injen technology SP1675 User manual

Other injen technology Automobile Accessories manuals

injen technology

injen technology SP7035 User manual

injen technology

injen technology EVO1107 User manual

injen technology

injen technology SP1571 User manual

injen technology

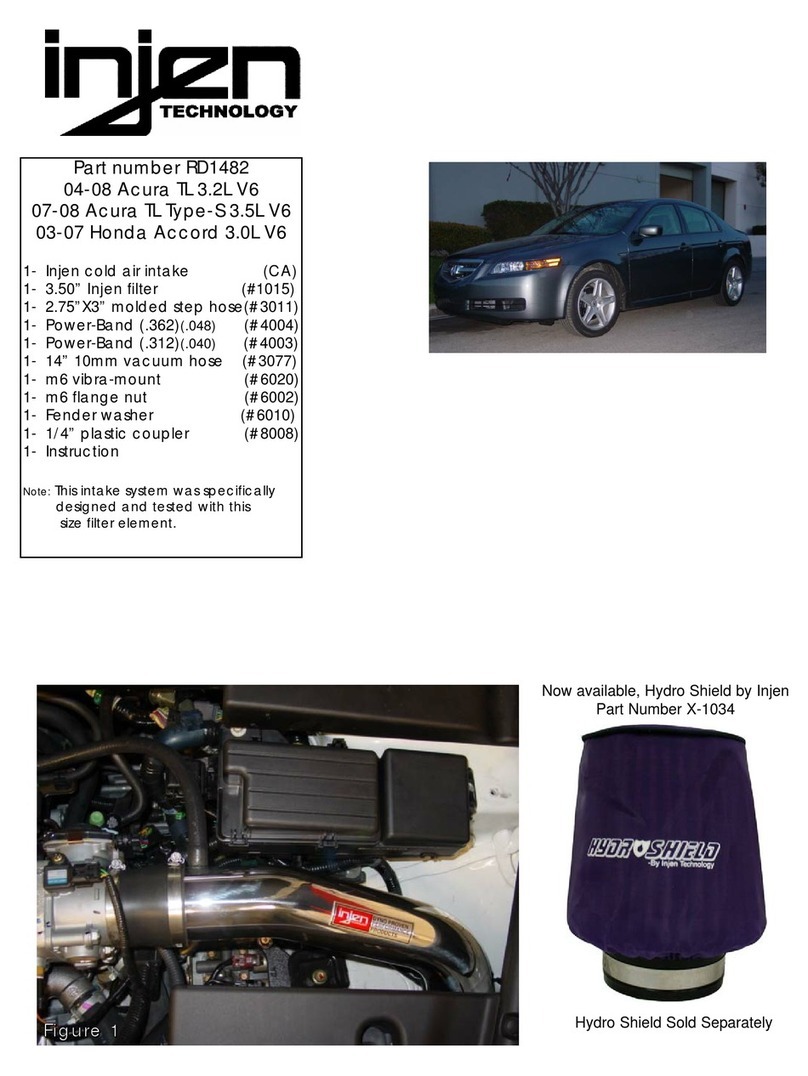

injen technology RD1482 User manual

injen technology

injen technology SP1870 User manual

injen technology

injen technology SP3028 User manual

injen technology

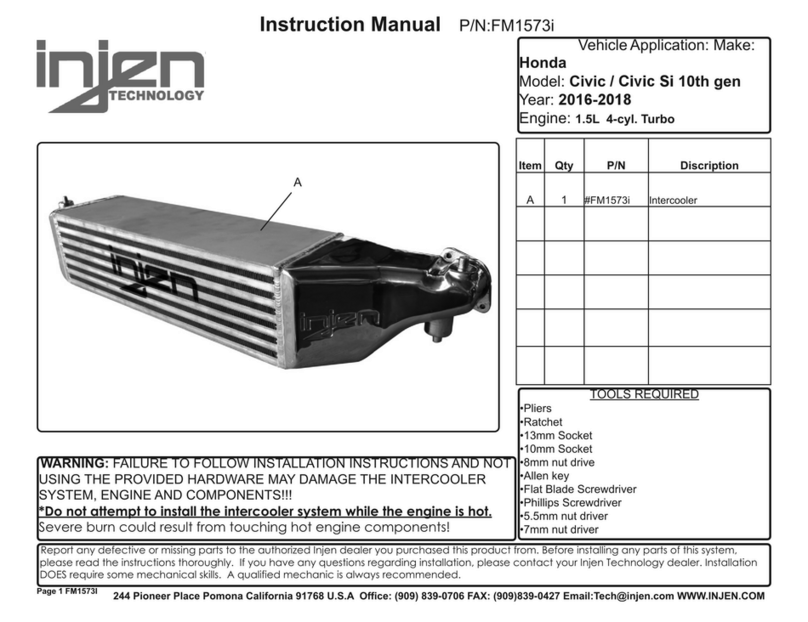

injen technology FM1573i User manual

injen technology

injen technology SP1230 User manual

injen technology

injen technology PF2057 User manual

injen technology

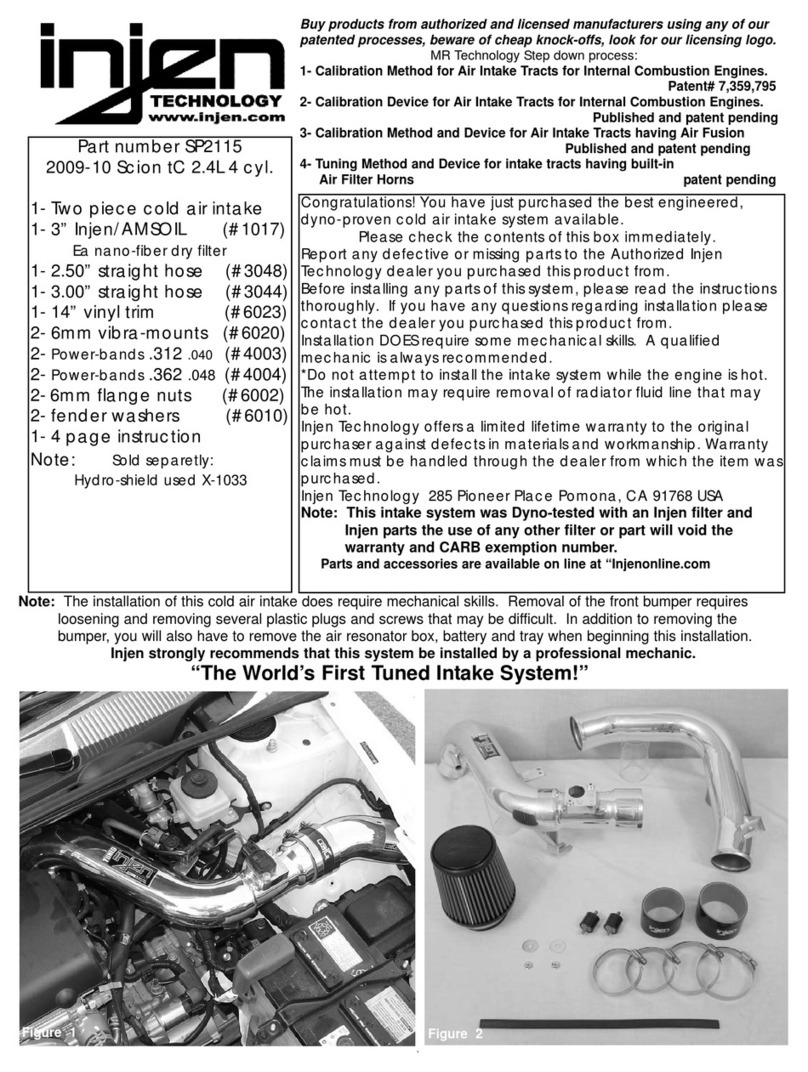

injen technology SP2115 User manual

Popular Automobile Accessories manuals by other brands

MB QUART

MB QUART GMR-1.5 Operator's Guide and Installation Instructions

Qdis

Qdis W213-CT installation manual

ADDON

ADDON 45-1629NUB Mounting instructions

BLACKHAWK!

BLACKHAWK! AUTOMOTIVE BH6221 Operating instructions and parts manual

Caraudio-Systems

Caraudio-Systems V5-NBT manual

Power Fist

Power Fist 8985988 manual

Premier Manufacturing Co.

Premier Manufacturing Co. 10005664 Installation, Inspection, Operation & Maintenance Guide

Air Lift

Air Lift 75670 instructions

HI-POD

HI-POD JS7A/2010 Instructions for installation & use

Whispbar

Whispbar K815W Fitting instructions

caron

caron PHC-9000 user manual

FALCON RIDGE

FALCON RIDGE HO-700-WD05 Instructions for Installation and Care