,

Part number SP2115

2009-10 Scion tC 2.4L 4 cyl.

1- Two piece cold air intake

1- 3” Injen/AMSOIL (#1017)

Ea nano-fiber dry filter

1- 2.50” straight hose (#3048)

1- 3.00” straight hose (#3044)

1- 14” vinyl trim (#6023)

2- 6mm vibra-mounts (#6020)

2- Power-bands .312 .040 (#4003)

2- Power-bands .362 .048 (#4004)

2- 6mm flange nuts (#6002)

2- fender washers (#6010)

1- 4 page instruction

Note: Sold separetly:

Hydro-shield used X-1033

Congratulations! You have just purchased the best engineered,

dyno-proven cold air intake system available.

Please check the contents of this box immediately.

Report any defective or missing parts to the Authorized Injen

Technology dealer you purchased this product from.

Before installing any parts of this system, please read the instructions

thoroughly. If you have any questions regarding installation please

contact the dealer you purchased this product from.

Installation DOES require some mechanical skills. A qualified

mechanic is always recommended.

*Do not attempt to install the intake system while the engine is hot.

The installation may require removal of radiator fluid line that may

be hot.

Injen Technology offers a limited lifetime warranty to the original

purchaser against defects in materials and workmanship. Warranty

claims must be handled through the dealer from which the item was

purchased.

Injen Technology 285 Pioneer Place Pomona, CA 91768 USA

Note: This intake system was Dyno-tested with an Injen filter and

Injen parts the use of any other filter or part will void the

warranty and CARB exemption number.

Parts and accessories are available on line at “Injenonline.com

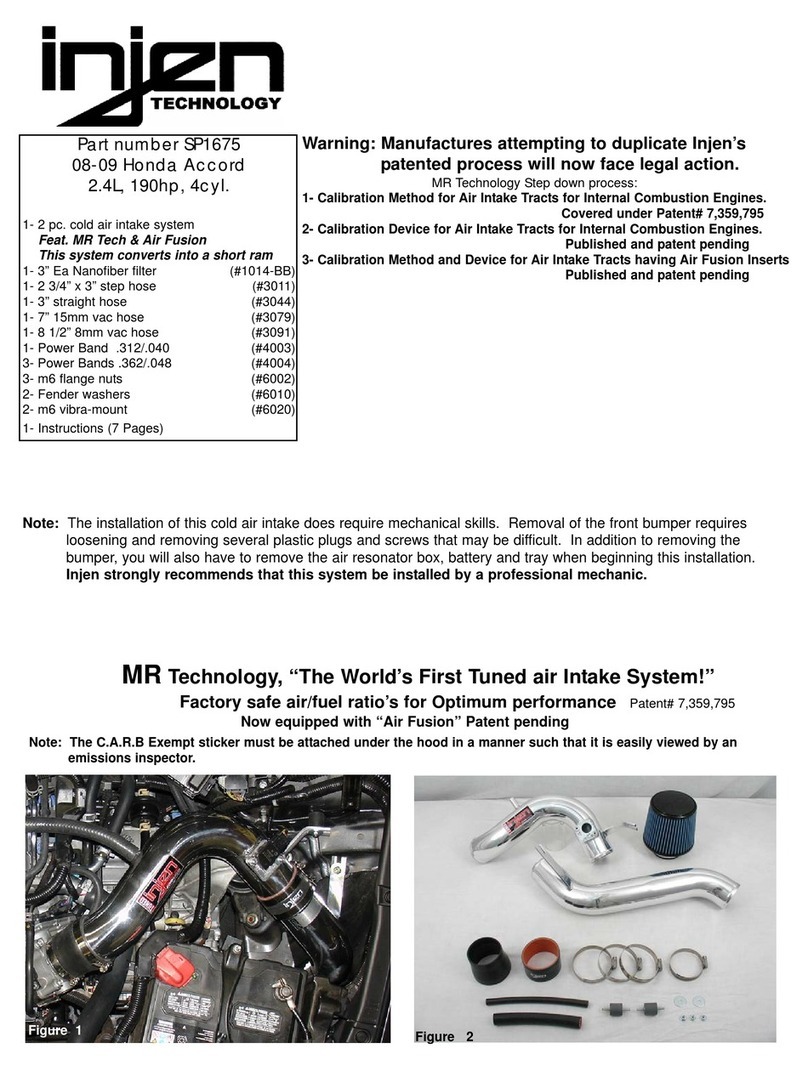

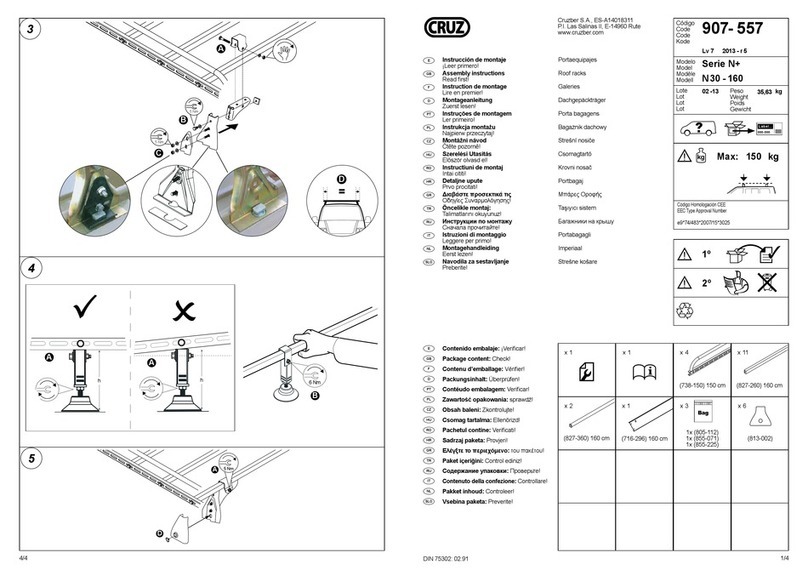

Note: The installation of this cold air intake does require mechanical skills. Removal of the front bumper requires

loosening and removing several plastic plugs and screws that may be difficult. In addition to removing the

bumper, you will also have to remove the air resonator box, battery and tray when beginning this installation.

Injen strongly recommends that this system be installed by a professional mechanic.

“The World’s First Tuned Intake System!”

Buy products from authorized and licensed manufacturers using any of our

patented processes, beware of cheap knock-offs, look for our licensing logo.

MR Technology Step down process:

1- Calibration Method for Air Intake Tracts for Internal Combustion Engines.

Patent# 7,359,795

2- Calibration Device for Air Intake Tracts for Internal Combustion Engines.

Published and patent pending

3- Calibration Method and Device for Air Intake Tracts having Air Fusion

Published and patent pending

4- Tuning Method and Device for intake tracts having built-in

Air Filter Horns patent pending

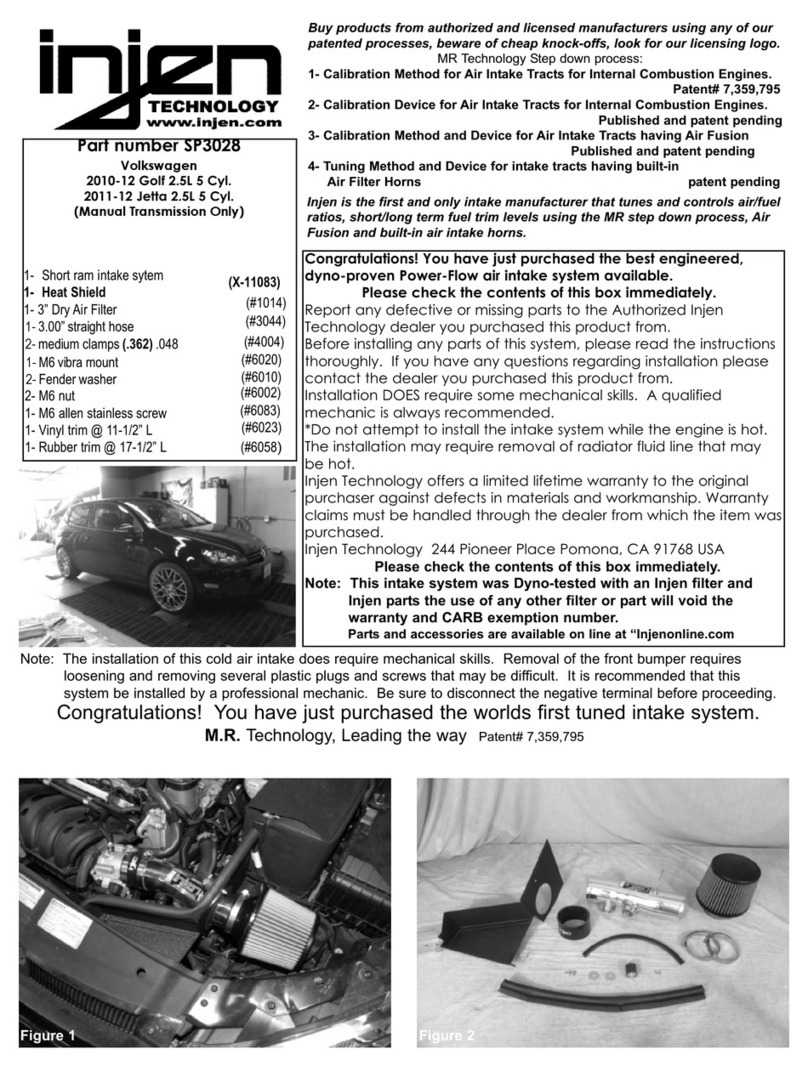

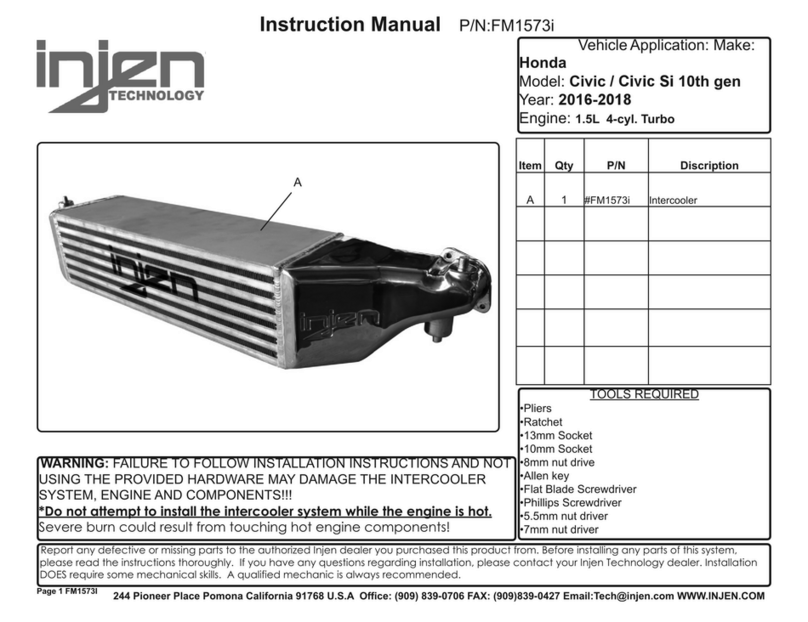

Figure 1 Figure 2