive gas.

With the surrounding walls or other electrical equipment to keep a

distance of 50 cm or more.

The power supply AC 220V 50HZ

only applies elevation 2000 meters below the safe use

8

1.2.2 Electricity safety

In order to use electricity safely and prevent electric shock and damage to the instrument, please

observe the following precautions.

Warning:

This instrument is only suitable for non-domestic use and cannot

be directly connected to the residential low-voltage power supply

network.

If there are external switches or fuses or protection devices for over

current , these switches or circuit breakers should be installed near

the equipment.

Do not place the instrument where it is difficult to operate the

disconnection device. If the plug of the power supply cannot be

disconnected immediately in an emergency, make sure that the wall

socket connected to the instrument's power supply can be touched

by hand at all times.

After the installation is completed, customers are not allowed to

move the instrument without authorization. If the instrument must

be moved, please contact the installation engineer for on-site

service.

This system is connected to the ground via ground wire. The power

ground wire must be grounded to avoid electric shock.

The AC power supply must be stable. It is forbidden to share the

power supply with high-power appliances.

When the user runs or maintains the instrument, do not touch the

power connector on the back of the system, otherwise there may be

danger of electric shock.

When the main power of the instrument is turned on,

non-authorized maintenance personnel must not disassemble the

cover of the instrument.

Spilling the solution into the instrument may cause the instrument

to malfunction and cause electric shock. Do not place objects on

the instrument. In the event of a spill, immediately turn off the

power and contact Biobase Biodustry(Shandong) Co., Ltd.

Customer Service or your local service representative.

Do not plug or unplug the power supply with wet hands.

Disconnect it from all power sources before opening the instrument

for any maintenance or repair which should only be performed by a

person who is skilled and understands the hazards.

Make sure that the replaced power supply meets the requirements

9

1.2.3 Electrical danger

To prevent electrical hazards, please observe the following precautions.

Warning:

The operator must always observe the electrical safety operation

regulations. Only professional personnel can perform electrical

repairs. Please wear static-free wrist straps or gloves during

maintenance to protect the sensitive components on the instrument

from electrostatic damage.

1.2.4 Mechanical danger

To prevent mechanical hazards, please observe the following precautions.

Warning:

The moving parts of the system may cause injury to personnel

during operation. During the experiment, the door of the instrument

compartment must be closed. It is strictly prohibited to extend body

parts into the working area of the machine, otherwise it may cause

injury to operators and damage to the instrument.

1.2.5 Electromagnetic interference prevention

To prevent electromagnetic interference, please observe the following precautions.

Warning:

In order to ensure the normal operation, the user has the

responsibility to ensure that the instrument operates in an

environment of electromagnetic compatibility

Electromagnetic interference may affect the normal operation of

the device. Do not install the device in an environment with strong

electromagnetic field interference.

Do not use other medical devices that may generate

electromagnetic interference around the instrument, otherwise it

may affect the normal operation of the instrument.

of this instrument.

If the instrument may be damaged, disconnect it from the power

outlet and do not operate it again.

10

1.2.6 Biological risk protection

To prevent biohazard effectively, please observe the following precautions.

1.2.7 Other precautions

To use the instrument correctly, please observe the following precautions:

Warning:

Do not smoke or eat near the instrument.

Avoid direct sunlight when the instrument is in operation..

Please use the software installation package provided by our

company when install the user software

During user software start-up or running, it is prohibited to change

the date and time of the host.

Do not run other applications while the user software is running

1.3 Accessories list

1.4 Consumable service life

In order to ensure the stability and efficiency of the internal pollution discharge system, it is

necessary to replace the consumables in the instrument on time.

Ultraviolet lamp: service life 1000 hours.

HEPA filter: service life 500 hours.

Biological risk:

All liquids and solids in the laboratory are considered to be

biological hazards and the user must take general laboratory

precautions.

All clinical samples are considered to be potentially infectious.

Improper use may result in infection. Do not touch the samples

directly with your hands. Always wear gloves and overalls to

prevent infection during operation. Wear protective glasses when

necessary.

If the sample accidentally comes into contact with the skin, please

immediately follow the work standards for users to handle it and

consult a doctor.

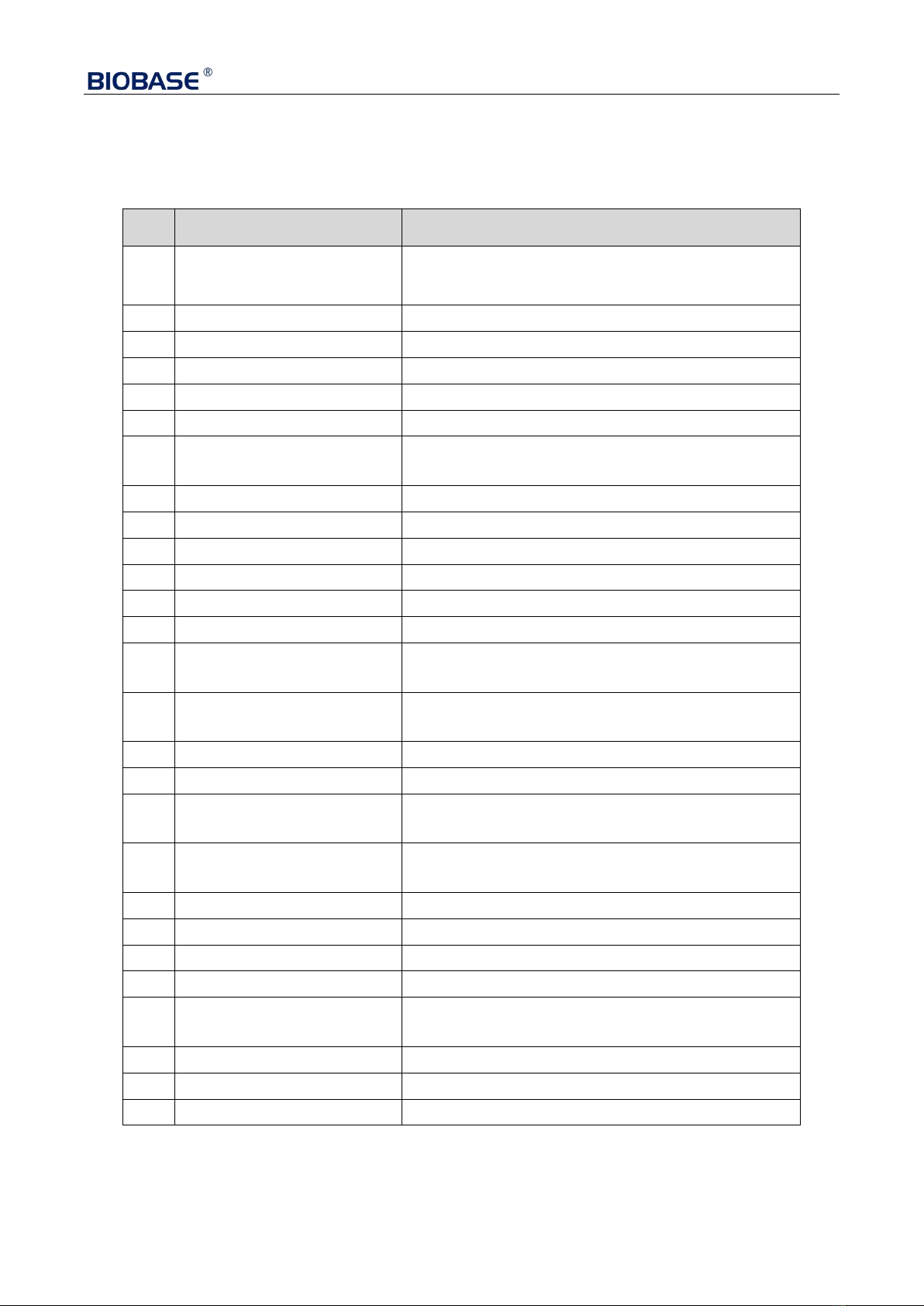

No.

Name

Specifications

Number

Note

1

Fuse

F3AL250V

2

11

2. Module function introduction

2.1 Performance parameters

No.

function

Technical parameters

1

Applicable specimen types:

Serum, plasma, lymph, allelic fluid, semen, saliva,

sputum, alveolar lavage fluid, oral swab, cell

culture supernatant or other liquid samples.

2

extraction method

Magnetic Bead Method

3

Sample throughput

32

4

Processing volume

20-1000ul

5

Processing time

15min-60min

6

Magnetic bead recovery

≥98%

7

Purification difference

between wells

<3%

8

Magnetic flux

4500Gs,Replaceable parts

9

Temperature control range

From room temperature to 100℃in lysis and

10

Oscillation function

Yes

11

Oscillation mode

Oscillating up and down(1 to 3 is adjustable)

12

Location number

2

13

Heating mode

The heating film

14

Temperature display

resolution

0.1℃

15

Sample protection function

Power on self-check, power off protection, high

temperature alarm, overtemperature protection

16

Disinfection and clean

UV lamp

17

floodlight

LED

18

Safety door design

The instrument is suspended when the safety door

is opened

19

Motor protection

The magnet motor is kept still during operation to

extend the service life of the motor and guide rail

20

The operating system

windows

21

Barcode scanning

Optional configuration

22

Item storage capacity

>1000

23

The interface type

USB(Ethernet interface can be optional)

24

Built-in air duct

The level 11 HEPA filter can effectively filter the

internal aerosol and prevent cross contamination.

25

IAP function

Yes, firmware can be updated online at any time

26

power supply

AC100-240V 50Hz/60Hz

27

Machine size

450mm*440mm*532mm

12

2.2 Module structure and function

2.2.1 Structure of magnetic rod and rod sleeve

Figure 3-1

The magnetic rod module and the rod sleeve module are independent and independently controlled

by the dual Z-axis motors. The rod sleeve module can run independently during the shake and lysis

process, and the magnetic rod module and the rod sleeve module also can run as a whole during

adsorption process. The motors do not interfere with each other during running.

2.2.2 Function of plate positions

Figure 3-2

There are two positions in the instrument where you can put the deep hole plate, a total of 24

columns of hole positions, of which:

Columns 1-8 identified in Figure 3-2 (the actual hole positions are columns 1, 6, 7, 12, 13, 18, 19, 24)

are heating modules, and the temperature control range is from room temperature to 100°C.

Four leaf springs are placed on both plate positions to fasten the deep hole plate.

2.2.3 Function of floodlight

This instrument is equipped with LED floodlights to observe the operating conditions in the cabin

during running.

Light on/off method: After the instrument is turned on, there is a "Light" button in the upper right

corner of the software interface (the position of the button will not be changed in any interface).

Click the "Light" button to turning on or turning off the light in any state.

13

2.2.4 Function of HEPA

This instrument uses the filter without partitions, which is made of fine glass fiber paper and hot melt

glue, and is used for air purification under normal temperature, normal pressure and normal humidity.

The HEPA filter can filter the aerosol generated when the instrument is heating or shaking and the

dust in daily work.

HEPA open/close method: After the instrument is turned on, there is a "Filter" button in the upper

right corner of the software interface (the position of the button will not be changed in any interface).

Click the "Filter" button to open or close the filter in any state.

15

3.Operation guidance

3.1 Boot

Turn on the power switch of the automatic nucleic acid extractor, turn on the instrument and perform

a system reset. After the reset is successful, it will enter the main menu interface.

The main interface contains 5 sub-menus such as "Run", "Program Manage", "Instrument Manage",

"UV Operator", and "About", as shown in Figure 3-1.

Figure 3-1

3.2 Program running

The program running interface contains three function buttons: "Run", "Scan code to run" and

"Select". You can view all the programs that have been entered in the list on the left.

Run: Click to select the program to be run, and then click the "Run" button to directly run the

selected program.

Scan code to run: Automatically enter the barcode in the identification kit through the external scan

code gun, and refer to chapter 3.3.3 for the introduction of System default program.

Select: Click the corresponding program, and then click "Select" to see the details of the selected

program.

16

Figure 3-2

3.2.1 Program viewing

Choose a program and click [Select] in the “Run” interface to entering the interface as Figure 3-3,

which displays the detailed steps of the program, including the steps name and the time of each step.

Figure 3-3

3.2.2 Program running

Choose a program and click [Run] in the “Run”interface to running the interface as Figure 3-4.

17

Figure 3-4

After clicking [Start], the program starts to run, [Step Remaining Time] is displayed as the remaining

running time of the current step, and [Total Remaining Time] is displayed as the overall remaining

running time of the program.

After the program starts running, the [Pause] and [Stop] keys will change from gray to clickable.

Click [Pause] to pause the program operation, and the [Pause] button to switch to [Continue], click

[Stop], the instrument stops the program operation and automatically resets.

Click [Return] to return to the upper interface.

Note:

1. Do not open the front safety door while the program is running or during the test. If the safety

door is opened, the operation will be immediately suspended until the safety door is closed and the

running program can continue.

2. When the program is not running, the [Pause] and [Stop] buttons are grayed out.

3. When the program is running, except for the [Pause] button and the [Stop] button, other buttons

are grayed out and cannot be operated until the program is finished.

4. When the running program is in the paused state, all buttons except the [Continue] and [Stop]

buttons are grayed out and cannot be operated.

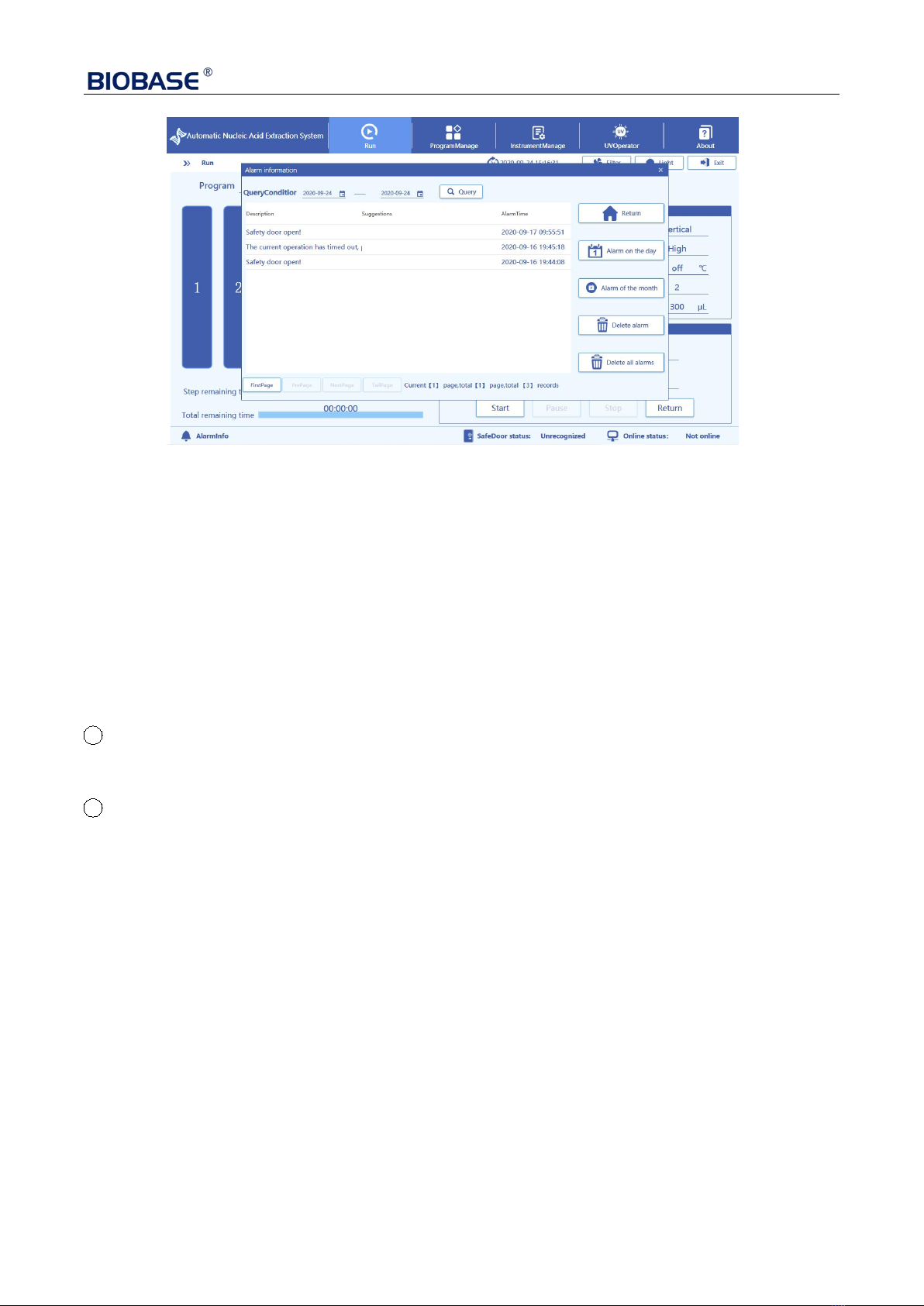

3.2.3 Alarming

If abnormal operation or abnormal reset occurs during operation, the instrument will emit a short

alarm sound, and at the same time, the alarm information will be displayed after [AlarmInfo] in the

lower left corner of the main interface of operation, as shown in Figure 3-5.

18

Figure 3-5

Common types of alarm information are as follows:

Reset failure of magnetic rod and magnetic sleeve X!

Magnetic sleeve Z reset abnormally!

The magnet Z is reset abnormally!

Cleavage temperature sensor abnormality!

Elution temperature sensor abnormality bit!

The cracking position oscillates abnormally!

Elution bit abnormal oscillation!

Safety door open!

Handling method after alarm:

1Open the safety door when the instrument is running, the safety door will alarm with a short

alarm sound and automatically suspends. The instrument cannot automatically resume operation

until the door is manually closed.

2Under the premise that the mechanical position of the instrument has not been altered without

authorization, the instrument will usually not alarm except for the opening of the safety door.

Once it happens, please contact the after-sales engineer immediately.

3.3 Program management

Click [Program Manage] to enter the program management interface as shown in Figure 3-6. All the

programs that have been entered will be displayed in this interface, and the programs can be edited,

deleted or added.

Add: Create a new program.

Edit: Select a program and click [Edit] to edit the parameters of the program.

Delete: Select a program and click [Delete] to delete this program.

Return: Return to the upper interface.

19

Figure 3-6

3.3.1 Add

Click [Add] to enter the interface as shown in Figure 3-7 to create a new program. Click [Add] after

"Program Name" to set the program name, and the [Add] button is replaced with [Cancel]. After

entering the program name, the following [Save] button changes from gray to clickable, click [Save]

to save the program name settings.

Figure 3-7

Table of contents

Other Biobase Laboratory Equipment manuals

Biobase

Biobase BCI-I User manual

Biobase

Biobase BBS-H1300 User manual

Biobase

Biobase BSC-3FA2-HA User manual

Biobase

Biobase BK-DH2000 User manual

Biobase

Biobase BBS-DDC User manual

Biobase

Biobase BBS-V800 User manual

Biobase

Biobase LC-4KC User manual

Biobase

Biobase BKQ-B Series User manual

Biobase

Biobase BK-AutoHS96 User manual

Biobase

Biobase BSC-3FA2-NA User manual

Popular Laboratory Equipment manuals by other brands

VistaLab

VistaLab Ovation 9060-4005 Replacement instructions

Forma Scientific

Forma Scientific 1284 instruction manual

Picotest

Picotest J2200A user manual

DRG

DRG BioCheck DxDATA user manual

illumina

illumina MiSeqDx Instrument Safety and compliance guide

Metkon

Metkon FORCIPOL Series Operation & instruction manual