Instructions for Use

Page 3

User Instructions

Reliance Self Retracting Lanyards

User Instruction Manual - Self Retracting Lanyards

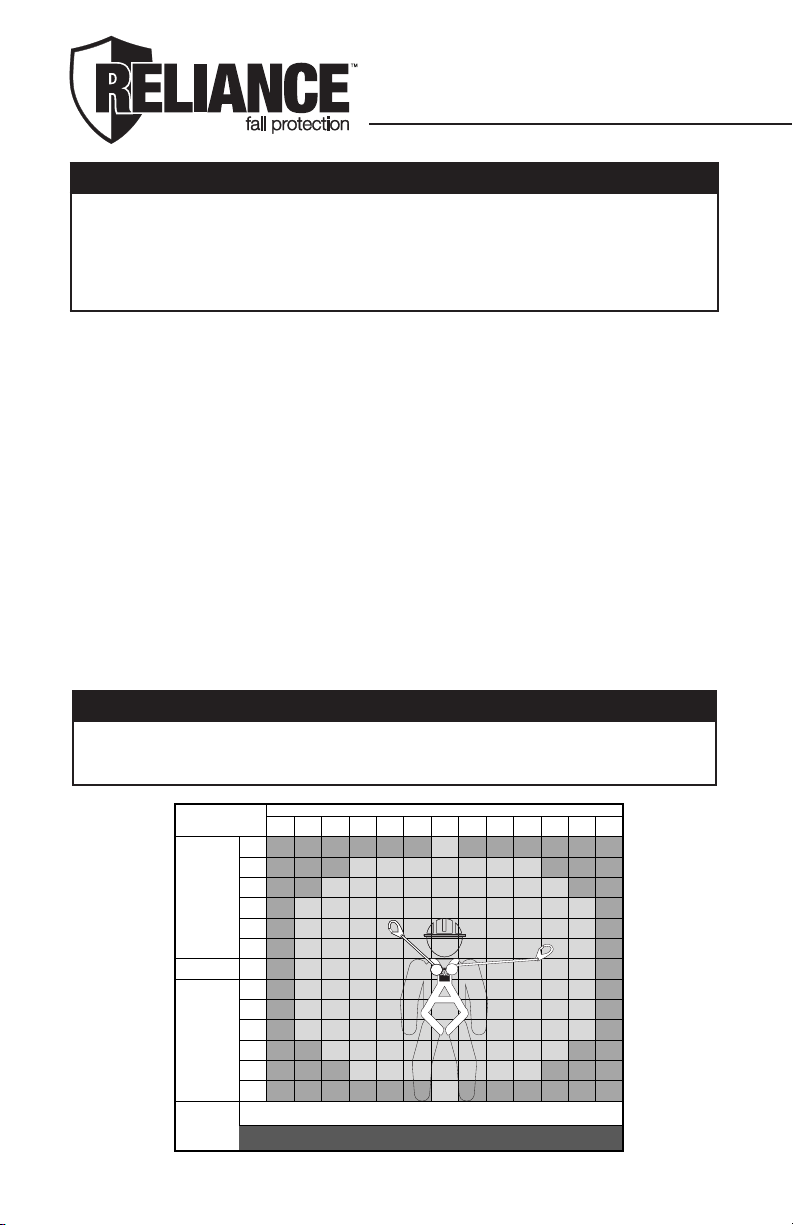

This manual is intended to meet the Manufacturer’s Instructions as required by

the current ANSI Z359.14-2014 ,and should used as part of an employee training

program as required by OSHA.

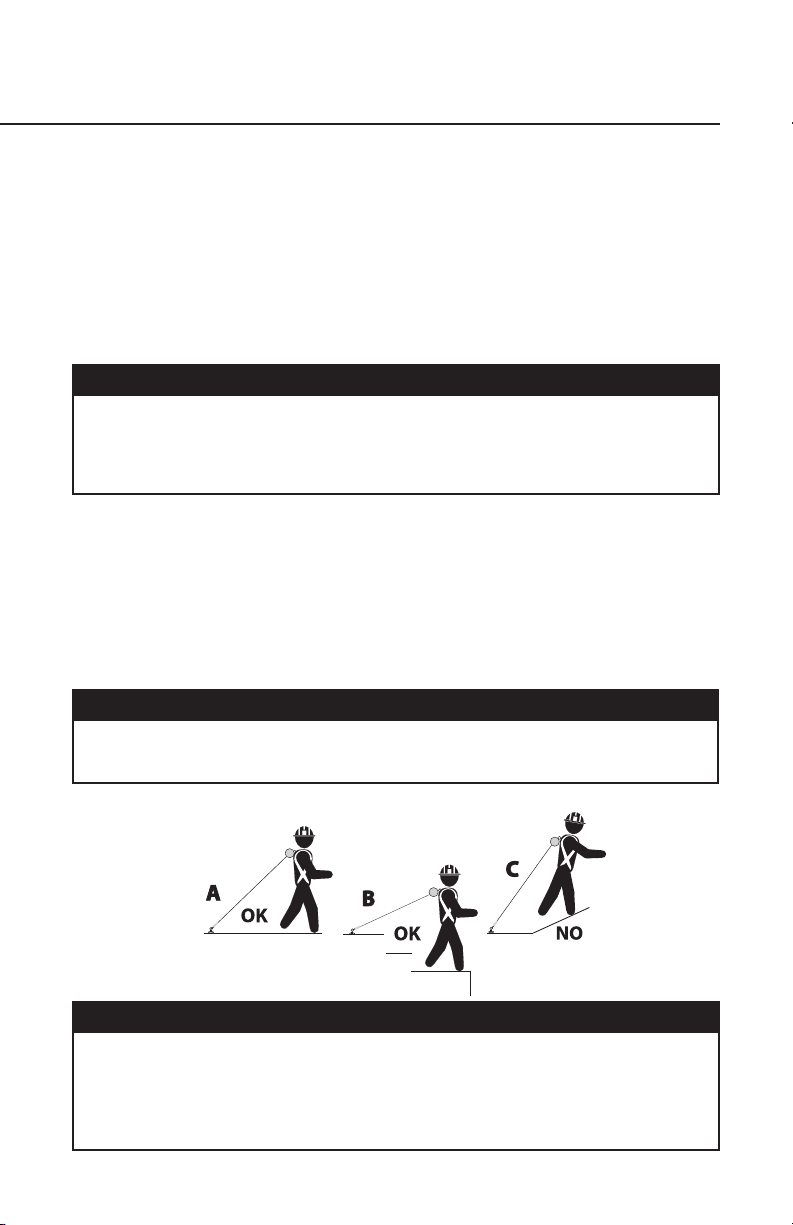

WARNING

This product is one part of a personal fall arrest, restraint, work positioning, personnel riding,

climbing, or rescue system. Without the other necessary components in such sub-systems

the Self Retracting Lanyard itself serves no useful purpose. The user must follow the manu-

facturer’s instructions for each component of the system. These instructions must be pro-

vided to the user before using this product and retained for ready reference by the user. The

user must read, understand (or have explained), and heed all instructions, labels, markings

and warnings supplied with this product and with those products intended for use in asso-

ciation with it before using this equipment. Manufacturer’s instructions must be followed for

proper use and maintenance of this equipment. National standards and state, provincial and

federal laws require the user to be trained before using this product. This manual can be used

as part of a such a user safety-training program that is appropriate for the user’s occupation.

IMPORTANT: Alterations or misuse of this product or failure to follow in-

structions may result in serious injury or death. If you have questions on the

use, care, or suitability of this equipment for your application, contact RELIANCE

Fall Protection for information.

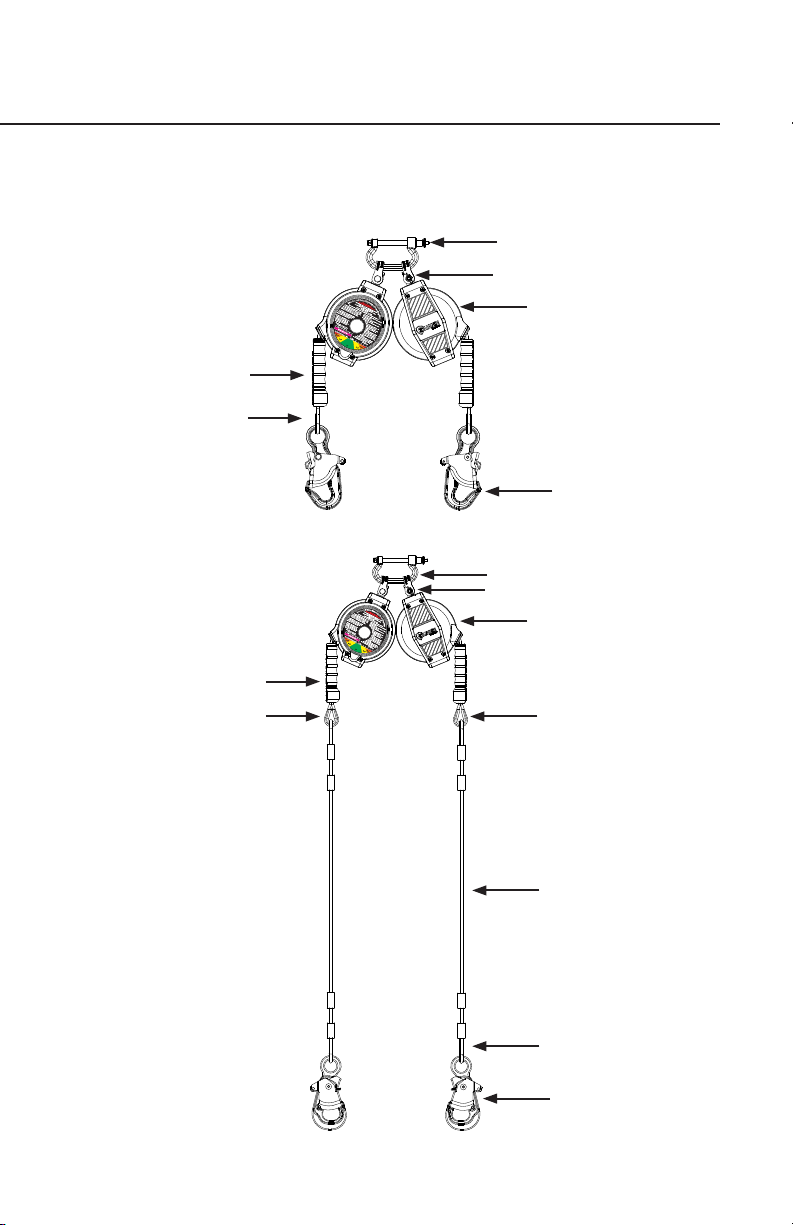

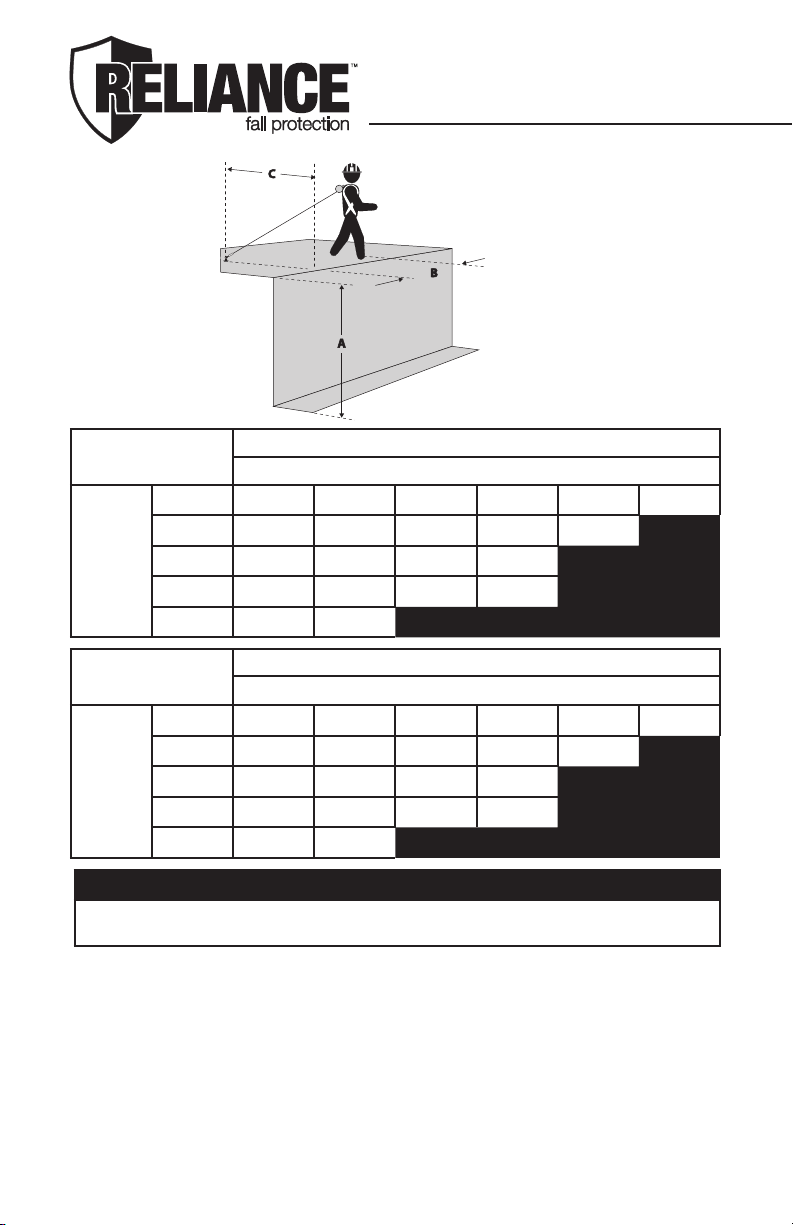

DESCRIPTION

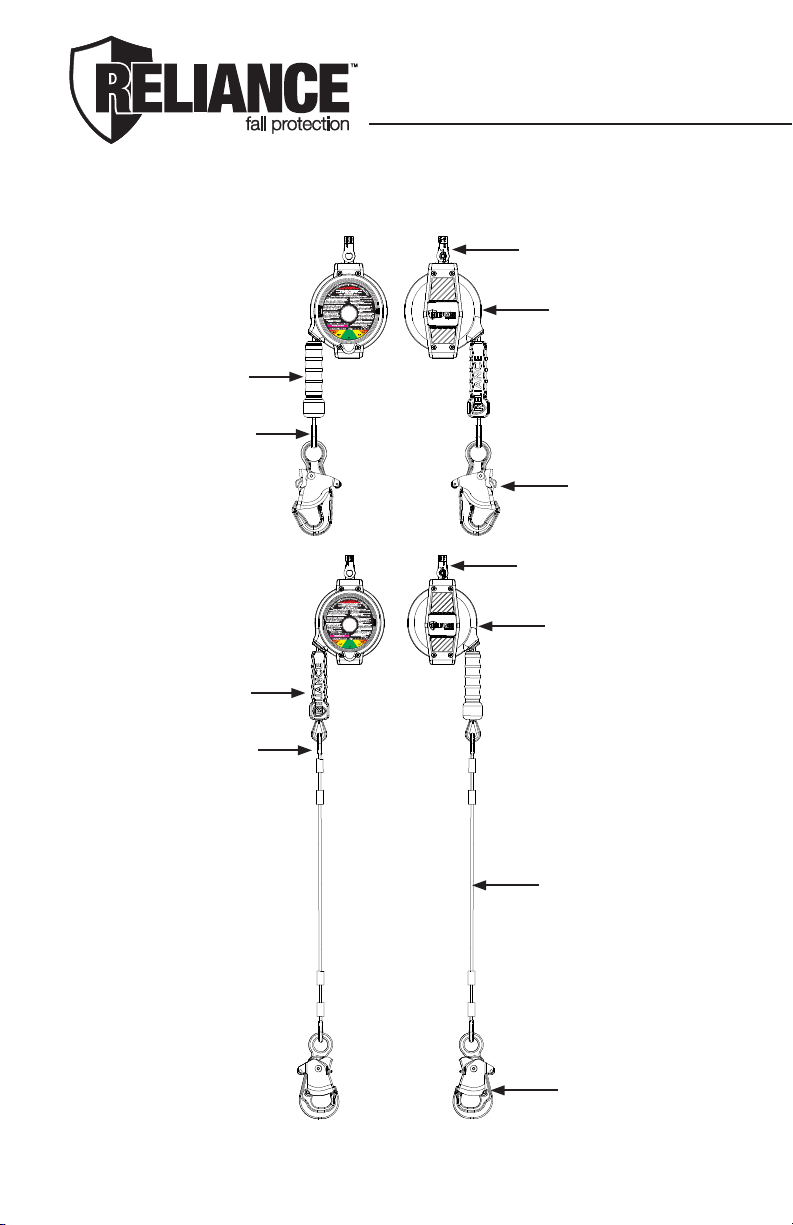

The Roto-Loc™ Leading Edge Self Retracting Lanyard (SRL-LE) is designed to

be a component in a personal fall arrest systems (PFAS). It may be used in most

situations where a combination of worker mobility and fall protection is required

(i.e. inspection work, general construction, maintenance work, steel stick work,

etc.). The Roto-Loc™ SRL-LE is designed for use by a single person weighing

up to 310 lbs [141kg] (body weight plus tools) Roto- Loc™ Leading Edge Self Re-

tracting Lanyard features a cam-action Stop-Cap Pawl system ensuring positive

lock-up even in the most demanding environments. The SRL-LE’s are mounted

at the dorsal D-ring location of the users full body harness. Models are available

in both single and twin SRL- LE congurations which incorporate both Pelican™

and Rebar snap hooks. The unique hook body design’s prevent the accidental

“false engagement” to the anchorage structure or D-ring, while the case swivel

provides an easy to see load indicator showing whether the Roto-Loc™ Leading

Edge Self Retracting Lanyard has been exposed to a fall arrest load and needs

to be serviced.