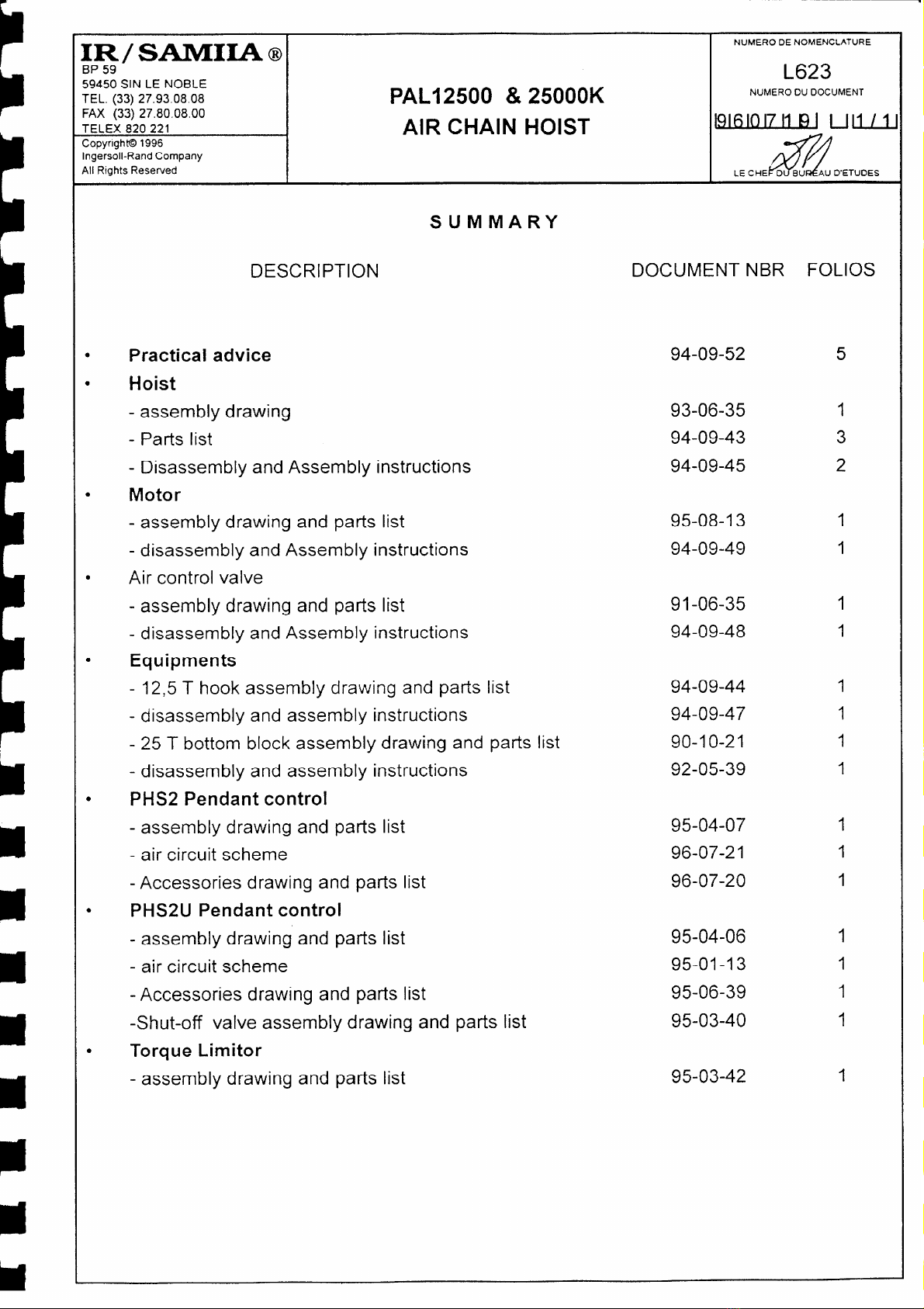

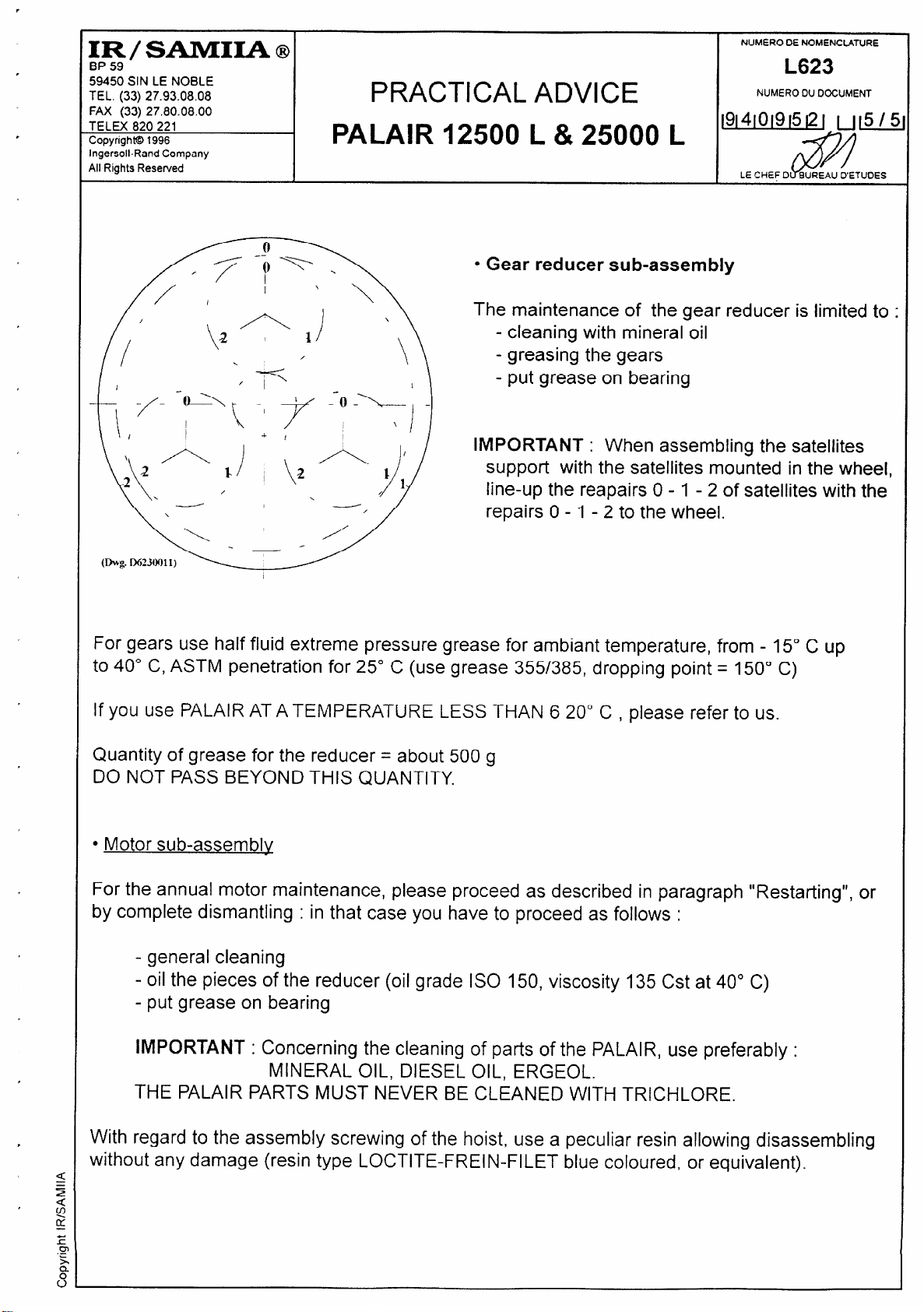

Ingersoll-Rand Samiia Palair Plus PAL12500K Installation guide

Other Ingersoll-Rand Chain Hoist manuals

Ingersoll-Rand

Ingersoll-Rand ELK Series User manual

Ingersoll-Rand

Ingersoll-Rand QCH Series User manual

Ingersoll-Rand

Ingersoll-Rand Quantum QCH Series Setup guide

Ingersoll-Rand

Ingersoll-Rand SM Series User manual

Ingersoll-Rand

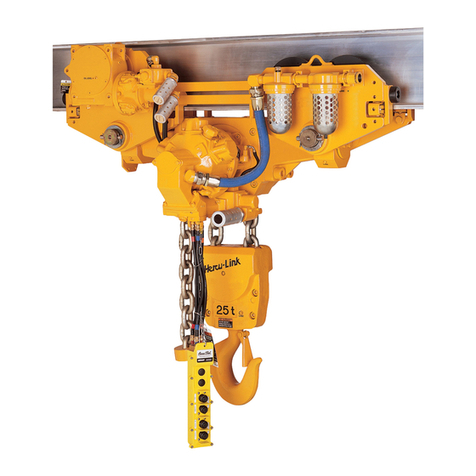

Ingersoll-Rand Hercu-Link HA1-005 Installation guide

Ingersoll-Rand

Ingersoll-Rand LC2A015SM User manual

Ingersoll-Rand

Ingersoll-Rand Quantum QCH Series User manual

Ingersoll-Rand

Ingersoll-Rand 7700-E Series Manual

Ingersoll-Rand

Ingersoll-Rand 7700-E Series User manual

Ingersoll-Rand

Ingersoll-Rand ELK Series Original instructions

Ingersoll-Rand

Ingersoll-Rand LCA750T Setup guide

Ingersoll-Rand

Ingersoll-Rand SMB010 Installation guide

Ingersoll-Rand

Ingersoll-Rand LV Series User manual

Ingersoll-Rand

Ingersoll-Rand KL Series User manual

Ingersoll-Rand

Ingersoll-Rand QUANTUM QMT Series Installation guide

Ingersoll-Rand

Ingersoll-Rand PAL250K-E User manual

Ingersoll-Rand

Ingersoll-Rand CL125K User manual

Ingersoll-Rand

Ingersoll-Rand MLK Series User manual

Ingersoll-Rand

Ingersoll-Rand LC2A015S User manual

Ingersoll-Rand

Ingersoll-Rand LC2A060S Setup guide

Popular Chain Hoist manuals by other brands

EINHELL

EINHELL Herkules H-F 1000 operating instructions

RED ROOSTER

RED ROOSTER TCR-250 user manual

POWERTEX

POWERTEX PCB-S1 Instructions for use

Parkside

Parkside PSZ 250 A1 Operation and safety notes

Creative Conners

Creative Conners CM Varistar Smart Chain Hoist Reference manual

Stagemaker

Stagemaker SR05 user manual