EN

16574162_ed4 EN-1

Product Safety Information

Intended Use:

These Air Percussive Chipping Hammers are designed for chipping, cutting, chiseling and breaking of hardened materials through repetitive

application of linear impacts of a tool steel that is retained and driven by the chipper.

For additional information refer to Product Safety Information Manual Form 04581450.

Manuals can be downloaded from ingersollrandproducts.com

Accessory Installation

Always use appropriate retainer, latch or sleeve, in addition to proper barriers to protect persons in surrounding or lower areas from

possible ejected accessories.

Always turn o the air supply, bleed the air pressure and disconnect the air supply hose when not in use, before installing, removing

or adjusting any accessory on this tool, or before performing any maintenance on this tool or any accessory.

For Plain-Type Retainer No. HH1-1190:

To remove chisel: Remove Lock Spring from the Retainer groove. Remove Retainer from Barrel. Raise chisel until the shank collar clears

the Retainer’s alignment grooves. Rotate the chisel 90° and remove it.

To install chisel: Insert the chisel shank into the front of the Retainer until it can turn 90°, allowing the collar to drop and rest on the

retainer shoulder. Attach the Retainer to the Barrel by aligning the Retainer slot with the barrel groove. Insert the Lock Spring through the

Retainer slot and push it around the Barrel and Retainer until the Retainer is secured to the Barrel.

For Quick-Change Type Retainer No. HH1-1191:

To remove chisel: It is not necessary to remove the Retainer from the Barrel. While lifting the Flat Spring and Pin, rotate the chisel 90° and

remove it.

To install chisel: Insert chisel shank into the Retainer until it stops against the Barrel. Rotate the chisel 90° until you see and feel the Flat

Spring and Pin snap into position to secure the chisel.

For Rubber BueredType Retainer No. HHW1-300 (for use with threaded barrel):

Grasp the Retainer and unscrew it from the Barrel against the pressure of the Retainer Lock Spring. Remove the buer and the chisel from

the rear of the Retainer. The Buer will split to allow the use of a wide chisel. To install a wide chisel, pass the shank of the chisel through

the hole in the Retainer and by opening the split in the buer, t it around the chisel making sure that the shoulder of the chisel locates in

the large counter bore of the buer. Slide the assembly into place in the threaded end of the Retainer.

Moil point and narrow chisels can be removed and installed without removing the buer from the Retainer.

Align the end of the chisel with the Nozzle and thread the retainer onto the Barrel. Tighten the Retainer clockwise on the Barrel until the

Retainer Lock Spring can be seen or heard to locate in place in the recess in the barrel thread. Check correct engagement by trying to

rotate the Retainer. If signicant resistance is felt, the Retainer Lock Spring is correctly engaged. If no signicant resistance is felt, rotate

the Retainer until the Retainer Lock Spring engages properly.

Prior to Use

Do not lubricate tools with ammable or volatile liquids such as kerosene, diesel or jet fuel. Use only recommended lubricants.

Use only proper cleaning solvents to clean parts. Use only cleaning solvents which meet current safety and health standards. Use

cleaning solvents in a well ventilated area.

Tools are coated inside and out with rust-resisting oil before leaving the factory. Before using the tool, remove this oil by dipping the tool in a

suitable cleaning solution to wash the oil from the exterior. Pour about 6 cm3of a clean, suitable, cleaning solution into the air inlet and operate

the tool for about 15 seconds. Dry the tool immediately after cleaning, pour 3 cm3of Ingersoll Rand No. 10 Oil into the air inlet and again

operate the tool for 5 seconds to lubricate all working parts.

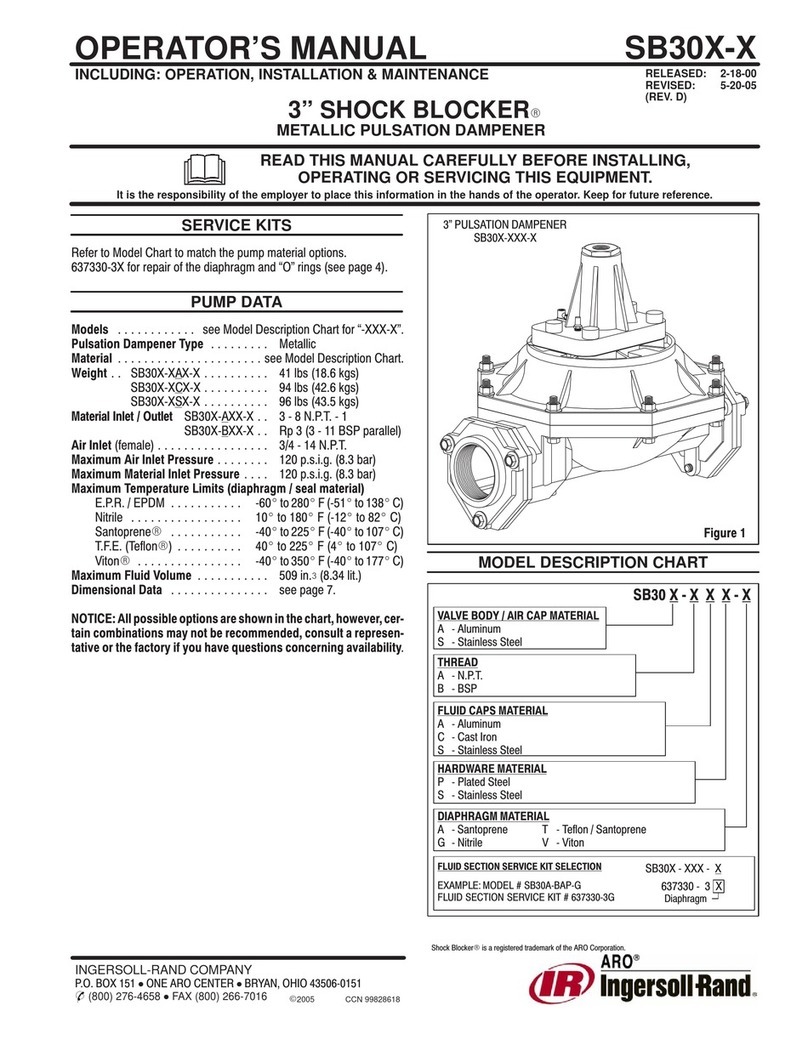

Product Specications

Model Retainer Type Shank Blows per

Minute

Stroke

Length

Sound Level dB (A)

(ISO15744)

Vibration

(ISO28927) m/s2

Required Supplied Size Inch Collar Inch (mm) † Pressure (Lp) ‡ Power (Lw) Level *K

1A1S Yes No 0.580 Hex Oval 2,500 1 (25) 109.9 120.9 18.1 5.4

1A1SA, 1A1SA-EU Yes Plain 0.580 Hex Oval 2,500 1 (25) 109.9 120.9 18.1 5.4

2A1S Yes No 0.580 Hex Oval 2,300 2 (51) 109.8 120.8 18.0 5.4

2A1SA, 2A1SA-EU Yes Plain 0.580 Hex Oval 2,300 2 (51) 109.8 120.8 18.0 5.4

3A1S Yes No 0.580 Hex Oval 1,725 3 (76) 112.2 123.2 17.7 5.3

3A1SA, 3A1SA-EU Yes Plain 0.580 Hex Oval 1,725 3 (76) 112.2 123.2 17.7 5.3

4A1S Yes No 0.580 Hex Oval 1,480 4 (102) 112.9 123.9 18.9 6.2

4A1SA, 4A1SA-EU Yes Plain 0.580 Hex Oval 1,480 4 (102) 112.9 123.9 18.9 6.2

•

•

•

•

•

•

•