6()

Book 22442552 (7/03)

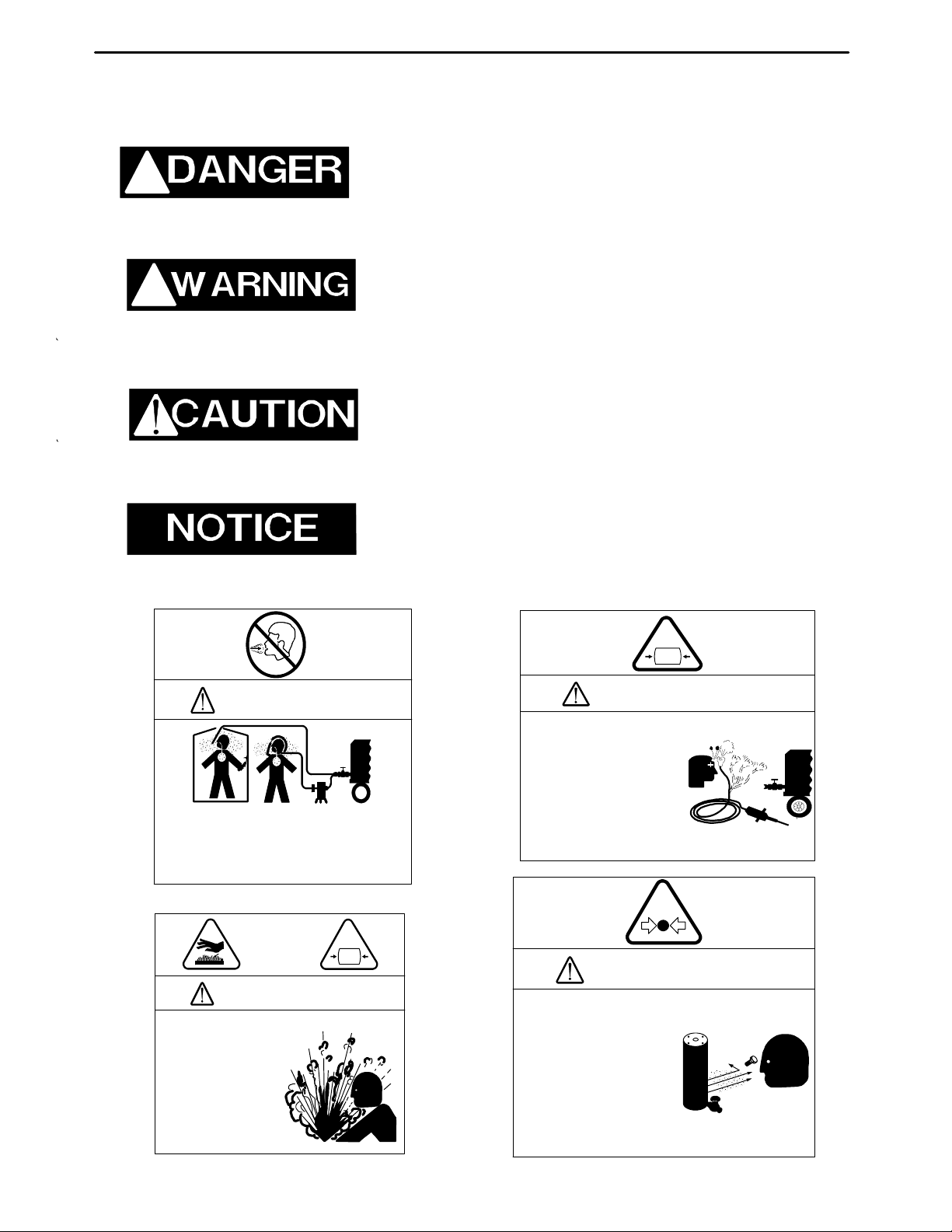

SECTION 1-- SAFETY

SAFETY PRECAUTIONS

General Information

Ensure that the operator reads and understands the

decals and consults the manuals before maintenance

or operation.

Ensure that the Operation and Maintenance manual,

and the manual holder if equipped, are not removed

permanently from the machine.

Ensure that maintenance personnel are adequately

trained, competent and have read the manuals.

Make sure that all protective covers are in place and

that the canopy/doors are closed during operation.

The specification of this machine is such that the ma-

chine is not suitable for use in flammable gas risk

areas. If such an application is required then all local

regulations, codes of practice and site rules must be

observed. To ensure that the machine can operate in

a safe and reliable manner, additional equipment such

as gas detection, exhaust spark arrestors, and intake

(shut--off) valves may be required, dependent on local

regulations or the degree of risk involved.

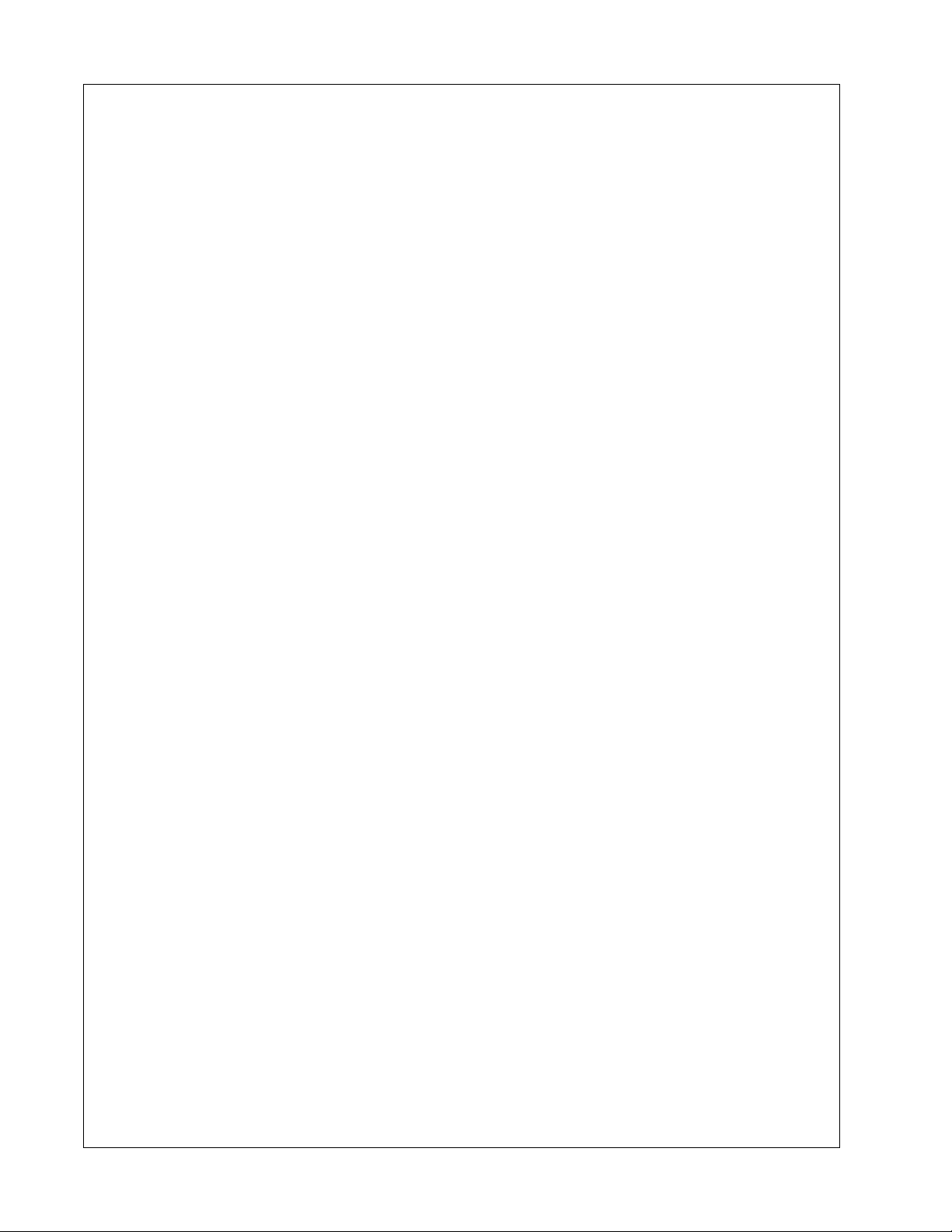

Air discharged from this machine may contain carbon

monoxide or other contaminants which will cause seri-

ous injury or death. Do not breathe this air.

Compressed air can be dangerous if incorrectly han-

dled. Before doing any work on the unit, ensure that all

pressure is vented from the system and that the ma-

chine cannot be started accidentally.

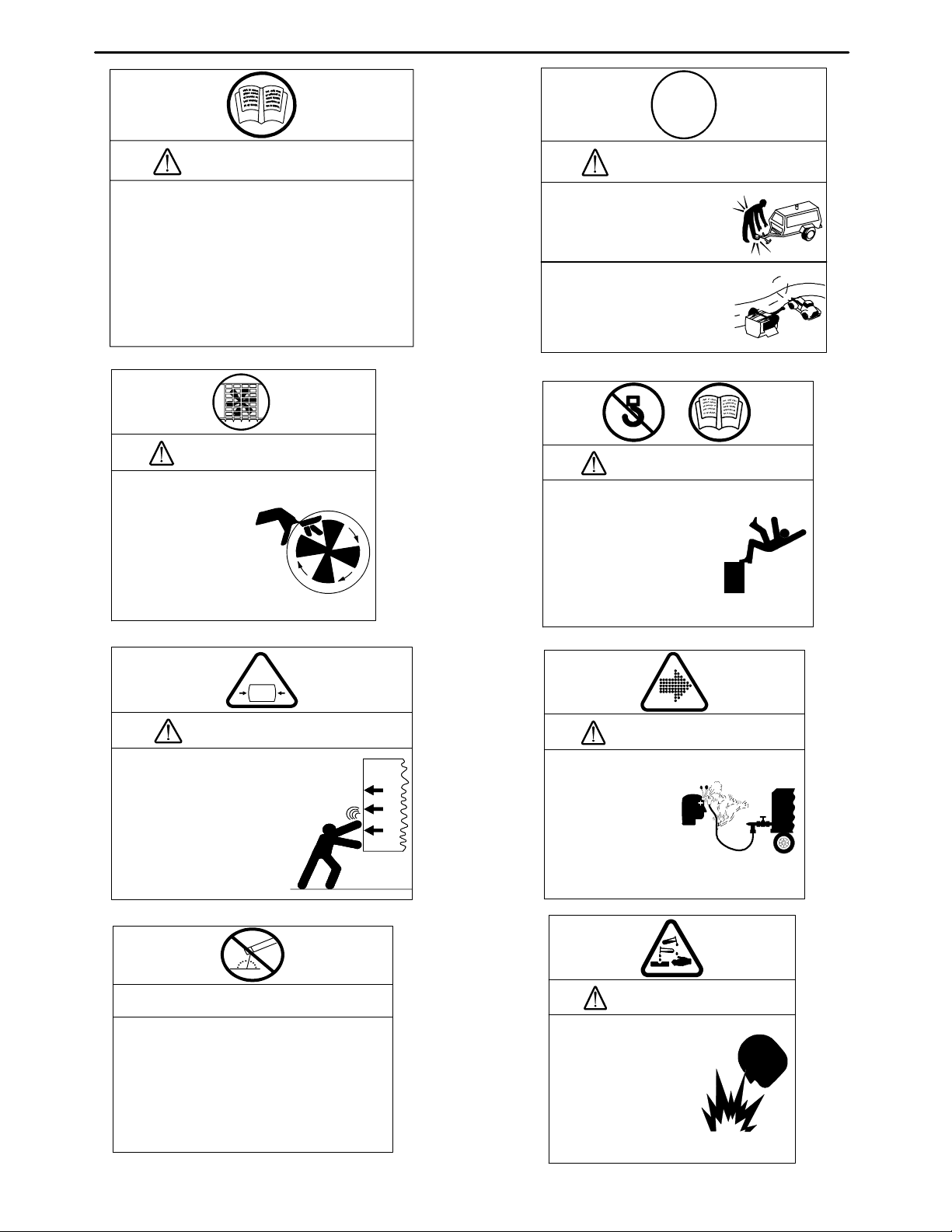

Ensure that the machine is operating at the rated pres-

sure and that the rated pressure is known to all rele-

vant personnel.

All air pressure equipment installed in or connected to

the machine must have safe working pressure ratings

of at least the machine safety valve rating.

If more than one compressor is connected to one com-

mon downstream plant, effective check valves and

isolation valves must be fitted and controlled by work

procedures, so that one machine cannot accidentally

be pressurized or over pressurized by another.

Compressed air must not be used for a feed to any

form of breathing apparatus or mask.

The discharged air contains a very small percentage

of compressor lubricating oil and care should be taken

to ensure that downstream equipment is compatible.

If the discharged air is to be ultimately released into a

confined space, adequate ventilation must be pro-

vided.

When using compressed air, always use appropriate

personal protective equipment.

All pressure containing parts, especially flexible hoses

and their couplings, must be regularly inspected, be

free from defects and be replaced according to the

Manual instructions.

Avoid bodily contact with compressed air.

The safety valve located in the separator tank must be

checked periodically for correct operation.

Never operate unit without first observing all safety

warnings and carefully reading the operation and

maintenance manual shipped from the factory with

this machine.

Never operate the engine of this machine inside a

building without adequate ventilation. Avoid breathing

exhaust fumes when working on or near the machine.

Do not alter or modify this machine.

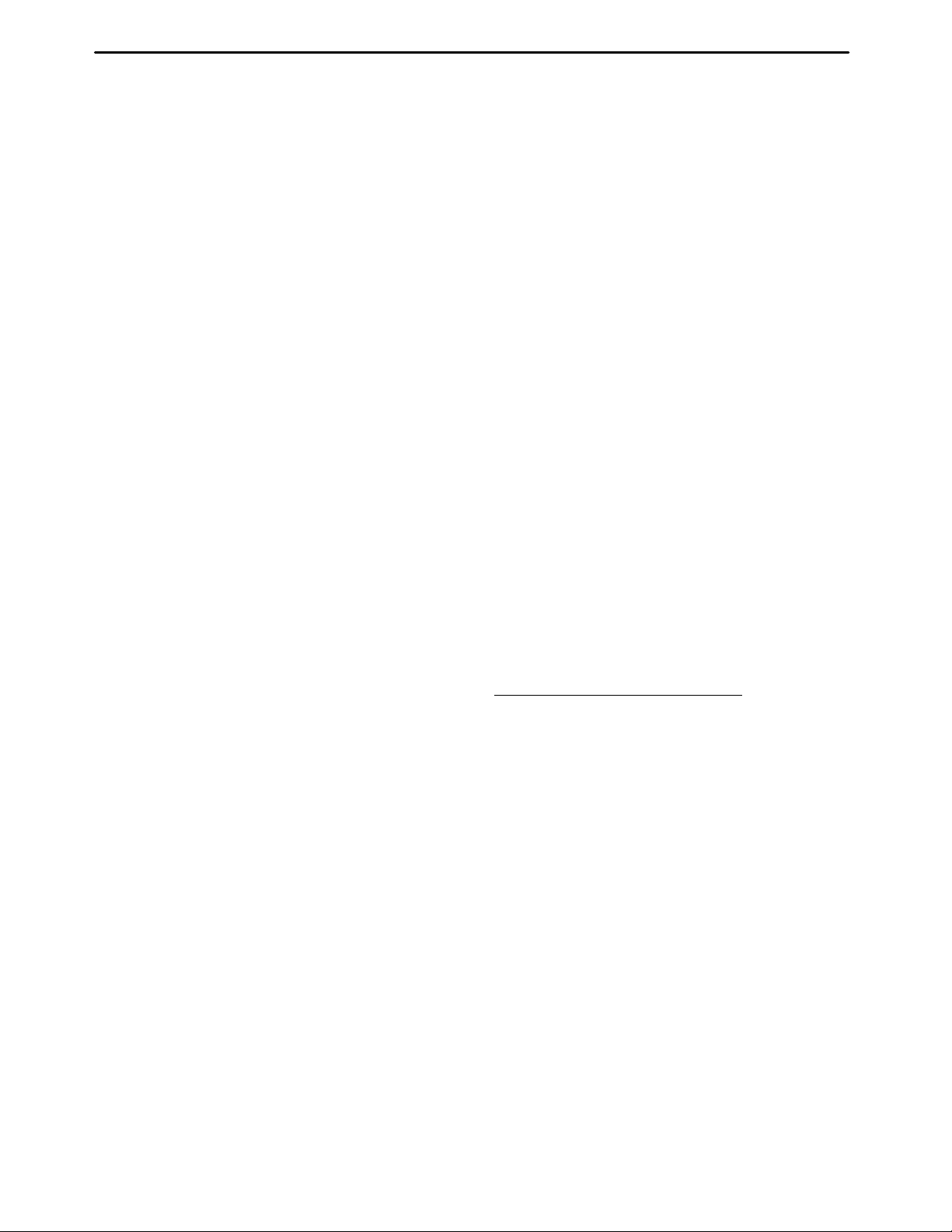

A battery contains sulfuric acid and can give off gases

which are corrosive and potentially explosive. Avoid

contact with skin, eyes and clothing. In case of contact,

flush area immediately with water.

Exercise extreme caution when using booster battery.

To jump battery, connect ends of one booster cable to

the positive (+) terminal of each battery. Connect one

end of other cable to the negative (--) terminal of the

booster battery and other end to a ground connection

away from dead battery (to avoid a spark occurring

near any explosive gases that may be present). After

starting unit, always disconnect cables in reverse or-

der.