InfoSense SL-RAT Sewer Series User manual

1

Table of Contents

1. Introduction..................................................................................................................................................3

2. SL-RAT Overview...........................................................................................................................................3

2.1. Features................................................................................................................................................3

2.2 Applications..........................................................................................................................................3

2.3 Identify Parts and Controls ...................................................................................................................4

2.4Transporting .........................................................................................................................................6

2.4.1. Transporting by Foot....................................................................................................................6

2.4.2. Transporting by Vehicle................................................................................................................7

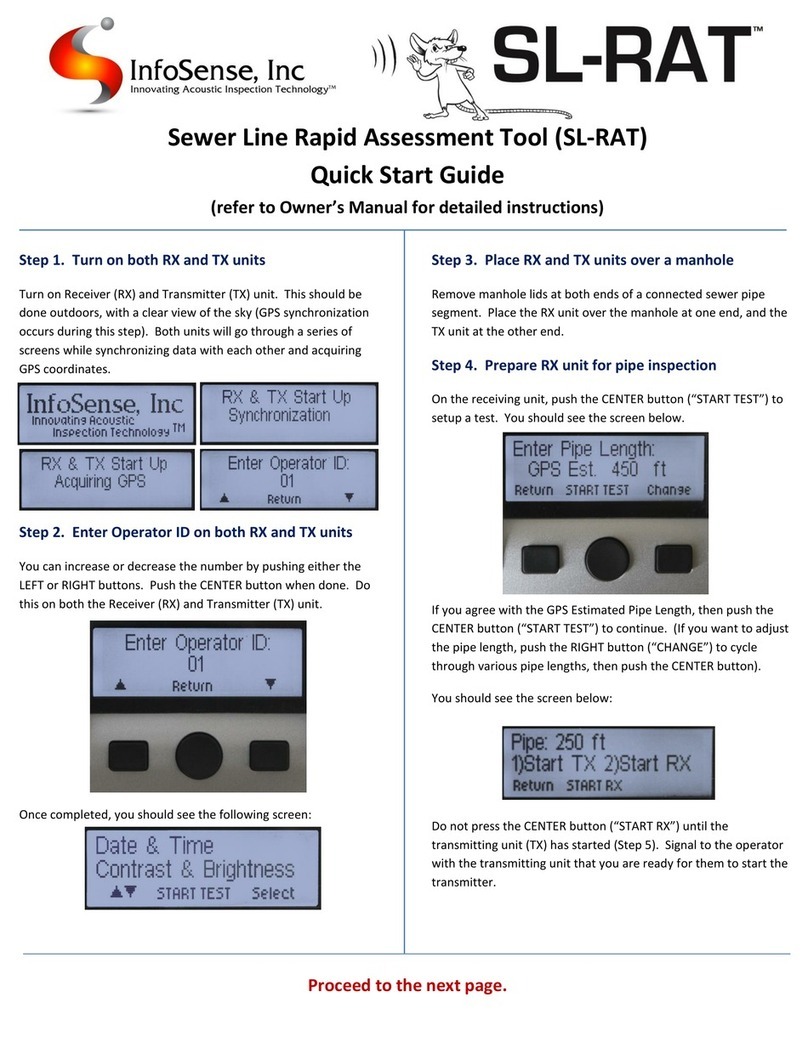

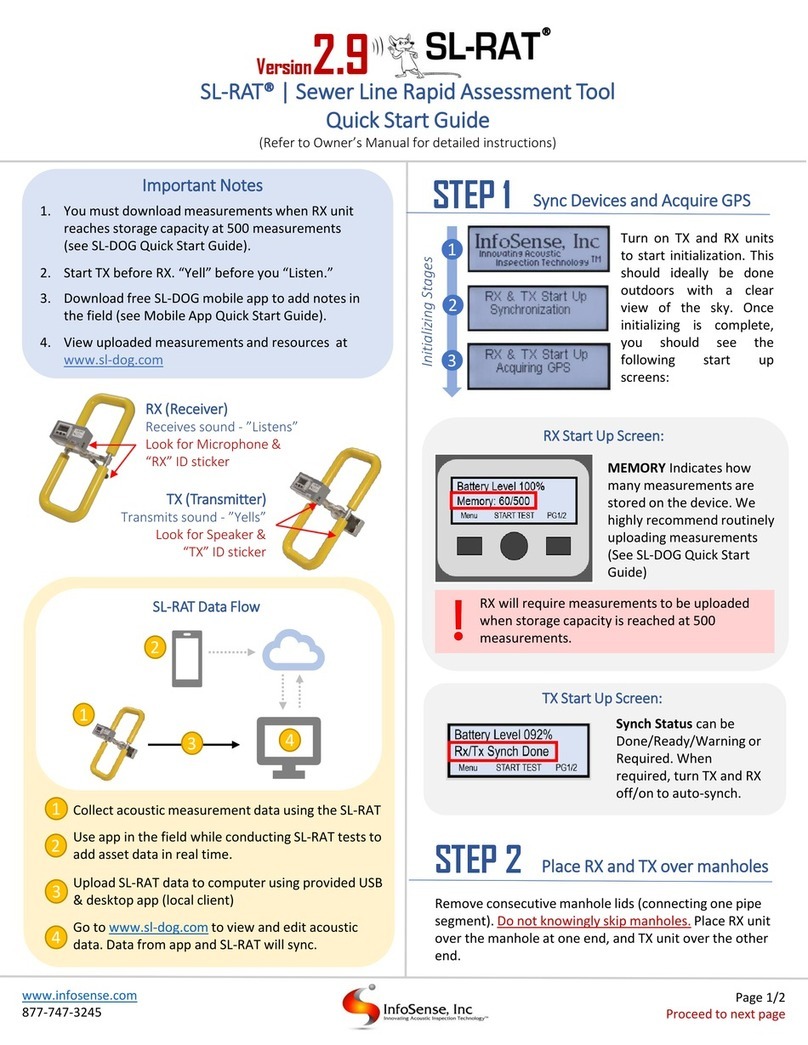

3. Daily Acoustic Operation Process .................................................................................................................7

3.1. STEP 1. Turn on both TX and RX Devices ..............................................................................................9

3.2. STEP 2. Deploy TX and RX units over Adjacent Manholes.....................................................................9

3.3 STEP 3. Prepare RX (Receiver) Unit for Inspection..............................................................................11

3.4. STEP 4. Start Test on TX unit, then Start Test on RX unit....................................................................12

3.5. STEP 5. Complete Test........................................................................................................................13

3.6. STEP 6. View Test Result on RX...........................................................................................................14

4. General Operations.....................................................................................................................................16

4.1 Menu Operations ...............................................................................................................................16

4.2. Startup Menu (2/2) –XBEE Status & GPS ...........................................................................................18

4.3. Battery................................................................................................................................................19

5. Sewer Line Data OrGanizer (SL-DOG®) ........................................................................................................20

5.1. Required Items for SL-DOG Access.....................................................................................................20

5.2. Desktop App Installation Instructions.................................................................................................20

5.3. Uploading Measurements from SL-RAT..............................................................................................22

5.3.1. Troubleshooting Issues with Uploading SL-RAT Data .................................................................23

5.4. Operating SL-DOG Web Portal............................................................................................................24

5.5. SL-DOG Term Definitions....................................................................................................................25

5.6. Exporting SL-DOG Reports..................................................................................................................27

5.6.1. Sample Report from CSV File (Excel)..........................................................................................29

5.6.2. Sample Report from KML File (Google Earth).............................................................................30

5.6.3. Sample Report from PDF File .....................................................................................................31

6. SL-DOG®Mobile App (optional) ..................................................................................................................32

7. SL-RAT, SL-DOG & Mobile App Workflow ...................................................................................................33

8. Additional Information................................................................................................................................34

8.1. Wireless Device ..................................................................................................................................34

8.2. Maintenance ......................................................................................................................................34

8.2.1. General Cleaning Recommendation...........................................................................................34

8.2.2. TX Speaker & RX Microphone.....................................................................................................34

2

8.2.3. Lock Knob Maintenance.............................................................................................................34

8.2.4. Battery........................................................................................................................................34

9. Specifications..............................................................................................................................................34

9.1. General...........................................................................................................................................34

9.2. Power .............................................................................................................................................35

9.3. Operational ....................................................................................................................................35

10. Document Revision History.........................................................................................................................36

User Manual for V2.8 –2/21/2020

3

1. Introduction

Thank you for purchasing the Sewer Line Rapid Assessment Tool or SL-RAT® device from InfoSense. The SL-

RAT® uses a patented technology to quickly provide an assessment of blockage conditions in gravity fed

sewer lines. Our device is comprised of two portable components –a transmitter unit (TX) that “yells” and a

receiver unit (RX) that “listens.” The TX and RX are placed on top of adjacent manholes, requiring no flow

contact or confined space entry. Our technology enables you to understand blockage conditions in real-time

and aids in effectively deploy cleaning resources.

The associated software, the Sewer Line Data OrGanizer or SL-DOG®, enables quality control and archiving of

SL-RAT data. Pipe segment location and length can be verified with the integrated GPS, and acoustic scores

can be integrated with GIS data. The full standard practice for prioritizing sewer pipe cleaning operations

using transmissive acoustic technology can be found in the F3220-17 ASTM Standard Guide (ASTM

International).

2. SL-RAT Overview

2.1. Features

•Low Operational Cost

•Rapid Results –Typically Under 3 minutes/segment

•Safe - No Flow Contact

•Field Tested –Ruggedized Design

•Easy to Use –Train Operators in Minutes

•Onsite Results –Easy to Interpret

•Portable –Transmitter and Receiver Combined Weight Less Than 30 lbs

•GIS Integration - GPS Enabled

•Wireless communication between TX and RX (XBEE)

2.2 Applications

•Focus Cleaning Crews on Dirty Pipes

•Perform Quick & Low Cost “Pre-maintenance” Basin Assessments

•Avoid Downstream Overflows Caused By Upstream Cleaning Activity

•Avoid Repeat Overflows –Identify Hot Spots After Spill Events

•Post-Cleaning –Quality Assurance

User Manual for V2.8 –2/21/2020

4

2.3 Identify Parts and Controls

The SL-RAT® device is composed of two parts. The transmitter (TX) component is identifiable by its bulkier

speaker housing containing a heavy-duty marine grade speaker, and its heavier weight (Figure 1). The

receiver (RX) is identifiable by its smaller sensor housing containing a high-quality microphone, and its lighter

weight (Figure 2). Each component is also labeled with a “TX” or “RX”.

Figure 1Major sub-components of the SL-RAT® device’s Transmitter (TX) Component

Figure 2 Major sub-components of the SL-RAT® device’s Receiver (RX) Component

User Manual for V2.8 –2/21/2020

5

1. User Display & 3 Button Control: (TX & RX) Provides the user interface for making acoustic

measurements and obtaining status information from the RX & TX components.

2. ON/OFF Switch: (TX & RX) Turn on by moving the toggle switch forward. This provides battery

power to the component. When in the on position (Forward), the User display & 3 Button

Control will be operational. If you are not planning on using the RX and TX components for an

extended period (more than one hour) - Turn off the power by moving the toggle switch back.

3. Battery Recharge Plug & Cap: (TX & RX) The battery is recharged by connecting the provided AC

adapter’s Battery Recharge Jack into the plug. To comply with the SL-RAT warranty, only use the

provided Battery Recharger which has been specifically engineered to support the SL-RAT

device. When not being charged the Battery Recharge Plug Cover must be securely fastened to

prevent moisture & dirt from entering the RX & TX components and to comply with the SL-RAT

warranty.

4. Speaker: (TX Only) Is a rugged heavy-duty marine-grade speaker used for generating the sound

signal received by the RX component. It needs to be inserted below the plane of the manhole

but never into waste flow during acoustic measurements. Care should be taken to make sure

speaker is not fouled with debris.

5. Microphone: (RX Only) Is a rugged harsh environment microphone used for detecting the sound

waves generated by the TX component. It needs to be inserted below the plane of the manhole

but never into waste flow during acoustic measurements. Care should be taken to make sure

microphone is not fouled with debris.

6. Lock Knobs: (TX & RX) Two lock knobs per RX & TX component which allow the TX speaker or RX

microphone to be transitioned from the open/measurement position to the closed/transport

position.

7. Frame Cushions: (TX & RX) Used to support the RX & TX component during measurements.

Provides limited protection to the electronics case and speaker or microphone during

transportation when Transporting directions are correctly followed.

8. USB Plug & Cap: (RX Only) Allows acoustic measurements conducted in the field are uploaded to

the SL-DOG® Portal via USB Cable. This allows secure historical archiving, and additional analysis.

When not being used the USB Plug Cover must be securely fastened to prevent moisture & dirt

from entering the RX component and to comply with the SL-RAT warranty.

9. Control Box: (TX & RX) Enclosure component that integrates user display and 3 button control,

ON/OFF Switch, & Battery Recharge plug & cap.

User Manual for V2.8 –2/21/2020

6

2.4 Transporting

2.4.1. Transporting by Foot

When transporting the SL-RAT® TX & RX

components by foot, follow the procedures in this

section to reduce the possibility of damage.

1. Place TX & RX in closed/transport position

(see Figure 3)

2. Securely tighten the two Lock Knobs on both

the TX & RX (see Figure 3)

3. When transporting the SL-RAT TX and RX by

foot over short distances, carry in

closed/transport position.

Fig. 3 –Transporting SL-RAT by foot –tighten lock

knobs to secure in closed position

User Manual for V2.8 –2/21/2020

7

2.4.2. Transporting by Vehicle

When transporting the SL-RAT TX & RX components

by vehicle the procedures in this section are required

to reduce the possibility of damaging the TX & RX

components and to comply with the SL-RAT warranty.

1. Place TX & RX in closed/transport position

(see Figure 3)

2. Securely tighten the two Lock Knobs on both

the TX & RX (see Figure 3)

3. Place TX in the carrying case on top of first

Foam Insert (see Figure 4)

4. Place second Foam Insert on top of TX

5. Place RX in the carrying case on top of second

Foam Insert (see Figure 4)

6. Place third Foam Insert on top of RX

7. Securely Close the carrying case (see Figure

4)

If dirty, we recommend wiping down the components

prior to placing in the carrying case with a

nonabrasive cleaning agent or damp cloth (see

Section 8.2.1 on General Cleaning Recommendation –

pg 34).This will reduce fouling of the Foam Inserts

and extend the service life of the carrying case.

Additionally, it is a good habit to inspect the

components prior to transport for damage, for

battery charge level, and for dirt or other foreign

material that may have become lodged in the

microphone or speaker housings.

3. Daily Acoustic Operation Process

At the start of each day prior to starting inspections, TX and RX operation should be verified. Use menu to

navigate to “Verify Operation” and run one verification test to ensure that units are synced and communicating

correctly (see pg.16 or reference ASTM Standard for details). We recommend deploying TX and RX in an

“inchworm method” for optimizing data management process. This means moving both the TX and RX, rather

than “leapfrogging” by moving only one of the devices to the next manhole (see figure 5).

Figure 3 Recommended closed/transport position,

and how to tighten knobs to secure for transporting

Figure 4 Transporting SL-RAT by Vehicle

Fig. 4 - Transporting SL-RAT by Vehicle

User Manual for V2.8 –2/21/2020

8

Steps for Using the SL-RAT® - Based on ASTM Standard Verification Process

Once started, the test is automated. The SL-RAT RX displays real time graphics indicating both the test’s

progress and the performance. The SL-RAT TX displays real time graphics indicating the number of tone

sequences completed. The SL-RAT RX & TX control and operation are performed through a series of screens

on the User Display and through the 3 Button Control.

STEP 1

Turn on both Transmitter (TX) and Receiver

(RX) by using toggle switch on the bottom

left side of the control boxes. Sync devices

and acquire GPS coordinates. Verify

Operation by going to menu and selecting

“verify operation.” (see page 16)

STEP 2

Deploy TX and RX by placing the devices on

adjacent manholes (Fig 6).

Do not knowingly skip manholes

STEP 3

Prepare RX unit for pipe inspection –do not

start test yet.

STEP 4

“Start Test” on TX device. Then press “Start

Test” on RX device.

Remember: Start the TX before you

start the RX. “Yell” before you

“Listen”

STEP 5

Test results displayed on the RX once test is

complete and the TX’s tones will

automatically be terminated. If the TX does

not automatically stop after score is

generated, manually stop test by pressing

and holding center button on display

Fig. 5 –When conducting acoustic tests, we recommend using inchworm method of deploying TX and RX rather

than leapfrog method to make it easier to manage and edit the data after downloading.

Fig. 6 –SL-RAT deployment for acoustic

measurement of the pipe segment between two

adjacent manholes.

User Manual for V2.8 –2/21/2020

9

IMPORTANT UPDATES FOR Version 2.8

•You are now required to download measurements when RX unit reaches storage capacity at 500

measurements to protect data. See SL-DOG Section for more information (page 21)

•If TX unit states “RX/TX Synch Required,” sync devices by turning both TX and RX units off (Step 1;

page 8) or going to menu and selecting “Data Sync” (Menu Operations – Pg. 16)

3.1. STEP 1. Turn on both TX and RX Devices

The SL-RAT TX and RX components are provided as a pair. They are

factory calibrated to operate as a single device when performing an

acoustic measurement.

The TX and RX automatically go through a series of initializing screens

on the user display when both devices are turned on (toggle switch is

turned to the “on” position) and positioned close to each other (less

than 50 ft). They will synchronize data and acquire GPS. It is best

practice to turn devices on outside, with a clear view of the sky, so

GPS coordinates can be easily acquired.

Once initializing is complete, operators see respective start up screens

in step 2 (RX) and step 3 (TX).

Verify Operation should be done once a day at the start of the day.

Select menu (see page 16 or reference ASTM Standard for details).

3.2. STEP 2. Deploy TX and RX units over Adjacent Manholes

An acoustic measurement is typically conducted by deploying the TX and RX components in adjacent manholes.

The following guidelines should be followed with Figures 7 and 8 illustrating typical deployments.

Do not knowing skip manholes in this process –see #5 below for exception case

Fig 7. Devices will automatically

go through the initializing stages

of synchronizing and acquiring

GPS when turned on.

TROUBLESHOOTING –GPS Reset/Cold Start

If a device cannot acquire GPS within three minutes, the operator is given the option of resetting the

GPS, by pressing the <Cold Start> button. Operator must verify that they wish to reset the GPS.

Please note, resetting the GPS takes 15-30 minutes. The device will continue to search for GPS when

the “GPS Reset” screen populates, so operator can choose to wait for device to acquire GPS without

cold starting, if desired.

User Manual for V2.8 –2/21/2020

10

1. Reasonable care should be used when deploying and removing TX and RX components from the

manhole to prevent damaging the speaker or microphone.

2. Deploy the RX & TX by setting the component on an open manhole in the Open/Measurement position

(See figures 8 & 9). The frame should rest securely on the frame/manhole cover when deployed.

3. Speaker/microphone should be approximately one foot below the plane of the manhole.

4. Speaker/microphone should be approximately centered within the manhole entrance. The area below

the speaker/microphone should have at least one-foot clearance from any obstruction within the

manhole.

5. If the distance between adjacent manholes is

less than 20 feet (6m), then the acoustic

measurement for the short segment should

be coupled together with the next adjacent

segment. For example, if the distance

between A and B is 200ft, and the distance

between B and C is <20ft, then two

measurements should be made.

1. First measurement should be between manholes A and B for the 200ft (61m) segment.

2. Second measurement should be between manholes A and C for the combined 200ft + <20ft where

B is skipped.

6. Measurements can be conducted with or without the manhole cover fully removed, as illustrated in

the Figures 8 and 9.

7. Once the acoustic measurement is completed, carefully remove the components from the manhole

and deploy to the next segment. (See Page 8, Figure 5 for recommended “inchworm” deployment

method.)

Fig 8. SL-RAT RX in Open/Measurement

position - deployed with microphone

centered and one foot below pane of

manhole. Manhole cover removed for

measurement.

Fig 9. SL-RAT TX in Open/Measurement

position - deployment with manhole cover

only partially removed for the measurement.

User Manual for V2.8 –2/21/2020

11

3.3 STEP 3. Prepare RX (Receiver) Unit for Inspection

During an acoustic inspection for a pipe segment, the RX component receives the sound signal generated by

the TX component. Based on the characteristics of the received signal, it assesses the condition of the pipe

segment between the TX location and the RX location. After correctly deploying the RX, the steps for

operating the RX are as follows:

Ref #

User Display

Description

RX1

RX Startup (1/2)

From the RX Startup Screen, start the RX acoustic

measurement operation by pressing the center button

<START TEST>.

Memory indicates how many acoustic measurements are

stored on the device.

The RX will require that records be uploaded to a

computer when it reaches storage capacity at 500

measurements.

RX2

Pipe Length Menu

The next screen is the Pipe Length Menu. If the RX and TX

are sufficiently close to each other, then the distance

between the components is estimated based on GPS. The

initial pipe length displayed on the screen will indicate if it

is a GPS Est. (GPS Estimate) or the Default value (350 feet).

Operator should verify or change this value as needed.

•Press the right key <Change> to cycle through

range of values (50ft to 750ft) in 100-foot

increments.

•Press the center key <Start Test> to proceed.

•Press the left key <Return> to return to Startup

Screen.

It is important for the operator to record accurate

pipe length distances to obtain accurate field

assessment results

RX3

RX Ready

By verifying the pipe length, the RX is ready for the TX unit

to begin test. Indicate to operator with TX to begin test –

this is typically done via hand signal or walkie talkie.

Remember: Start the TX before you start the RX.

“Yell” before you “Listen”

As soon as TX begins tone sequence (end of Step 4), press

center button <START RX>.

User Manual for V2.8 –2/21/2020

12

3.4. STEP 4. Start Test on TX unit, then Start Test on RX unit

During an acoustic inspection for a pipe segment, the TX transmits a sequence of tones and this sequence is

repeated up to 12 times over the duration of the measurement. The TX needs to be started prior to starting

the RX. After correctly deploying the TX, the steps for operating the TX are as follows:

Ref #

User Display

Description

TX1

TX Startup (1/2)

From the TX Startup Screen, start the TX acoustic

measurement operation by pressing the center button

<START TEST>.

Rx/Tx Synch Status indicates whether RX and TX need to

synch. The devices automatically sync every time they are

turned on.

The TX will require synch if it reaches 200

unsynchronized records. Status can be as follows:

•RX/TX Synch None: All measurements are synched

•RX/TX Synch Ready: 1-150 measurements waiting

to synch

•RX/TX Synch Warning: 150-199 measurements

waiting to synch

•RX/TX Synch Required: Data must be synced to

continue operation. Devices have reached capacity

at 200 unsynchronized measurements.

TX2

TX Start Test

Once operator with RX signals that RX is ready, press the

right button <Start>.

Operator with RX can press <Start RX> as soon as the TX

begins emitting sound tones (Ref #RX3).

User Manual for V2.8 –2/21/2020

13

3.5. STEP 5. Complete Test

The following screens will display as the test is being conducted. The TX will go through a series of tones 6 to

12 times. The test is complete once the RX provides an acoustic blockage assessment score (GOOD, FAIR,

POOR, BLOCK):

During Testing: TX Display Screen

During Testing: RX Display Screen

Ref #

User Display

Description

RX4

RX Real-time Display

The RX Real-Time Display will provide graphics to indicate

the RX is in test mode. The status bar on the right is

incremented at one second intervals. After 16 seconds, a

graphical display appears, which provides measurement

status for individual components used in assessing the pipe

status.

Ref #

User Display

Description

TX3

TX Real Time Display

The TX Real Time Display counts tone sequences transmitted.

If TX and RX are able to communicate wirelessly, the TX should

automatically stop producing tones once RX displays score

(Ref #RX5). If it does not, operator can manually stop test by

pressing and holding down center button <END>. At a

maximum, the TX automatically ends the transmission after 12

tone sequences.

While it is best to “END” the TX operation to maximize battery

life once RX has reached an assessment, running through

additional tone sequences does not impact the assessment

score.

TX4

TX Results

TX Results screen shows how the test was terminated, and

what the GPS and Satellites

•GPS Status (0 –no estimate; 1 –normal; 2 –

differential; Other value –tracking modes, typically

with limited or no satellites in view)

•#SATS: Number of satellites used to estimate TX

location

•Indicates how the test was terminated (User, RX via

RF interface, or Normal)

Press <Return> to go back to startup screen

User Manual for V2.8 –2/21/2020

14

3.6. STEP 6. View Test Result on RX

Ref #

User Display

Description

RX5

Pipe Segment Classification

Once the testing is complete, the Pipe Segment

Classification (see figure 9) is displayed first. The

classification can be one of the following five possibilities:

•GOOD (Pipe Segment Assessment from 7 to 10)

•FAIR (4 to 7)

•POOR (1 to 3)

•BLOCK (0)

•NOISE –indicates that noise impairment was

enough to invalidate test. If this occurs, it may be

possible to either repeat the test and/or to swap

the locations of the TX and RX.

•CLOSE - The SL-RAT transmitter unit (TX) and the

SL-RAT receiving unit (RX) were too close during

the measurement. The Pipe assessment may be

corrupted.

If the TX is continuing to produce sound (Ref #TX3) after RX

displays pipe segment classification, manually stop test.

Press <Return> to proceed to Pipe Assessment Details

RX6

Pipe Assessment Details

The Pipe Assessment Details shows the following:

•Measurement ID: a unique ID number for the test

•Result: Numeric result from 0 to 10

•GPS: The first number indicates GPS Status, and

the second number (following the decimal)

indicates number of satellites. The GPS Status can

be any of the following: 0 –no estimate; 1 –

normal; 2 –differential; Other value –tracking

modes, typically with limited or no satellites in

view.

Operator can press <SAVE> to save measurement data. By

pressing <REJECT>, operator still saves measurement but

flags the data as being rejected by operator.

For data protection purposes, there is no way to

delete measurements on device. They can be

removed for viewing purposes in SL-DOG.

User Manual for V2.8 –2/21/2020

15

To view collected acoustic data, download data then go to www.sl-dog.com and log in to access data in a

secure, cloud-based web portal. Operators must create an account to access data. See Sewer Line Data

OrGanizer (SL-DOG) Section in Manual for more information (See page 20).

Assessment

Typical Condition / Interpretation

10

No significant obstructions within the pipe

7-9

Minor impediments within the pipe such as joint offsets, partial sags,

protruding laterals, debris, minor grease, and/or minor root fibers.

4-6

Impediments within the pipe such as joint offsets, partial sags, protruding

laterals, debris, grease, and/or root fibers. Single or multiple occurrences.

1-3

Significant impediments within the pipe such as multiple joint offsets, near

full pipe sag, multiple protruding laterals, significant debris, significant

grease, significant root fibers and/or root balls. Single or multiple

occurrences.

0

Full pipe sag; single or multiple obstructions within the pipe reaching or

nearly reaching the flow.

Table 1. Description of typical conditions for each acoustic assessment score.

User Manual for V2.8 –2/21/2020

16

4. General Operations

4.1 Menu Operations

The menu can be accessed by pressing the left button

<Menu> on the Startup Screen. Menu list is displayed in

Figure 10. The left key is used to scroll through the

options.

To select, bring desired option to the top line by using left

key and press right button <Select>. A test can be started

by returning to the startup screen by pressing the center

button <Return>.

To return to menu after selecting an item, press the center

button <Return>. Each option is described below, and is

available on both TX and RX, unless noted otherwise:

Data Synch: (RX Only) Initiates data synchronization between the TX and RX, if they are in communication

range of each other (less than 50’ and free of obstructions between) and should remain close while the

transfer takes place). Once the transfer is completed, both displays will automatically return to the Startup

screen. The time required for data synchronization depends on the number of measurements conducted

since the last synchronization. We recommend Data Synch to be conducted at least once every 10

measurements. Synchronization allows measurements to be validated. Table 2 lists the possible outcomes

for the measurement validation process and the measurement condition which causes the outcome.

Table 2. Data Synch Status and descriptions

Verify Operation: Provides method for verifying the TX and RX functional operation. The test is conductied

with the TX tone sequence at a lower sound pressure level (-16 dB from normal test). To conduct a Verify

Operation Test –the TX and RX should be located within one foot of each other. To start the test select

Verify Operations on first the TX and then the RX .

Measurement

Status

Condition

Valid

No anomalies in the measurement conditions were detected

Early

The SL-RAT transmitter unit (TX) was stopped prior to the SL-RAT receiving

unit (RX) completed its processing. The Pipe assessment may be corrupted.

Late

The SL-RAT transmitter unit (TX) was started after the SL-RAT receiving unit

(RX). The Pipe assessment may be corrupted.

No TX

The SL-RAT transmitter unit (TX) was not turned on during SL-RAT receiving

unit (RX) measurement. The Pipe assessment is corrupted.

Fig 10 - The Menu can be accessed by

pressing the left button, <Menu>, on the

Startup screen of both TX and RX units

User Manual for V2.8 –2/21/2020

17

Operator ID: Allows the operator to select/change the Operator ID recorded for each measurement.

Operator ID values range from 1 to 30. The button on the left and right provide up and down scroll directions

to change the Operator ID value. Center button returns to the Main Menu and selects the current value

displayed as the Operator ID.

Review Results: Previous measurements can be reviewed. The RX & TX components can store up to 500

measurements. Once 500 measurements are reached, the RX will require that records be uploaded to a

computer. The button on the left and right provide up and down scroll directions, respectfully.

•RX Display:Unique ID, Measurement Classification, Measurement Status (Synch –if the TX & RX

have not been synchronized), Measurement’s Date & Time, Pipe Length, Measurement Assessment.

•TX Display: Unique ID, Temperature, Measurement’s Date & Time, Measurement Duration,

Termination Condition (User Terminated, Normal, Low Battery).

System Info: The button on the left and right provide up and down scroll directions, respectfully.

•RX Display: Battery Level, RX Operator ID, Number Measurement Conducted on the RX, RX

component serial number (Corresponds to the Face Plate SN), TX component serial number, Number

of test requiring synchronization between the RX and TX, RX Firmware Version Number, RX

Hardware Version Number, RX Build Date.

•TX Display: Battery Level, TX Operator ID, Number Measurement Conducted on the TX, TX

component serial number (Corresponds to the Face Plate SN), TX Firmware Version Number, TX

Hardware Version Number, TX Build Date.

Options:

•XBEE Disable Option: The XBEE refers to the wireless protocol between devices. To disable the XBEE,

scroll down to the “XBEE Disable” Option and change to yes <Y>. To disable or enable the XBEEs,

both TX and RX need to have their XBEE modules disabled. Disabling the XBEE will impact numerous

operations. For more information on XBEE, reference page 18, Startup Menu (2/2) –XBEE Status &

GPS

Power Save: Allows the operator to place units in power save mode when selected. In addition, the RX & TX

components will automatically enter power save mode if left idle for 2 minutes. When in power save mode,

screen will periodically remind operator the RX and/or TX component is still turned on. To exit power save

mode, press the center key. Operator should turn off the SL-RAT if it is not in use for an extended period of

time (more than one hour).

Contrast & Brightness: The contrast & brightness on user display can be adjusted to improve visibility. Every

time the device is turned off and on, display returns to the default settings (132). Changing the contrast

value too far from the default can cause the screen to blank or saturate. Increasing brightness can improve

visibility in reduced light setting (e.g. indoors or at night). If the SL-RAT is being used outdoors during the day,

reducing the brightness can typically improve battery performance. The button on the left is used to cycle

between fields within the contrast & brightness. The button on the right is used to change the selected field.

Date & Time: Current date and time are provided based on GPS.

GPS Monitor: Provides the current GPS location data for the component. The GPS location is updated at 15

second intervals.

•RX Display: RX Latitude & Longitude specified in degrees, minutes, estimated distance to TX; RX and

TX GPS status indicating both the type of GPS tracking and the number of satellites.

User Manual for V2.8 –2/21/2020

18

•TX Display: TX Latitude & Longitude specified in degrees, minutes, TX GPS status indicating type of

GPS tracking and the number of satellites.

4.2. Startup Menu (2/2) –XBEE Status & GPS

The startup menu display is switched from page 1 to 2 by pressing the right bottom button <1/2>. The second

startup menu displays the GPS Status and the XBEE status.

GPS Status: The first number indicates the operation status, and the values after the decimal indicate the

number of satellites the GPS module is tracking. The operation status is as follows: (0 –no estimate; 1 –

normal; 2 –differential; Other value –tracking modes, typically with limited or no satellites in view)

XBEE Status: Indicates the status of the wireless communication between the RX and TX devices. The XBEE

status can be reported as GOOD, FAIR, LOW, Out of Range, and Disabled. Disabled is displayed for the XBEE

status if the operator of the unit has disabled the XBEE through the options menu.

XBEE Disable Option: To disable the XBEE, operator must select Options from the Menu and scroll down to

the “XBEE Disable” Option and change to yes <Y>. When the option is set to yes, the unit will display the

following message:

To disable or enable the XBEEs, both the TX and RX need

to have their XBEE modules disabled.

To re-enable the XBEE, power both RX and TX devices off and

on. For correct operation, the unit should first be returned to

the Startup Menu at least once, prior to turning the device off.

If the XBEE is disabled, the following operations no longer function:

1. Data Synch –warning message displayed on the RX

2. GPS based pipe length estimate made at the start of a blockage assessment. Pipe length estimate is

set to the default 350 feet.

3. On the RX GPS Monitor, the distance estimate and TX GPS information is invalid.

4. Blockage assessment tests will not be automatically ended

User Manual for V2.8 –2/21/2020

19

4.3. Battery

The SL-RAT RX and TX are powered by a 11.1v Li-Ion battery pack rated at 44.4 Wh, 10A rate. The following

directions are essential for correct operation and to avoid damage or loss caused by misuse.

1. Prior to using the SL-RAT RX and TX components in the field, verify the Battery levels are sufficient

for the day’s planned number of acoustic measurements.

2. To maximize use of battery, the device should not be consistently operated at low battery levels. It is

recommended that device should be fully charged each time it is charged.

3. A Low Battery Warning occurs when the battery can no longer support additional measurements

without being recharged. When a low battery warning occurs, the component should be turned off

and recharged. Failure to do so can cause damage to both the battery and the component’s

electronics.

4. Only use the battery charger provided to recharge the units. Failure to do so can result in battery

pack overheating and potentially catching fire.

5. The battery recharger jack is keyed to the plug on the RX & TX components. Make sure the keys are

correctly aligned and do not force the connection. Failure to do so can result in battery pack

overheating and potentially catching fire.

6. Prior to using the battery recharger visually inspect the wires for any damage. If damage is observed

do not use, contact manufacture for a replacement battery recharger. Failure to do so can result in

battery pack overheating and potentially catching fire.

7. Battery Recharger is for indoor use only. Do not expose the battery recharger to moisture or water.

8. Do not recharge battery while RX & TX are in the SL-RAT carrying case.

9. Do not open the cover of the battery recharger –High Voltage inside the charger can cause serious

injury.

10. Do not operate the SL-RAT while recharging the batteries.

11. Do not use the battery charger to charge any other battery or battery pack.

12. In order to maximize the use of the battery, it is strongly recommended to disconnect the power

plug from the wall socket after the battery is charged. The battery should be recharged every three

months when it is not used.

13. If at any time you witness smoke, discontinue charging process immediately, disconnect the battery

charger and observe the component in a safe place for approximately 15 minutes. Smoke maybe an

indication of battery failure, and the reaction with air may cause the chemicals to ignite, resulting in

fire.

14. Since delayed chemical reaction can occur, it is best to observe the battery as a safety precaution.

Observation should occur in a safe area outside of any building or vehicle and away from any

combustible material.

15. Never store or charge battery pack inside your car in extreme temperatures, since extreme

temperature could lead to overheating of the battery and potential cause a fire. When transporting

or temporarily storing in a vehicle, temperature range should be greater than 20 degrees F but no

more than 150 degrees F.

16. Store battery at room temperature between 40- and 80-degrees Fahrenheit for best results.

17. Storing battery at temperatures greater than 170 degrees F for extended periods of time (more than

2 hours) may cause damage to battery and possible fire.

Table of contents

Other InfoSense Tools manuals

Popular Tools manuals by other brands

Virutex

Virutex SVN460 operating instructions

Powerbuilt

Powerbuilt 640818 Operating and maintenance instruction manual

Westfalia

Westfalia 50 50 81 instruction manual

Wolfcraft

Wolfcraft 6907 Translation of the original operating instructions

Lion Precision

Lion Precision SPINDLECHECK user guide

HURST

HURST 3162023 installation instructions