Inficon TC3000L Quick guide

Translation of the original operating instructions

TC3000L

Large rigid test chamber for ELT3000

mimc95en1-01-(2112)

Catalog No.

600-101

From software version

--

INFICON GmbH

Bonner Strasse 498

50968 Cologne, Germany

INFICON Table of contents

TC3000L-Operating-instructions-mimc95en1-01-(2112) iii

Table of contents

1 About this manual ..........................................................................................................................................4

1.1 Target groups ...........................................................................................................................................4

1.2 Warnings...................................................................................................................................................4

1.3 Definition of terms.....................................................................................................................................5

2 Safety...............................................................................................................................................................6

2.1 Intended use .............................................................................................................................................6

2.2 Duties of the operator ...............................................................................................................................8

2.3 Owner requirements .................................................................................................................................8

2.4 Dangers ....................................................................................................................................................9

3 Scope of delivery, transport ........................................................................................................................11

4 Description....................................................................................................................................................12

4.1 Function ..................................................................................................................................................13

4.2 Markings on the device...........................................................................................................................13

4.3 Technical data ........................................................................................................................................14

5 Installation.....................................................................................................................................................15

6 Operation.......................................................................................................................................................18

6.1 Carrying out leak testing .........................................................................................................................20

7 Cleaning and maintenance ..........................................................................................................................21

8 Sending in the device...................................................................................................................................23

8.1 Disposal ..................................................................................................................................................23

9 Declaration of Contamination .....................................................................................................................24

10 Declarations of Conformity .........................................................................................................................25

1 | About this manual INFICON

4 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112)

1 About this manual

1.1 Target groups

This instruction manual is intended for operators and technically qualified personnel

with experience in leak detection technology and the integration of leak detectors in

leak detection systems. In addition, the installation and use of the device require

knowledge of electronic interfaces.

1.2 Warnings

DANGER

Imminent hazard resulting in death or serious injuries

WARNING

Hazardous situation resulting in potential death or serious injuries

CAUTION

Hazardous situation resulting in minor injuries

NOTICE

Hazardous situation resulting in damage to property or the environment

INFICON About this manual | 1

TC3000L-Operating-instructions-mimc95en1-01-(2112) 5 / 28

1.3 Definition of terms

Minimum detectable leak rate

The minimum detectable leak rate that can be detected by the leak detector under

ideal conditions (< 1 x 10-6 mbar l/s*).

* Helium equivalent leak rate for DMC with a pressure difference of 1000 mbar versus

0 mbar.

GCU

Gas Control Unit (basic unit, operating unit)

GDU

Gas Detection Unit

DMC

Dimethyl carbonate, typical solvent in battery electrolyte. CAS No. 616-38-6

MSDS

Material Safety Data Sheet

2 | Safety INFICON

6 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112)

2 Safety

2.1 Intended use

The test chamber is designed for leak testing of Li-ion cells and Li-ion batteries.

Uncharged cells/batteries can be tested safely. For testing charged cells/batteries,

further safety measures must be taken to avoid personal injury and damage to

property.

• For validation of the test, cells prepared as leaky are placed in the chamber. The

preparation of the cells, which creates further hazards, is performed by the

operator and is not an integral part of the test or the device. Testing of leaking

cells will result in soiling of the test chamber and possibly "contamination". Cells to

be tested with the test chamber must be pre-qualified. For this purpose,

uncharged cells are examined, for example, to determine whether they can

withstand the stresses of the leak testing. Suitable measures for the safety of man

and machine must be taken by the operator.

• The test objects must be filled with an electrolyte in which one solvent component

ideally consists of dimethyl carbonate (DMC, CAS No. 616-38-6).

• Depending on the internal structure of the test objects and the external

geometries, local mechanical stresses can occur on the test objects. This can

damage the test objects themselves, but also other components located in the test

chamber.

• Make sure that the test chamber and the outer wall of the test objects are clean.

Leak testing with charged test objects represents an additional safety risk and

should only be carried out by appropriately trained personnel and with the

installation of further safety measures.

• To avoid short circuits between the test object and chamber wall, use the insulator

included in the scope of delivery.

• An external pump may optionally be connected to the ISO-KF16 connection

according to the specifications in the documentation. The pump is not included in

the scope of delivery. The pump capacity must be at least 40 L/min up to 1000 L/

min. The optional external pump must be connected via an electrically switchable

valve, a corrugated hose and, if required, a suitable adapter.

Incorrect usage Avoid the following unintended uses:

• Testing of partially or fully charged cells and batteries without further safety

measures.

• Use outside the technical specifications, see "Technical Data".

• Testing of non-vacuum Li-ion cells, batteries or other test objects.

INFICON Safety | 2

TC3000L-Operating-instructions-mimc95en1-01-(2112) 7 / 28

• Testing of Li-Ion cells, batteries or other test objects that cannot withstand the

stresses that occur during testing. Depending on the internal structure of the test

objects and the external geometries, local mechanical stresses can occur on the

test objects. This can damage the test objects themselves, but also other

components in the test chamber.

• Testing of test objects whose current collectors can be short-circuited via the test

chamber (e.g. via the lid or other conductive parts).

• Testing of test objects that come into contact with the sealing lips of the chamber.

• Testing of wet or moist test objects.

• Testing of test objects with significant temperature differences to the environment.

• Testing of damaged test objects, batteries or other test objects.

• Testing of test objects without insulator.

• Testing of components or substances other than lithium-ion batteries.

• Testing of contaminated test objects.

• Operation of a contaminated test chamber.

• Installation and operation in potentially explosive atmospheres.

• Installation and operation in locations with very low humidity.

• Operation of the chamber by inadequately trained personnel.

• Insufficient distance between the test objects in the test chamber.

• Use beyond the technical specifications.

• Use in radioactive areas.

• Closing the test chamber while your fingers are in the rotation range of the test

chamber.

• Use of unauthorized accessories or spare parts.

• Mounting by untrained or unauthorized personnel. Only trained personnel or

INFICON employees are permitted to carry out the assembly.

• Interchanging the exhaust air ("INLET") and supply air ("VENT") lines on the

ELT3000.

• Pumping out liquids or vapors that can condense.

• Using an improperly dimensioned optional external pump.

• Use of the optional pump connection for abrupt venting.

• Testing of test objects that are too small or too light and may move uncontrollably

during venting.

• Use of tools that may damage the sealing surfaces of the test chamber during

mechanical cleaning.

2 | Safety INFICON

8 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112)

This device is not intended to be used in residential areas and cannot ensure

adequate protection of radio reception in such environments. The battery leak detector

does not perform a safety function. In the event of strong electromagnetic interference,

measured values could be falsified. It is recommended to check the function of the test

chamber regularly (e.g. with a calibration leak).

2.2 Duties of the operator

• Read, observe, and follow the information in this manual and in the work

instructions provided by the owner. This concerns in particular the safety and

warning instructions.

• Always observe the complete operating instructions for all work.

• If you have any questions about operation or maintenance that are not answered

in this manual, contact customer service.

2.3 Owner requirements

The following notes are for companies or any person who is responsible for the safety

and effective use of the product by the user, employees or third parties.

Safety-conscious operation

• Only operate the test chamber and the battery leak detector if it is in technically

perfect condition and shows no signs of damage.

• Only operate the test chamber and the battery leak detector as intended, in a

safety-conscious and hazard-conscious manner and in compliance with these

operating instructions.

• Provide ambient conditions that are suitable for operating staff, the test chamber

and the test specimen.

• Adhere to the following regulations and observe their compliance:

– Intended use

– General applicable safety and accident prevention regulations

– International, national and local standards and guidelines

– Additional device-related provisions and regulations

• Only use original parts or parts approved by the manufacturer.

• Keep this instruction manual available on site.

Personnel qualifications

• Only allow instructed personnel to work with the test chamber and the battery leak

detector. The instructed personnel must have received appropriate training. This

includes knowledge of the dangers posed by leaking electrolyte/solvent.

INFICON Safety | 2

TC3000L-Operating-instructions-mimc95en1-01-(2112) 9 / 28

• Make sure that authorized personnel have read and understood the instruction

manual and all other applicable documents.

2.4 Dangers

The measuring instrument was built according to the state-of-the-art and the

recognized safety regulations. Nevertheless, improper use may result in risk to life and

limb on the part of the user or third parties, or damage to the unit or other property

may occur.

WARNING

Danger to health due to hazardous materials and substances

Test specimens are usually filled with substances that are hazardous to health. If

these substances leak during the test, they are freely accessible to the operator after

the test.

► Wear appropriate protective clothing, especially gloves, gowns, and face shields.

► Ensure sufficient ventilation at the installation location.

► Avoid contact with skin, eyes, or clothing.

► Avoid inhaling these substances.

► Only test specimens for leak tightness that do not show any damage or smell of

electrolyte or solvent after initial inspection.

► Before removing the test specimen (visual check and smell test), check whether

any contents of the test specimen have leaked out.

► Pay attention to the risks posed by released electrolyte components and their

reaction products.

► Defective test specimens can develop gross leaks during the leak testing. In the

case of test specimens with gross leaks, observe the company's internal regulations

for handling electrolyte and the safety instructions in the safety data sheets.

► Do not pump out toxic or corrosive gases.

► Clean the device regularly and keep it clean at all times.

► Observe the safety instructions in the safety data sheets for the test objects.

► Operate the device only with a connected exhaust air connection and in well-

ventilated rooms. Alternatively, the device may be used in rooms where hazardous

substances under test are monitored.

► When nitrogen or argon is used as a purge gas, it can cause asphyxiation at

dangerous room concentrations. Suitable measures must be taken. The pressure in

the gas line to the purge gas connection must not exceed 100 mbar over

atmospheric pressure. An exhaust gas line must be connected.

2 | Safety INFICON

10 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112)

WARNING

Fire and explosion hazard

Reaction products during combustion can lead to further health risks.

► Do not operate the device unattended.

► Only operate the device with the exhaust hose connected.

► Do not pump off explosive gases.

CAUTION

Warning about hand injuries

Danger of crushing by opening the flap if the clearance is too small at the top and rear.

Danger of crushing when closing the test chamber lid in the gap between the test

chamber lid and the test chamber, or between the test chamber rings.

► Ensure that there is sufficient space where the devices are located, see also

"Setup".

► Only open and close the test chamber when your fingers are outside the test

chamber halves and outside the pivoting range of the test chamber.

► Do not touch the hinge when closing the test chamber.

Measurement inaccuracies due to dirty test chamber

Escaping electrolyte can contaminate the test chamber.

► After detecting leakage, check the test chamber for contamination caused by

escaping electrolyte.

► Avoid inhaling harmful gases or vapors.

► Keep the gasket of the test chamber clean. Do not use grease or lubricants.

► Remove coarse soiling with a dust-free cloth. This soiling can falsify the

measurement results. The device features a purging function which can be carried

out in case of minor soiling, see ELT3000 instructions "Purging the device". Use

personal protective equipment.

INFICON Scope of delivery, transport | 3

TC3000L-Operating-instructions-mimc95en1-01-(2112) 11 / 28

3 Scope of delivery, transport

Scope of delivery Item Quantity

Test chamber TC3000L 1

Operating instructions 1

Insulator 1

Inline Filter 1

"VENT" hose 1

"INLET" hose 1

Angle clips 12

►Check the scope of delivery after receipt of the product to make sure it is complete

and it has no visible damage.

Transport

NOTICE

Damage caused by transport

Transport in unsuitable packaging material can damage the device.

► Keep the original packaging.

► Only transport the device in its original packaging.

4 | Description INFICON

12 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112)

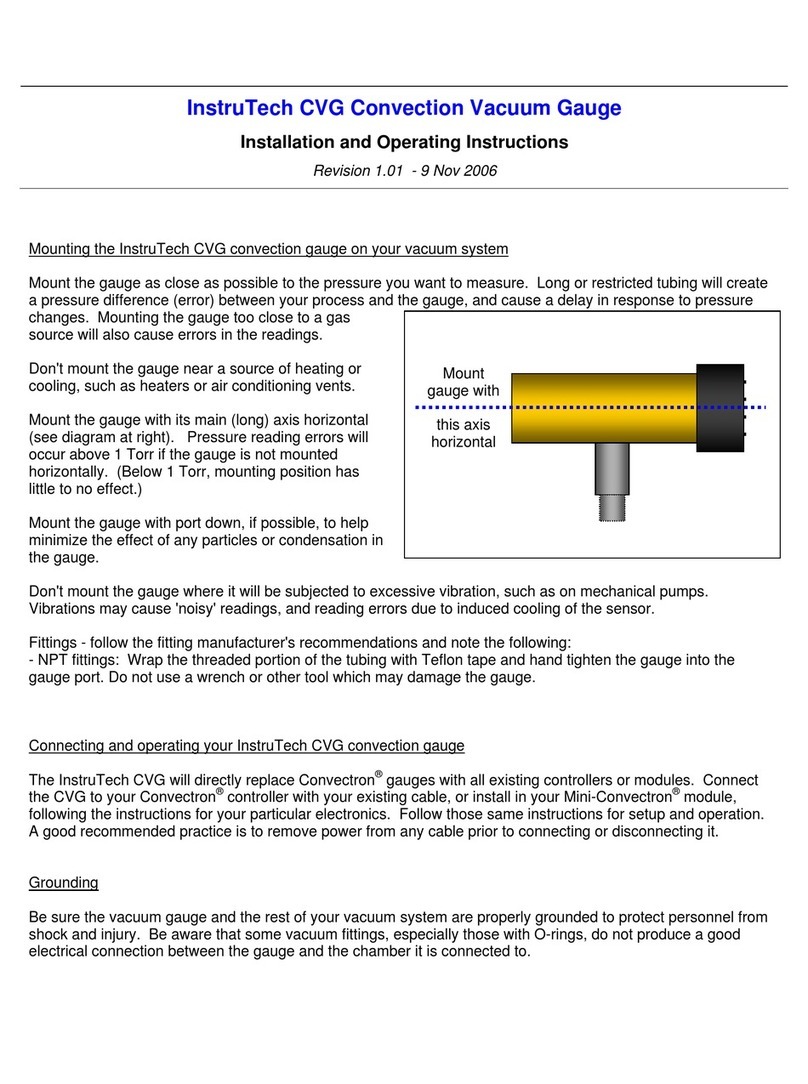

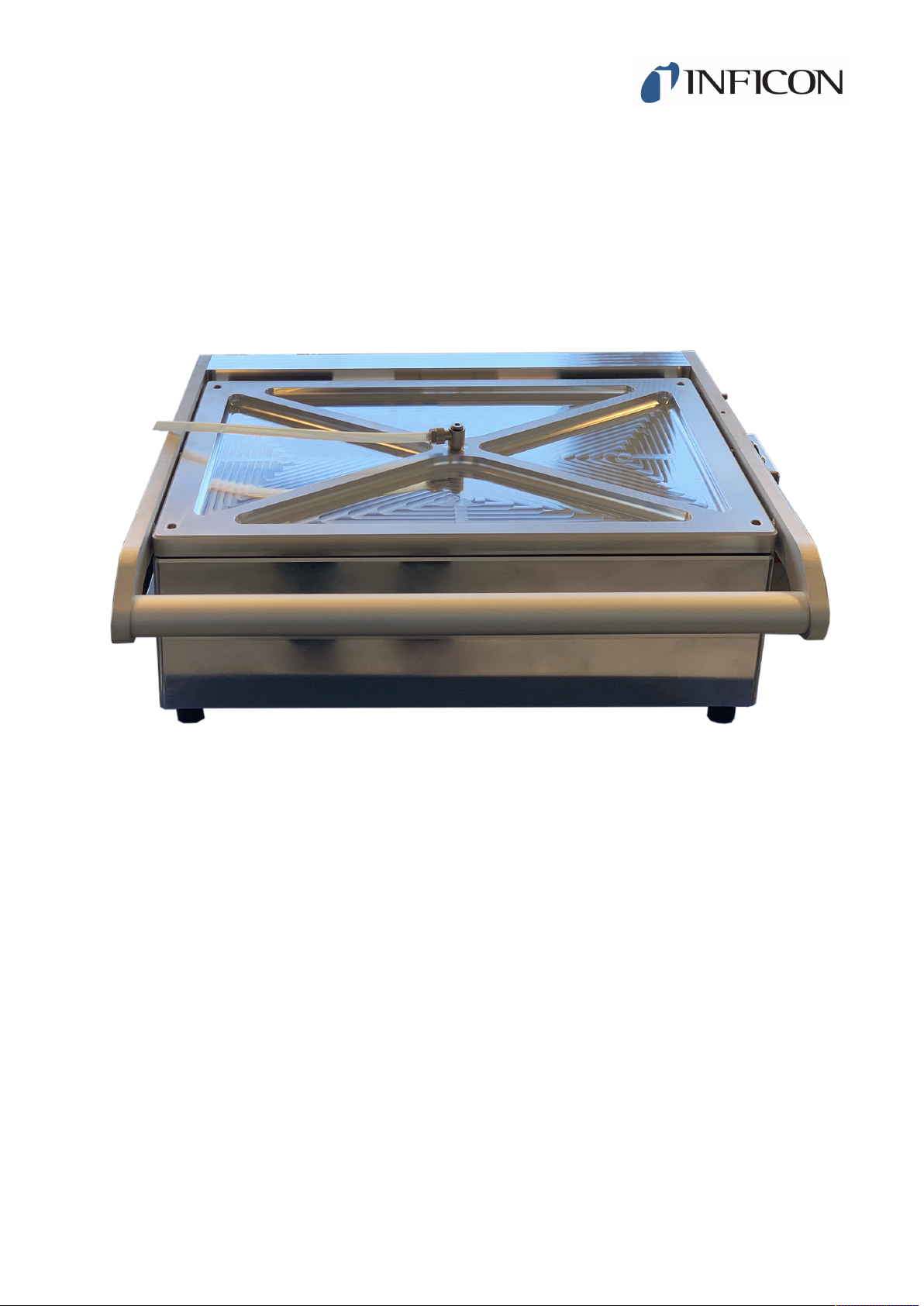

4 Description

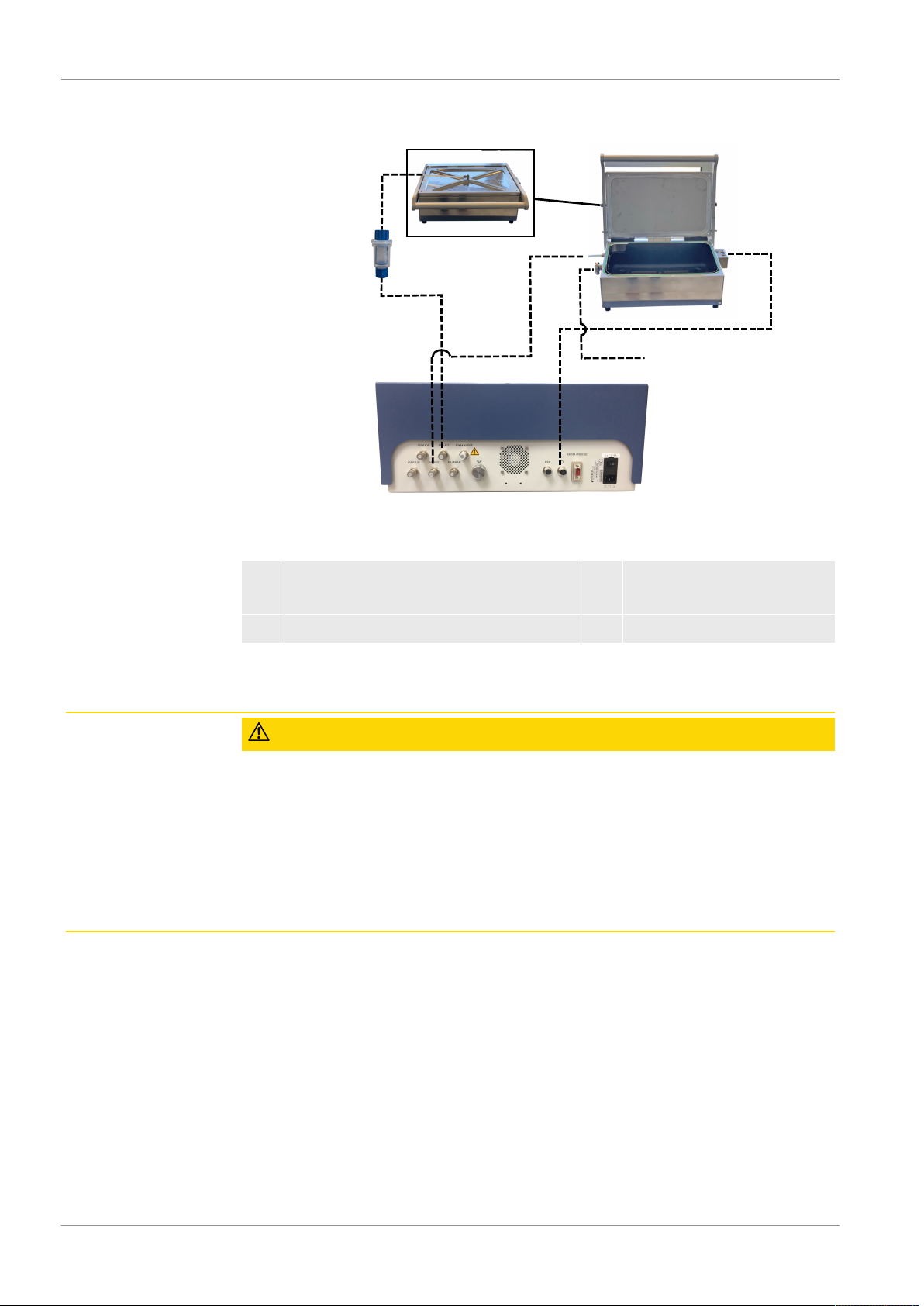

TC3000L overview

1 2 3

5

8 7 6

4

Fig.1: TC3000L

1 "INLET" connection 5 Connection for optional auxiliary pump

2 "VENT" connection 6 Hinge (spring-mounted)

3 Proximity switch with red-green display

(for automatic measurement start)

7 Hinge (dampened)

4 Insulator 8 Hinge (spring-mounted)

INFICON Description | 4

TC3000L-Operating-instructions-mimc95en1-01-(2112) 13 / 28

4.1 Function

The test chamber, in conjunction with the Gas Control Unit of the ELT3000, makes it

possible to perform leak testing on test objects. Test objects that are not vacuum-tight

can thus be tested for leak tightness.

Place the test object in the test chamber. By pumping out the air from the test

chamber, a pressure gradient between test object and test chamber is generated.

Due to this pressure gradient, gas flows through leakages out of the test object and

into the test chamber. This gas is sent to the GDU (Gas Detection Unit) for analysis.

After the analysis, the result is compared with the setpoint. A distinguishable leak-

proof/leaky signal is output.

4.2 Markings on the device

The markings on the device have the following meanings:

Device cannot be disposed of as normal domestic waste.

Note: Only put objects that are obviously undamaged and vacuum-tight in

the device.

Warning about hand injuries

Read operating instructions

4 | Description INFICON

14 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112)

4.3 Technical data

Mechanical data

Dimensions (L × W × H) 420mm x 550mm x 200mm

Installation depth 600mm

Weight 17.0 kg

Electrical data

Operating voltage 24V DC

Power consumption 5VA

Physical data

Pressure range 1080 hPa to 1 hPa

Ambient conditions

Temperature range (°C) 10 °C to 40 °C

Relative humidity (%) 80 % at 30 °C, linear decrease to 50% at

40 °C

Height above sea level (m) 2000m

Degree of contamination II

INFICON Installation | 5

TC3000L-Operating-instructions-mimc95en1-01-(2112) 15 / 28

5 Installation

WARNING

Risk of injury from escaping electrolytes

► Make sure that you do not incorrectly swap the vent line and the inlet line when

connecting the lines on the ELT3000 battery tester.

CAUTION

Risk of injury from falling or tipping device

If the device slips off its surface, it can fall down and crush your feet.

► Only place the test chamber on a clean, horizontal, non-slip and vibration-free

surface.

► The recommended installation height of the chamber is 27.6 - 35.4 in. (70 - 90 cm).

The choice of the best ergonomic installation height is the responsibility of the

owner.

► Do not place the test chamber on the gas control unit.

► Use non-slip rubber bumpers for the device feet.

NOTICE

Property damage due to improper installation

It is recommended to have the installation carried out by INFICON or by trained

personnel.

5 | Installation INFICON

16 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112)

Installation scheme

1

2

3

4

1 "INLET" connection 3 External pump connection

(optional)

2 "VENT" connection 4 Proximity switch connection

Connecting an external pump (optional)

CAUTION

Uncontrolled movements of chamber lid or test objects

An incorrectly selected or incorrectly connected external pump can lead to hazards

from the lid or test objects, which can move uncontrollably due to excessive air flows.

► Only use an external pump that complies with the permitted technical data.

► When installing and commissioning an external pump, be sure to follow the

instructions below.

To increase the pumping capacity, you can connect an external pump to the ISO-

KF16 connection. The ISO-KF16 connection is closed with a blind flange when

delivered. To do this, connect an electrically switchable valve with a minimum nominal

diameter of DN4 to the ISO-KF16 connection. The valve must be suitable for a

pressure range of at least 0 to 1.5 bar (absolute). This enables the external pump to

be switched on and off later. When using an IO1000 module connected to the

ELT3000, the valve can be switched via one of the PLC outputs. Please note that the

valve is switched with 24V, with a maximum current consumption of 0.75 A. You can

connect a suitable pump to the valve via a corrugated hose and adapter. For this

INFICON Installation | 5

TC3000L-Operating-instructions-mimc95en1-01-(2112) 17 / 28

purpose, we recommend the use of a single-phase, dry vacuum pump with a pumping

capacity of at least 40 L/min (up to 1000 L/min). The external pump is not operated via

the ELT3000, but must be permanently operated externally.

6 | Operation INFICON

18 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112)

6 Operation

WARNING

Risk of injury from explosion

If both battery poles come into contact with the electrically conductive test chamber, a

short circuit and thus high temperatures can occur in the tested battery.

► Do not perform a battery test without the original insulator.

► Make sure that the battery connections do not touch the test chamber cover.

► Only test vacuum-tight and obviously undamaged battery cells in this test chamber.

► Make sure that there is no material in the test chamber that could damage the

battery (e.g. pointy, sharp objects).

► Leave batteries in the chamber only for the test period, and not permanently.

► Keep the test chamber clean and clean it regularly.

► No smoking.

► Keep ignition sources away from the test chamber.

WARNING

Respiratory tract irritation

The solvents in lithium-ion batteries can cause respiratory irritation and loss of

consciousness if they leak from the battery.

► To avoid irritating your airways, avoid contact with electrolytes.

► Only place vacuum-tight and obviously undamaged battery cells in this test

chamber.

WARNING

Damage to battery cells due to pointed foreign objects

Pointed foreign bodies can penetrate battery cells during the test procedure and

trigger a short circuit.

► Make sure that the test chamber is always free of pointed foreign bodies.

CAUTION

Warning about hand injuries

► Only open and close the test chamber when your fingers are outside the pivoting

range of the test chamber.

INFICON Operation | 6

TC3000L-Operating-instructions-mimc95en1-01-(2112) 19 / 28

CAUTION

Danger due to physical stress / ergonomics

Continuous opening and closing of the test chamber cover can result in fatigue of the

arm muscles.

Incorrect setup of the test chamber can impair its moving parts.

► Plan enough breaks to avoid fatigue.

► Set up the test chamber so that there is no impairment of its moving parts.

ðWhen setting up the test chamber, pay attention to the height and distance

from the operator.

ðPay attention to the arrangement of the test object trays.

► Do not lean on the handle of the test chamber.

► If a sudden change in opening or closing forces is observed while operating the

chamber, check all hinges immediately and replace if necessary.

NOTICE

Property damage due to accumulation or blockage in detachable parts

with solvents

Accumulation or blockage in detachable parts due to solvents lead to functional

problems.

► Replace the particle filter as needed or annually.

► Replace all gaskets and hoses as necessary, otherwise annually.

6 | Operation INFICON

20 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112)

6.1 Carrying out leak testing

This test chamber is used to perform leak tests on vacuum-tight and undamaged test

objects (lithium-ion batteries).

üThe test chamber and Gas Control Unit are properly connected, see also

"Installation".

üThe Gas Control Unit is switched on. The two LEDs flash simultaneously during

startup.

1Place the test object in the test chamber.

2By closing the cover you actuate the proximity switch and the measurement is

started.

ðThe air is pumped out of the test chamber.

ðAfter the analysis, the result is compared with the setpoint and shown on the

display of the Gas Control Unit.

ðThe red LED lights up when a leak greater than the configured setpoint has

been detected.

ðThe green LED lights up when a leak less than the configured setpoint has

been detected.

3You can now open the lid and remove the test object. Skin contact with

electrolytes when cleaning the test chamber or removing leak-tested test

objects should be avoided.

Table of contents

Other Inficon Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

DIGISYSTEM

DIGISYSTEM DSB-500D instruction manual

NACALAI TESQUE

NACALAI TESQUE COSMOSIL PACKED COLUMN quick start guide

Bruker BioSpin

Bruker BioSpin CryoProbe RF CRP RF UNIT Technical manual

Drummond

Drummond Pipet-Aid XL 4-000-105 Operation manual

Nouvag

Nouvag MD 30 Operation manual

Datacolor

Datacolor CONDITIONER Operation manual

Thermo Scientific

Thermo Scientific 3911 operating manual

Datalogic

Datalogic Heron HD3430 Product reference guide

Bruker

Bruker Ascend 400'89 user manual

Ametek

Ametek Spectro MIDEX Original operating instructions

Agilent Technologies

Agilent Technologies 1290 infinity user manual

Teledyne

Teledyne ASX-560 Quick installation guide