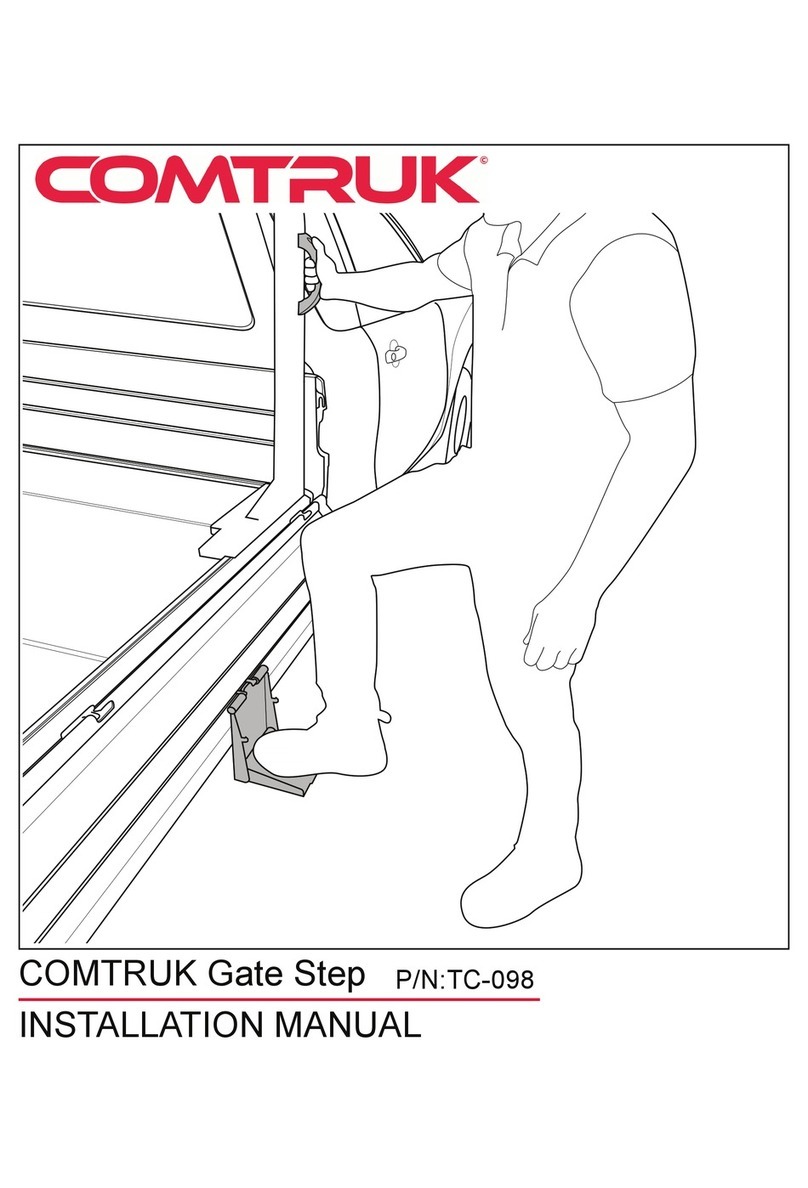

Part number PF2057

2006 Toyota FJ 4.0L V6

1- MR Tech Power-flow Intake system

1- 8” Inverted top power filter (#1022)

1- Power Box-contents: PB400P-8

1- Powerbox skin plate (A) (#6043)

1- Stabilizer top (B) (#6041)

1- Connecting bottom base (C) (#6042)

1- Top panel pre-filter screen (D) (#6044)

1- 4” velocity stack inlet (E) (#6045)

1- Rect. front pre-filter screen (F) (#6046)

2- main body halfs. (G) (#6048)

4- m6 x 45mm socket head (H) (#6052)

4- m6 x 65mm socket head (I) (#6055)

4- m6 x 12mm socket head (J) (#6056)

1- Power-Box mounting bracket (K) (#20079)

1- 4” straight hose (#3129)

1- 3” straight hose (#3044)

1- 18”- 4mm heater hose (#3104)

2- large Power-Band .462 (.064) (#4006)

2- Power-Band .362 (.048) (#4004)

1- 8mm Vibra- mount (#6062)

1- 8mm flange nut (#6017)

1- 5 page instruction

Note: All parts and accessories are sold

on-line at: “injenonline.com”

Congratulations! You have just purchased the best engineered,

dyno-proven Power-Flow air intake system available.

Please check the contents of this box immediately.

Report any defective or missing parts to the Authorized Injen

Technology dealer you purchased this product from.

Before installing any parts of this system, please read the instructions

thoroughly. If you have any questions regarding installation please

contact the dealer you purchased this product from.

Installation DOES require some mechanical skills. A qualified

mechanic is always recommended.

*Do not attempt to install the intake system while the engine is hot.

The installation may require removal of radiator fluid line that may

be hot.

Injen Technology offers a limited lifetime warranty to the original

purchaser against defects in materials and workmanship. Warranty

claims must be handled through the dealer from which the item was

purchased.

Injen Technology 285 Pioneer Place Pomona, CA 91768 USA

Please check the contents of this box immediately.

Note: This intake system was Dyno-tested with an Injen filter and

Injen parts. The use of any other filter or part will void the

warranty and CARB exemption number. Parts and accessories

are available on line at “Injenonline.com

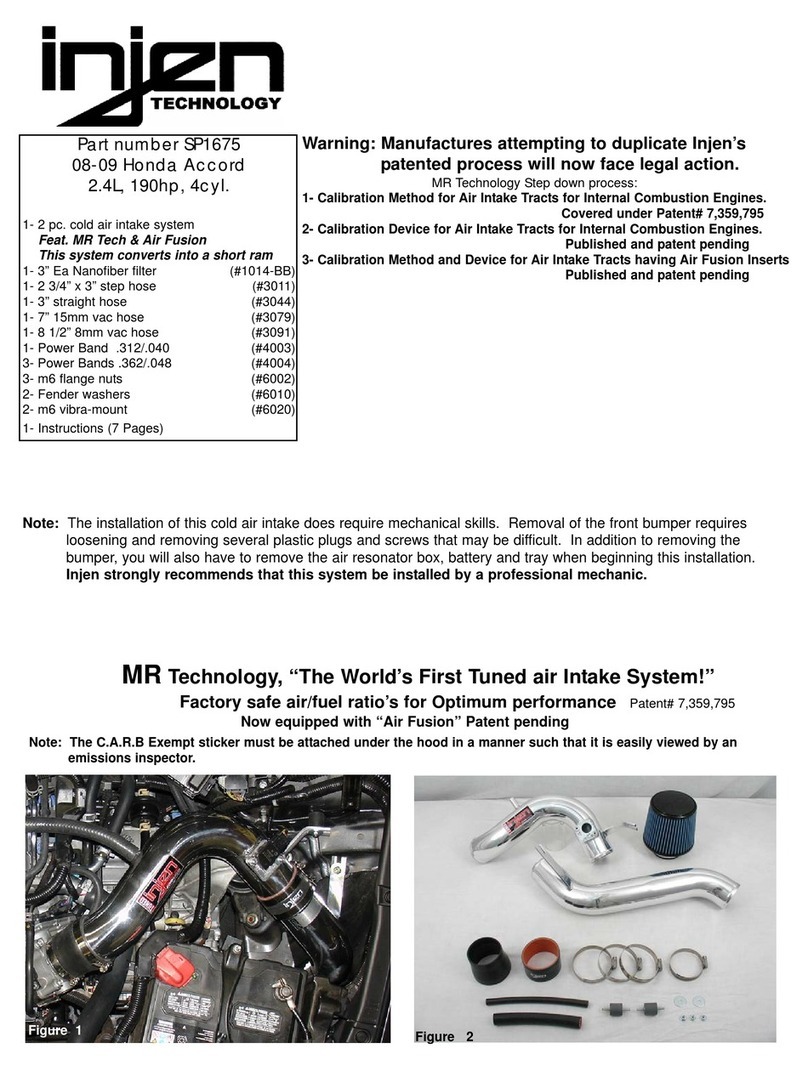

Note: The installation of this cold air intake does require mechanical skills. Removal of the front bumper requires

loosening and removing several plastic plugs and screws that may be difficult. It is recommended that this

system be installed by a professional mechanic. Be sure to disconnect the negative terminal before proceeding.

Congratulations! You have just purchased the worlds first tuned intake system.

MR Technology, Leading the way!

Patent pending

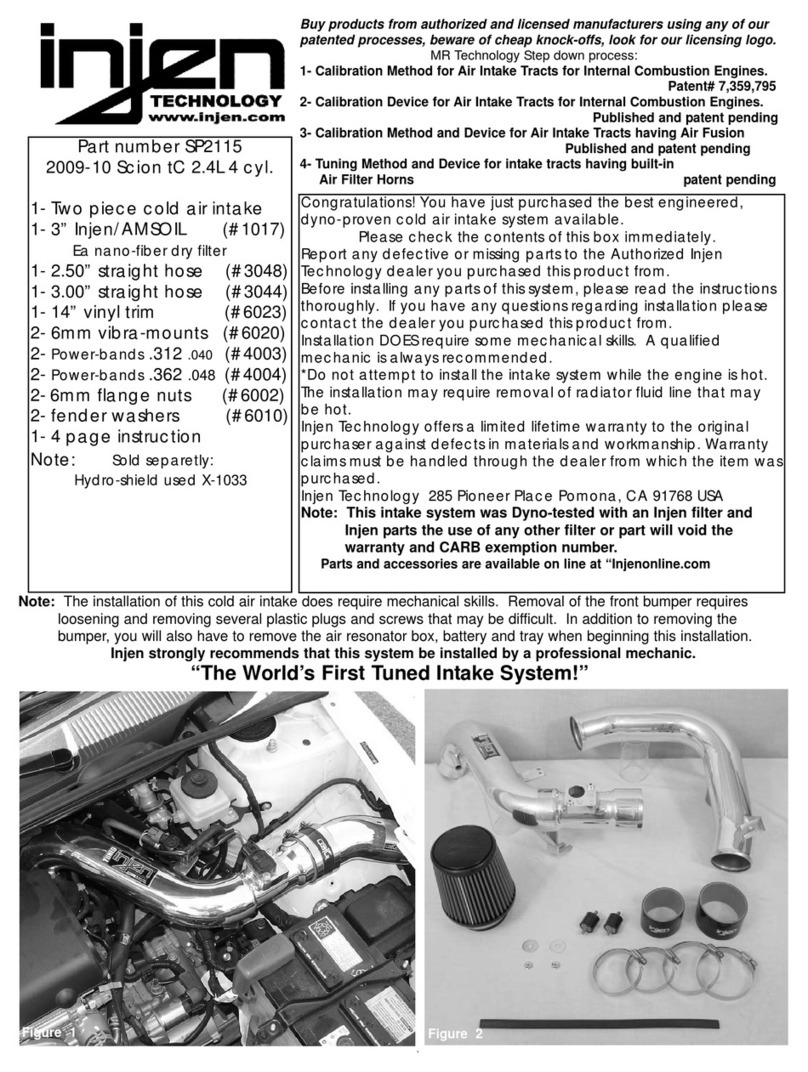

#1022

(A) and (G)

(B)

(D)

(K)

(E)

Power-Box contents:

POWER-FLOW:An air intake evolution

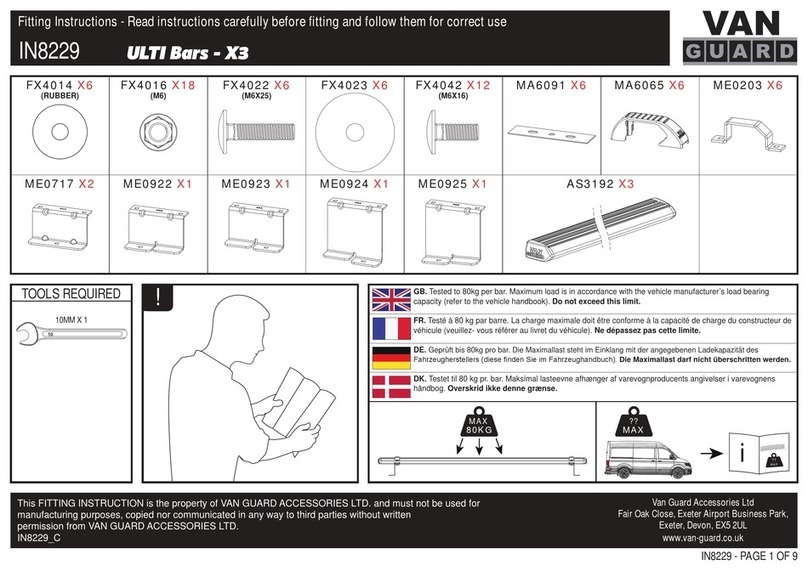

Tools required:

1- 8mm socket

1- 10mm socket

1- 12mm socket

1- Phillips screw driver

1- 8mm nut driver

1- 55mm allen wrench

1- Disc grinder or Dremel

(C)

(F)

(I)

(H)

(J)

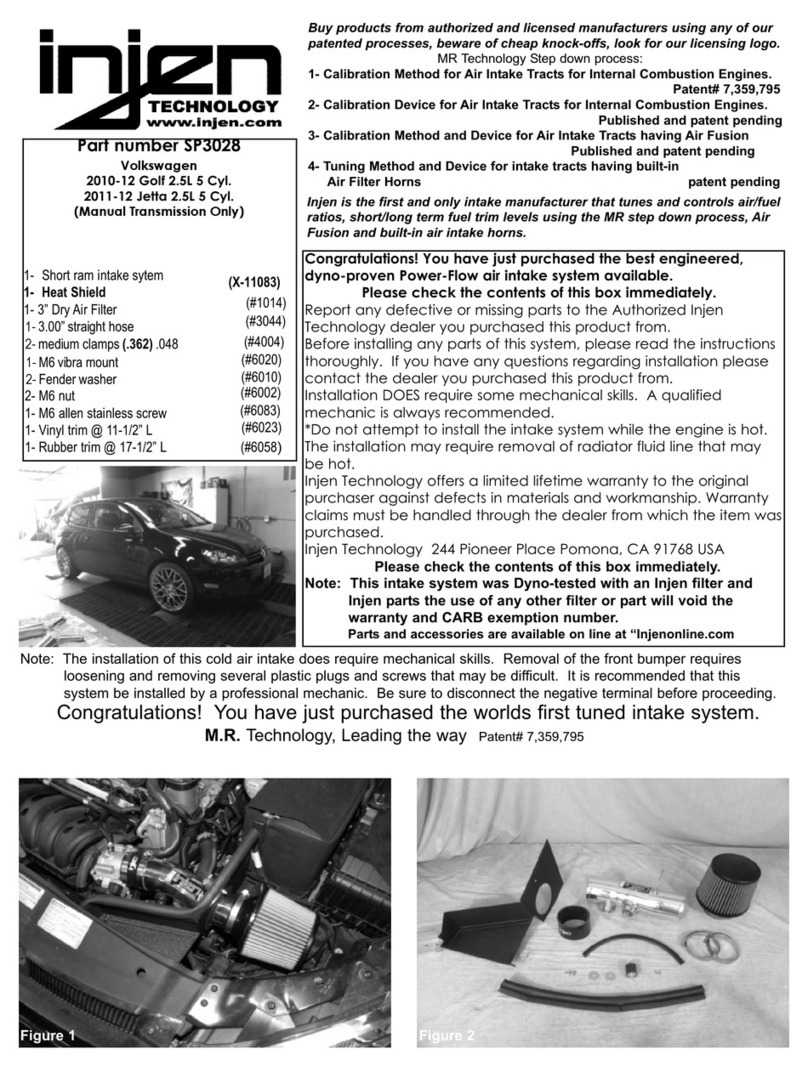

Figure 1