INGOS Ltd. RVO 400 Page 17

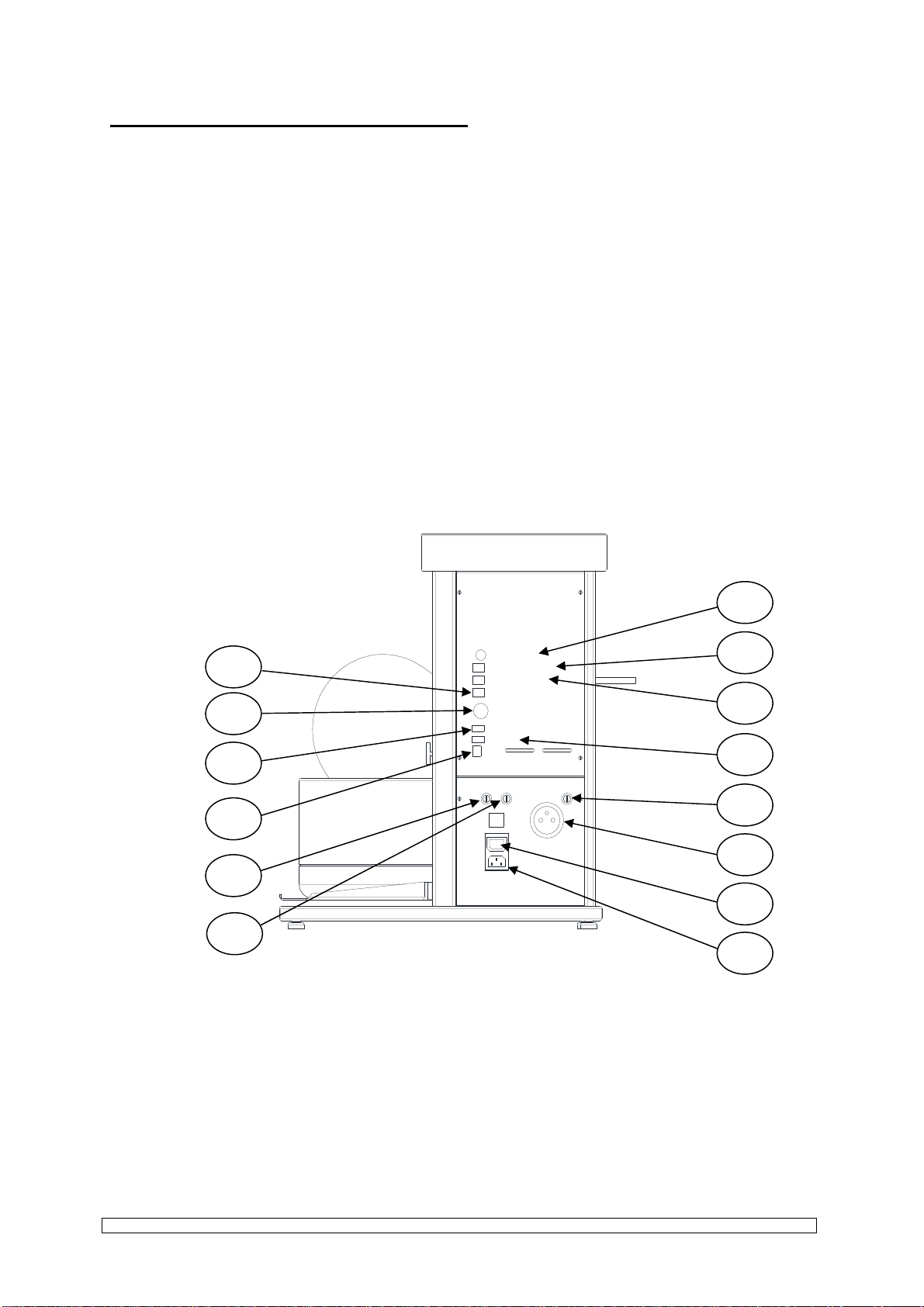

not running, even the pump mains cable is correctly plug in the rear of evaporator as well as vacuum

connecting hose. Check the vacuum pump fuse, possibly replace it with new one featuring the same

parameters (fig. 2, T3,15A).

6. SAFETY AND OPERATION CONDITIONS

6.1 Operation safety

Ensuring of rotation of the sample to be vaporized: Current protection of the driving

motor. If the

resistance against rotation has increased above the

prespecified limit, the driving motor voltage will be

disconnected. (This situation will be signaled by the

flashing of the rotation icon)

Protection of the heating bath lift: Friction coupling between the driving motor and

lifting equipment. In the case of an increase in resistance

during the lifting of the bath above the specified limit the

friction coupling could slip.

Protection of bath heating: Electronically by means of a thermal protection

Against overheating. There will not be any heating if the

incorporated sensor of the heating bath has been

connected or if the difference of temperatures between

sensors rises above the limit pre-specified by the

manufacturer. (This situation will be signaled by the

flashing of the icon for heating)

6.2 Operation conditions

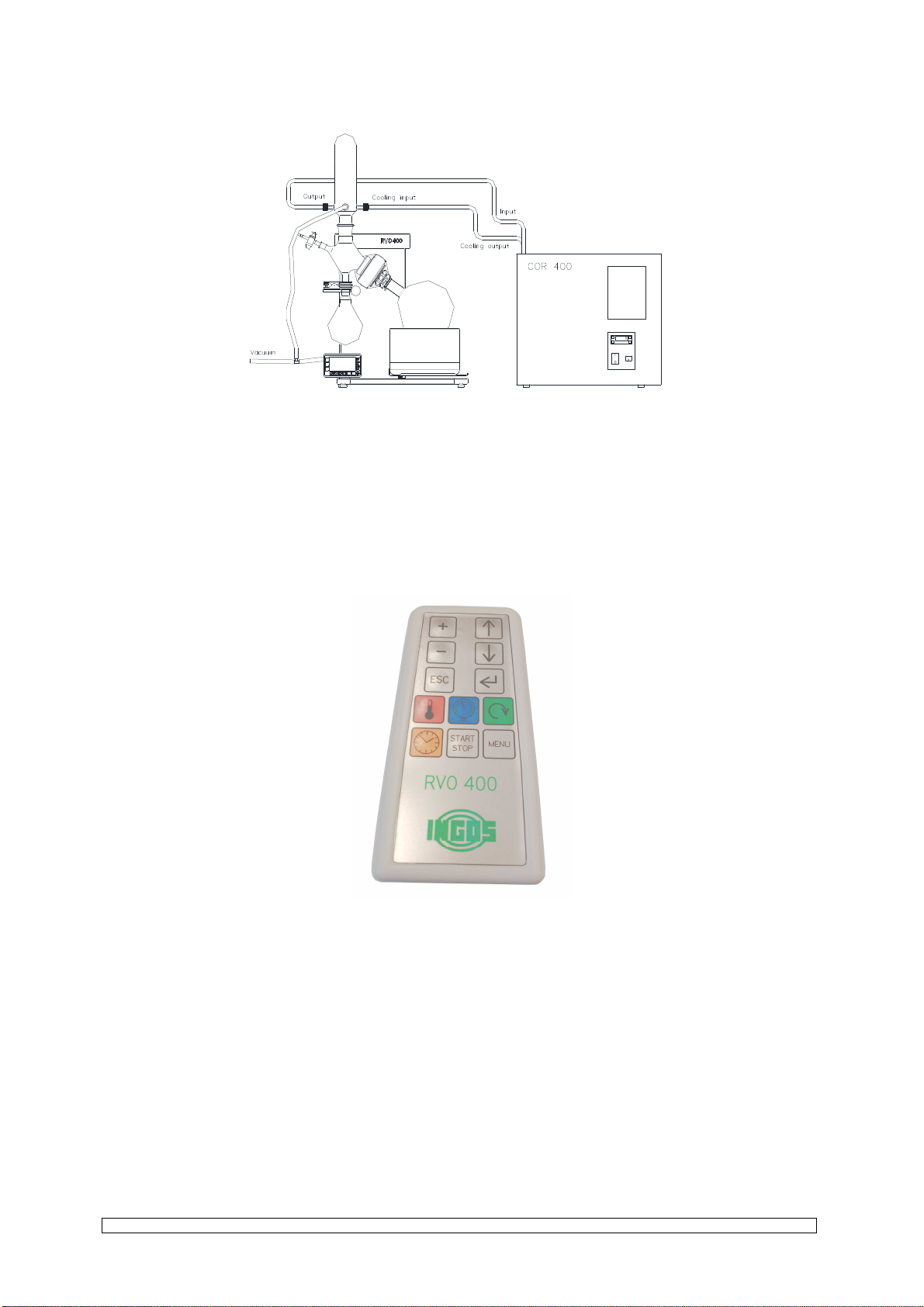

The apparatus is designed for the work under ordinary laboratory conditions at temperatures of 10

to 30°C and air humidity up to 80% . The power supply is 230 V, 10 A, 50 Hz. The inlet cord should

be connected into a socket circuit featuring protection from 10 A or 16 A. The inlet cord cannot be in

contact with the heating bath. The socket designed for the connection of the heating bath is designed

exclusively for this bath. Oil used in the bath must be designed for a temperature of at least min.

200°C for temperature to 180°C (230°C for temperature to 210°C). The bath volume shall not exceed

2 l.

It is forbidden to handle any bath which has been heated to a temperature exceeding 40°C in any

other way than by using the apparatus lift. If you want to fill the liquid into the heating bath, always

switch the vaporized sample rotation OFF. For temperatures up to 100°C use water as the filling of the

heating bath (with regard to its higher thermal capacity).

During the evaporation of aggressive substance engage behind the cooler outlet bottle gas

wasching acc. to Drechsler.

Terms of service vacuum pump are in the user manual.

Caution! If you are replacing the round-bottom flask after the vaporized solution has become

thicker, pay particular attention and if it is not possible to remove the flask easily from the cone, carry

out any other handling only after the cooling of the bath.