INGAL ET2000 User manual

www.ingalcivil.co.nz

Release 03/18

ET2000™ PLUS is licensed to Ingal Civil Products by Trinity Industries Inc. of the U.S.A.

Product Manual

ET2000

Guardrail Extruder Terminal

2

Release 03/18

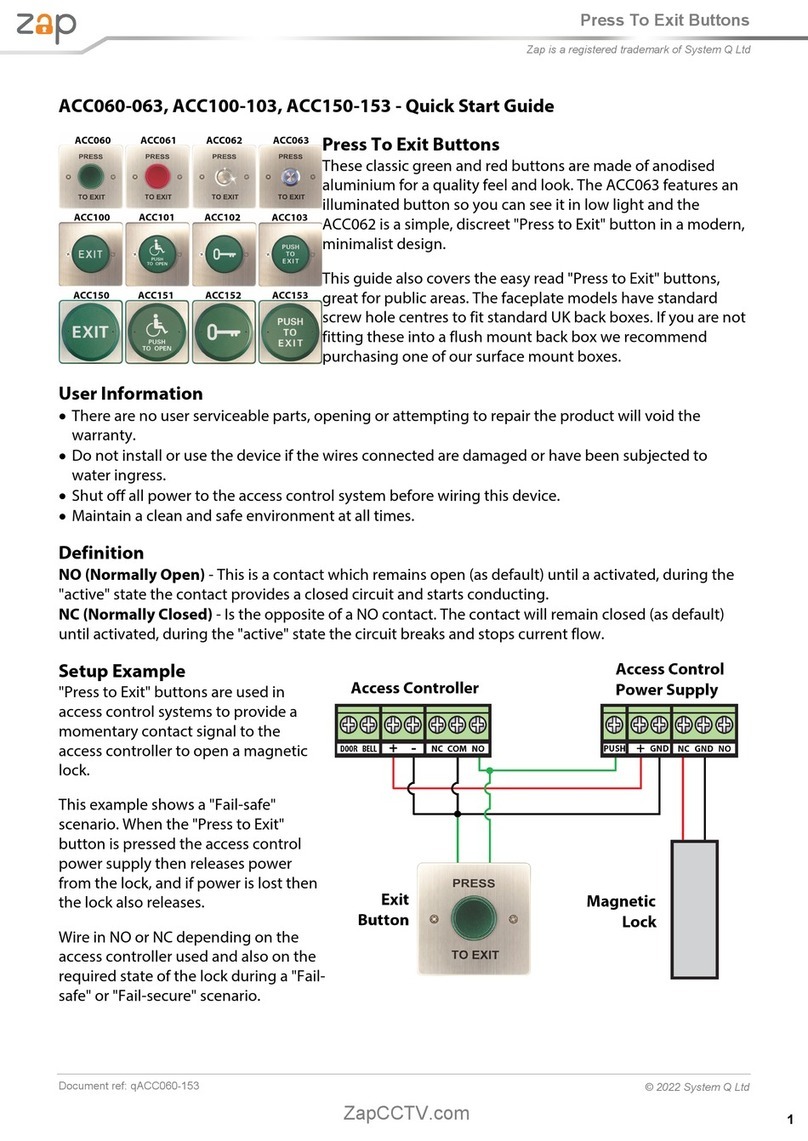

ET2000 Guardrail Extruder Terminal

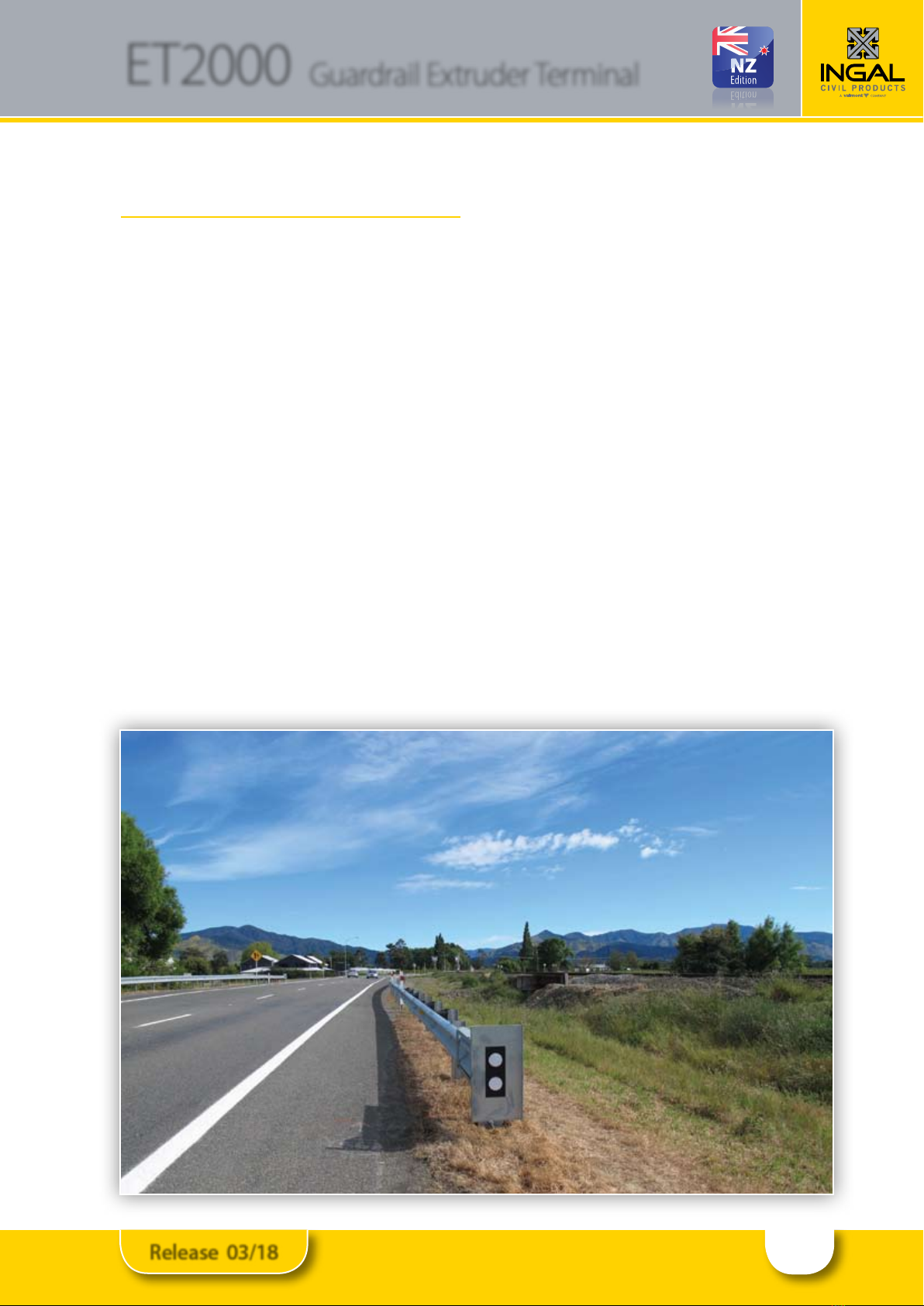

1.0 Introduction

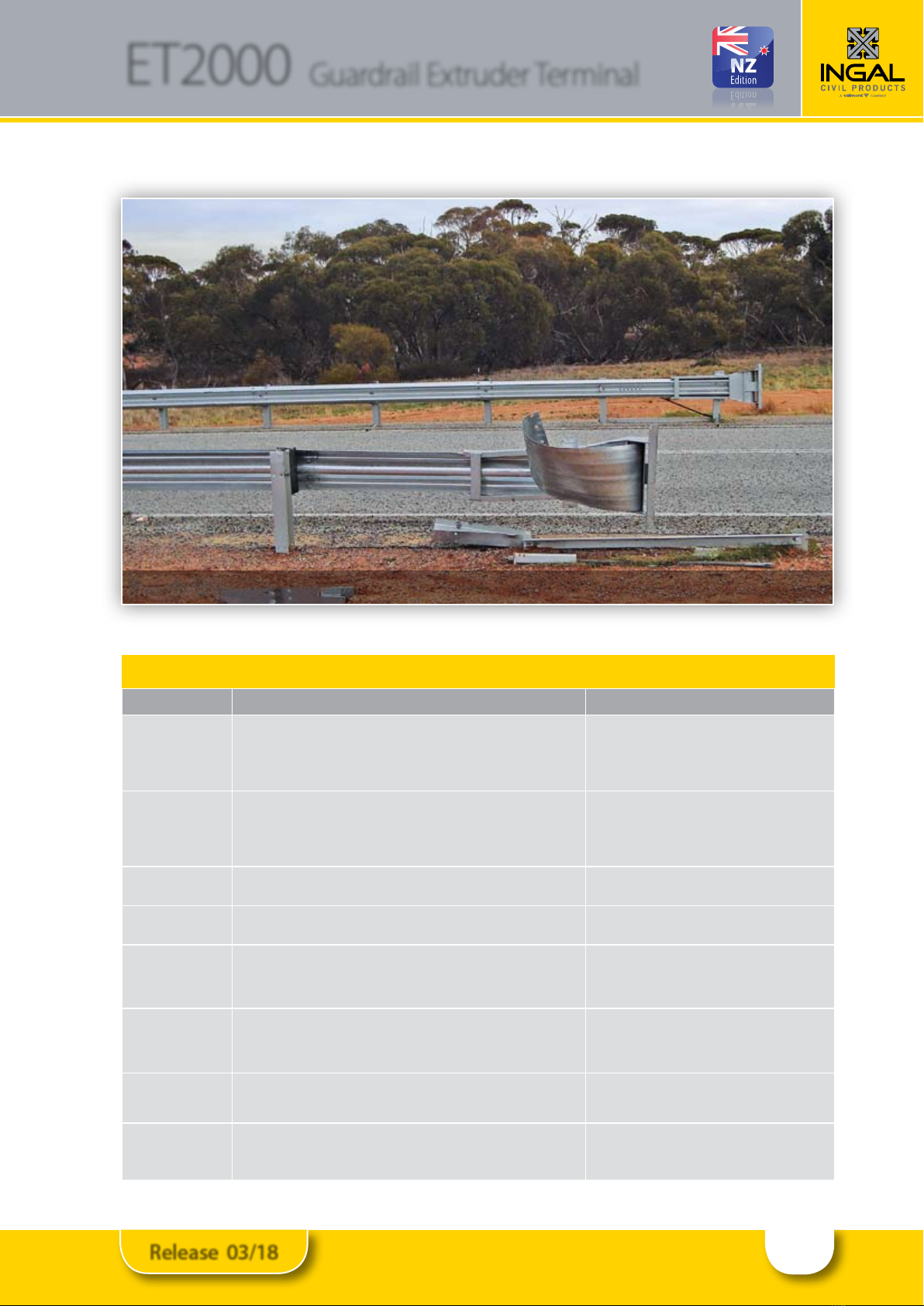

The ET2000 Plus guardrail extruder terminal is engineered

to absorb the kinetic energy of an impacting vehicle at

a controlled rate, providing a soft ride-down for vehicle

occupants.

Unlike traditional ared guardrail terminals, the ET2000

Plus is a tangential end treatment that is installed on a

straight alignment. The use of an ET2000 Plus provides

an end treatment solution for applications where there

is insucient space for a ared end terminal or when it

is cost prohibitive to place an embankment for a ared

terminal.

The ET2000 Plus is available in two sizes. The compact

7.62m TL2 terminal is an economical solution where

the posted speed is less than or equal to 70km/h. The

standard 15.24m TL3 terminal is acceptable for all posted

speeds greater than 70km/h.

2.0 Functionality

Upon impact, the extruder head travels horizontally

along the guardrail beams, attening the w prole of the

beam and extruding the attened section away from the

trac face. It is this action that absorbs the kinetic energy

of the impacting vehicle.

The guardrail beams are supported by specially

engineered Steel Yielding Terminal (SYT) posts that are

designed to yield when the terminal is impacted end-on,

and provide redirection for side-on impacts.

3.0 Crash Test Details

The ET2000 Plus has been crash tested and assessed in

accordance with Test Level 2 (TL2) and Test Level 3 (TL3)

of the National Cooperative Highway Research Program

(NCHRP) Report 350.

Product acceptance details are available upon request

from your local Ingal representative. Acceptance

of product variants should be conrmed prior to

installation.

4.0 Specications

4.1 Material:

Guardrail Beams: Grade 350MPa

STY Posts: ASTM A36

Blocking Pieces: Composite HDPE / crumb rubber

Delineation: Class 1A reective sheeting

Allsteelcomponents arehotdip galvanizedinaccordance

with AS/NZS 4680.

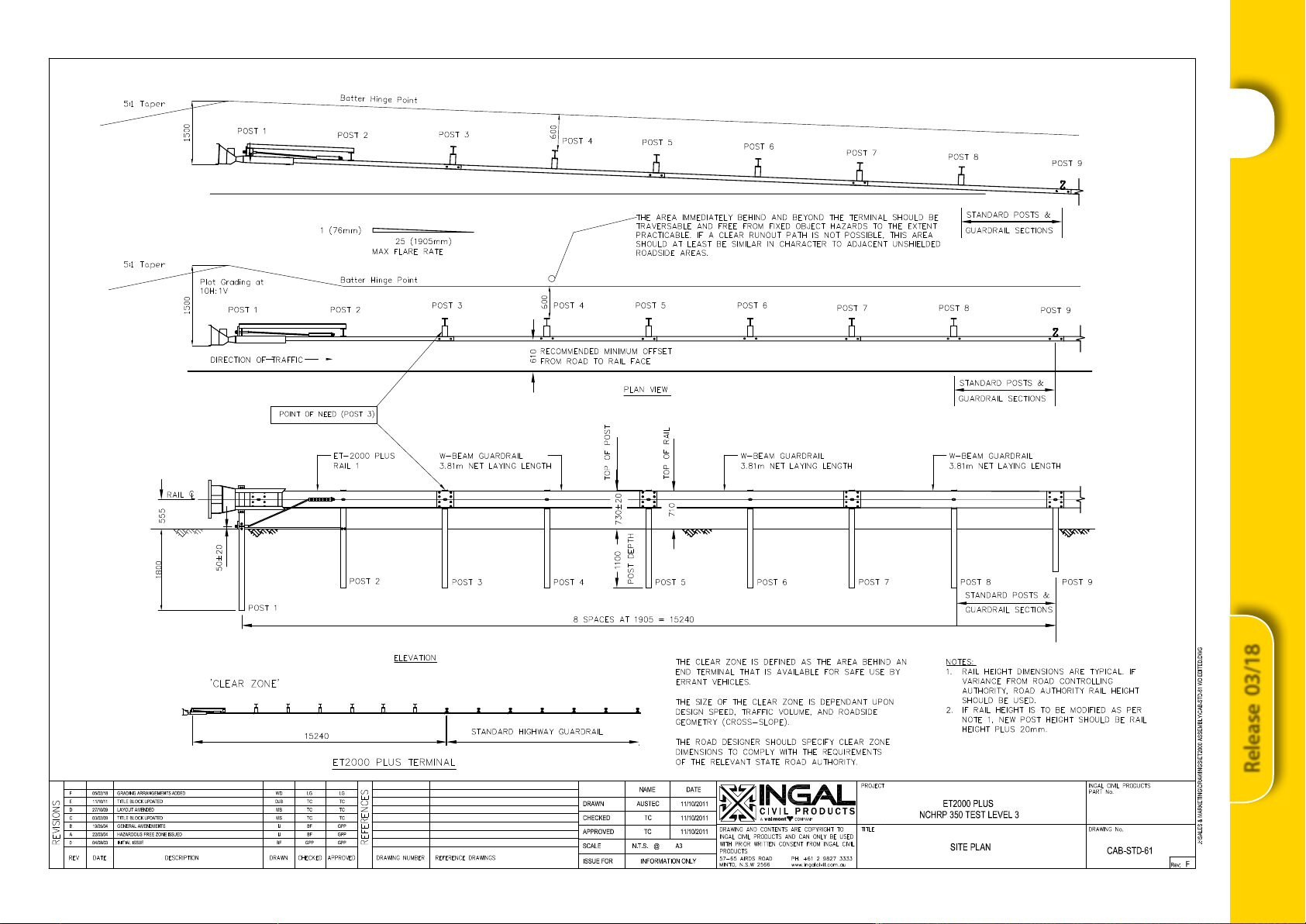

4.2 System Dimensions:

TL2 Terminal: 7.62m overall length

TL3 Terminal: 15.24m overall length

SYT Post Spacing: 1,905mm

Point of Need: Post 3

4.3 Packaging:

The ET2000 Plus is available packaged as individual units

to facilitate rapid installation and minimise disruption to

trac.

TL2 Package Mass: 330kg

TL3 Package Mass: 540kg

NCHRP350 COMPLIANT & NZTA APPROVED

3

Release 03/18

ET2000 Guardrail Extruder Terminal

5.0 Installation

Only items provided by Ingal are to be used for the

installation of the ET2000 Plus. The following written

instructions are to be read in conjunction with Ingal’s

drawings. A generic Safe Work Method Statement is

available upon request for installation operations.

5.1 Site Preparation.

The site should be prepared free of obstructing vegetation

and other hazardsthatmay interfere withthe installationor

operational performance of the system.This includes kerbs

below the system and other hazards that may hinder the

extruder head as it travels horizontally along the guardrail

beams. Some sites may require minor grading if installed

beyond the edge of the pavement shoulder.

Impacts occurring prior to the location of the 3rd post

(point of need) may allow the vehicle to pass behind the

barrier system. Therefore, the area immediately behind the

terminal should be reasonably traversable and free from

xed object hazards. If a clear run-out is not possible, this

area should be similar in character to adjacent unshielded

roadside areas.

Since the terminal functions by extruding rail away

from the trac face, a risk assessment is recommended

if pedestrians and/or cyclists will be accessing the area

behind the terminal.

5.2 Set-Out

When the downstream guardrail system is installed parallel

to the edge of the roadway without any oset, a 25:1 or

atter are over the length of the ET2000 Plus may be

used to locate the extruder head away from the roadway.

When the ET2000 Plus is installed at the end of guardrail

following a curved alignment, the following should be

adopted for the layout of the terminal. For both conditions,

the ET2000 Plus must be straight over the length of the

system. All osets are measured to the face of the rail.

Outside of the Curve. The ET2000 Plus is to be installed

with a maximum oset of 610mm from the curve.

Inside of the Curve. For a curve radius of 300m or less,

the ET2000 Plus is to be installed with a maximum oset

of 305mm from the curve. For a curve radius greater than

300m, the ET2000 Plus is to be installed with a maximum

oset of 610mm from the curve.

When establishing the post locations of the terminal, take

care to note the following;

•The rst two posts from the end of the terminal have

no oset blocking piece;

•The 200mm oset block used in the terminal is wider

than conventional w-beam oset blocking pieces.

4

Release 03/18

ET2000 Guardrail Extruder Terminal

5.3 Installing the HBA Bottom Post

The rst post of the ET2000 Plus is a Hinged Breakaway

(HBA) post that comprises a top and bottom halve.

Installation commences by rst installing the bottom half

of the post as an individual item. This may be achieved by

•Driving the bottom post with an approved driving head

to the appropriate depth, approximately 1,800mm

or

•Auguring a 300mm diameter pilot hole approximately

1,800mm deep and force the HBA post to the

appropriate depth by impact or vibratory means with

an approved driving head after compaction. Backll

material shall be placed in 150mm lifts and compacted

with pneumatic equipment or heavy hand tampering

equipment for optimal compaction.

If rock is encountered when installing the HBA bottom

post, use either of the following procedures unless there

is a more restrictive Regulatory Authority specication

that should be followed:

•If rock is encountered with less than 500mm required

to complete the installation of the HBA bottom post

to full depth, drill a 300mm diameter hole in the

rock to the depth required to install the HBA bottom

post to full depth. Backll and compact the hole in

accordance with Section 5.6.

•If rock is encountered and more than 500mm is

required to install the HBA bottom post to full depth,

drill a 300mm diameter hole 560mm deep into the

rock. Install the HBA bottom post in the hole, cutting

o the bottom of the HBA bottom post so that its top

is at the correct elevation for proper installation. Backll

and compact the hole in accordance with Section 5.6.

Care must be taken to ensure the HBA bottom post is

installed perpendicular to the nished ground level. Once

installed the HBA bottom post should not protrude more

than 100mm above the ground line.

5.4 Installing the HBA Top Post

•Install the HBA top post by aligning the holes of the

ears on the HBA top and bottom posts. Refer to Figure

1 for the correct orientation

•In the 11mm diameter holes, install 3/8” (10mm)

diameter x 2” (50mm) hex head bolt (C1625) with a

3/8” (10mm) washer (C1620) and secure with a 3/8”

(10mm) lock washer (C1622) and 3/8” (10mm) hex

nut (C1626). The bolts should be installed so that the

nuts are on the inside of the ears

•In the 21mm diameter holes, install a .” (20mm)

diameter x 2.” (63mm) hex head high strength bolt

(C1619) with a .” (20mm) washer (C1617) and secure

with a .”(20mm) lock washer (C1624) and .”(20mm) hex

nut (C1618). There is no torque requirement for these

bolts. They should be tightened to a snug position. Do

not install the bolt on the shoulder side until the strut

is ready to be installed.

The HBA Top Post must be installed perpendicular

to the nished ground level. (±1° or 15mm angular

displacement at top of post).

5.5 Installing the SYT Posts

The SYT posts may be installed by using any of the

following methods:

•Driving the posts with an approved driving head to

the appropriate elevation, 730mm ± 20mm. Note

there is little tolerance in relative height of posts to

one another. Care in setting the posts to the same

height will facilitate a quicker installation.

or

•Auguring a 300mm diameter pilot hole approximately

1,100mm deep. Backll native material shall be placed

in 150mm lifts and compacted with pneumatic

equipment or heavy hand tampering equipment

for optimal compaction. Force the SYT post into

backlled hole to an appropriate depth by impact or

vibratory means with an approved driving head.

•If rock is encountered, drill a 300mm diameter hole in

the rock to the depth required to install the SYT post to

full depth. Backll and compact the hole. The material

removed from the hole may be used for the backll.

5.6 Backll of Posts in Excavated Rock Holes

Native materials may be used for backlling in overlying

soil. Backll material in excavated rock hole should be

compliant to ASTM C33 coarse aggregate size number

57 – reference Table 1.

Figure 1: Orientation of HBA Post

Trac

Side

Table 1: Grading Requirements for Coarse Aggregate

Size

No.

Amounts ner than each laboratory

sieve (square - openings), mass percent

37.5mm 25.0mm 12.5mm 4.75mm 2.36mm

57 100 95 to 100 25 to 60 0 to 10 0 to 5

5

Release 03/18

ET2000 Guardrail Extruder Terminal

Backll material shall be placed and compacted to 95%

maximum dry density in 150mm lifts. When the top of

the drilled hole is not at the surface, the soil above the

drilled hole should consist of native soil re-compacted to

existing specications. The post should be driven into the

backlled hole after compaction.

5.7 Installing the Angle Strut

•Place the angle iron strut (C1798G) between post 1

(HBA post) and post 2 (rst SYT post).

• Attach the strut to post 1 (HBA post) with a ¾”(20mm)

diameter x 2½” (63mm) hex head high strength bolt

(C1619) with a ¾” (20mm) washer (C1617) and secure

with a ¾”(20mm) lock washer (C1624) and ¾”(20mm)

hex nut (C1618). Install so that the nut is on the inside

of the ears.

• Attach the strut to post 2 (rst SYT post) with 2 o

7/16” (11mm) diameter x 1½” (38mm) hex head bolts

(C1629) with 2 o 7/16” (11mm) washers (C1628) and

secure with 2 o 7/16” (11mm) lock washer (C1630)

and 7/16” (11mm) hex nut (C1627). Install so that the

nut is on the inside of the ange

There is no torque requirement for any of these bolts.

They should be tightened to a snug position.

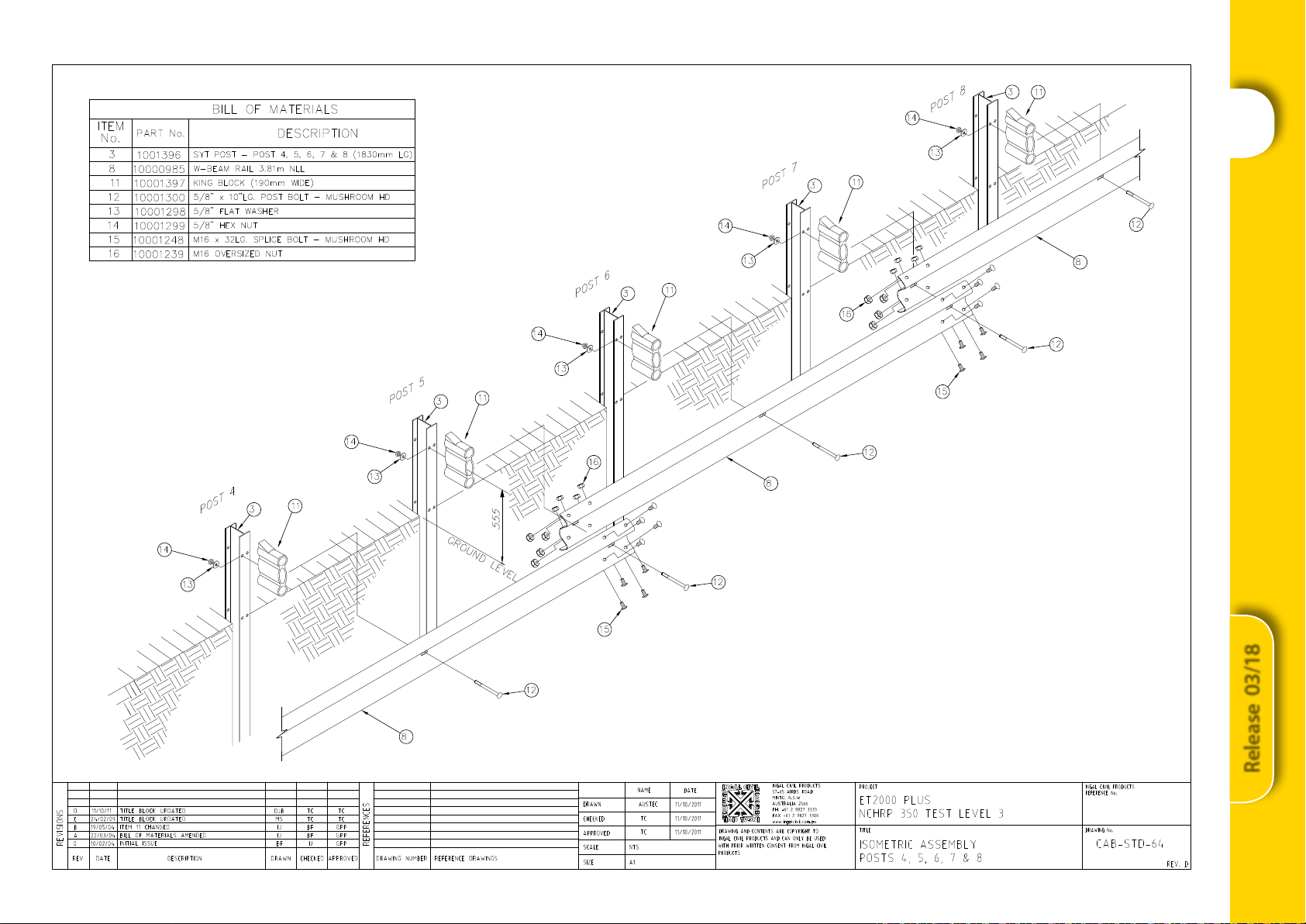

5.8 Installing Blocking Pieces and Rails

• Place the 190mm plastic King Block (C1797) on posts 3

through 8.

• Select 3 o 3.81m rail panels (C1355G) and 1 o

3.81m anchor rail (C1811G). The anchor rail should be

orientated with the anchor bracket holes closest to

the terminal end.

• At posts 3 through 8, bolt rail panels with the

correct lap orientation with a 5/8” (16mm) diameter

x 10” (255mm) long mushroom head post bolt. A

5/8”(16mm) diameter round washer (C1631) and a

5/8”(16mm) hex nut (C1632) secures the rail and block

to the post. The washer is located between the post

and the nut. See Figure 2.

• At post 2, bolt the rail panel directly to the SYT post

with a 16mm diameter x 32mm long mushroom head

post bolt (C1550) and a 16mm washer (C1631) and

hex nut (C1520). The washer is located between the

post and the nut. No post bolt is used at post 1.

• Splice the 3.81m rail panels together with eight 16mm

diameter x 32mm long mushroom head splice bolts

(C1550) and hex nuts (C1520).

Figure 2: Attachment of King Block

SYT Post (upper)

King Block

Mushroom head

post bolt with hex

nut & washer

SYT Post and King Block

SYT Post and King BlockStrut Connection at Post 1

6

Release 03/18

ET2000 Guardrail Extruder Terminal

Cable Anchor Fitting

Cable Attachment to Post 1

5.9 Installing the Cable Anchor Assembly

• The cable anchor tting (C1813G) is secured to the

anchor rail panel (C1811G) by inserting the protruding

hooks into the slots in the rail. It is locked into place by

pulling the bracket towards the terminal end.

• Slide one end of the cable (C1162) into the cable anchor

tting (C1813G) and the other end through post 1 (HBA

post). Secure the cable to the anchor tting with a 1”

(25mm) washer and 1”(25mm) hex nuts.

• Place the bearing plate (C1479G) with the 125mm

dimension up and the 75mm dimension down.

Secure the cable with a 1” (25mm) washer and 1”

(25mm) hex nut

• Restrain the cable with vice grips at the end being

tightened to avoid twisting the cable. Make sure the

nuts are tight and the cable is tightened to a tension

of 50Nm.

5.10 Installing the Extruder Head

The nal piece to attach is the extruder head:

• Place the extruder head (C1812G) over the end of the

anchor rail panel (C1811G). The extruder head can be

used on the left hand or right hand shoulder. Be sure

that the extruder is orientated with the exit slot on the

rear side of the guardrail system, so that the guardrail

is extruded away from trac.

• The extruder head should be pushed along the

anchor rail panel as far as it will go. Centre the rail in

the tail of the extruder.

• Thetopandbottomattachmentbracketsoftheextruder

head each have three holes to provide tolerance in

the installation. Choose the hole in the attachment

bracket that is closest to the predrilled hole in the post

to allow the extruder head be parallel with the W-Beam

rail. Secure the extruder head with a 3/8” (10mm)

diameter x 11⁄2 (38mm) hex head bolt (C1623) and a

3/8” (10mm) washer (C1620) and lock washer (C1621)

between the 3/8”(10mm) nut (C1626) and the post at

the top and bottom attachment brackets

• If not already xed, attach regulatory authority

approved reective/chevron sheeting (specications

dier in each state) to the face of the extruder

head. Note the orientation of the reective/chevron

sheeting may depend on what side of the road the

terminal is installed relative to.

5.11 Installation of the TL2 ET2000 Plus

The installation of the TL2 system follows that of the

longer TL3 system however, the following needs to be

observed:

• The system comprises of 1 o HBA post assembly and

3 o SYT posts

Extruder Head Orientation

7

Release 03/18

ET2000 Guardrail Extruder Terminal

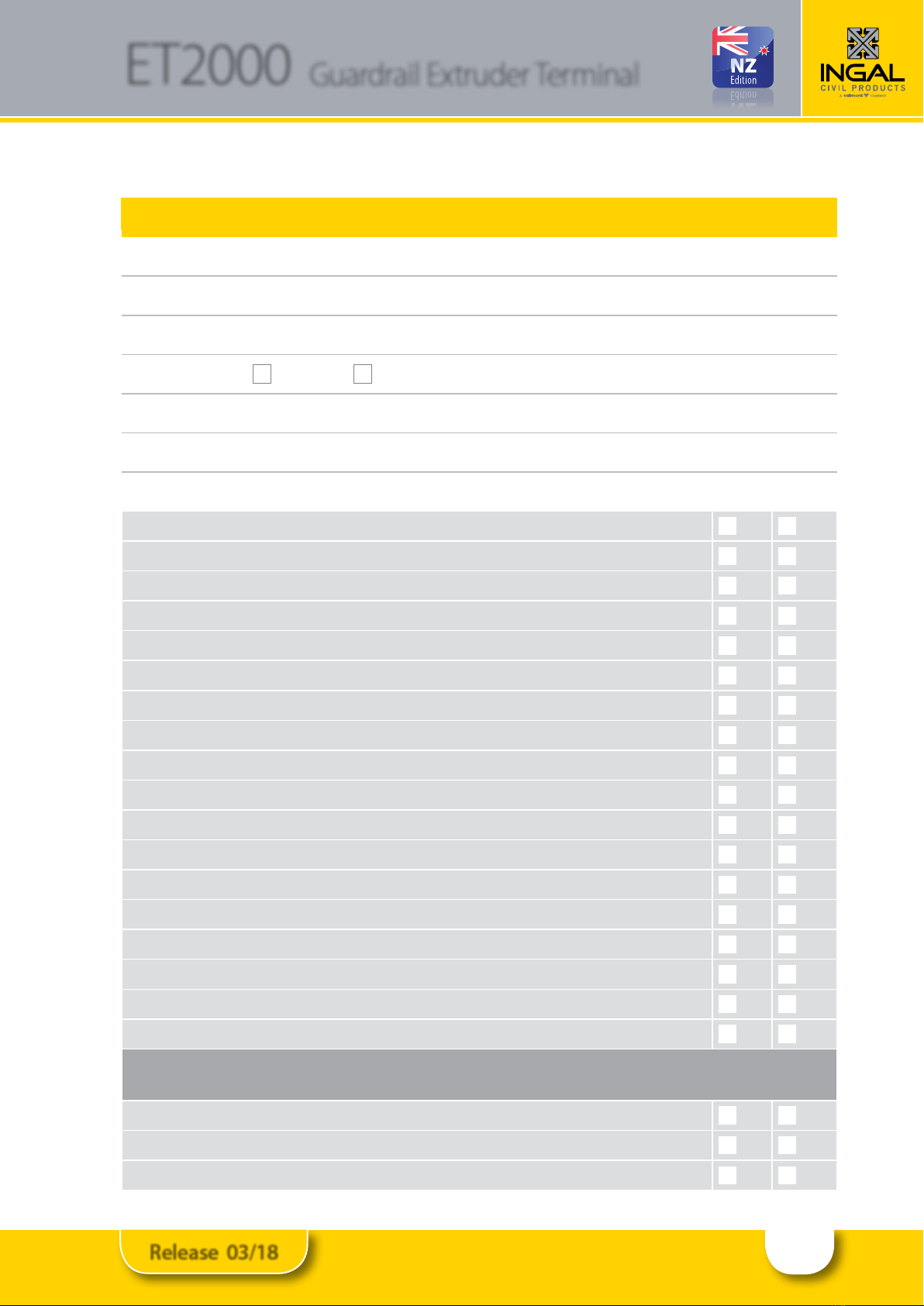

Ezy-Guard Smart Installation Checklist

ET2000 Plus Installation Checklist

Customer:

Project:

Barrier ID:

Terminal Type: TL2 TL3

Checked By:

Signed:

Date

Have the SYT posts been positioned every 1,905mm Yes No

Does the bottom half of post 1 (HBA) protrude not more than 100mm above ground level Yes No

Are all bolts securing the top to the bottom of the HBA post tight Yes No

Are the SYT posts at the correct height of 730mm ±20mm above ground level Yes No

Is the extruder head pushed to its maximum along the anchor rail Yes No

Is the extruder head correctly orientated with the exit slot facing the rear of the guardrail system Yes No

Is the area below the guardrails free from hazards so that the extruder head can travel freely upon impact

Yes No

Is the extruder head properly secured to post 1 through the attachment brackets Yes No

Has delineation been attached to the extruder head Yes No

Have the rails been secured to posts 2 through 8 (posts 2 through 4 for the TL2 system) Yes No

Have the rails been spliced with M16x32mm mushroom head bolts Yes No

Are all splice bolts and post bolts snug tight Yes No

Is the ll material around each post suitably compacted Yes No

Is the anchor cable secured between the anchor rail and post 1 Yes No

Is the bearing plate correctly orientated Yes No

Is the cable tensioned to 50Nm Yes No

Has any minor damage been repaired using two coats of an organic zinc rich paint Yes No

Does the terminal form a smooth line vertically and horizontally when viewed along the system Yes No

Surface Mount Variant

Has the appropriate footing been used to support the terminal, as per CAB-STD-127 or 128 Yes No

Are all anchors installed correctly without excessive bolt extending above the nut Yes No

Are all anchor nuts snug tight Yes No

Note: If the ET2000 terminal has been involved in an end-on impact, the extruder head shall be replaced.

8

Release 03/18

ET2000 Guardrail Extruder Terminal

6.0 Attachments

TheET2000Plushasbeenassessedthroughfullscalecrash

testing. The attachment of items, such as motorcycle rub

rails or handrails may alter the functionality of the terminal

as a guardrail end treatment. Only items sanctioned by

Ingal are to be attached to the ET2000 Plus.

6.1 Extruder Head Cover

Manufactured from UV stabilised Polyethylene, the

extruder cover provides protection for vulnerable road

users. The cover slides over the extruder head and can

be secured with tek screws along the sides. Retroective/

Chevron sheeting is attached directly to the face of the

cover.

6.2 Motorcyclist Protection Shield

A side impact protection shield for motorcylist

protection is also available, this shield is designed to

help reduce the risk of vulnerable road users snagging

on the extruder head when impacting from the reverse

direction. Refer drawing CAB-STD-136 for installation

detail.

7.0 Maintenance

Except for repairs due to impacts, there is virtually no

maintenance required for the system. It is recommended

that annual inspections be performed to ensure the

following;

•The terminal is appropriately delineated.

•Debris has not accumulated around the terminal that

may impede the travel of the extruder head.

•The anchor cable is taut and the nuts have not been

removed from the cable.

•The blocking pieces have not rotated.

7.1 Bush Fire Damage

All steel items used for the assembly of the ET2000 Plus

are hot dip galvanized. The performance of galvanized

coatings when subjected to res depends upon a

number of factors, such as ame duration, intensity and

the characteristics of the galvanized coating.

Typical bushre conditions may expose steel structures

to an air temperature of 800°C for periods of up to 120

seconds, however zinc coatings are generally reective

and will not absorb heat at the same rate as an uncoated

steel surface. Depending on the section thickness of

the steel, the actual steel surface temperature may not

exceed 350°C.

Typically, the bushre ame duration and intensity are

not high enough to compromise the structural strength

of the steel. The hot dip galvanized coating will also

typically remain unaected through a bushre event. If

the bushre causes damage to the galvanized surface,

then the item(s) shall be replaced.

If an item to be replaced is a post or rail, it is recommended

that the blocking pieces be replaced at these locations.

7.2 Damage Assessment

In the event of a vehicle impact, damage to the terminal

is to be assessed in accordance with Table 2.

A Safe Work Method Statement is available upon request

to assist in the safe repair of the ET2000 Plus.

Only items purchased from Ingal shall be used for the

repair of the ET2000 Plus.

When replacing posts, ensure that the disturbed

foundation material is suitably compacted prior to the

installation of replacement posts.

Motorcylist Protection Shield

Extruder Head with Cover - Rear View

Extruder Head with Cover - Front View

9

Release 03/18

ET2000 Guardrail Extruder Terminal

Damaged ET2000 Plus Terminal

Table 2: Damage Assessment of ET2000

Type of Defect Description of the Defect Action to be Taken

Galvanizing damage

on Posts.

The sum total of the damaged area does not exceed 45cm2(0.5% of the total surface

area) and no individual damaged area exceeds 40cm2.

The sum total of the damaged area exceeds 45cm2(0.5% of the total surface area) or

an individual damaged area exceeds 40cm2.

An organic zinc rich epoxy paint is to be applied to the

repair area in two coats.

The post is to be replaced.

Galvanizing damage

on rails.

The sum total of the damaged area does not exceed 200cm2(0.5% of the total

surface area) and no individual damaged area does not exceed 40cm2.

The sum total of the damaged area exceeds 200cm2(0.5% of the total surface area)

and/or an individual damaged area exceeds 40cm2.

An organic zinc rich epoxy paint is to be applied to the

repair area in two coats.

The rail is to be replaced.

Mechanical damage on

blocking pieces

The blocking piece has chips or cracks. The blocking piece is to be replaced.

Mechanical damage on

SYT posts.

The post is bent. The post is to be replaced.

Mechanical damage on

extruder head

The extruder head has minor damage that will not prevent its travel along the rail.

The extruder head is bent which will prevent its travel along the rail.

The delineation tape is damaged.

The extruder head may be reused.

The extruder head is to be replaced.

The delineation tape is to be replaced.

Mechanical damage

on rail.

The rail is dented, twisted or flattened.

There are nicks in any part of the rail.

The slots in the rail are distorted.

The rail is to be replaced.

The rail is to be replaced.

The rail is to be replaced.

Mechanical damage

on bolts.

The body of the bolt is distorted.

The thread of the bolt is damaged.

The bolt is to be replaced.

The bolt is to be replaced.

Disturbance of material

around posts.

The material around the post is loose or uncompacted. Any disturbed pavement or material around a post shall

be left dense, tight and smooth so that resistance to water

penetration is similar to that of the adjacent surface.

Note: If the ET2000 terminal has been involved in an end-on impact, the extruder head shall be replaced.

10

Release 03/18

11

Release 03/18

12

Release 03/18

13

Release 03/18

14

Release 03/18

15

Release 03/18

www.ingalcivil.co.nz

contact us on the web

Head Oce: Sydney

57-65 Airds Road, Minto, NSW 2566

Ph: +61 2 9827 3333

Fax: +61 2 9827 3300

Free call (within Australia):

1800 803 795

Email: [email protected]

Auckland

40 Tironui Road, Takanini

Auckland 2112 New Zealand

Ph: 0212 464 997

Email: [email protected]o.nz

For more information

Table of contents

Other INGAL Safety Equipment manuals

Popular Safety Equipment manuals by other brands

TEUFELBERGER

TEUFELBERGER hipSTAR FLEX 12,7mm Manufacturer's information and instructions for use

Spencer

Spencer Logic user manual

Storch

Storch Craftsman sun operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley GuardShield 450L-B4FNxYD user manual

ABB

ABB Jokab Safety Safeball JSTD1 Original instructions

SKYLOTEC

SKYLOTEC PEANUT Series Instructions for use